EMGA 320.005 series User manual

FILTERBREW &

SERVING CONCEPT

TECHNICAL MANUAL

*320.005

320005 en ma 2014 02 1/20

CONTENT

CONTENT..........................................................................................................................................................................................2

GENERAL.............................................................................................................................................................................................4

Introduction ......................................................................................................................................................................................................4

Warnings............................................................................................................................................................................................................4

Precautions........................................................................................................................................................................................................4

Intended use......................................................................................................................................................................................................4

CLEANING AND CARE.............................................................................................................................................................5

Rinse Thermos, Decanter and Serving station ..........................................................................................................................................5

Dayly cleaning ...................................................................................................................................................................................................6

Weekly cleaning................................................................................................................................................................................................6

Cleaning Serving station.....................................................................................................................................................7

Exterior cleaning ..............................................................................................................................................................................................7

PROGRAMMING ............................................................................................................................................................................8

A-2, DA-4,Thermos A, Mega Gold A ...........................................................................................................................................................8

Cater................................................................................................................................................................................................................10

To w e r ...............................................................................................................................................................................................................14

HVA/HVM.......................................................................................................................................................................................................16

Grinder Original ..........................................................................................................................................................................................17

POSSIBLE SOLUTION ..............................................................................................................................................................19

Original A/M...................................................................................................................................................................................................19

Cater,Tower, HVA/HVM .............................................................................................................................................................................. 20

320005 en ma 2014 02 2/20

IMPORTANT!

INFO.

CAUTION!

INFO.

More INFO. INFO.

Some important information may appear in textboxes seen below

Note

320005 en ma 2014 02 3/20

GENERAL

Read the user guide before using the machine.

This guide contains important instructions for

proper and safe use of the vending machine.

Always keep this guide close at hand for future

reference.

Introduction

Thank you for choosing a FILTERBREWER coffee machine.

We hope you enjoy it !

Warnings

Never immerse the machine, plug or mains

cable in water because there is a danger of

electric shock.

The appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they

have been given supervision or instruction

concerning the use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure they

do not play with the appliance.

Do not use the machine if the mains cable, plug

is damaged or the machine has fallen down.

If the mains cable is damaged it must be

replaced by the manufacturer, service agent or

similarly qualified persons in order to avoid a

hazard.

Only plug the machine into a properly installed

earthed safety socket whose line voltage

matches the technical data for the machine.

Do not use the machine outdoors so it can be

exposed to weather (rain, snow, frost).It will

cause material damage to the machine.

Do not try to open the machine or repair it in

any way.To avoid danger only have the machine

repaired in a technical workshop, Service

Centre or by a qualified person.

Remove the mains cable from the socket when

the machine is not in use for longer periods.To

do this, pull the plug not the cable.

This appliance must be placed in a horizontal

position which is resistant to any water that

may leak.

Place the machine out of the reach of children.

Position the mains cable so that people cannot

trip over it.Keep it away from sharp edges and

heat sources.

The new hose-sets supplied with this appliance

are to be used, old hose-sets must not be re-

used.

This appliance is not suitable for installation in

an area where a water jet could be used.

This appliance must not be cleaned by a water

jet.

This appliance is intended to be used in

household and similar applications such as:

-Staff kitchen areas in shops.

-

environments.

-On agricultural estates.

-By clients in hotels, motels and other

residential type environments.

-Bed and breakfast type environments.

For the optimal performance of the machine

these parameters shall not be exceeded:

-Maximum permissible inlet water pressure :

800KPa (8Bar)

- Minimum permissible inlet water pressure:

200KPa (2Bar)

- Maximum working temperature: 40°ºC

- Minimum working temperature: 10°ºC

Precautions

Intended use

Offices and other commercial working

320005 en ma 2014 02 4/20

CLEANING AND CARE

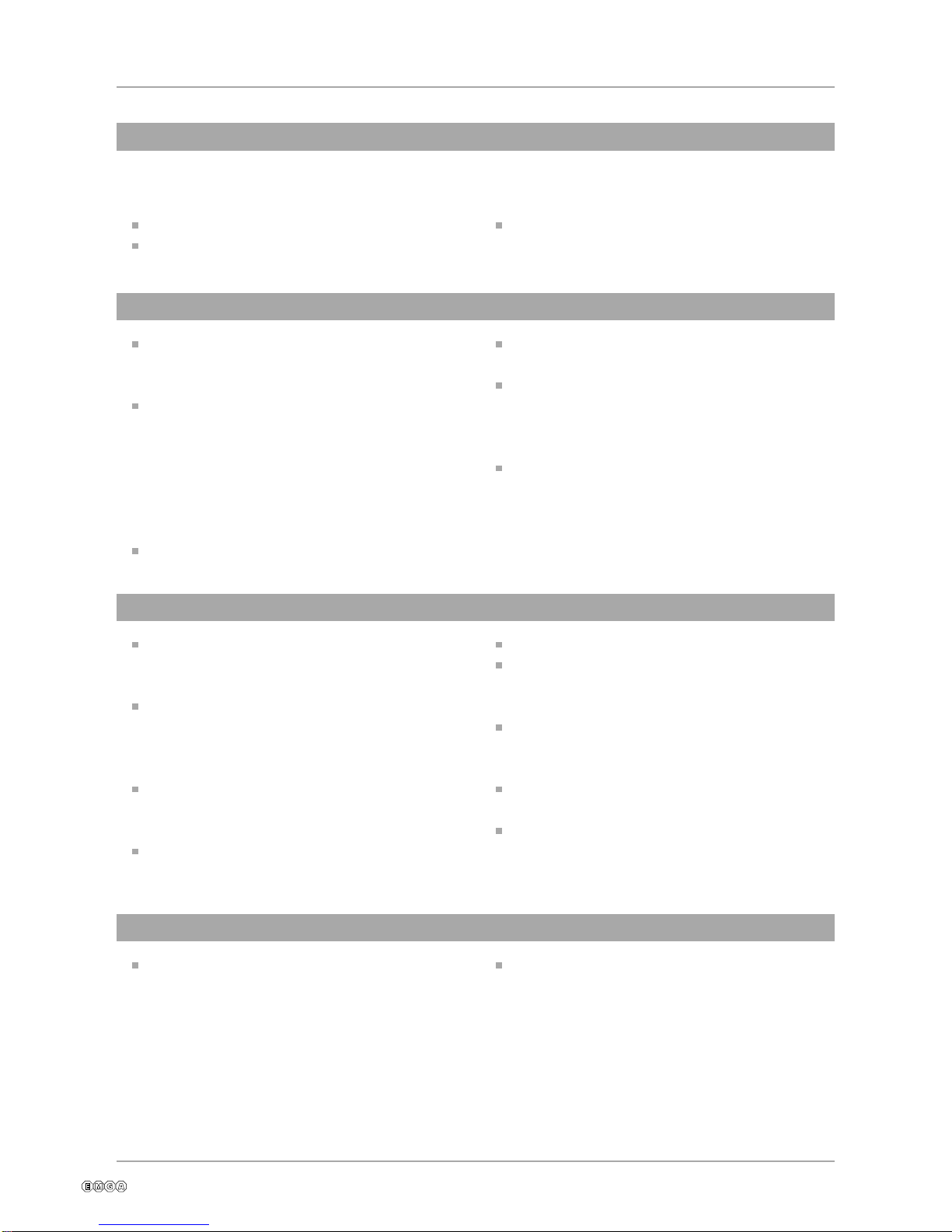

Before each brewing, rinse the thermos, decanter or serving station with fresh tap water.

