Tecfluid Series LT User manual

R-MI-LT Rev.: 3 english version

Instructions manual

The art of measuring

Series LT

Level gauge

2

Thank you for choosing a product from Tecfluid S.A.

This instruction manual allows the installation, configuration,

programming and maintenance. It is recommended to read it before

using the equipment.

This document shall not be copied or disclosed in whole or in any

part by any means, without the written permission of Tecfluid S.A.

Tecfluid S.A. reserve the right to make changes as deemed

necessary at any time and without notice, in order to improve the

quality and safety, with no obligation to update this manual.

Make sure this manual goes to the end user.

Keep this manual in a place where you can find it when you need

it.

In case of loss, ask for a new manual or download it directly from

our website www.tecfluid.com Downloads section.

Any deviation from the procedures described in this instruction

manual, may cause user safety risks, damage of the unit or cause

errors in the equipment performance.

Do not modify the equipment without permission. Tecfluid S.A. are

not responsible for any problems caused by a change not

allowed. If you need to modify the equipment for any reason,

please contact us in advance.

PREFACE

WARNINGS

3

TABLE OF CONTENTS

SERIES LT

1 INTRODUCTION .......................................................................... 6

2 WORKING PRINCIPLE .................................................................. 6

3 MODELS ...................................................................................... 6

4 RECEPTION ................................................................................. 7

5 HANDLING ................................................................................... 7

6 INSTALLATION ............................................................................. 7

6.1 Minimum distances ............................................................. 8

7 LEVEL ASSEMBLY IN TWO SECTIONS .......................................... 10

7.1 Model LT106 (stainless steel) .............................................. 10

7.2 Model LT14 (plastic) ........................................................... 14

8 LEVEL READING ........................................................................... 18

9 FLOAT TYPES .............................................................................. 18

10 AMD LIMIT SWITCH ....................................................................... 19

10.1 Introduction ........................................................................ 19

10.2 Operation ........................................................................... 19

10.3 Switching point adjustment ................................................. 19

10.3.1 LT models ............................................................. 19

10.3.2 LTL models ........................................................... 20

10.4 Electrical connection ........................................................... 20

10.5 Mounting ........................................................................... 21

11 AMM LIMIT SWITCH ..................................................................... 21

11.1 Introduction ........................................................................ 21

11.2 Operation ........................................................................... 21

11.3 Switching point adjustment ................................................. 21

11.3.1 LT models ............................................................. 21

11.3.2 LTL models ........................................................... 22

11.4 Electrical connection ........................................................... 23

11.5 Mounting ........................................................................... 23

12 APR LIMIT SWITCH ...................................................................... 24

12.1 Introduction ........................................................................ 24

12.2 Operation ........................................................................... 24

12.3 Switching point adjustment ................................................. 24

4

12.3.1 LT models ............................................................. 24

12.3.2 LTL models ........................................................... 25

12.4 Electrical connection ..................................................................... 25

13 AAR LIMIT SWITCH ...................................................................... 27

13.1 Introduction ........................................................................ 27

13.2 Operation ........................................................................... 27

13.3 Switching point adjustment ................................................. 27

13.4 Electrical connection ........................................................... 28

14 LTE TRANSMITTER ...................................................................... 29

14.1 Introduction ........................................................................ 29

14.2 Operation ........................................................................... 29

14.3 Models ............................................................................... 29

14.4 Remote transmitter .............................................................. 30

14.4.1 Electrical connection .............................................. 30

14.4.2 Mounting ............................................................... 30

14.5 Compact transmitter ........................................................... 31

15 LTDR TRANSMITTER ................................................................... 32

16 MAINTENANCE ............................................................................ 32

16.1 Series LT ........................................................................... 32

16.2 AMD limit switch maintenance ............................................. 32

16.2.1 Electrical verification ................................................ 32

16.3 AMM limit switch maintenance ............................................ 33

16.4 APR limit switch maintenance .............................................. 33

16.5 AAR limit switch maintenance .............................................. 33

17 TECHNICAL CHARACTERISTICS ................................................... 34

17.1 Series LT ........................................................................... 34

17.2 AMD limit switch ................................................................. 34

17.3 AMM limit switch ................................................................ 35

17.4 APR limit switch ................................................................. 35

17.5 AAR limit switch ................................................................. 35

17.6 LTE transmitter .................................................................... 35

5

18 SAFETY INSTRUCTIONS ............................................................... 36

18.1 Pressure equipment directive ............................................. 36

18.2 Certificate of conformity TR CU (EAC marking) ..................... 36

19 ADDITIONAL INSTRUCTIONS FOR THE ATEX VERSION ................. 37

19.1 Flameproof enclosure ......................................................... 37

19.1.1 Surface temperature .............................................. 37

19.1.2 Connecting conductive parts to earth ....................... 37

19.1.3 Maintenance .......................................................... 38

19.1.4 Technical characteristics of the ATEX version .......... 38

19.1.5 Marking ................................................................. 38

20 NAME PLATE ................................................................................ 39

21 DIMENSIONS ................................................................................ 40

22 ATEX CERTIFICATE ....................................................................... 44

23 ATEX DECLARATION OF CONFORMITY ........................................ 46

6

1INTRODUCTION

The level gauges series LT are very robust equipment and resistant to extreme conditions of

temperature and pressure, as well as corrosive chemicals, depending on the manufacturing

materials used.

They can fit switches that allow to detect a specific level and provide an alarm signal to a

remote device. They can also fit a resistive sensor with a 4-20 mA transmitter proportional to

the level.

2 WORKING PRINCIPLE

A float inside a chamber communicated with the tank whose liquid level needs to be

measured, floats on the liquid surface and moves together with it, as level increases or

decreases.

The float is designed for the specific working liquid density and shows the tank level by

means of magnetic coupling.

This is possible thanks to an external float housed in a borosilicate glass pipe (LT models)

that rises or falls depending on the height of the level in the tank, or by a magnetic strips rail

(LTL models), that mounted externally and isolated of the level gauge chamber, changes its

colour with the magnetic field.

3 MODELS

LT ... LTL106 Body in AISI 316L, flanged connection

LT ... LTL116 Body in AISI 316L, threaded connection

LT ... LTL14 Body in PVC, PVC-C, PP or PVDF, flanged connection

LT ... LTL15 Body in SS 316L with internal PTFE coating, flanged connection

7

The working temperatures are given for an ambient temperature of 20ºC.

