EMH ITZ Guide

Edition: 25.11.2008 ITZ-PHB-E-1.00

Product manual for the

digital tariff meter ITZ

Installation I Device description I Operation

2

All of the contents published in this manual are copyright. Translating,

reprinting, duplicating and also saving of this manual in data processors

requires the exclusive permission from EMH.

All of the trademarks named in this manual are the property of EMH

Elektrizitätszähler GmbH & Co KG or the respective title holders.

EMH Elektrizitätszähler GmbH & Co KG is certified accord. to DIN ISO

9001:2000 and continually endeavours to improve their products

The contents of this manual and the technical specifications can be extended,

altered or removed without prior notice.

The description of the product specifications in this manual does not represent

part of a contract.

© 2007-2008 EMH Elektrizitätszähler GmbH & Co KG. All rights reserved.

If you have any questions or inspirations you can contact us at:

EMH Elektrizitätszähler

GmbH & Co KG

Südring 5

19243 Wittenburg

GERMANY

Tel.: +49 38852 645-0

Fax: +49 38852 645-129

Web: www.emh-meter.de

3

Contents page

1 Prologue.........................................................................................................6

1.1 Safety tips........................................................................................................6

1.2 Maintenance- and guarantee tips ....................................................................6

2 Mounting and installation .............................................................................7

2.1 Mounting the meter..........................................................................................7

2.2 Connecting the meter ......................................................................................7

2.3 Terminal blocks................................................................................................8

2.3.1 Transformer operated meter............................................................................8

2.3.2 Direct connected meter 60 A ...........................................................................8

2.3.3 Direct connected meter 100 A .........................................................................9

3 General features ..........................................................................................10

4 Standards and regulations .........................................................................11

5 Housing-, operating- and display elements ..............................................12

6 Technical description..................................................................................13

6.1 Technical data ...............................................................................................13

6.2 Functional circuit diagram..............................................................................14

6.3 Tariff switching clock......................................................................................14

6.4 Data interfaces...............................................................................................15

6.4.1 Optical data interface D0 ..............................................................................15

6.4.2 Electrical data interface RS232 .....................................................................15

6.4.3 Electrical data interface RS485 .....................................................................16

6.4.4 Electrical data interface CL0 (CS)..................................................................17

6.4.5 raconet radio interface...................................................................................17

6.5 Inputs.............................................................................................................18

6.6 Outputs..........................................................................................................18

6.7 Housing .........................................................................................................18

6.7.1 Baseplate.......................................................................................................18

6.7.2 Sealable meter cover.....................................................................................19

6.7.3 Sealable terminal cover.................................................................................19

7 Operating the meter.....................................................................................20

7.1 Operation modes...........................................................................................20

7.1.1 Parameter status (PAR-Status) .....................................................................20

7.1.2 Test mode......................................................................................................20

7.1.3 Standard operation mode ..............................................................................20

7.1.3.1 Standard display............................................................................................20

7.1.3.2 Error status display........................................................................................20

7.2 Display...........................................................................................................21

7.2.1 Installation error recognition ..........................................................................22

7.2.2 Manipulation recognition................................................................................25

7.3 Display control...............................................................................................27

7.3.1 Display control (Firmware 4.XX)....................................................................27

7.3.2 Display control (Firmware 5.XX and 6.XX) ....................................................28

8 Special features...........................................................................................29

8.1 Energy registration.........................................................................................29

8.2 Registration of instantaneous values.............................................................29

8.3 Measuring of the maximum demand..............................................................29

9 Meter readout...............................................................................................30

9.1 Communication software...............................................................................30

10 Appendix ......................................................................................................31

10.1 OBIS (Object-Identification-System)..............................................................31

10.2 EC Declaration of conformity.........................................................................33

4

Figure index

Table 1: Housing- and display elements.........................................................................12

Table 2: Technical data ..................................................................................................13

Table 3: Specifications of RS232....................................................................................15

Table 4: Specifications of RS485....................................................................................16

Table 5: Specifications of CL0........................................................................................17

Table 6: Specifications of inputs.....................................................................................18

Table 7: Specifications of outputs...................................................................................18

Table 8: Elements of the display.....................................................................................21

Table 9: OBIS-codes......................................................................................................32

Table index

Table 1: Housing- and display elements.........................................................................12

Table 2: Technical data ..................................................................................................13

Table 3: Specifications of RS232....................................................................................15

Table 4: Specifications of RS485....................................................................................16

Table 5: Specifications of CL0........................................................................................17

Table 6: Specifications of inputs.....................................................................................18

Table 7: Specifications of outputs...................................................................................18

Table 8: Elements of the display.....................................................................................21

Table 9: OBIS-codes......................................................................................................32

5

Abbreviations

A Active energy

+A Positive active energy (customer imports from utility)

-A Negative active energy (customer exports to utility)

lAl Measuring of absolute value of A

Cl. Accuracy class

DIN Deutsches Institut für Normung e.V.