When cleaning the outside, use a soft rag with liquid cleaning agent to prevent scratches.

5LQVH7KHUPRV'HFDQWHUDQG6HUYLQJVWDWLRQ

&$87,21

The machine should not be submerged

in water or washed in a dishwasher. it

will result in machine damage.

320005 en ma 2014 02 5/20

Descaling and cleaning.

Pour 50 ml descaling / cleaning solution in a decanter and ll it up with cold water.

Pour the mixture in the machine and proceed with a brewing without a lterpaper or coffee.

Rinse the machine thoroughly by brewing at least 3 times with clean water so that the particles from

descaling solution disappear.

Regular descaling will ensure optimum brewing performance and a longer life of the machine.

When cleaning the decanter in a dishwasher. Dismantle lid and place decanter upside down in the

dishwasher.(A)

Pitcher

371R

A

B

CLEANING AND CARE

'D\O\FOHDQLQJ

:HHNO\FOHDQLQJ

Wash the thermos, decanter(B) and the lter holder with liquid solution for coffee machines.Always

remove the lter immediately and clean the lter holder daily, coffee will get moldy.

Clean the spray nozzle(A) and the surrounding area.

Use a soft rag and liquid solution that does not scratch.

Descaling agent

PT No. 110412

A

B

320005 en ma 2014 02 6/20

CLEANING AND CARE

'LVDVVHPEOHWKHOHYHOWXEHDQGFOHDQLW

HYHU\ZHHNZLWKWKHHQFORVHGEUXVK

7DNHRIIWKHPDLQOLGDQGFOHDQWKHPL[HU

WXEH$

)LOOWKHVHUYLQJVWDWLRQZLWKKRWZDWHU)XOO

EUHZLQJZLWKRXWFRIIHHDQGILOWHU

3XWWDEOHVSRRQZLWKFOHDQLQJSRZGHULQWKH

VHUYLQJVWDWLRQDQGZDLWDWOHDVWPLQXWHV

7DSRXWRIWKHFOHDQLQJVROXWLRQ

&OHDQWKHVHUYLQJVWDWLRQZLWKWKHFOHDQLQJEUXVK

Rinse the serving station with fresh tap water

several times before reuse.

&OHDQLQJ6HUYLQJVWDWLRQ

&OHDQLQJRI6HUYLQJVWDWLRQ

A

IMPORTANT!

Rinse the inside of

the serving station

several times with

fresh tap water.

([WHULRUFOHDQLQJ

When cleaning exterior of the machine, use a soft rag with liquid cleaning agent

to prevent scratches.