The couplings to the tank must be aligned and perpendicular.

Flange bolts should be tightened progressively in a criss-cross sequence to avoid causing

stress.

With threaded connections, they should be tightened progressively and together.

For the LT models (with a glass tube), it is recommended to remove this tube before

mounting the level to the tank.

4 RECEPTION

The series LT level gauges are supplied conveniently packaged for their protection during

transportation and storage, together with their instructions manual for installation and

operation.

All the instruments have been verified in our facilities, ready for installation and operation.

LT level gauges are supplied with the float blocked in its bottom position by means of a stop

introduced into the lower side coupling.

Before mounting on the tank, this stop must be removed.

5 HANDLING

It must be done carefully and without blows.

6 INSTALLATION

Important: Check that the maximum working pressure is below the limit shown on the

identification label of the equipment. Check that the maximum working temperature of the

liquid is within the limits given in the following chart.

Materials Liquid temperature range

EN 1.4404 (AISI 316L) -20ºC … 400ºC

EN 1.4404 (AISI 316L) -20ºC … 200ºC

PP -10ºC … 80ºC

PVDF -20ºC … 145ºC

PTFE -20ºC … 150ºC

Model

LT106

LTL106

LT … LTL14 / PP

LT … LTL14 / PVDF

LT … LTL15 / PTFE

LT … LTL14 / PVC-C PVC-C 0ºC … 70ºC

LT … LTL14 / PVC PVC 0ºC … 45ºC

8

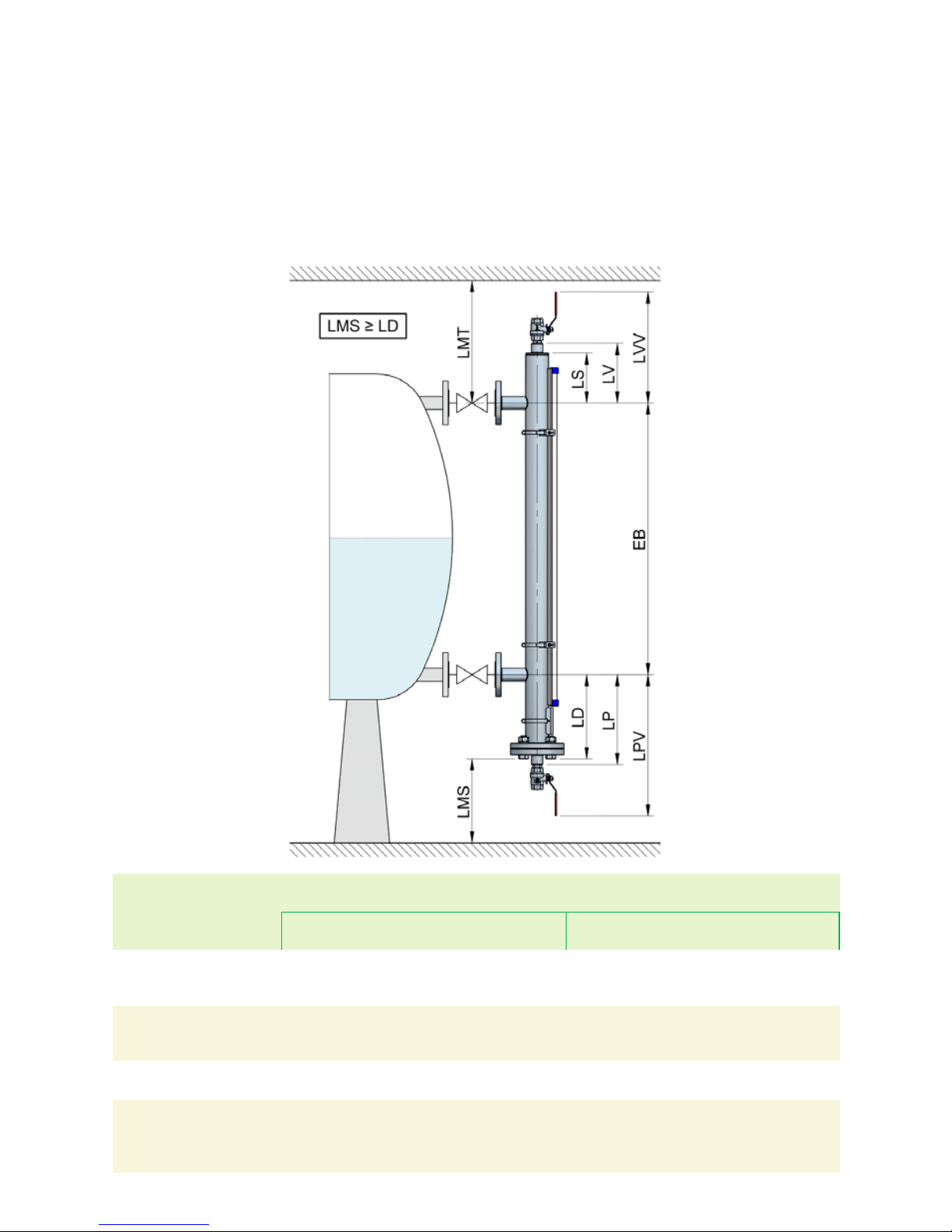

6.1 Minimum distances

It is important to take in account some distances that must be kept in order to remove the

float due to a change in density or for maintenance purposes.

Distance LMS between the lowest side of the level gauge and the floor must be kept longer

or equal to LD distance.

On the other hand, the lower dimension LD, LP or LPV of series LT level gauges is variable

depending on the working liquid density. The lower the density, the longer the dimension.

Model Liquid

density (kg/l)

Lower dimension

Without

drain (LD)

With drain

(LP)

With drain +

valves (LPV)

Without

vent (LS)

With vent

(LV)

With vent +

valve (LVV)

LT … LTL /

AISI 316L

0,55 ... 0,59

0,60 ... 0,91

≥ 0,92

430

340

260

445

355

275

590

500

420

130 155 300

LT … LTL /

PVC

0,60 ... 0,79

0,80 ... 0,89

≥ 0,90

400

310

240

525

435

365

150 140 265

LT ... LTL /

PP ≥ 0,70 240 365 150 165 290

LT … LTL /

PVDF

0,80 ... 0,89

0,90 ...0,99

1,00 … 1,19

≥ 1,20

415

340

290

240

540

465

415

365

150 165 290

Upper dimension

9

For the LT level gauges, once the level is connected to the tank, fill the glass tube, and next

reassemble the glass tube on the chamber.