(German Institute for standards)

EN European standards

EVU Utility

IEC International Electromechanical Commission

Imp. Impulse

Imp./kWh Impulse per kWh

Imp./kvarh Impulse per kvarh

L1, L2, L3 External conductor

LED Light Emitting Diode

MP Measuring period (only for maximum demand measuring)

N Neutral conductor

P Active power

+P Positive active power (customer imports from utility)

-P Negative active power (customer exports to utility)

PTB PTB (German certified body)

Q Reactive power

+Q Positive reactive power

+R Positive reactive energy

-R Negative reactive energy (customer exports to utility)

lRl Measuring of absolute value of R

RTC Real Time Clock

S0 Interface accord. to DIN 43 864

raconet radio readout system of EMH

6

1 Prologue

In this manual, all design variants of the ITZ meter are described. Please note, that

the meters can be designed differently regarding for example configuration, interfaces,

in-/outputs etc. It is therefore possible that meter features are described in this manual

which do not apply to the meter(s) used by you.

1.1 Safety tips

The meters are to be used exclusively for measuring electrical energy and must only

be operated within the specified technical data (see nameplate).

When installing or changing the meter the conductor to which the meter is connected

must be de-energised. Only the intended screw terminals may be used for this.

Contact of parts under voltage is extremely dangerous. Therefore the relevant back-up

fuse is to be removed and stored so that other people cannot insert this unnoticed.

Before opening the meter the secondary circuit to the current transformer must be short

circuited. The high voltage on the current transformer is extremely dangerous and

destroys the current transformer.

With incorrect meter installation the S0-inputs can lead to line voltage.

Attention: Danger!

The local standards, guidelines, regulations and instructions are to be obeyed.

Only authorised personnel are permitted to install the electricity meters.

1.2 Maintenance- and guarantee tips

The meter is maintenance-free. With damages (e.g. due to transportation, storing) no

repairs may be carried out independently. As soon as the meter is opened, the

guarantee claims cease. The same applies in case the defect can be traced back to

external influences (e.g. lightning, water, fire, extreme temperatures and weather

conditions, improper or negligent use or treatment).

7

2Mounting and installation

2.1 Mounting the meter

Meters form the series ITZ are suitable for wall mounting in accordance with

DIN 43 857-2.

Figure 1: Meter dimensions

2.2 Connecting the meter

When connecting the meter it is very important to take notice of the connection diagram

which can be found in the terminal cover and also in the delivery documents:

Example:

Figure 2: Connection diagram

- 3x230/400 V; 5(60) A

- 1 control input (ES)

- 1 output Opto-MOSFET (HR)

- Electrical interface RS485

Note: Direct connected meters are to be fused against short circuits with a back-up fuse

of 63 A or 100 A and transformer operated meters in the voltage circuit with a back-up

fuse of < 10 A.

8

2.3 Terminal blocks

2.3.1 Transformer operated meter

Current

terminals

Voltage

terminals

Auxiliary

terminals

Terminal dimensions

W x H (d) mm

4.6

4.6

9-block: 3.2 x 3

12-block: 3

Max. connection-

cross section (mm²)

6

6

2.5

Maximum torques

for terminals (Nm)

1.5

1.8

0.5

Head/size of thread

slot/M4

PZ1/M4

slot/M3

Figure 3: Terminal block for transformer operated meter

2.3.2 Direct connected meter 60 A

Current terminals

Voltage and auxiliary

terminals

Terminal dimensions

W x H (d) mm

6.5

3

Max. connection-

cross section (mm²)

16

2.5

Maximum torques

for terminals (Nm)

2.7

0.5

Head/size of thread

PZ2/M5

slot/M3

Figure 4: Terminal block for direct connected meter 60 A

In normal operation the

voltage bridges are closed

and are only opened for

testing the device!

opened

closed

9

2.3.3 Direct connected meter 100 A

Current terminals

Voltage and auxiliary

terminals

Terminal dimensions

W x H (d) mm

9,5

3

Max. connection-

cross section (mm²)

35

2,5

Maximum torques

for terminals (Nm)

3,1

0,5

Head/size of thread

PZ2/M6

slot/M3

Figure 5: Terminal block for direct connected meter 100 A

For testing the device the

voltage path is interrupted by

the path separator. With

normal operation the path

separator is removed.