OPTIONS

Part No. CLEANING PARTS

&OHDQLQJSRZGHU

&OHDQLQJEUXVK

&OHDQLQJEUXVKIRUOHYHOWXEH

PL[HUWXEH

320005 en ma 2014 02 7/20

6HOHFWPDFKLQHW\SH

PROGRAMMING

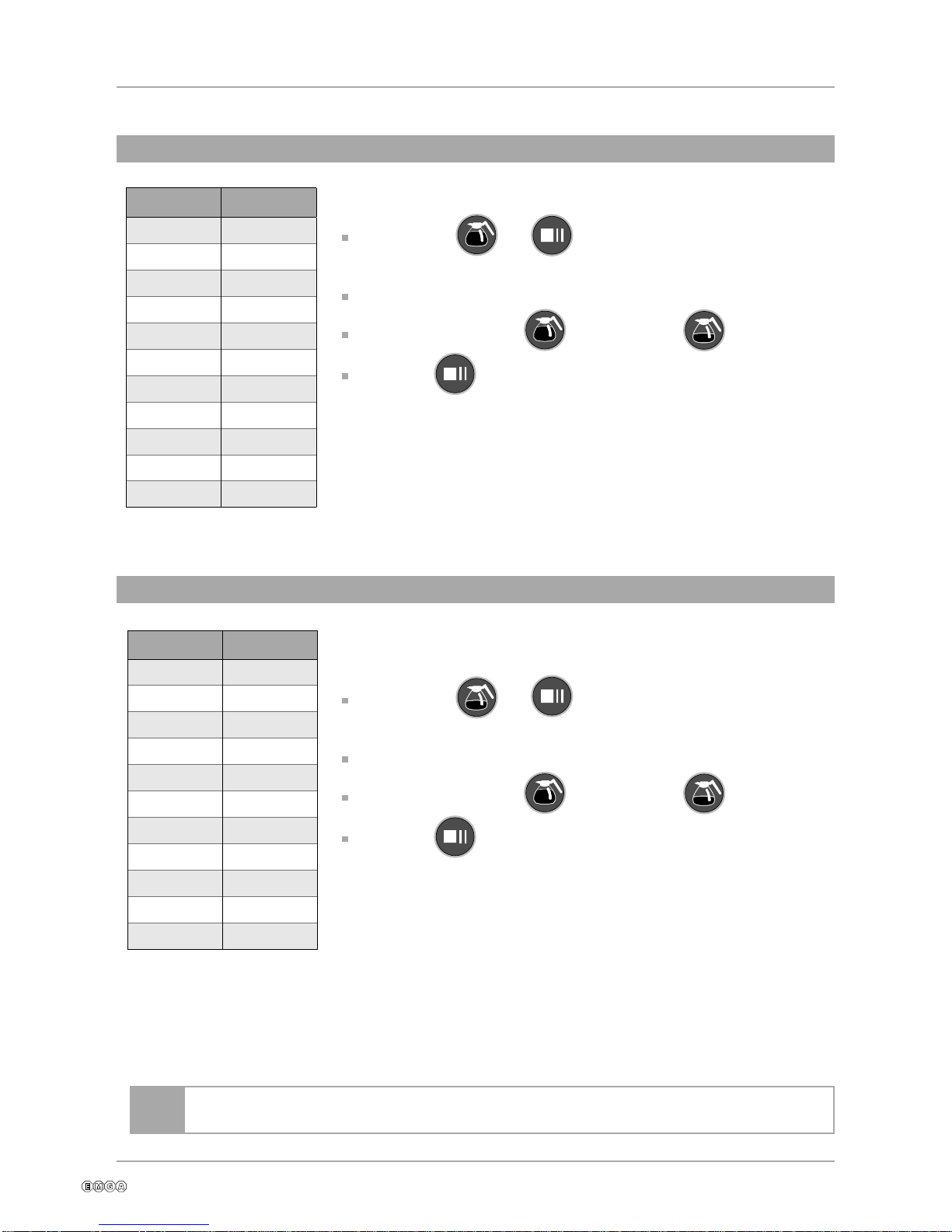

$'$7KHUPRV$0HJD*ROG$

MACHINE

TYPE DISPLAY CUPS CUPS TIME BUZZER TIME

DA/A-2 T1 4-12 9.25 s 247

Termos A T2 4-15 9.25 s 292

Mega A T3 4-17 9.25 s 344

Enter the procedure to select machine type is the following:

Press all three buttons , and at tKHVDPHWLPH

before turning on the mains switch The buzzer beeps once.

The display shows the current setting.

Step up with button and step down with button .

Press the button to save setting and exit to normal mode.

320005 en ma 2014 02 8/20

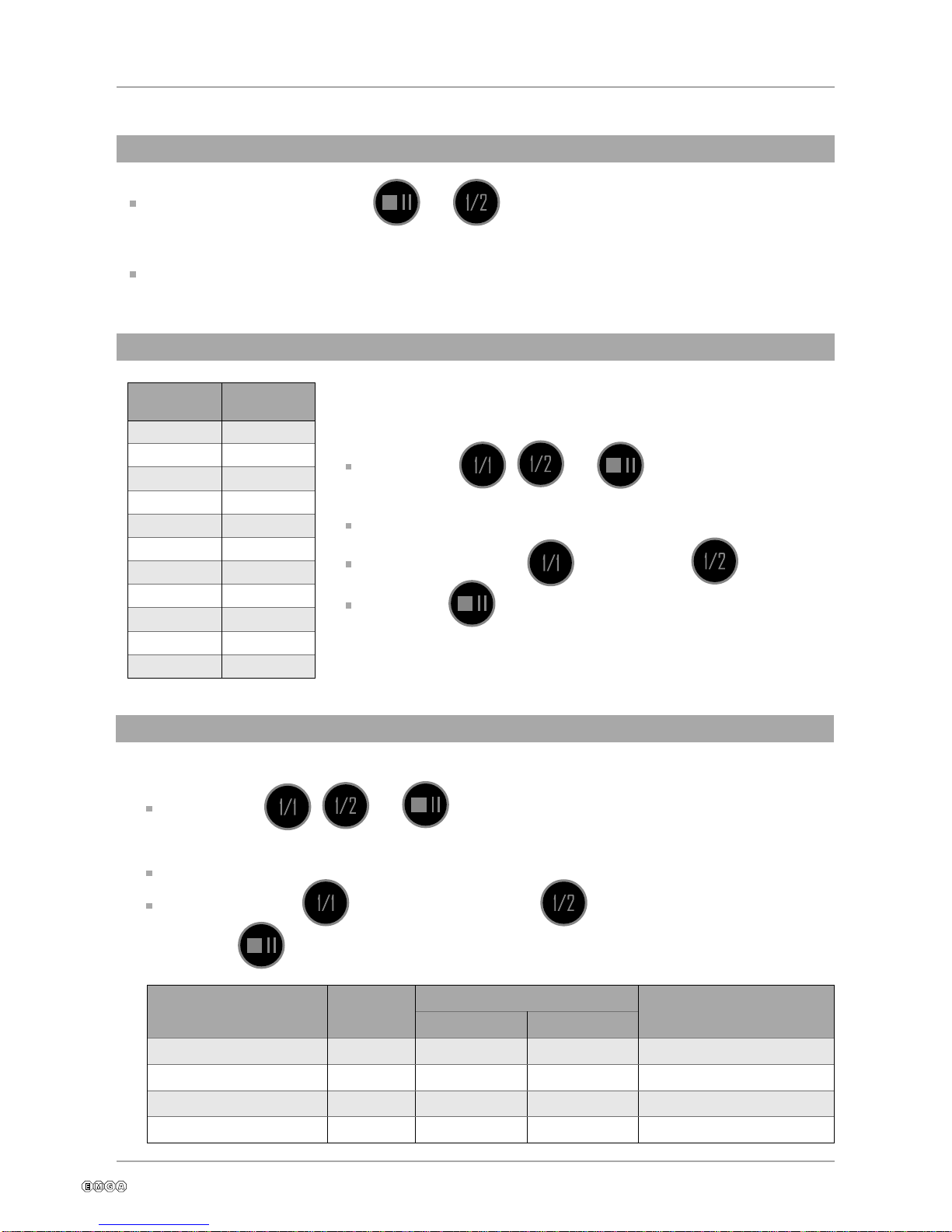

$GMXVWZDWHUDPRXQW

PROGRAMMING

Adjust amount of brew water

Press the buttons and at same time in 5 seconds.

The buzzer beeps twice. Display shows 0.

- Press the button to increase amount of water.

- Press the button to decrease amount of water.

- 1 step = 5%

- Press the button to conrm the change.

Adjust the brew time

Press the buttons and at same time in 5 seconds.

The buzzer beeps four times. Display shows 0.

- Press the button to increase brewing time.

- Press the button to decrease brewing time.

- 1 step = 5%

- Press the button to conrm the change.

Display shows and machine is ready to use.

