EMGA coffee queen 320.504 series User manual

COFFEE QUEEN

Servicemanual

*320.

320504 en ma 2012 07

320504 en ma 2012 07 2/15

Contents.

Contents 2

Introduction 3

Functionaldescription 4

Installationandstarting 5-6

Programming: Calibration 7

Faultindications 8

Important 9

Care 10

Programming:Automat–Manual 11

Exploded view, HVA 12

Explodedview,Tankcomplete 13

List of spare parts. 14

Sketch of dimensions 15

320504 en ma 2012 07 3/15

Introduction.

HVA/HVM Hot water automat

CongratulationsonchoosinganHVA/HVMhotwaterautomat.

Read through the instructions before you use the machine.

- Thismanualcontainsimportantinstructionsforcorrectandsafeusageofthehotwater

automat.

- Alwayskeepthemanualinahandyplace.

Coffee Queen AB is certified according to ISO 9001 and ISO 14001 standards

and therefore has a minimum impact on the environment.

HVA/HVM Hot water automat

- Digital display with temperature indication

- Electronictemperaturecontrol

- Manufacturedinbrightstainlesssheetmetal.

Facts mm005thgieH mm522htdiW mm014htpeD

Tank capacity 7.5 litres

Electricalconnection 230 V / 2200 W

3-phaseelectricalconnection 380 V / 8000 W

Coldwaterconnection ½”externalthread

81:yticapaC litres/hour

Capacity: 3 phase 67litres/hour

320504 en ma 2012 07 4/15

Functional description.

