THE LINEAR FIELD TRANSDUCER

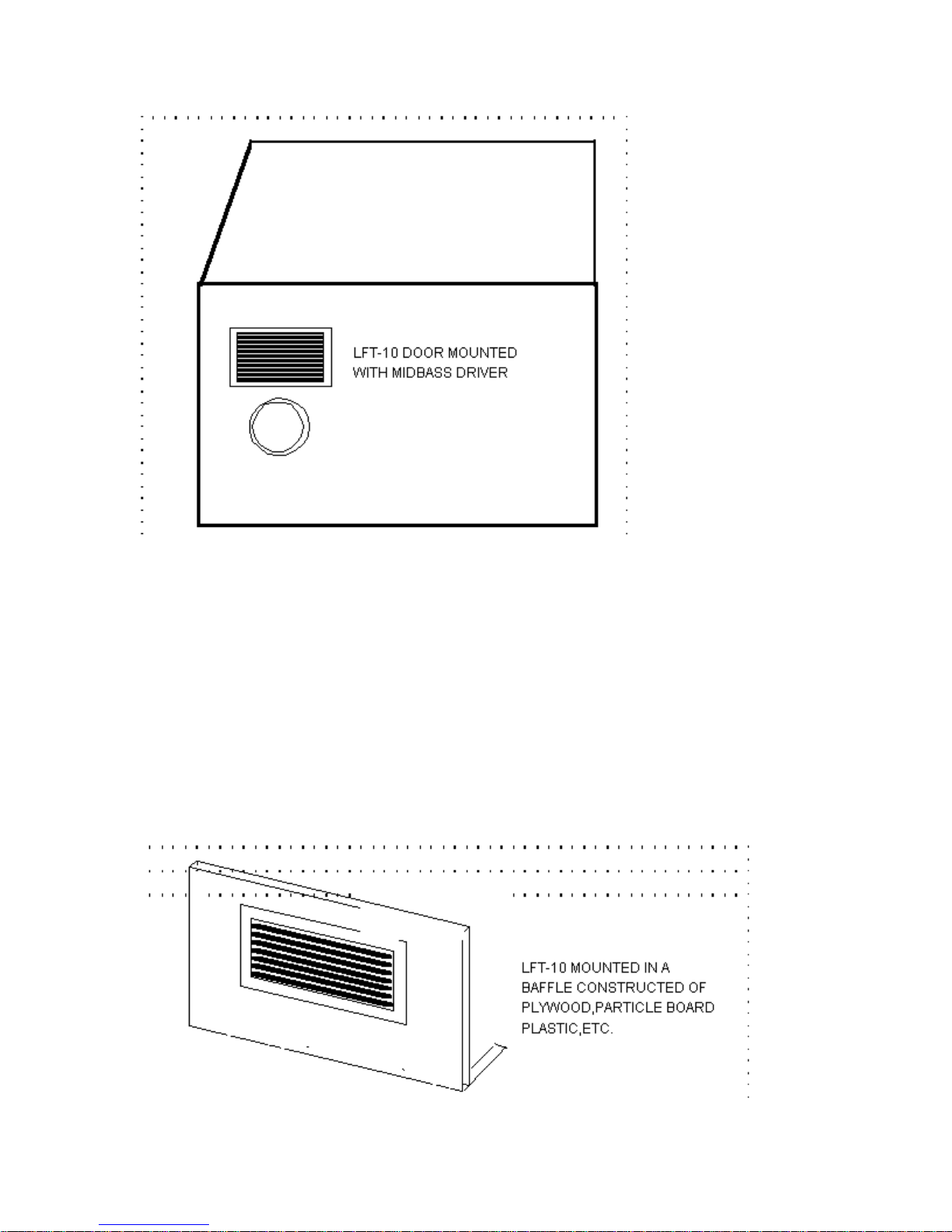

Eminent Technology's Linear Field Transducer, introduced as the LFT, represents a new

approach to the design and construction of a high-quality car loudspeaker*. It builds on

the strengths of previous planar designs while eliminating many of their drawbacks to

allow use in a car.

DIAPHRAGM CONSTRUCTION

The construction of the LFT-10 begins by laminating a very thin sheet of aluminum foil

to a half-mil-thick sheet of Mylar. A voice grid pattern, created by means of CAD

(Computer-Aided Design) technology, is silk-screened onto the foil side; the remainder

of the aluminum--the part not covered by ink from silk-screening is chemically etched

away, in a manner similar to the etching of traces on a printed-circuit board. The ink is

then washed away, leaving a voice grid of near perfect uniformity. This technique results

in a diaphragm/voice coil grid that is still less than two mils in total thickness, and also

permits relatively narrow spaces between the individual traces, so the diaphragm can be

evenly driven over its entire surface.

THE MAGNET / FRAME STRUCTURE

The magnet/frame structure developed for the LFT-10 is also unique. Eminent

Technology builds its magnets into individual steel channels, the size and shape of which

have been carefully designed to help "focus" the magnetic flux lines and concentrate the

strength of the magnetic field on the appropriate area of the diaphragm/voice grid. These

channels are then welded to steel frames, which in turn are bolted to the frame that holds

the diaphragm in place.

Interestingly, one of the biggest challenges faced in creating a true push-pull dynamic

speaker was not a design consideration but rather a matter of construction difficulty: to

assemble a perfect rigid structure with very powerful permanent magnets at the front and

the rear, both sides opposing each other with tremendous force. The second design

challenge is making a planar speaker both small enough and efficient enough for use in

car stereo.

* The design and construction of the LFT-10 is patented

By applying such new techniques to planar loudspeaker construction, Eminent

Technology has been able to eliminate many of the flaws inherent in earlier designs

Cloth is used on the back side of the speaker to resistively load the diaphragm. This

lowers the Q of the diaphragms free air resonance.