This process should be done in the following way:

Remove the M8 upper allen screw (1).

Withdraw the glass tube from its support and remove the plug at the top (3).

Fill the glass tube (4) with the liquid supplied with the level gauge.

Insert the plug (3) in the tube and maintain in a vertical position.

To place the tube on the body, proceed as follows:

Check that the rubber seal (5) is in its position.

The bottom of the glass tube (4) should rest on the rubber seat (5).

Mount the spacer (2) in its position.

Assemble the glass tube in its position and screw the allen screw (1) into the plug (3).

The M8 DIN 912 allen screw (1) should not be tightened too hard, it is enough to tighten until

a slight resistance is felt.

10

7 LEVEL ASSEMBLY IN TWO SECTIONS

When the level gauge is delivered in two sections, due to its total length, the following

instructions must be followed carefully for its correct installation.

The numbering of the different elements corresponds to the different figures.

NOTE: Handle the glass tube sections with care.

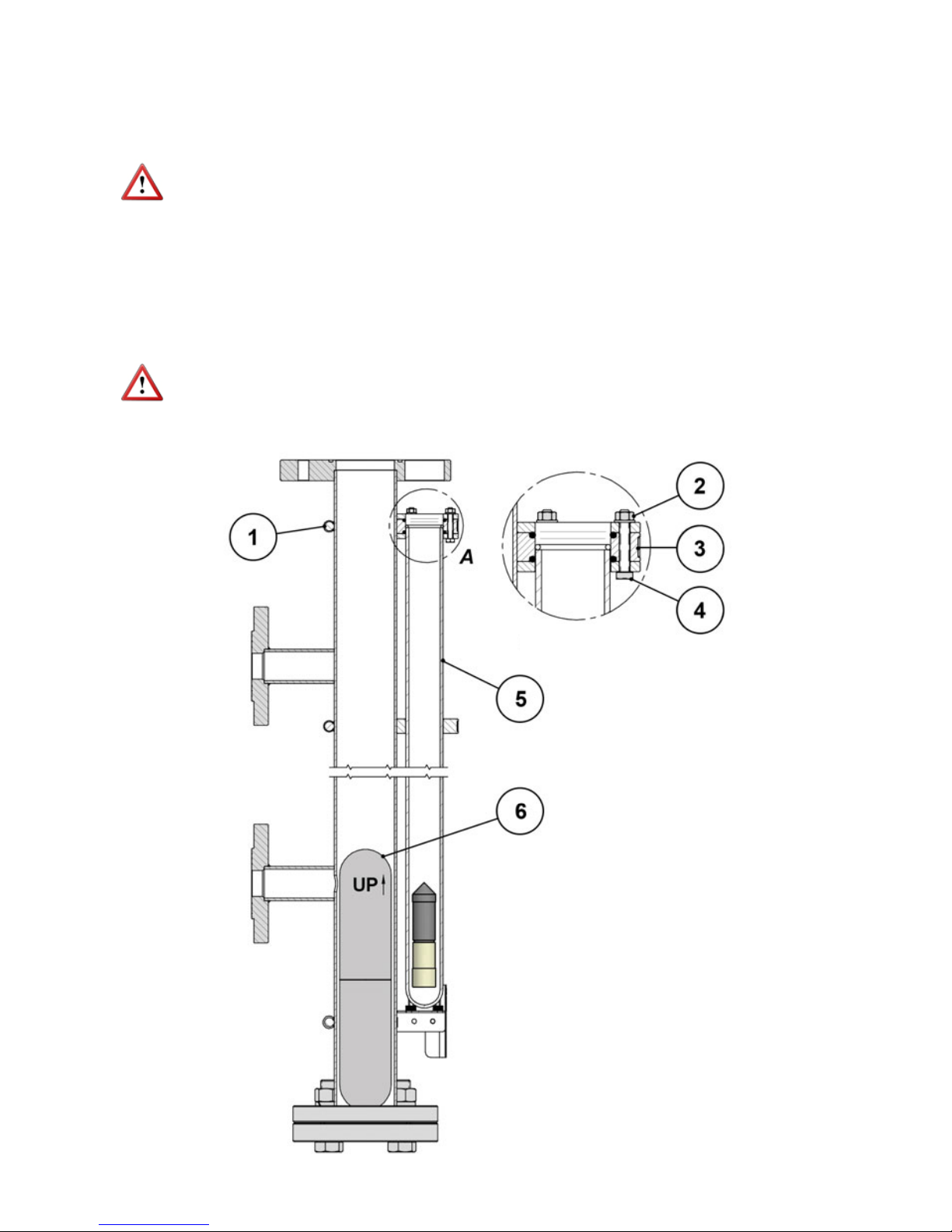

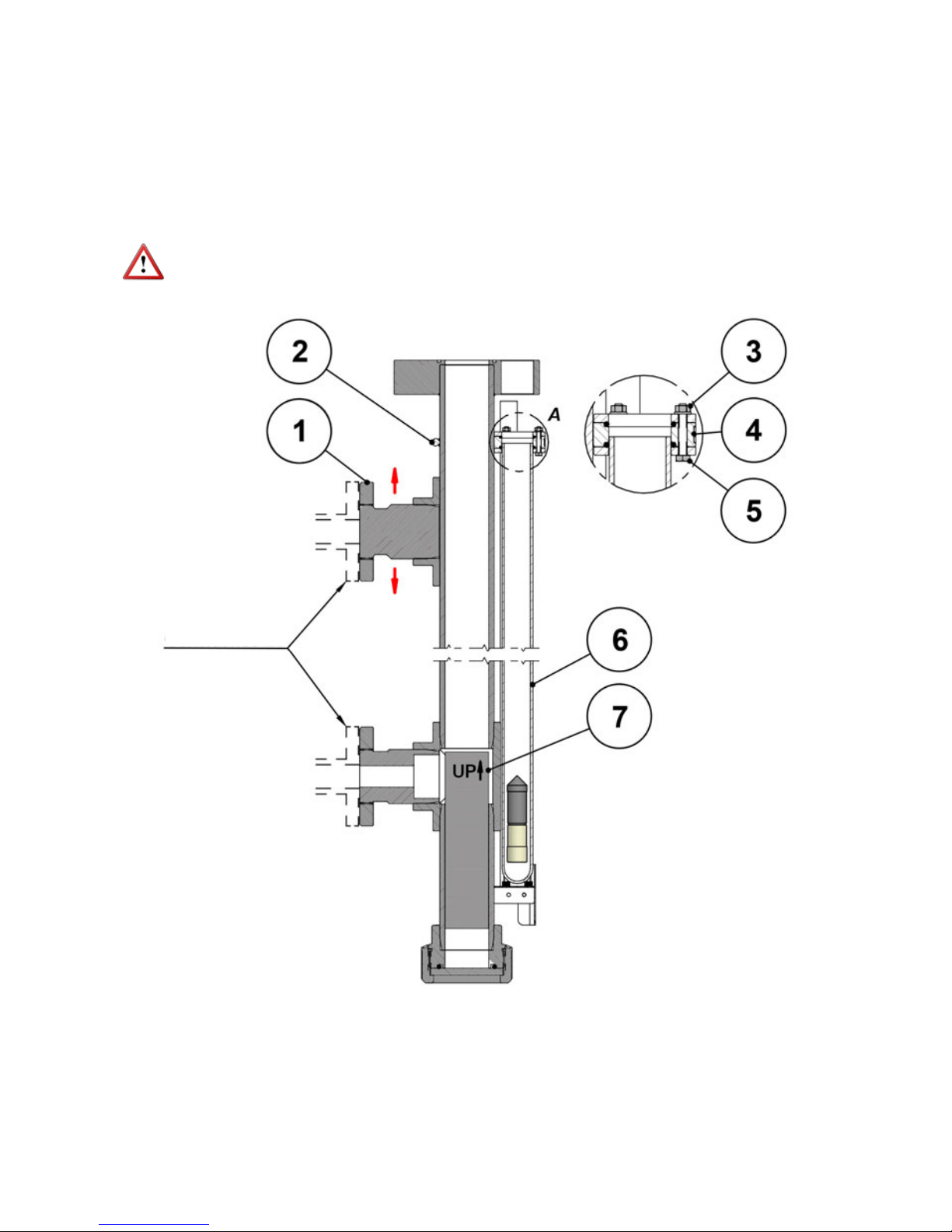

7.1 Model LT106 (stainless steel)

Fix the lower half of the level to the installation.

Remove the adhesive tape from the lower glass tube (5) and loosen the 3 screws DIN933

M5 x 30 (4) without removing the nuts (2).

In case there is not enough space to introduce the float (6) through the lower part of the

gauge body once the assembly is completed, the float must be in its correct position inside

this lower half at the time of installation.

NOTE: The clamp (1) that fixes the guide-support (3) should never be loosened.

DETAIL A

11

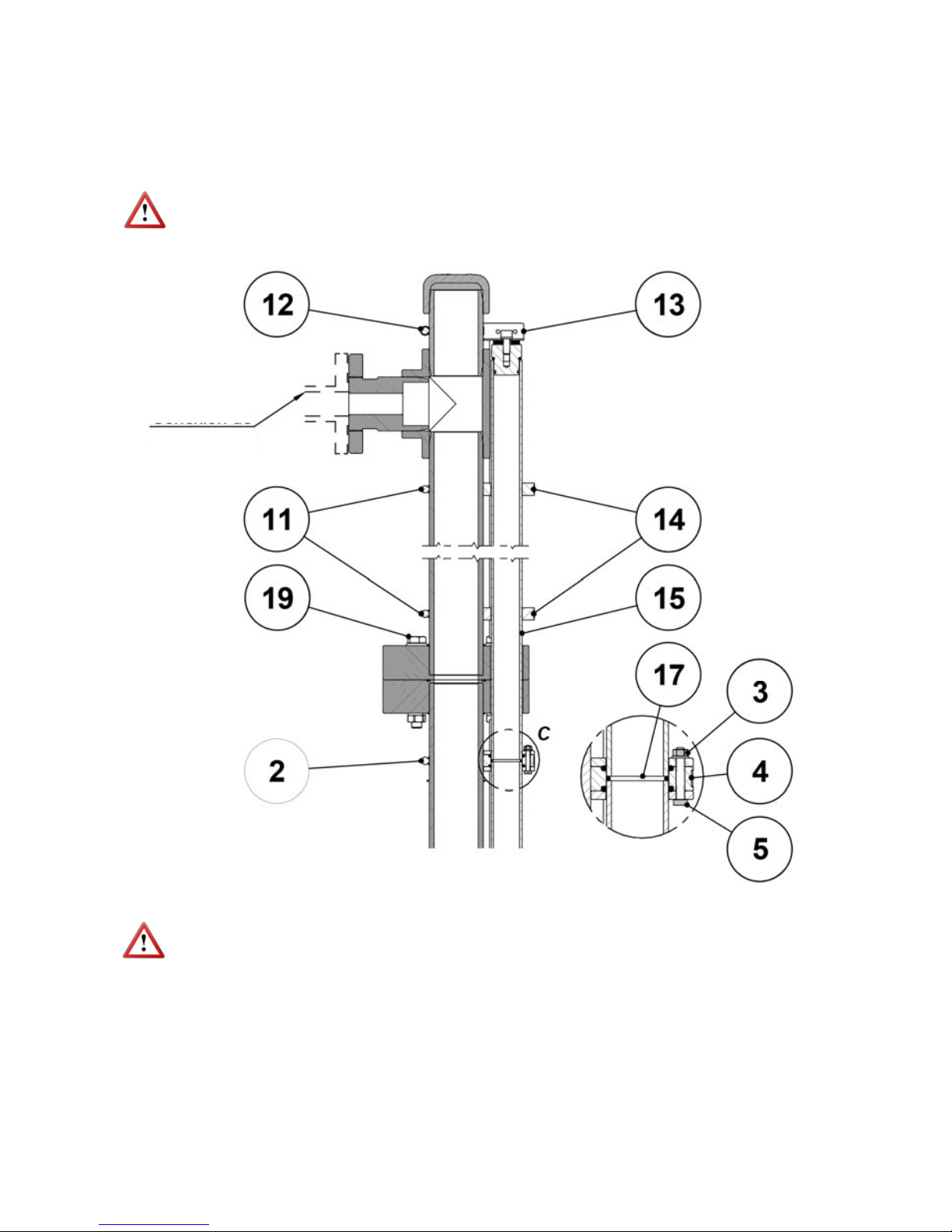

Check the placement of the NBR gasket Ø63 x 3 (15) in its seat on top of the lower flange

(7) and the NBR gasket Ø31.42 x 2.62 (16) on top of the lower glass tube (5).