10

3General features

-Direct connected or transformer operated meter for measuring active energy

-Registration of the energy can be parameterised at the factory as follows:

-Measuring of +A with non-reverse ratchet

-Measuring of +A and -A

-Measuring of absolute value of A

-Measuring of +R with non-reverse ratchet

-Measuring of +R and -R

-Measuring of absolute value of R

-Meter designs:

Voltages

3x230/400 V

3x220/380 V

3x58/100 V

3x63/110 V

3x115/200 V

3x127/220 V

3x132/230 V

Currents

5(60) A

5(85) A

5(100)A

10(60) A

10(65) A

10(100) A

5ll1 A

1(6) A

5 A

-Max. 4 tariff registers + 1 tariffless register, 15 pre-values each for every measuring

type (Firmware 6.XX)

-1 maximum register (24 h continuously active), 15 pre-values a for every measuring

type (Firmware 6.XX)

-Impulse output for the transfer of energy proportional impulses

-Test-LED for measuring device test

-Data interfaces:

-Optical data interface D0

-Electrical data interface CL0, RS485 or RS232

-raconet radio interface

-Real time clock with calendar function

-Manipulation recognition

11

4Standards and regulations

DIN EN 50470-1 Electricity metering equipment (a.c.) - Part 1: General

requirements, tests and test conditions - Metering

equipment (class indexes A, B and C)

DIN EN 50470-3 Electricity metering equipment (a.c.) - Part 3: Particular

requirements - Static meters for active energy (class

indexes A, B and C)

DIN EN 60529 Degrees of protection provided by enclosures (IP-Code)

(IEC 60529:1989 + A1:1999)

DIN EN 61000… Electromagnetic compatibility (EMC)

DIN EN 61038 Time switches for tariff and load control

(IEC 61038:1990, amendment)

DIN EN 62052-11 Electricity metering equipment (AC) - General requirements,

test and test conditions - Part 11: Metering equipment

(IEC 62052-11:2003)

DIN EN 62053-21 Electricity metering equipment (a.c.) - Particular

Requirements - Part 21: Static meters for active energy

(classes 1 and 2) (IEC 62053-21:2003)

DIN EN 62053-23 Electricity metering equipment (a.c.) - Particular

Requirements - Part 23: Static meters for reactive energy

(classes 2 and 3) (IEC 62053-23:2003)

DIN EN 62056-61 Electricity measuring - Data exchange for meter reading,

tariff and load control - Part 61: Object identification system

OBIS (IEC 62056-61:2002)

ITU-T V.11 Electrical characteristics for balanced double-current

interchange circuits operating at data signaling rates up to

10 Mbit/s

TIA/EIA-485 Electrical characteristics of generators and receivers for use

in balanced digital multipoint systems

ITU-T V.24 List of definitions for interchange circuits between data

terminal equipment (DTE) and data circuit terminating

equipment (DCE).

ITU-T V.28 Electrical characteristics for unbalanced double-current

interchange circuits

VDEW-Lastenheft 2.1 Elektronische Lastgangzähler (Electronic load profile meter)

12

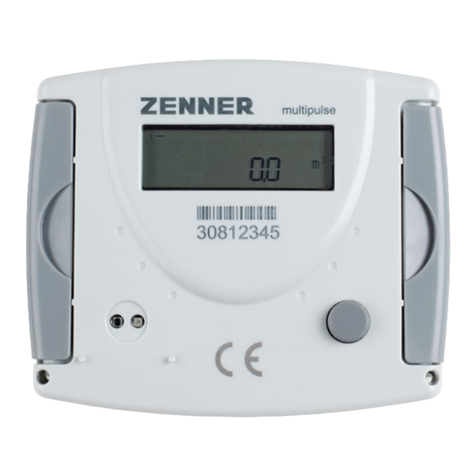

5Housing-, operating- and display elements

Figure 6: Housing-, operating- and display elements

No.

Description

Function

1

Meter cover

---

2

Test-LED

Meter test

3

LC-display

Display of measured values and

status information

4

Parameterisation button

Operation of this button transfers

the meter into the parameterization

mode (found under the meter cover

5

Mechanical call-up button

Call-up of the display contents

in the LC-display

6

Sealing screw

Fastening the terminal cover

7

Terminal cover

Covering for the terminal block

8

Optical call-up button

Call-up of the display contents

in the LC-display

9

Optical data interface D0

For communication between the

meter and a readout device

10

Mechanical reset button

Carrying out certain actions such

as setting the clock etc.