$GMXVWEUHZWLPH

$'$7KHUPRV$0HJD*ROG$

ADJUST DISPLAY

25% 5

20% 4

15% 3

10% 2

5% 1

0% 0

-5% -1

-10% -2

-15% -3

-20% -4

-25% -5

320005 en ma 2014 02 9/20

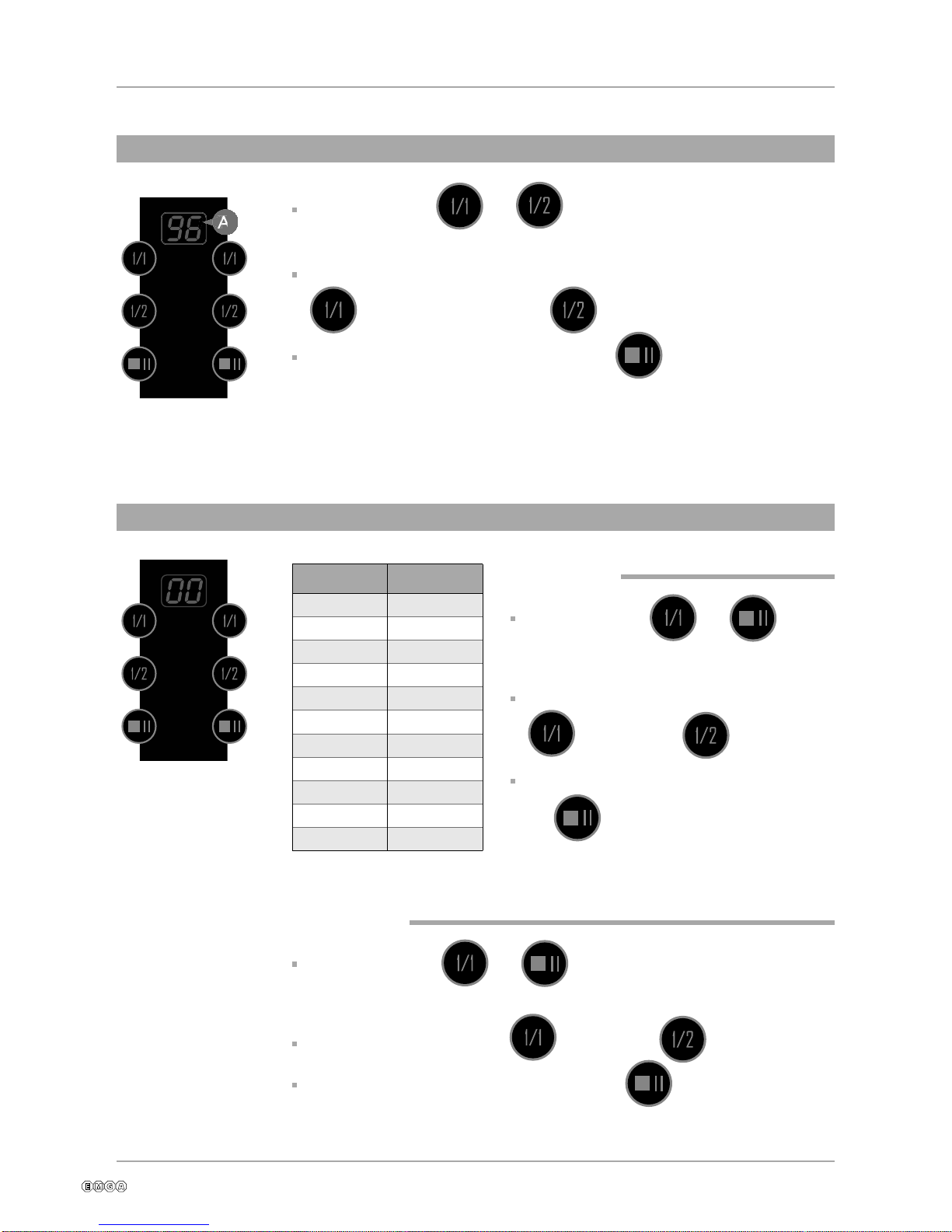

PROGRAMMING

ADJUST DISPLAY

+5°C 5

+4°C 4

+3°C 3

+2°C 2

+1°C 1

00

-1°C -1

-2°C -2

-3°C -3

-4°C -4

-5°C -5

&DWHU

$GMXVWLQJRIZDWHUWHPSHUDWXUH

1RUPDORSHUDWLRQZLWKUHGXFHGRXWOHWWLPH

3UHVVEXWWRQV DQG DWWKHVDPHWLPHIRUVHFRQGVXQWLO\RX

KHDURQHEHHS'LVSOD\VKRZVWKHSUHVHQWVHWWLQJ

$GMXVWZLWKWKHEXWWRQV LQFUHDVHDQG GHFUHDVH

&RQILUPWKHQHZVHWWLQJVE\SUHVVLQJWKH EXWWRQ

Ĉ& PLQWHPSHUDWXUH

Ĉ& PD[WHPSHUDWXUH

7KLVPRGHLVHQWHUHGE\SUHVVLQJWKH DQG EHIRUHWXUQLQJWKH

PDLQVVZLWFKRQ7KHEX]]HUJLYHVDVEHHSWRLQGLFDWHWKLVPRGH

7KLVPDFKLQHRSHUDWHVOLNHLQQRUPDOPRGHEXWWKHRXWOHWWLPHVDUHUHGXFHGE\

LQRUGHUWRDOORZIDVWHUDGMXVWPHQWRIYDOYHWLPHV

$GMXVWLQJRIWHPSHUDWXUHVHQVRU

In this mode a temperature offset for the NTC sensor can be adjusted.

The procedure to enter this mode is the following:

3UHVVEXWWRQV DQG DWWKHVDPHWLPHIRU

VHFRQGVXQWLO\RXKHDUEHHSV

The display shows the current setting.

$GMXVWZLWKWKHEXWWRQV LQFUHDVHDQG GHFUHDVH

3UHVVLQJWKH EXWWRQWRVDYHQHZVHWWLQJVDQGUHWXUQWRQRUPDO

PRGH

320005 en ma 2014 02 10/20

PROGRAMMING

&DWHU

$GMXVWLQJRIZDWHUTXDQWLW\

$GMXVWLQJRIEUHZLQJWLPH

ADJUST DISPLAY

25% 5

20% 4

15% 3

10% 2

5% 1

0% 0

-5% -1

-10% -2

-15% -3

-20% -4

-25% -5

7KHSURFHGXUHWRHQWHUWKLVPRGHLVWKHIROORZLQJ

3UHVVEXWWRQV DQG DWWKHVDPHWLPHIRUVHFRQGVXQWLO

\RXKHDUEHHSV

The display shows the current setting.

$GMXVWZLWKWKHEXWWRQV LQFUHDVHDQG GHFUHDVH

3UHVVHWKH EXWWRQWRVDYHQHZVHWWLQJVDQGUHWXUQWRQRUPDO

PRGH

,QWKLVPRGHWKHWLPHIRUthe brewing done buzzer activation can be

adjusted7KHSURFHGXUHWRHQWHUWKLVPRGHLVWKHIROORZLQJ

3UHVVEXWWRQV DQG DWWKHVDPHWLPHIRU

VHFRQGVXQWLO\RXKHDUEHHSV

The display shows the current setting.

$GMXVWZLWKWKHEXWWRQV LQFUHDVHDQG GHFUHDVH

3UHVVHWKH EXWWRQWRVDYHQHZVHWWLQJVDQGUHWXUQWR

QRUPDOPRGH

The brewing time is the same regardless adjustment of the outlet valve time.