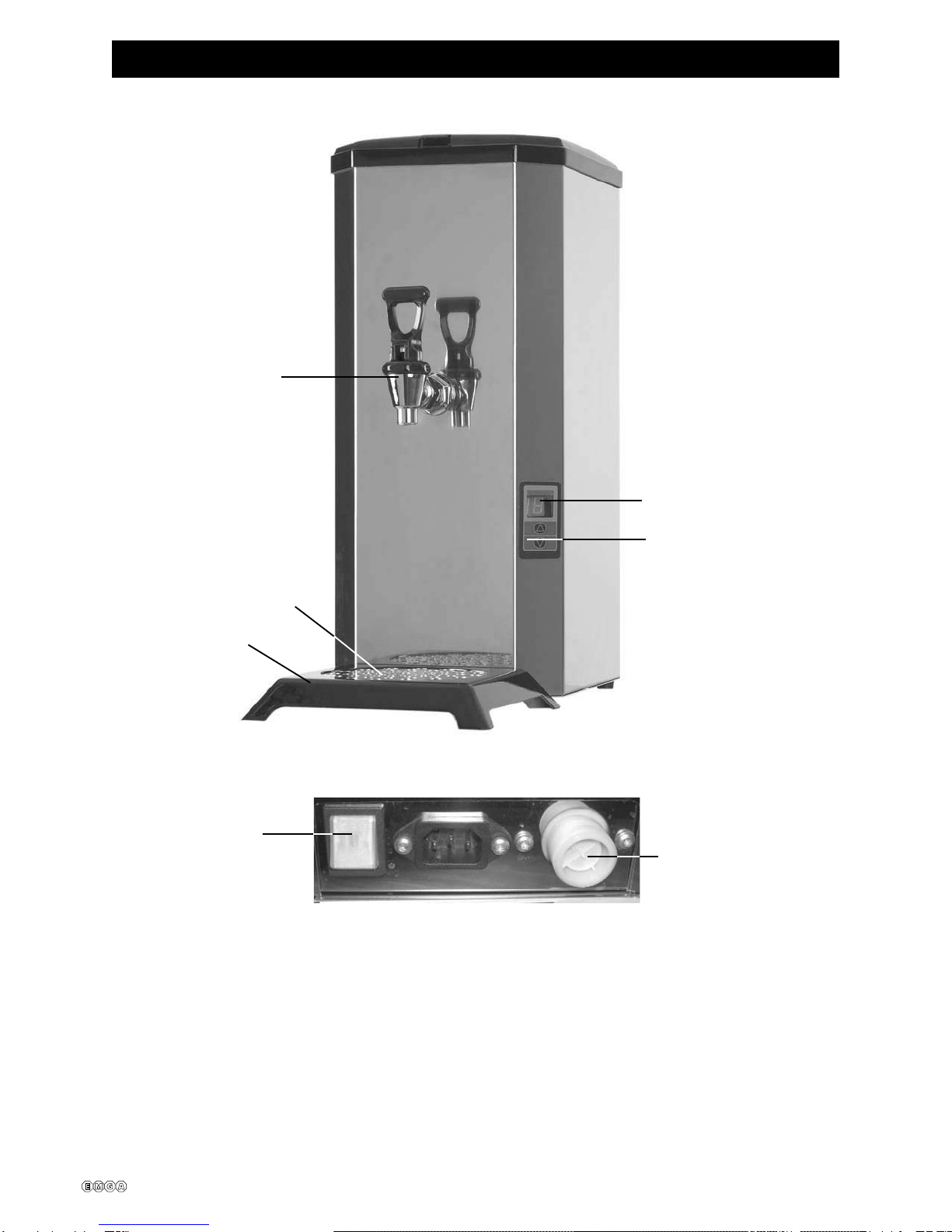

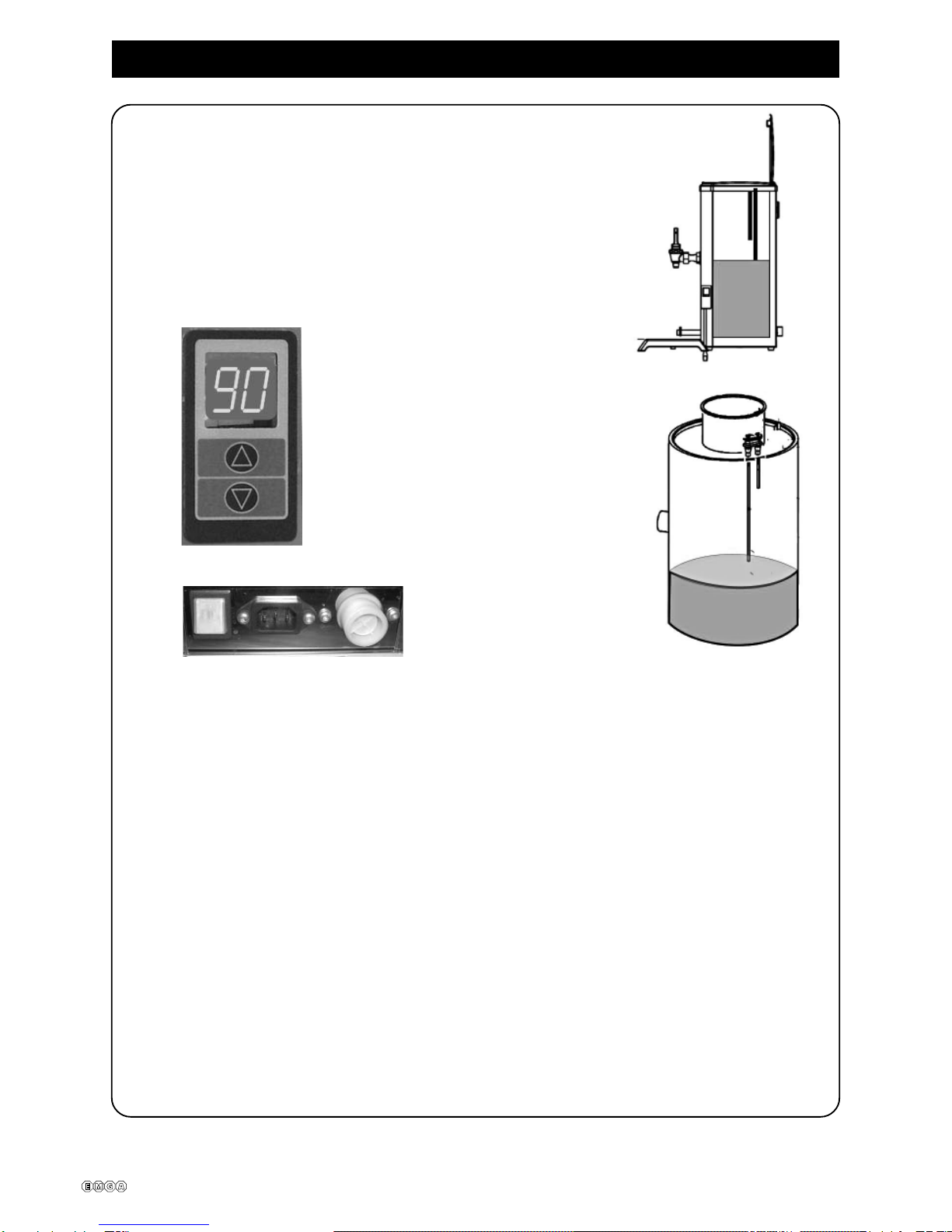

Hot water tap

Display

Electronic temperature

control

Drip tray insert

Functional description

Thehotwaterautomatcomprisesatankwhichholds7.5litres.

Thewater level is regulated by alevelguardthatswitchesandopens a solenoid

valve.

Thewatertemperatureisregulatedbyathermostatandanelement.

Hotwaterautomatconnectedtothewatersupply.

Drip tray

ON/OFF-

switch Connection for

filling with water

320504 en ma 2012 07 5/15

Installation and starting.