11

Manipulation recognition

Recognition of opening the terminal

cover and recognition of magnetic

fields (under the meter cover

12

Sealing screw

Fastening the terminal cover to

the terminal block

Table 1: Housing- and display elements

2

9

10

11

3

4

5

8

1

6

7

12

13

6Technical description

6.1 Technical data

Voltage

4-wire meter

3x230/400 V, 3x220/380 V, 3x58/100 V, 3x63/110 V,

3x115/200 V, 3x127/220 V, 3x132/230 V

Current

5(60) A, 5(85) A, 5(100) A, 10(60) A, 10(65) A, 10(100) A;

5II1 A, 1(6) A, 5 A

Frequency

50 Hz, 60 Hz

Accuracy

active energy

Cl. A or Cl. B acc. to DIN EN 50470-1, -3

(Cl. 2 or Cl. 1 acc. to IEC 62053-21)

reactive energy

Cl. 3 or Cl. 2 acc. to IEC 62053-23

Measuring types

active energy

+A (with non-reverse ratchet), Option: +A/-A or IAI

reactive energy

+R (with non-reverse ratchet), Option: +R/-R or IRI

Meter constants

LED (Imp./kWh)

500 - 40 000 (depending on meter type)

output (Imp./kWh)

250 - 20 000 (depending on meter type)

Energy registers

maximum number (FW 6.XX)

4 tariff registers + 1 tariff less register, 15 pre-values each for

every measuring type

Maximum registers

maximum number (FW 6.XX)

1 maximum register (24 h continuously active) for for every

measuring type

measuring period

5, 6, 10, 12, 15, 20, 30, 60 min (parameterable)

Real Time Clock

accuracy

within 5ppm

synchronization

via data interfaces or control input

running reserve battery/capacitor

> 20 years/> 7 days

Control inputs

maximum number

3 pieces

S0

1 piece

system voltage

max. 2 pieces

Data retention time

without voltage in the EEPROM, at least 20 years

Display

type

LCD

digit size

8 x 4 mm (value range)

additional display

status information about phase failure, phase sequence, tariff,

meter start-up, manipulation and running reserve of RTC

meter start-up, manipulation and running reserve of RTC

Operation

mechanical buttons

for display call-up and reset (sealable)

optical sensor

for display call-up

radio module

functions

meter remote readout via bi-directional communication,

(integrated)

online mode, transferring of commands, automatic network

build-up etc.

transmitting frequency

868 MHz in license free ISM-band

certification

acc. to DIN EN 300220, CE-mark

Data interfaces

optical data interface

optical data interface D0 (Mode C up to 4800 baud)

electrical data interface

RS485, RS232 or CL0 (fixed or Mode C up to 9600 baud)

data protocol

IEC 62056-21

Outputs

maximum number

3 pieces (S0, Opto-MOSFET, relay or high load relay)

Energy supply

switched-mode power supply

3-phase from the measuring voltage

mains buffering time

> 200 ms

Power consumption

per phase (Basic Meter)

voltage path

< 1.3 VA/< 0.8 W

current path

< 0.03 VA

EMC characteristics

isolation resistance

isolation: 4 kV AC, 50 Hz, 1 min

surge voltage

EMC: 4 kV, impulse 1.2/50 μs, 2 Ω

ISO: 6 kV, impulse 1.2/50 μs, 500 Ω (measuring paths

and in- and outputs)

resistance against HF-fields

30 V/m (under load)

Temperature range

operating/limit range

-25°C ...+60°C/-40°C ...+70°C

storage and Transport

-40°C ...+70°C

Relative humidity

95% acc. to IEC 62052-11, EN 50470-1 and IEC 60068-2-30

Housing

dimensions

approx. 178 x 328 x 61 (W x H x D) mm

class of protection

2

degree of protection housing/terminals

IP 51/IP 31

housing material

polycarbonate glass-fibre-reinforced, without halogen, recyclable

fire characteristics

acc. to DIN EN 62052-11

weight

up to 60 A approx. 1.35 kg, up to 100 A approx. 1.6 kg

Table 2: Technical data

14

6.2 Functional circuit diagram

Figure 7: Functional circuit diagram

6.3 Tariff switching clock

The tariff switching clock works on the basis of a Real Time Clock (RTC) and can be set

via the D0-interface. The accuracy is within 5 ppm. The tariff switching clock gives the

time when the tariff switching should take place. Tariff switching can be parameterised,

one tariff is always active. External tariff control is possible; thereby the internal tariff

control is automatically deactivated. The ITZ has separate daily switching clocks for

weekdays and holidays.