Place the upper half of the level gauge above the lower half and in the coaxial position, and

carefully go down by passing the upper glass tube (14) through the corresponding hole in

the lower flange (7) until the upper flange (9) rests on the NBR gasket Ø63 x 3 (15).

Pay special attention in this phase of the assembly, since at the same time the two

guide pins (8) are inserted in the guide-holes of the lower connecting flange (7) at the same

time as the upper glass tube (14) passes through the guide-supports of the join group (17,

3).

During this step, do not remove the adhesive tape from the upper glass tube (14) or loosen

the clamp (11) that fixes the upper support (12).

NOTE: The clamps (10) that fix the guide-supports (13) should never be loosened.

DETAIL B

12

Join the two halves of the level by means of the 4 screws DIN933, variable metric according

to model (18), and their corresponding washers and nuts, and fix the level to the upper

connection of the installation.

Slightly loosen the clamp (11) that fixes the upper support (12), remove the adhesive tape

from the upper glass tube (14) and lower it until it rests on the seal (16). Gently press the

tube longitudinally against the seal and tighten the 3 screws (4) and their nuts (2).

NOTE: The clamps (1, 10) that fix the guide-supports (3,13) should never be loosened.

IMPORTANT NOTE: The joint group of the 2 sections of glass tube does not fix its

longitudinal displacement, but ensures the correct sealing of the joint.

DETAIL C

13

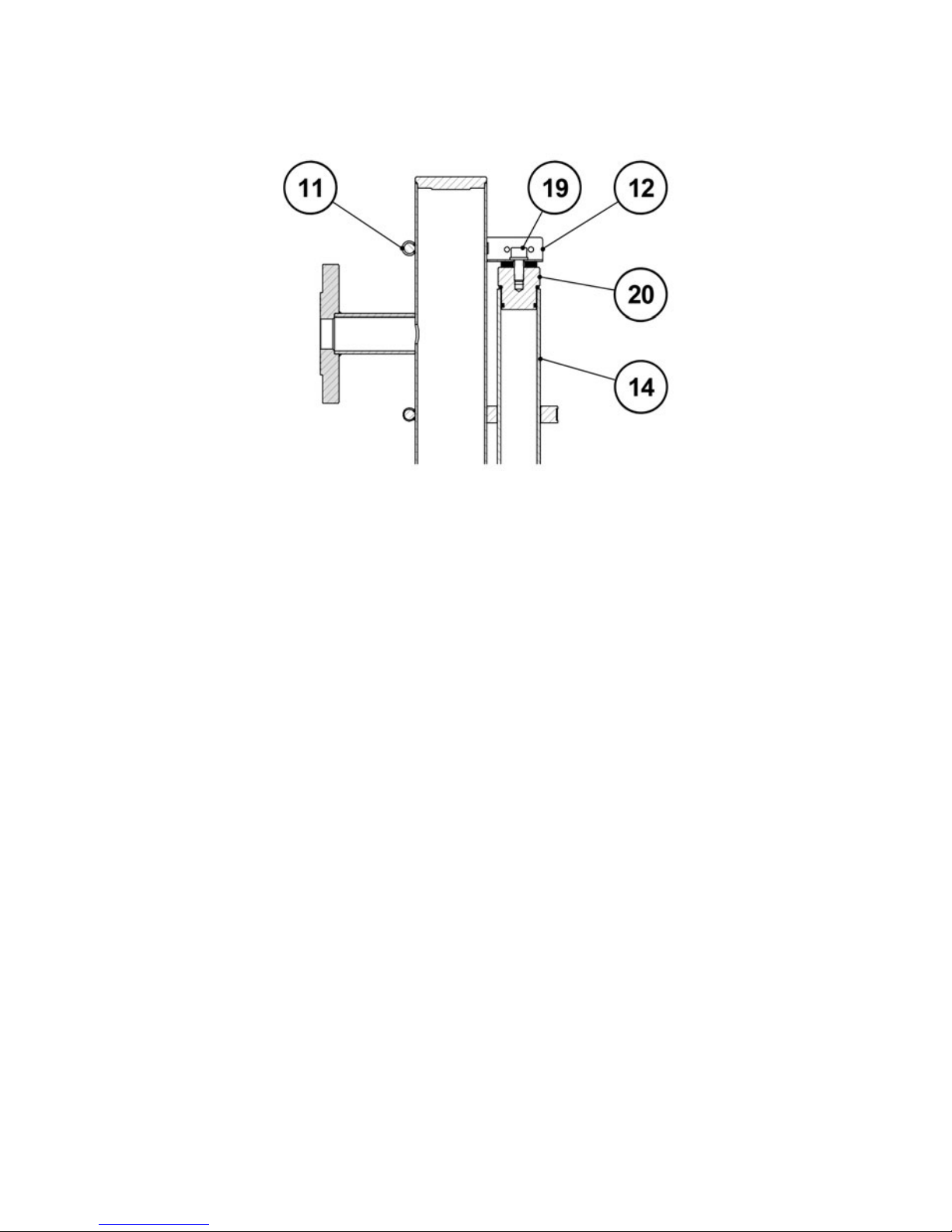

Remove the screw (19) and the plug (20) and proceed to fill the glass tube (14+5). Re-insert

the plug (20) into the tube (14) and, keeping the upper support (12) slightly pressed down,

tighten the clamp (11) and the screw (19).

14

7.2 Model LT14 (plastic)

Fix the lower half of the level gauge to the installation. The mobile flange-group (1) allows

adjusting its anchoring height.

Remove the adhesive tape from the lower glass tube (6) and loosen the 3 screws DIN933

M5 x 30 (5) without removing the nuts (3).

In case there is not enough space to introduce the float (7) through the lower part of the

gauge body once the assembly has been completed, the float must be in its correct position

inside this lower half at the time of installation.

NOTE: The clamp (2) that fixes the guide-support (4) should never be loosened.