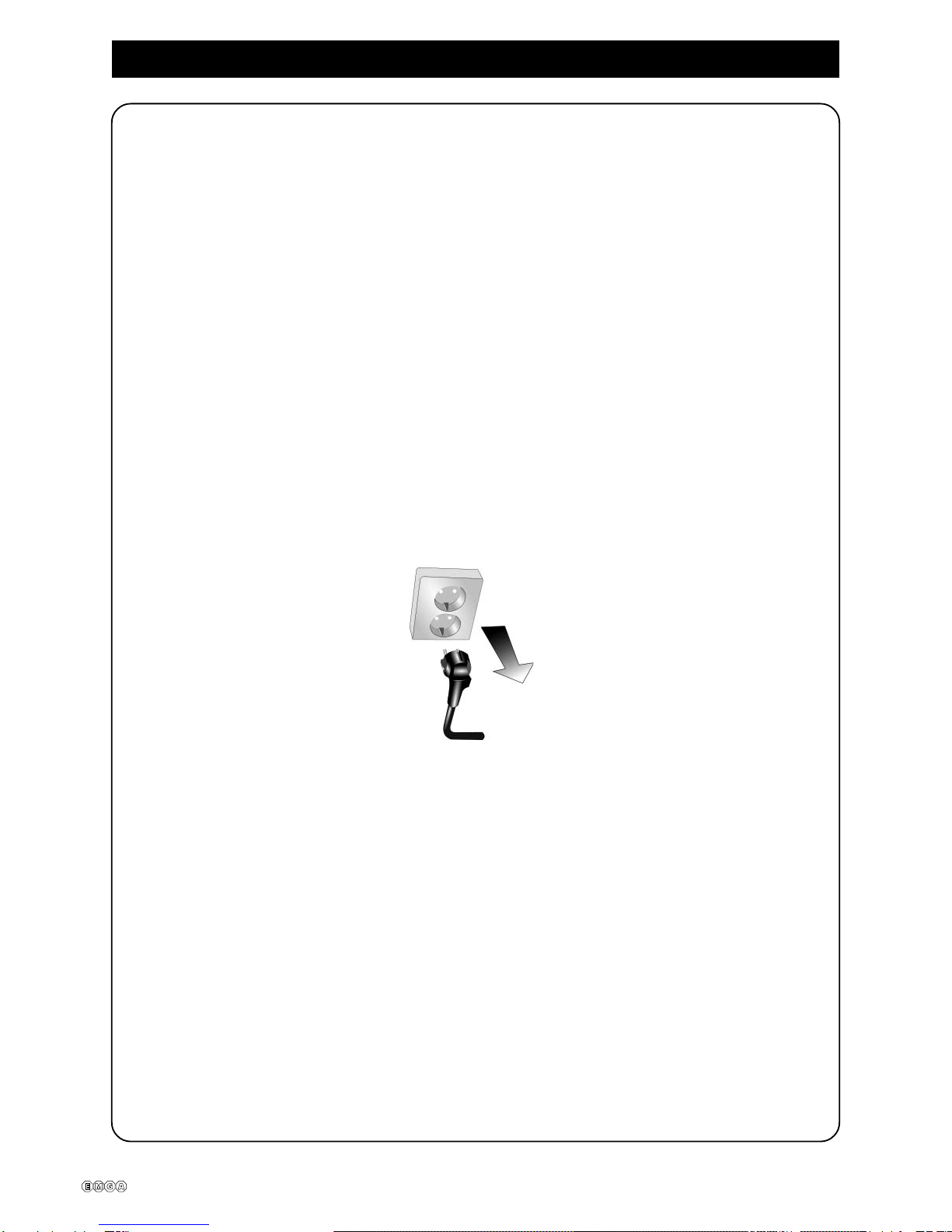

1.3. Insertthepowerpluginaseparately-earthed wall

socket. 230 V, 10 A.

1.1. Placethemachineonalevelandwatertight

surface.

1.4. Switchonusingtheswitchthatis located at the

backof the machine.

Checkthatthelightcomeson.

1.2. ConnecttotheColdwatersupplyusingthehose

provided. The most appropriate connection is to

atapthatcanbeturnedoff.

The pressure shall be 14.5 – 72.5 PSI

(1 – 5 bar) for the automat to function

properly

Refer to Programming on page 11 when filling

thewatermanually.

320504 en ma 2012 07 6/15

Installation and starting.