The following day types are supported:

a) Monday - Friday

b) Saturday

c) Sunday

d) Holidays

Setting the date and time

The date and time can be set with the software EMH-COM or EMH-COMBI-MASTER

2000 either via the optical- or the electrical interface. In Germany, according to the PTB

requirements, the latter may only be carried out once after ending the parameter status

or after voltage return.

Synchronisation of the Real Time Clock takes place via:

a) the internal quartz or

b) the synchronisation input.

Buffering of the Real Time Clock takes place

a) with battery or

b) with capacitor.

The battery guarantees a running reserve of > 10 years, the capacitor of > 7 days.

With a completely discharged capacitor the charging time is approx. 20 minutes after

applying the phase voltage (90% voltage). If the running reserve is exhausted then in the

display the relevant symbol is displayed (see page 21). After voltage return the Real

Time Clock is set to the time of the network power failure. Furthermore, the energy is

registered in a fixed register (depending on the configuration 1.8.0, 1.8.1, 1.8.2, 1.8.3 or

1.8.4).

15

6.4 Data interfaces

The data readout takes place according to 62056-21 via:

optical data interface D0

electrical data interface (RS232, RS485 or CL0)

raconet radio interface

6.4.1 Optical data interface D0

The D0-interface is designed according to IEC 62056-21 with Mode C. The following

baud rates can be set: 300, 1200, 2400 or 4800 baud.

6.4.2 Electrical data interface RS232

The electrical interface (galvanically de-coupled) is found at the additional terminals

under the sealable terminal cover (see connection diagram).

The electrical interface RS232 is a symmetrical two-wire interface designed according to

ITU-T V.24 and ITU-T V.28. The distance between the readout device and the meter

may not exceed 15 m.

Features

Number of connected meters

1

Maximum cable length

up to 15 m

Data transmission rate

300 ... 9600 baud

Signal according to ITU-T V.28

logical “1”

- 3 V to - 15 V

logical “0”

+ 3 V to + 15 V

Table 3: Specifications of RS232

16

6.4.3 Electrical data interface RS485

The electrical interface (galvanically de-coupled) is found at the additional terminals

under the sealable terminal cover (see connection diagram).

The electrical interface RS485 is a symmetrical two wire interface and is designed

in accordance with TIA/EIA-485 / ITU-T V.11. Up to 32 meters can be connected

to a meter modem with RS485-interface. The distance between the readout device and

the meter may not exceed 1,000 m.

Features

Number of connected meters

up to 32

Maximum cable length

up to 1,000 m

Data transmission rate

300 ... 9600 baud

Signal according to

TIA/EIA-485 / ITU-T V.11

logical “1”

-0.3 V to -6 V

logical “0”

+0.3 V to + 6 V

Table 4: Specifications of RS485

RS485 Bus

Up to 32 devices can be operated by one RS485 Bus. Usually in a bus system the first

and last device should be terminated with a terminating resistor between wire „A“ and

„B“ in order to eliminate conduction reflections.

Bus structure:

Figure 8: System layout - RS485-two wire bus

Detail: Please note:

The terminating resistor may only be

installed at the first and last device.

See detail

See detail

B

A

B

A

B

A

. . .

Device 1 Device 2 Device 32

RS485-two wire bus

RS485

23 24 25

A

B

RTERM= 120

Shield

17

6.4.4 Electrical data interface CL0 (CS)

The electrical interface CL0 (galvanically de-coupled) is found at the additional terminal

under the sealable terminal cover (see Figure 3 on page 8).

The CL0 interface conforms to DIN 66348, Part 1. It is a passive two wire interface, i.e.

possesses no own power source. Data is transmitted as mark/space at a nominal current

of 20 mA. For that reason, it is also called a 20 mA current interface.

The voltage drop of the series switched transmitters and receiver in the meter is about

4 V. Thus a maximum of four meter outputs can be switched in series and operated by

one modem. The meters can be addressed and called up specifically. The CL0 interface

can be used for data transmission up to 1,000 m.

