Empower Elektrobank 14 User manual

Version 5.0

Page 2 of 33

AMENDMENT RECORD

Issue Number

Date

Description

1.0

4th Dec 2020

First draft release sent to Austest for validation

2.0

22nd Apr 2021

Updated to meet all safety standards and CEC listing

requirements

3.0

16th July 2021

Replaced Backup RCD Type B requirement with RCD

Type A requirement. Added 2nd option to protective

earthing option

4.0

31st Jan 2022

Updated to meet new 4777.2:2020

5.0

2nd Mar 2022

Updated for public release

Associated / Referenced documents

Document number /

Revision number

Date

Document title

Version 5.0

Page 3 of 33

1Table of Contents

1TABLE OF CONTENTS...................................................................................................5

2MARKINGS & SYMBOLS................................................................................................8

2.1 Battery Markings.......................................................................................................................9

3EXTERNAL RCD REQUIREMENTS ................................................................................9

4WARNINGS ...................................................................................................................10

5DIMENSIONED DRAWING............................................................................................12

6PACKING LIST..............................................................................................................13

7MOUNTING THE UNIT .................................................................................................. 14

7.1 Wall Mount:............................................................................................................................15

7.1.1 Install wall bracket ..........................................................................................................15

7.1.2 Mount unit on wall bracket .............................................................................................16

7.2 Floor Mount............................................................................................................................16

7.3 Battery Installation..................................................................................................................17

7.4 Close and fasten door..............................................................................................................19

8WIRING..........................................................................................................................20

8.1 External Isolation Device Requirements...................................................................................20

8.2 Port Locations .........................................................................................................................21

8.3 Ferrite Attachments ................................................................................................................22

8.4 Grid Port Including Protective Earthing....................................................................................22

8.5 Backup Port.............................................................................................................................23

8.6 UPS Safety Stickers..................................................................................................................24

8.7 PV Ports ..................................................................................................................................24

8.8 DRM0......................................................................................................................................25

8.9 Ethernet..................................................................................................................................25

8.10 Meter Connections..................................................................................................................26

8.10.1 Acrel ...............................................................................................................................26

9COMMISSIONING ......................................................................................................... 28

9.1 Closing Unit.............................................................................................................................28

9.2 Connecting to the unit for the first time via its hotspot ...........................................................28

9.3 Installer Inputs (inc Regional Settings) .....................................................................................28

9.3.1 Connect the unit to the house internet............................................................................28

9.3.2 PV Settings......................................................................................................................29

9.3.3 Grid settings (inc Regional Settings and Power Quality Modes)) ......................................29

Version 5.0

Page 4 of 33

9.3.4 Earth Fault Alarm ............................................................................................................31

9.3.5 User Training...................................................................................................................31

9.3.6 Read-only inverter settings..............................................................................................32

10 MAINTENANCE.............................................................................................................33

10.1 Turning off the Unit.................................................................................................................33

10.2 User Maintenance...................................................................................................................33

10.3 Trained Service Professional Maintenance ..............................................................................33

11 ELECTRICAL RATINGS................................................................................................35

12 APPENDIX A –METER PROGRAMMING..................................................................... 36

12.1 Programming the ADL400 meter.............................................................................................36

Version 5.0

Page 5 of 33

2Markings & Symbols

1. To identify the location where the operator's manual is stored or to identify

information that relates to the operating instructions. To indicate that the

operating instructions should be considered when operating the device or

control close to where the symbol is placed.

2. To identify equipment that has risk of electric shock.

3. To identify energy storage timed discharge –that is the time required after

disconnecting the unit from all energy sources and turning off the battery

circuit breaker until the capacitor energy storage in the unit is less than

48VDC.

4. To indicate that caution is necessary when operating the device or control

close to where the symbol is placed, or to indicate that the current situation

needs operator awareness or operator action to avoid undesirable

consequences.

5. To identify any terminal which is intended for connection to an external

conductor for protection against electric shock in case of a fault, or the

terminal of a protective earth (ground) electrode.

Version 5.0

Page 6 of 33

2.1 Battery Markings

Battery Type

Secondary (rechargeable) Li or Li-ion

Cell Designation

IFpP/34/201/173/M/-10+40/90

Module Designation

IFpP34/201/173[8S]M/-10+40/90

Battery System Designation

IFpP34/201/173[48S]M/-10+40/90

System Capacity

100Ah

Nominal Voltage

153.6V

Watt-hour

15.36kWh

Caution Statement

WARNING! A battery can present a risk of electrical shock,

fire, or explosion from vented gases. Observe proper

precautions.