Note

ADJUST DISPLAY

25% 5

20% 4

15% 3

10% 2

5% 1

0% 0

-5% -1

-10% -2

-15% -3

-20% -4

-25% -5

320005 en ma 2014 02 11/20

PROGRAMMING

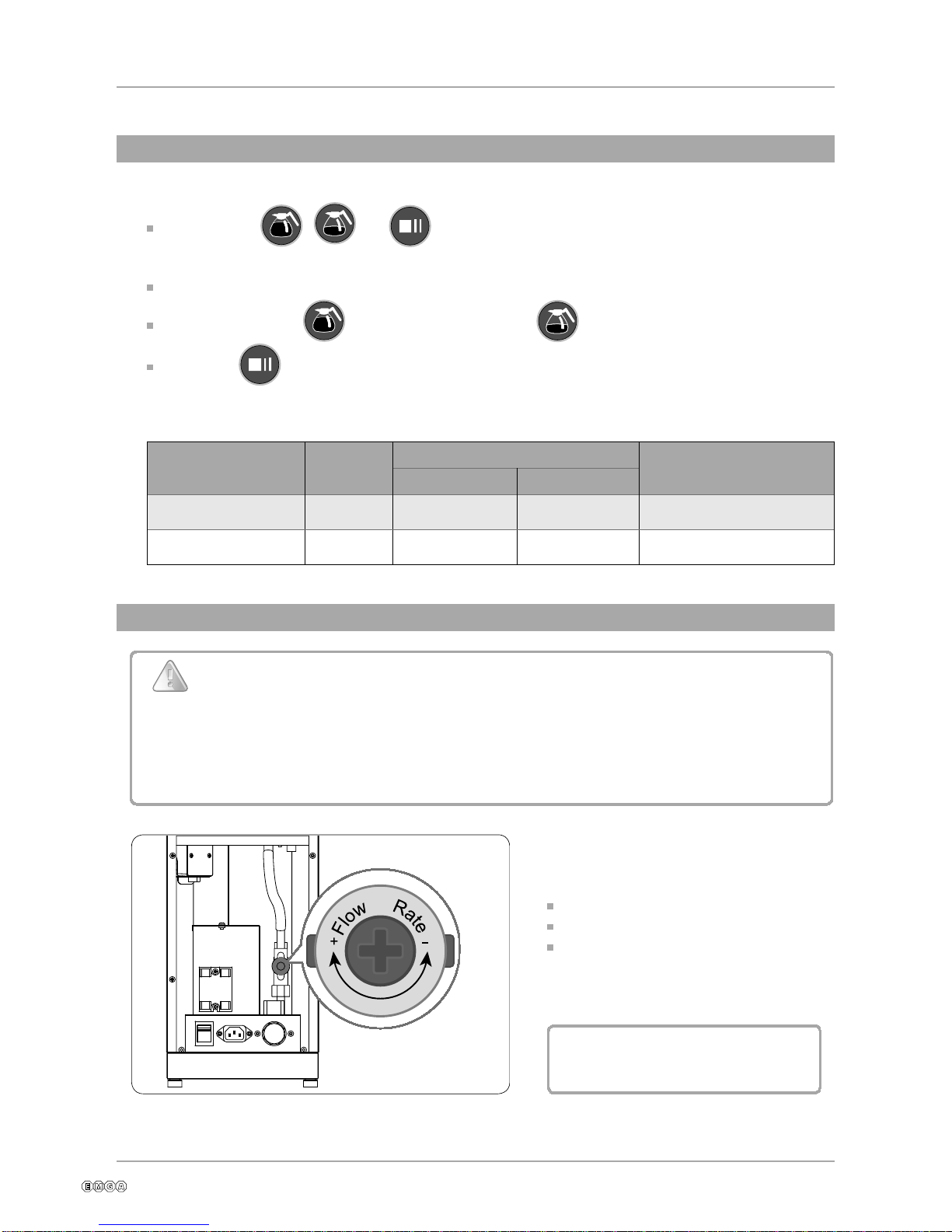

&DWHU

6HOHFWPDFKLQHW\SH

$GMXVWLQJRIIORZZDWHU

In this mode the machine type can be chosen7KHSURFHGXUHWRHQWHUWKLVPRGHLVWKHIROORZLQJ

3UHVVEXWWRQV DQG DWWKHVDPHWLPH

before turning the mains switch onXQWLO\RXKHDUEHHSV

The display shows the machine type.

Step up with button DQGstep down with button

3UHVVHWKH EXWWRQWRVDYHQHZVHWWLQJDQGUHWXUQWR

QRUPDOPRGH

&KHFNWKHZDWHUIORZ

7KLVVKRXOGEH/PLQXWH

$GMXVW3'6YDOYHLIQHFHVVDU\

6HHILJ$

Shall been done by an authorized

installation engineer

,03257$17

From date 091001 Cater is delivered with an adjustable PDS valve.This is to improve the

water ow into lter holder.The ow of PDS valve is set to 0.95 litre /minute. Depending

on the coarseness and amount of coffee that’s used when brewing, the ow might need

adjustments to prevent overow in the lter holder.

A

PDS valve

Machine type Display Outlet time (s) Buzzer time (s)

Half Full

1.8L T1 56 113 90

2.5L T2 79 158 90

320005 en ma 2014 02 12/20

7HVWIXQFWLRQV

3UHVVEXWWRQV DQG DWWKHVDPHWLPHbefore turning the mains

switch on,puts the control board into test mode for time and temperature

controlled machines.

For the other types pressing EXWWRQV DQG before power-on results

in test mode.

A test sequence starts:

- Turn all outputs off

- Turn V_WATER on for 3 s

- Turn V_OUT_A on for 3 s

- Turn HEAT on for 3 s

- Turn buzzer on for 2 s

- Show NTC temperature on displayed

- If button is pressed display b1

- If button is pressed display b2

- If button is pressed display b3

- If LVL_SAFE is passive display L1

- If LVL_REF is passive display L2

PROGRAMMING

&DWHU

320005 en ma 2014 02 13/20

PROGRAMMING

In this mode a temperature offset for the NTC sensor can be adjusted.

The procedure to enter this mode is the following:

Press buttons

seconds until you hear 2 beeps.

The display shows the current setting.

Adjust with the buttons

Pressing the

Select machine type

In this mode the machine type can be chosen.The procedure to enter this mode is the following:

Press buttons , and at the same time before turningthe mains switch on until

you hear 6 beeps.

The display shows the machine type.

Step up with button and step down with button .

Presse the button to save new setting and return to normal mode.