General features

Number of connected meters

4

Maximum cable length

up to 1,000 m

Data transmission rate

300 ... 9600 baud

Electrical features

Signal

one

zero

Sender

11 mA

≤ 2.5 mA

Receiver

9 mA

≤ 3 mA

Permitted voltage drops

Sender

max. 2 V

Receiver

max. 3 V

Maximum values

Current

30 mA (short circuit)

Voltage

30 V (open current circuit)

Table 5: Specifications of CL0

6.4.5 raconet radio interface

The raconet radio interface enables a wireless bi-directional communication like data

readout and transmission of commands between meter and data collector.

The data transmission takes places with 868 MHz in the licence free and regulated ISM-

Band.

The antenna of the radio interface can be designed as integrated antenna or as housing

antenna.

Further information for raconet readout system you can find in separately documents.

18

6.5 Inputs

The ITZ can be equipped with max. 3 inputs:

- 2 control inputs with low- or system voltage (potential free) and

- 1 S0 input (not potential free)

Specifications

S0 input

max. 27 V DC, 27 mA (active)

Low voltage

5..40 V DC

System voltage

58..230 V

Table 6: Specifications of inputs

6.6 Outputs

The ITZ can be equipped with a maximum of 3 outputs:

- max. 3 as S0 output according to DIN 43 864 or

- max. 2 relays (make contact [NO]) resp. a high load relay (make contact [NO]) or

- max. 3 as Opto-MOSFET output (break contact [NC] or make contact [NO])

Specifications

S0 output

Impulse time 20-500 ms (25-1 Hz) in 20 ms steps;

energy impulses 100-10,000 Imp./kWh;

max. 27 V DC, 27 mA (passive)

Relay

max. 250 V AC/DC, 100 mA

High load relay

max. 250 V AC/DC, 10 A

Opto-MOSFET

max. 250 V AC/DC, 100 mA

Table 7: Specifications of outputs

6.7 Housing

6.7.1 Baseplate

The baseplate is made of grey polycarbonate with the upper hanging eye-hook and the

two lower hanging eye-hooks.

Figure 9: Baseplate

19

6.7.2 Sealable meter cover

The meter cover is made of crystal clear polycarbonate. The window area is transparent

and the remaining cover surface has an eroded structure. The meter cover is hung at the

top of the baseplate and fastened at the bottom with two sealed screws.

Figure 10: Meter cover

6.7.3 Sealable terminal cover

The terminal cover is made of grey polycarbonate. It is screwed to the terminal block by

means of sealing screws. Inside the terminal cover there is a pin for manipulation

recognition. With this pin every attempt to remove the terminal cover is registered.

On the inside of the terminal block you can find the connection diagram.

Figure 11: Terminal block with the pin for manipulation recognition

20

7Operating the meter

7.1 Operation modes

7.1.1 Parameter status (PAR-Status)

The PAR-Status is used for configuration of the meter at the factory. For activation

of this mode press the PAR-Status button. This button is found on the meters main

PC-Board and is protected by a seal.

7.1.2 Test mode

In the test mode the resolution of the energy register is 100 times higher than the

resolution in the standard operation mode. This also applies for the readout table.

The test mode is also addressed via the write command 1.58.T(N) for active energy

and 3.58.T(N) for reactive energy.

„N“ = 1 means activate, „N“ = 0 means deactivate. „T“ stands for the number of the tariff

which is activated with the command.

Activation of the test mode is shown by the simultaneous flashing of the star symbol

and the exclamation mark in the display (see page 21). After 24 hours uninterrupted

operation the test mode is automatically deactivated.

7.1.3 Standard operation mode

When the meter is in normal operation then it is always in the standard operation mode.

7.1.3.1 Standard display

After meter installation and running through the display tests the meter is in the standard

display. With a multi tariff design, the energy value and the designation of the active tariff

are shown in the display.

With a two tariff meter with static display the energy value for high tariff is displayed in

the value area and the energy value for low tariff in the OBIS code area. Thereby the

digitness of the high tariff value is reduced from 8 to 7.

From every condition the display returns back to the standard display providing that the

display was not operated within the configured delay period (5 to 30 minutes).

7.1.3.2 Error status display

During operation of the meter a continual check takes place of the register data, the code

and also the checksum. If during the check an error is recognised then an error code is

shown in the display.

Table of contents

Other EMH Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Precision Digital Corporation

Precision Digital Corporation PD663 instruction manual

PCB Piezotronics

PCB Piezotronics 352A74 Installation and operating manual

Campbell

Campbell CS616 instruction manual

Zenner

Zenner multipulse Installation and operating manual

SICK

SICK Mounting kit 2 Mounting instructions

Ametek

Ametek Chandler Engineering 8340 instruction manual