DETAIL A

Installation

connections

15

Check the placement of the NBR gasket Ø63 x 3 (16) in its seat on top of the lower flange

(8), and the NBR gasket Ø31.42 x 2.62 (17) on top of the lower glass tube (6).

Place the upper half of the level gauge above the lower half and in the coaxial position, and

carefully go down by passing the upper glass tube (15) through the corresponding hole in

the lower flange (8) until the upper flange (10) rests on the NBR Ø63 x 3 gasket (16).

Pay special attention in this phase of the assembly, since at the same time the two

guide pins (9) are inserted in the guide-holes of the lower connection flange (8) at the same

time as the upper glass tube (15) passes through the guide-supports of the join group (18,

4).

During this step, do not remove the adhesive tape from the upper glass tube (15) or loosen

the clamp (12) that fixes the upper support (13).

NOTE: The clamps (11) that fix the guide-supports (14) should never be loosened.

DETAIL B

16

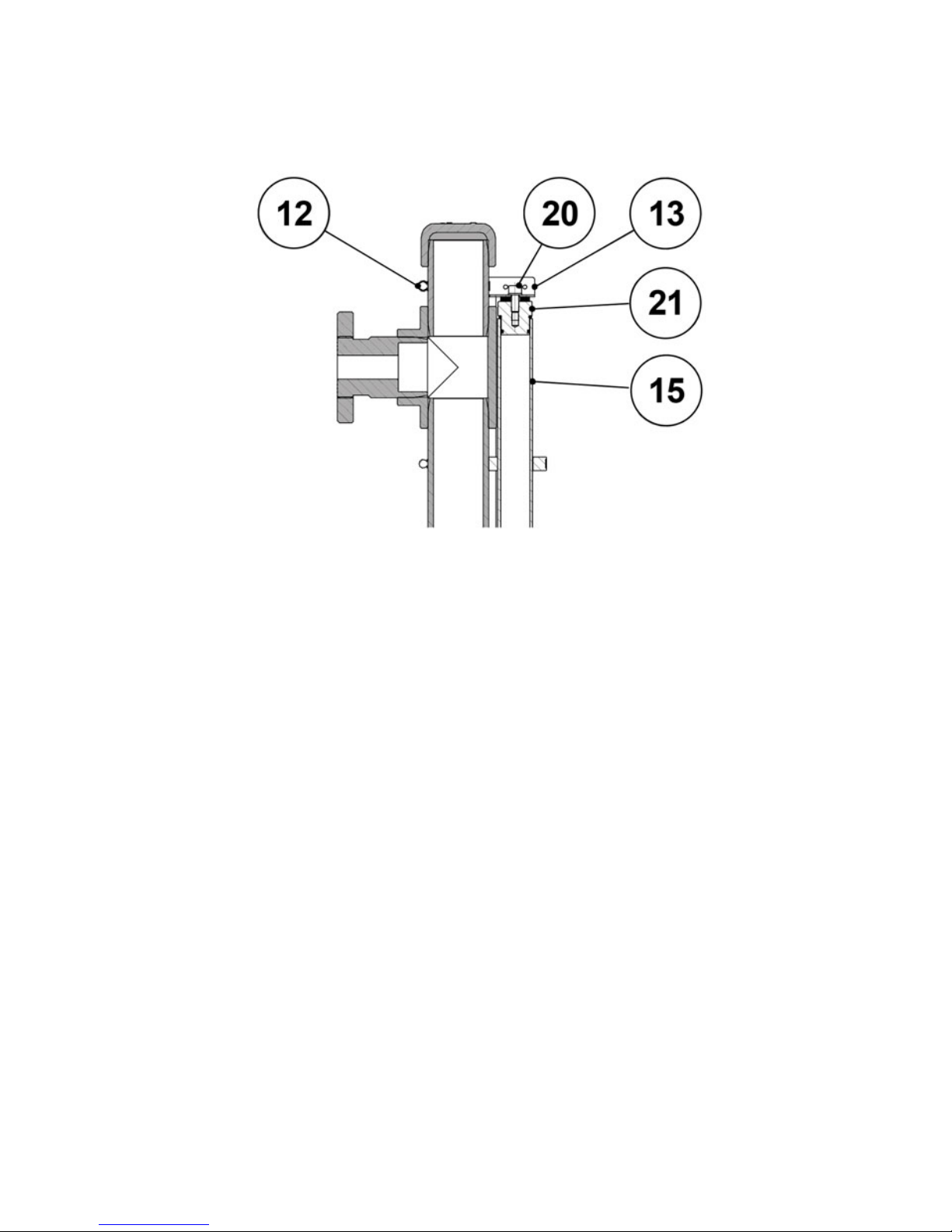

Join the two halves of the level gauge by means of the 4 screws DIN933, variable metric

according to model (19), and their corresponding washers and nuts, and fix the level gauge

to the upper connection of the installation.

Slightly loosen the clamp (12) that fixes the upper support (13), remove the adhesive tape

from the upper glass tube (15) and lower it until it rests on the seal (17). Gently press the

tube longitudinally against the seal and tighten the 3 screws (5) and their nuts (3).

NOTE: The clamps (2, 11) that fix the guide-supports (4,14) should never be loosened.

IMPORTANT NOTE: The joint group of the 2 sections of glass tube does not fix its

longitudinal displacement, but ensures the correct sealing of the joint.

DETAIL C

Installation

connection

17

Remove the screw (20) and the plug (21) and proceed to fill the glass tube (15+6). Re-insert

the plug (21) into the tube (15) and, keeping the upper support (13) slightly pressed down,

tighten the clamp (12) and the screw (20).

18

8 LEVEL READING

For level gauges with a glass tube (LT models), the value of the level is read on the scale at

the height of the top of the external follower. For level gauges with indication by means of

magnetic strips (LTL models), the reading is taken where the strips change from red to

white.

LTL models can be supplied with graduated scale on request.

ReadingReading

9 FLOAT TYPES

Material Maximum

pressure

Titanium 0.55 ... 0.83 PN40

Titanium 0.68 … 0.83 PN63

Titanium 0.77 … 0.83 100 bar max.

EN 1.4404 0.84 ... 2.00 PN40

EN 1.4404 0.84 ... 2.00 PN63

EN 1.4404 0.84 ... 2.00 PN100

PVC 0.60 ... 2.00 PN10

PP 0.70 ... 2.00 PN10

PVDF 0.80 ... 2.00 PN10

Liquid density

kg/l

EN 1.4404 Titanio Plástico

EN 1.4404 Titanium Plastic

19

10 AMD LIMIT SWITCH

10.1 Introduction

The AMD limit switch can be used to generate an alarm or an operation when the level that

the instrument is measuring reaches a preset value. It is a bi-stable limit switch.