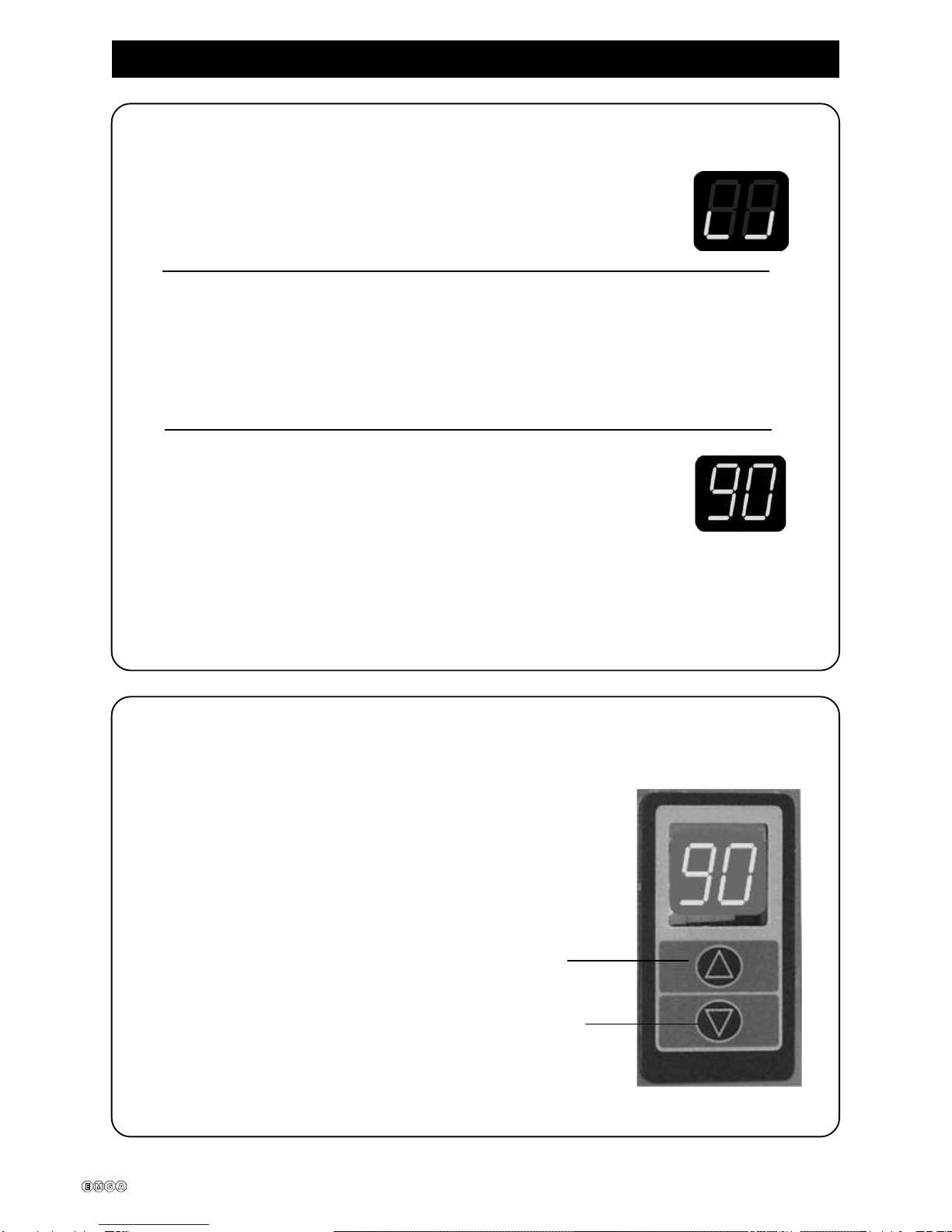

2. Setting the water temperature.

2.1. Adjust the water temperature using the membrane

switch. Max temperature 96ºC.

2.2. Increase the temperature.

2.3. Reduce the temperature.

1. The hot water automat will now start to fill and heat the water.

1.1. The display will flash when the automat fills with water

1.2. While the machineisheatingthewaterthedisplayshowstheactual

temperatureuntilthepre-selectedtemperatureisreached.

1.3. The display light stays on when the water has reached

the preset temperature of 90oC.

1.4. Thehotwaterautomatisnowreadyforuse.

Theoperatingtemperatureofthehotwaterautomatispresetatthefactory.

320504 en ma 2012 07 7/15

Programming. Calibrating the temperature sensor - SERVICE

CALIBRATING THE TEMPERATURE SENSOR. 90oC recommended.

1. Press buttons (symbol) and (symbol) at the same time for 5 seconds

anduntilyouhear2beeps.

Thedisplayshowsthecurrentsetting.

Adjust using the buttons (symbol) and (symbol).

2. Press (symbol) and (symbol) at the same time to save the current

setting.

NOTE The current temperature in the water tank must be entered when calibrating.

Adjust Signal

98° -2

97° -1 Max.

96° 0

95° 1

94° 2

93° 3

92° 4

91° 5

Av 6

ON

320504 en ma 2012 07 8/15

Fault indications - SERVICE

Fault indications E1, E2, E3 and E4 are shown in the display.

NOTE Remove the power plug from the wall during any installation work.

LEVEL CONTROL

TEMPERATURE CONTROL

E1 shown on the display = The level sensor’s short electrode is Clean thelevel sensor.

earthed but not the long one. Replace.

Cables connected incorrectly.

E4 shown on the display = The automat fills slowly. Restart the machine.

Poorwater pressure.

Water tap not open

E2 shown on the display= Temperatureoutsidethe 5°C-105°C.

statedrange

The temperature sensor is broken. Replace.

Cableloose.

E3 shown on the display .enihcamehttratseR.gnolootemitgnitaeH= Solid state broken. Replace.

Element broken. Replace.

Overheatingguardtripped or broken.

NOTE The installation work and all repairs shall be done by a competent

electrician.

320504 en ma 2012 07 9/15

IMPORTANT!

Important.