MACHINE TYPE DISPLAY OUTLET TIME (s) BUZZER TIME(s)

HALF FULL

5L T1 150 300 300

10L T2 300 600 300

6L T3 180 360 300

12L T4 360 720 300

sniamrogulp,enihcamehtesremmireveN Do not use the machine if the mains cable, plug

PROGRAMMING

ADJUST DISPLAY

+5°C 5

+4°C 4

+3°C 3

+2°C 2

+1°C 1

00

-1°C -1

-2°C -2

-3°C -3

-4°C -4

-5°C -5

To w e r

Normal operation with reduced outlet time

Adjusting of temperature sensor

In this mode a temperature offset for the NTC sensor can be adjusted.

The procedure to enter this mode is the following:

Press buttons , and at the same time for 5

seconds until you hear 2 beeps.

The display shows the current setting.

Adjust with the buttons = (increase) and = (decrease).

button to save new settings and return to normal

mode.

This mode is entered by pressing and before turning the mains

switch on.The buzzer gives a 5s beep to indicate this mode.

This machine operates like in normal mode but the outlet times are reduced by 90% in order to allow

faster adjustment of valve times.

320005 en ma 2014 02 14/20

$GMXVWLQJZDWHUWHPSHUDWXUH

$GMXVWLQJZDWHUTXDQWLW\

3UHVVOHIWEXWWRQV and DWWKHVDPHWLPHIRUVHFRQGVXQWLO

\RXKHDUEHHS'LVSOD\VKRZVWKHSUHVHQWVHWWLQJ$

$GMXVWZLWKWKHOHIWEXWWRQV

LQFUHDVHZDWHUWHPSDQG GHFUHDVHZDWHUWHPS

&RQILUPWKHQHZVHWWLQJVE\SUHVVLQJWKHOHIW EXWWRQRQFH

Ĉ& PLQWHPSHUDWXUH

Ĉ& PD[WHPSHUDWXUH

For left side

3UHVVOHIWEXWWRQV DQG DWWKH

VDPHWLPHIRUVHFRQGVXQWLO\RXKHDU

EHHSV the display shows the current setting.

$GMXVWZLWKWKHOHIWEXWWRQV

LQFUHDVHDQG GHFUHDVH

&RQILUPWKHQHZVHWWLQJVE\SUHVVLQJWKH

OHIW EXWWRQRQFH

For right side

3UHVVULJKWEXWWRQV DQG DWWKHVDPHWLPHIRUVHFRQGVXQWLO

\RXKHDUEHHSV the display shows the current setting.

$GMXVWZLWKWKHULJKWEXWWRQV LQFUHDVHDQG GHFUHDVH

&RQILUPWKHQHZVHWWLQJVE\SUHVVLQJWKHULJKW EXWWRQRQFH

ADJUST DISPLAY

25% 5

20% 4

15% 3

10% 2

5% 1

0% 0

-5% -1

-10% -2

-15% -3

-20% -4

-25% -5

PROGRAMMING

7R Z H U

A

320005 en ma 2014 02 15/20

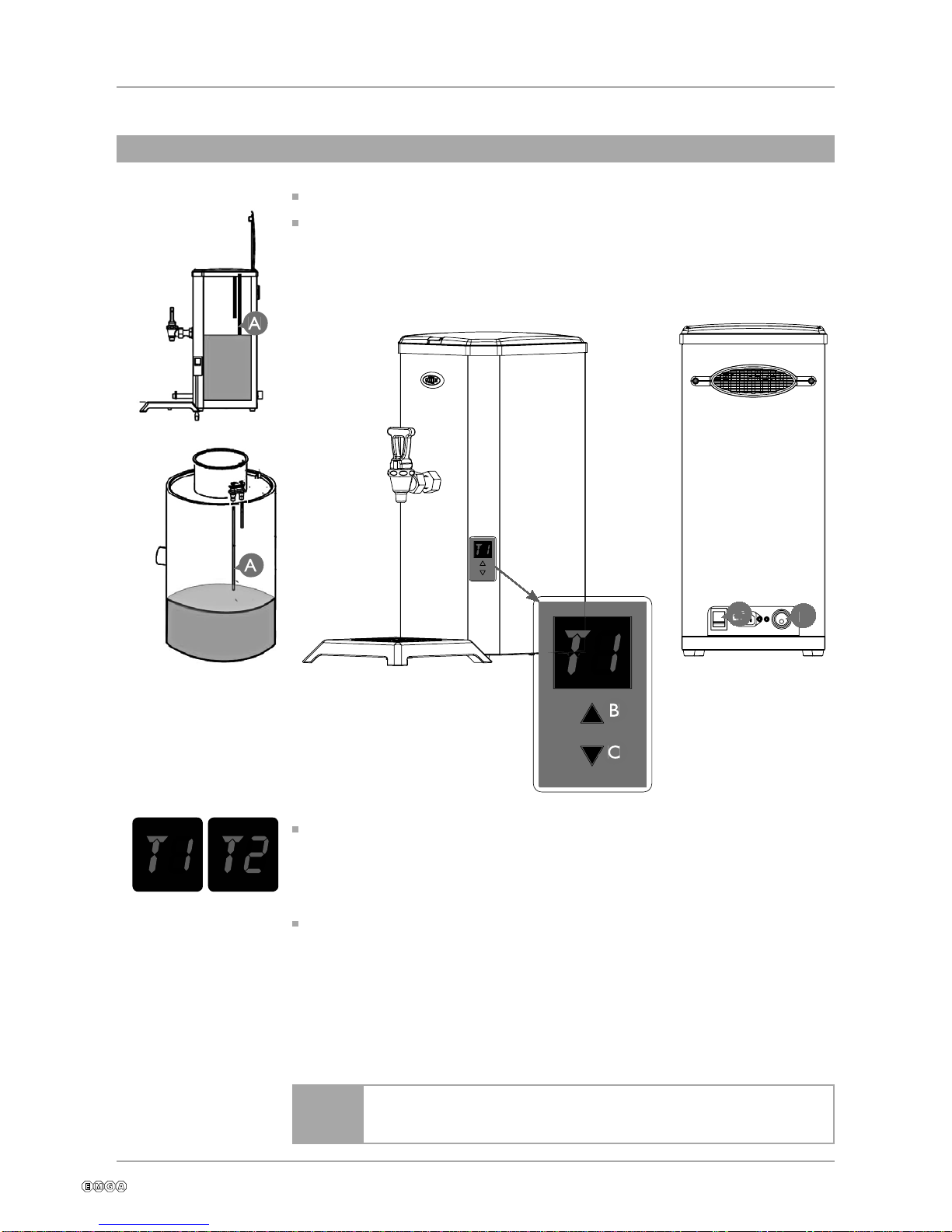

6HOHFWPDFKLQHW\SH

Install the plug supplied in the inlet valve (E) to avoid possible

leakage.