It consists of a NAMUR slot type inductive sensor, that is actuated by the float, by means of

a vane that changes its position from one detection position to the other.

10.2 Operation

When the float passes through the point where the limit switch is positioned, it changes the

state of the inductive sensor, and therefore the output state. This is maintained until the float

passes in the opposite direction by the point where the switch is, returning again to the

previous state.

As an optional element, a NAMUR amplifier with a switching relay as an output element can

be supplied.

10.3 Switching point adjustment

10.3.1 LT models

To fix the limit switch on the level gauge, completely loosen the clamp (D) and open it. With

the clamp open, place the limit switch in the body of the level indicator and close the clamp

on the tube.

Place the level switch at the desired level and tighten the clamp.

The position of the reading point of the float with respect to the switching point of the limit

switch can vary from one type of float to another. If it is the first time that the switching point

is adjusted, with the float in a stable position, move the limit switch until the inductive sensor

switches.

D

20

10.3.2 LTL models

To fix the limit switch on the level gauge, loosen the nuts (D), move the switch to the desired

height and tighten the nuts (D) again.

The position of the reading point of the float with respect to the switching point of the limit

switch can vary from one type of float to another. If it is the first time that the switching point

is adjusted, with the float in a stable position, move the limit switch until the inductive sensor

switches.

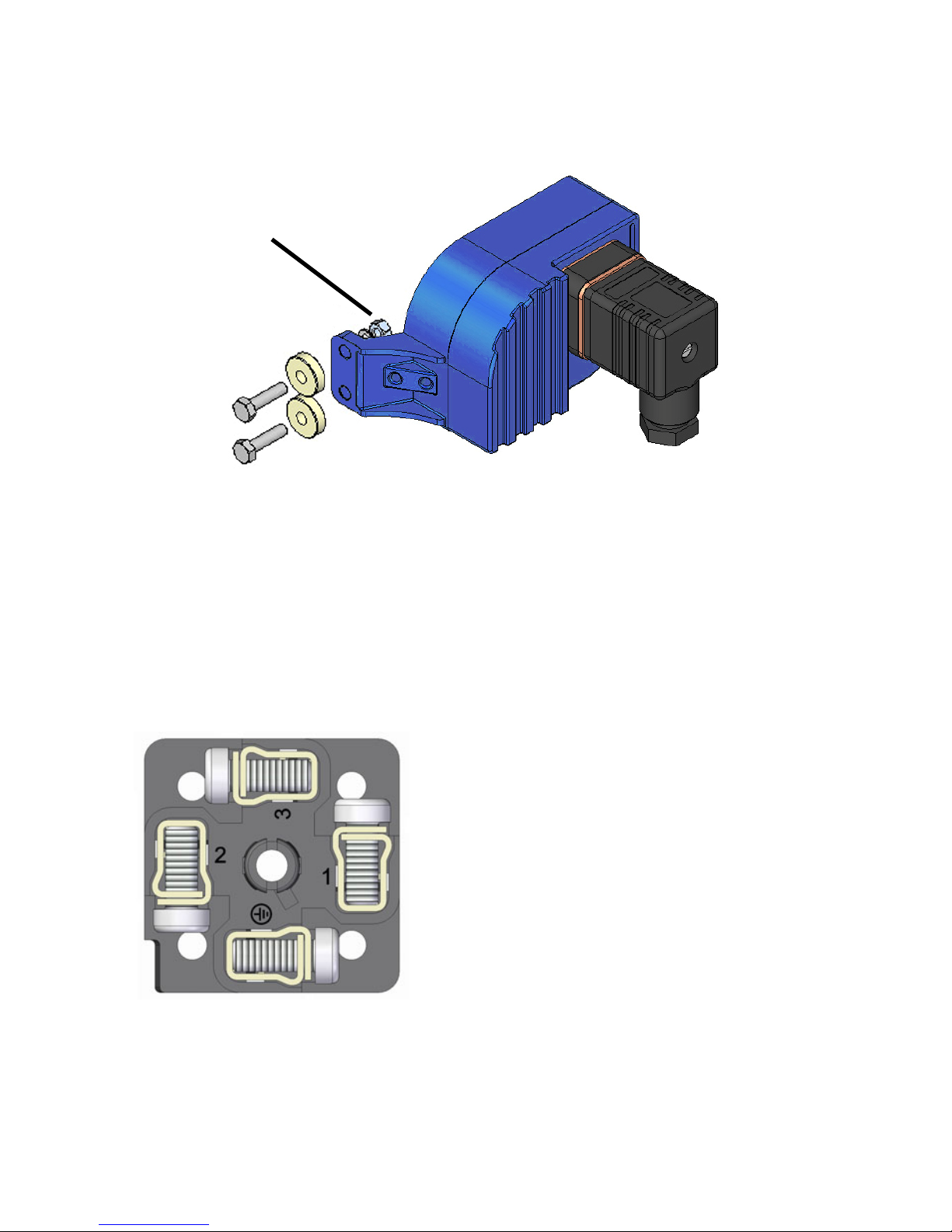

10.4 Electrical connection

For the electrical installation it is recommended to use multiple conductor cables, and not

single cables, in order to guarantee the cable gland will stay watertight. The connector has a

PG9 cable gland for cables with outer diameters between 5 mm and 7 mm. The numbering

of the terminals is the following:

In the female connector (A):

Terminal 1: Negative (Blue sensor cable)

Terminal 2: Positive (Brown sensor cable)