Donotdoanythingtothehotwaterautomat.Incorrectactioncanleadto personal injury

andfaults.The hot water automat should standonalevelsurfacetoworksatisfactorily.

Thehot water automat must be placedonawaterproofsurfacesothatany water leakage

isvisible.Makesure that kinks are not formed in the connectionhosewhenthehotwater

automat is pushed into place.

Thehotwaterautomat’ssupply and drain connection shallbecheckedregularly.

Checkthatnoleakagehasoccurredinconnectionwithinstallation.

Thewater connection always presents ariskofleakageirrespective of safety equipment.

Neverleavethehotwaterautomatunattended when it isinuse.Turnthetapoffwhenthe

machineis not in use.

Switchoffthesupplybeforeworkingonthehotwaterautomat.Thiscanbedoneby

removingthepowersupplyplugfromthewallsocket.

All installation work must be done by a qualified person.

320504 en ma 2012 07 10/15

Care.

NOTE Cleaning the outside of the machine

Never use aggressive cleaning agents when cleaning the hot water automat.

Use a soft cloth together with a

liquid cleaning agent that does

not scratch.

320504 en ma 2012 07 11/15

Programming.

1. Programming automatic controls for manual water filling.

1.1. FillthewatertoAinthe tank up to the long sensor pin.

See fig. 1.Approximately 4 litres.

1.2. Keep button ( B) pressed and switch on the machine

with theswitch ( D)at the same time.

A

fig.1.

fig.2.

B

C

D

1.3. Thedisplay shows T1

Changethe type of machine with buttonsBor C.

1.4. T1 = HVAautomat

T2= HVM manual

1.5. Confirm the choice by holding down the buttons (B) and (C) at the same time

forapproximately5seconds.

NOTE Install the plug supplied in the inlet valve (E) to avoid possible leakage.