Note

The display will show T1, change the type of machine with buttons (B) or (C).

7 +9$DXWRPDWLF

7 +90PDQXDO

Conrm the choice by holding down the buttons (B) and (C) at the same

time for approximately 5 seconds.

Use a decanter to ll up the water tank to the long sensor pin.(A)

Keep button (B) pressed while turning on the power switch.(D)

PROGRAMMING

+9$+90

D

E

320005 en ma 2014 02 16/20

1RUPDORSHUDWLRQ

$GMXVWWLPHSHUFXS

There are several sub modes for this mode:

READY

The machine is in this mode after power on. The motor is off and timers are

stopped.

Pressing the button and changes the number of cups to be

prepared.The number of cups is displayed on the 2 digit display. The range is 4 -34

cups.The latest number of cups will be used even after power cycling the machine.

Pushing the button to start the motor timer (number of cups x time per

cup) and activates the motorV_MOTOR and moves the machine into GRINDING

mode.

GRINDING

The display is blinking at 0.5 Hz.The timer is checked.After the motor time has

expired the the motor is turned off. Pushing the button again pauses the

timer, deactivates the motor and moves into PAUSED mode. If button is

pressed more than 5 s the machine moves to READY mode.

PAUSED

The displays is blinking at 2 HZ. If the button is pressed again a beep

signals the recognition of the button press and the machine moves back to

GRINDING mode after 2 s unless the is still pressed and keeps pressed

more than 5 s which moves the machine to READY mode.

PROGRAMMING

*ULQGHU2ULJLQDO

In this mode the time for the motor activation per selected

number of cups can be adjusted.The procedure to enter this

mode is the following:

Press buttons and for 5 seconds XQWLO\RXKHDU

EHHSV

The display shows the current setting.

Increase inlet valve time with and decrease with .

Press to save new settings and return to normal mode.

The adjustment is made in 0.1 s steps.The range is 1.0 to 9.9 s

per cup.

The time per cup is saved permanently.

TIME/CUP DISPLAY

'LJLW 'LJLW

320005 en ma 2014 02 17/20

$GMXVWFRIIHHDPRXQW

$GMXVWFRIIHHJULQG

7HVWLQJ

The grinding degree is preset from the factory.

Push the knob and turn counterclockwise (A) for coarser grind or clockwise (B)

for ner grinding.

Press buttons and simultaneously for 6 seconds.

The display (A) shows the current time setting for grinding.

You can now choose to increase or decrease the time 15 = 1.5 seconds for

grinding, by pressing the buttons or .

This means that you increase or decrease the amount of coffee grounds.

A

B

PROGRAMMING

*ULQGHU2ULJLQDO

Pressing the and buttons before turning the mains switch on

puts thecontrol board into test mode.

A test sequence starts:

- Turn all outputs off

- Turn V_MOTOR on for 3 s

- Turn buzzer on for 2 s

- If button is pressed display b1

- If button is pressed display b2

- If button is pressed display b3

320005 en ma 2014 02 18/20

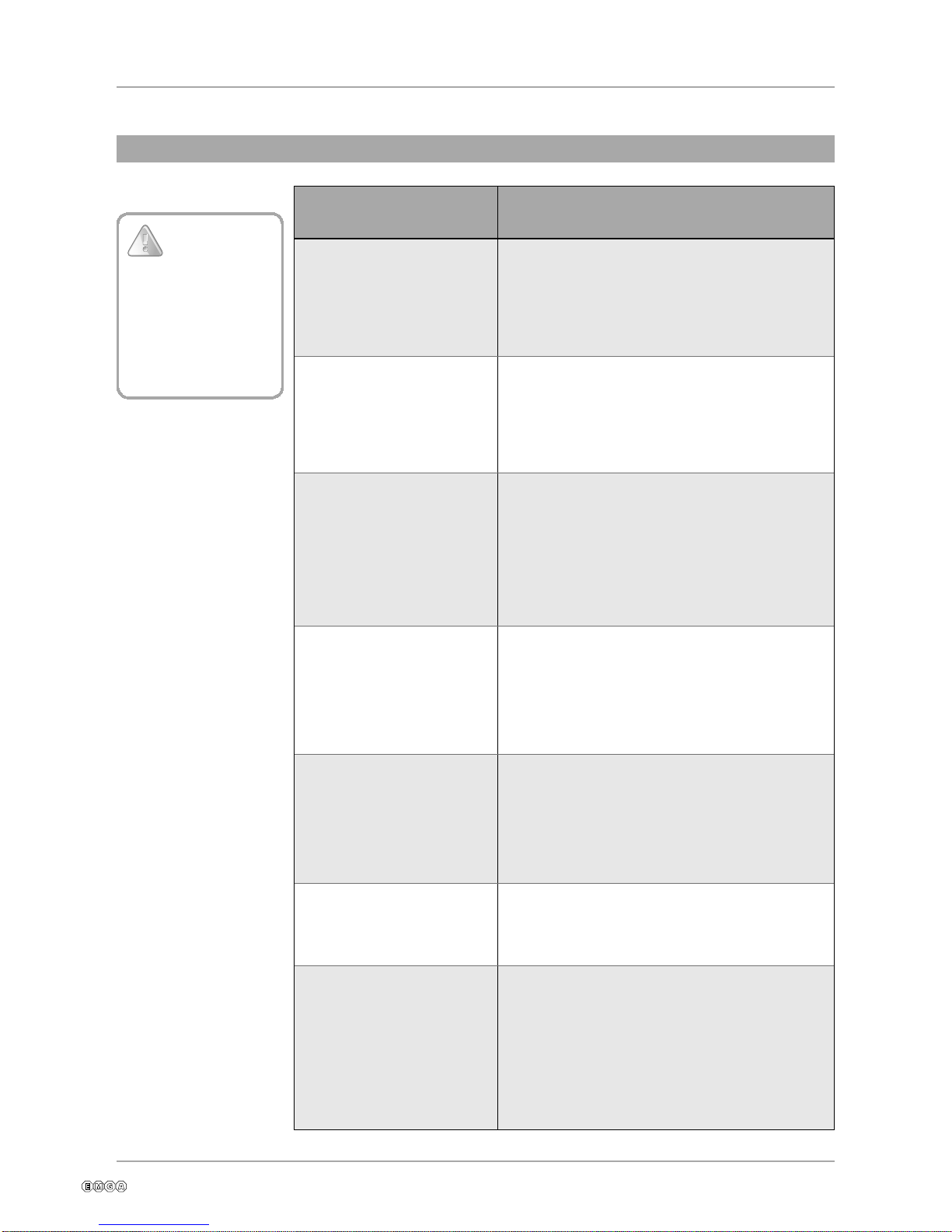

POSSIBLE SOLUTION

)DXOWDQGVROXWLRQ

FAULT POSSIBLE SOLUTION

Power switch does not lit

- Check plug connection to wall socket.