Terminal 3: Not connected

Earth terminal: Earth

D

This manual suits for next models

12

Table of contents

Other Tecfluid Measuring Instrument manuals

Tecfluid

Tecfluid FLOMID Series User manual

Tecfluid

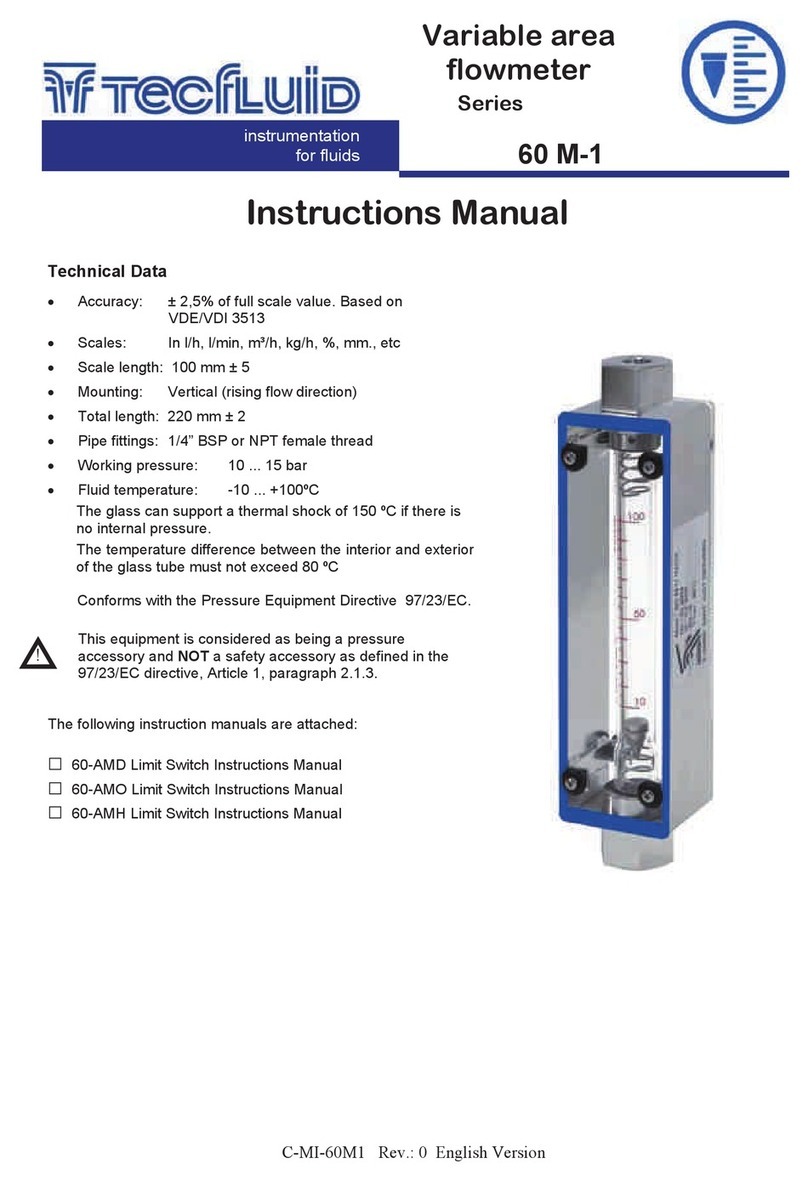

Tecfluid 60 M-1 Series User manual

Tecfluid

Tecfluid AD Series User manual

Tecfluid

Tecfluid LTDR series User manual

Tecfluid

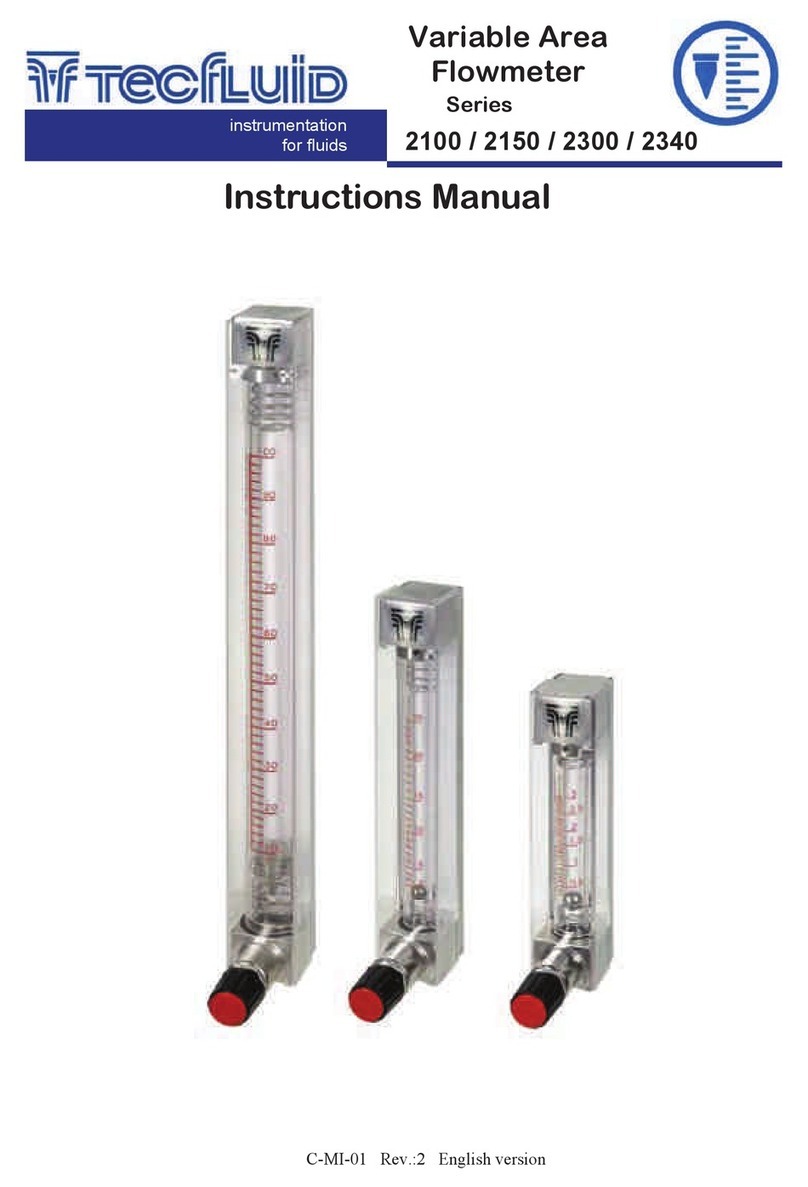

Tecfluid 2100 Series User manual

Tecfluid

Tecfluid FLOMAT FX FlomatFX User manual

Tecfluid

Tecfluid M21 User manual

Tecfluid

Tecfluid FLOMID Series User manual

Tecfluid

Tecfluid CU Series User manual

Tecfluid

Tecfluid LS Series User manual