E

320504 en ma 2012 07 12/15

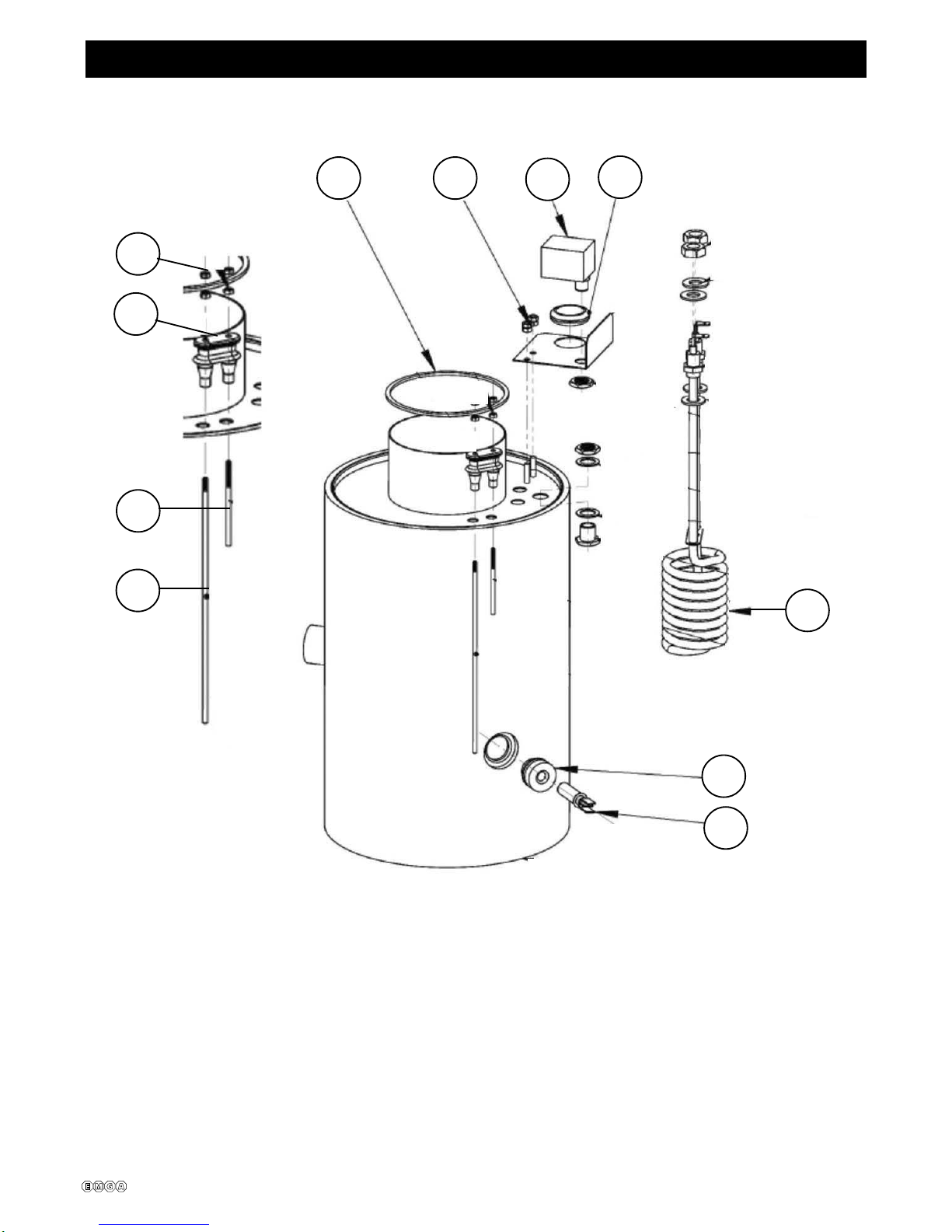

16

2

1

3

4

8

5

7

13

12 11 10

14 15

6

9

Exploded view. HVA

18

19

17

320504 en ma 2012 07 13/15

30 29 28

25

27

26

31

32

33

34

35

Exploded view Tank complete HVA

320504 en ma 2012 07 14/15

HVA.strapfotsiL

Item Part number Description Qty/unit

1 1304061 1revoccitsalP

2 1304062 Top 1revoc,noitces

3 1203527 T 1etelpmocAVHkna

4 120422 V 1dirgnoitalitne

5 1505022 Cold water hose, silicon L = 1

6 120624-01 Single valve, 2.5 l/m, 230 V 1

7 160801-04 1hctiwS

8 1604203 1etatsdiloS 4tooF-9

10 1031641 1xobscinortcelE

11 1603853 1hctiwsenarbmeM

12 1304063 1yartpirD

13 253207 1tresniyartpirD 1paT20-00202141

15 1802120 Tap 1noitcennoc 1SUS7X3MPNPwercs10

wercS-61

17 1031301 1sselniats,revocedisnI

18 160565 1eporuE/elbactnempiuqE

18 160566 Equipment cable / SouthAfrica 1

18 160567 1KU/elbactnempiuqE

19 160570 1telnisutarappA

——

TANK

25 1604133 1ro

tsimrehtCTN

26 160536 1rotsimrehtCTN,temmorG

27 1601311 Element 2200 W / 230 V HVA SUS 316 1

28 160536 Rubber grommet, TRP 30.0 RUBBER 1

29 220220 1drauggnitaehrevO

30 140108 1SUSmm74MtuN

31 1206589 T 1laeskna

32 140101 1SUS3MtuN

33 1605362 Doublegrommet,level sensor 1

34 1205302 13332trohsniprosneS

35 1205303 Level sensor pin HVAlong 2333 1

320504 en ma 2012 07 15/15

Sketch of dimensions.

Table of contents

Other EMGA Coffee Maker manuals

Popular Coffee Maker manuals by other brands

Coffee Queen

Coffee Queen Future TT Combi automat user manual

BRAYER

BRAYER BR1108 instruction manual

Breville

Breville VCF152X Instructions for use

Gorenje

Gorenje GFACM20S instruction manual

Classic Coffee Concepts

Classic Coffee Concepts RCB130 Instructions for installation, operation, maintenance

Cuisinart

Cuisinart PRC-12 Series Instruction booklet