- Check fuse in plug.

- Check if hot plate becomes warm, if so

replace power switch.

Hot plate does not become

warm although switch is lit.

- Check connection to hot plate.

- If hot plate is defective, replace.

Brewer excess steam.

- Machine may require descaling.

- Spray nozzel may need unblocking.

- Hose may be bent.

- Inlet to boiler may be blocked. Descale

machine - if boiler still defective - replace.

Machine will not brew.

- Check overheating protection.

- Check microswicth.

- Check connection to boiler.

- Boiler unit may need replacing.

The machine does not take

in water

- Make sure water tap is open.

- Make sure the water hose is not bent.

- Check inlet valve.

- Check that the display is blinking.

The machines does not

stop taking in water.

- Dirt in the inlet valve.

- inlet valve is defective - replace

- PCB is defective - replace

The machine is giving

wrong amount of water.

- Check water tap.

- Water hose is bent.

- Dirt in inlet valve.

-Water amount adjustment set in display is

adjusted faulty. Adjust according to page 21.

- Defect oatregulator in inlet valve - replace

,03257$17

All maintenance

and installations

must be done

of an authorized

technician.

2ULJLQDO$0

320005 en ma 2014 02 19/20

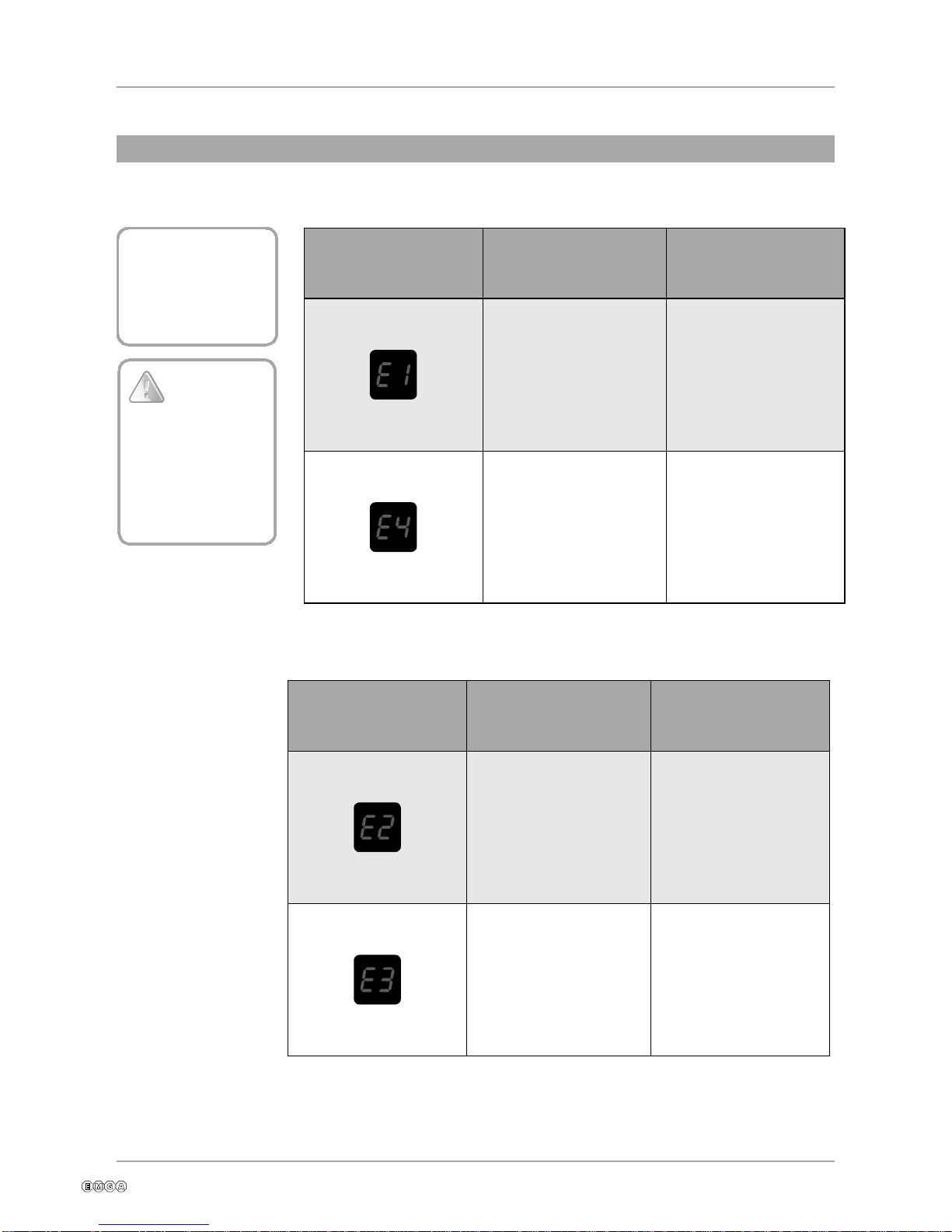

LEVEL CONTROL

TEMPERATURE CONTROL

SHOWN ON THE

DISPLAY POSSIBLE FAULT POSSIBLE

SOLUTION

- The high water level

sensor is triggerd

before the low level

sensor.

- Clean the level sensor.

- Replace.

- Cables connected is

incorrectly.

- The machine lls slowly.

- Poor water pressure.

- Water connection tap

is not open

- Check water

connection.

- Restart machine.

SHOWN ON THE

DISPLAY POSSIBLE FAULT POSSIBLE

SOLUTION

- Temperature sensor

out of range.

- Temperature sensor is

broken.

- Cable loose.

- 50C - 1050C.

- Replace temperature

sensor.

- Check cables.

- Heating time too long.

- Solid state broken.

- Element broken.

- Overheating guard

tripped or broken.

- Restart the machine.

- Replace element.

- Replace solid state.

- Check overheating

protection.

Remove the power

cord from the wall

socket during any

installation work.

POSSIBLE SOLUTION

&DWHU7RZHU+9$+90

,03257$17

All maintenance

and installations

must be done

of an authorized

technician.

)DXOWDQGVROXWLRQ

320005 en ma 2014 02 20/20

Table of contents

Other EMGA Coffee Maker manuals