Disposal

Electronic Device: Do not throw away

Proper disposal of batteries is required. Refer

to your local codes for disposal requirements.

Recommended Charge

instructions

Charging is only allowed using the provided Elektrobank 14

system, do not try charging with a different charger

3External RCD Requirements

This product requires an external RCD Type A, 30mA to be installed on every

subcircuit powered by the backup port

Version 5.0

Page 7 of 33

4Warnings

1. When the photovoltaic (PV) array is exposed to light, it supplies a d.c. voltage to the PCE.

2. External RCD Type A 30mA is required on backup port (if connected).

3. An RCD is not permitted on the grid/supply side of the device as it is a multi-mode inverter and

an RCD would allow disconnection of the neutral MEN connection for backup loads.

4. It is required that any PV modules connected to the device have an IEC 61730 Class A rating.

5. If the equipment is used in a manner not specified by the manufacturer, the protection provided

by the equipment may be impaired.

6. Only a qualified professional (e.g. service person) may install the Elektrobank 14.

7. Servicing or replacement of batteries shall not be conducted in the field by anyone other than

Empower personnel. Initial installation is allowed as per this manual.

8. CAUTION: Do not dispose of batteries in a fire. The batteries may explode.

9. CAUTION: Do not open or damage batteries. Released electrolyte is harmful to the skin and eyes.

It may be toxic.

10. CAUTION: The backup port should not be used for devices providing safety or health critical

devices

11. SAFE HANDLING: Elektrobank 14 and battery modules are heavy. To minimise risk when handling

the goods, lift and transport the goods carefully and wear personal protective equipment such as

steel-toe boots and gloves. Use of lifting equipment is recommended

12. SAFE TRANSPORT: Always transport the goods to site in the original packaging. During unpacking,

inspect the goods for damage such as large dents or deep scratches, which may indicate the unit

was dropped. Do not use Elektrobank 14 if it is defective or appears damaged in any way,

internal or external. Contact your supplier for further advice.

13. Touch current is above the limit. Ensure 10mm2 copper PE cable is used for connection to PE

terminal.

14. The Elektrobank 14 cannot be used in multiple inverter combinations as per section 5 of the

AS/NZS 4777.2:2020.

Version 5.0

Page 8 of 33

Figure 1 - Warnings from product warning label

Version 5.0

Page 9 of 33

5Dimensioned Drawing

Version 5.0

Page 10 of 33

6Packing List

The product Elektrobank 14 contains the following parts:

1) Main Enclosure box, including:

a. Main Enclosure

b. Wall Mount Bracket

c. Front of House Meter –PN: ADL400/C

d. 3 x Current Transformers –PN: AKH-0.66/K K-24 150/5A

e. Installer Manual

f. Polythene Bag containing

i. 28 x M6 Battery Mounting bolts

ii. 28 x M6 Battery Mounting Washers

iii. Assortment of glands and plugs for cable entry

iv. EMC Ferrites for grid, backup and ethernet wires

v. 4 x Phoenix Contact PV Connectors

2) Battery Assembly 1

3) Battery Assembly 2

4) Battery Assembly 3

5) Battery Assembly 4

6) Battery Assembly 5

7) Battery Assembly 6

Version 5.0

Page 11 of 33

7Mounting the Unit

Installation shall follow and comply with AS 5139, AS 3000 as well as any requirements

from this manual.

1. Find a suitable mounting location as per AS 5139

•a risk assessment for the mounting location shall be completed

2. The Elektrobank 14 can be mounted on a wall with the wall mount kit or floor standing, with the

addition of the floor mount kit.

•The wall mount bracket shall always be used

•The wall shall always be capable of taking the full weight of the unit, whether wall

mount or floor standing.

3. Mounting Location

•The Elektrobank 14 is rated to IP66 so can be mounted inside or outside

•Do not mount the Elektrobank 14 in a location with direct sunlight. Outdoor suggested

(but not limited to) locations include:

i. Under an awning

ii. On a South Facing wall

•Ensure no animals or insects are likely to be able to nest close to the unit.

•No plants can be growing inside 1m radius from the mounting location

•Ensure there are no obstructions (to ensure adequate ventilation) inside the dimensions

from Figure 1, including, but not limited to:

i. Wall, floor, Ceiling/roof

ii. Any other devices or equipment

iii. Vents to any wall or other structure

iv. Any Heat sources

•No heat source should be within the clearance limits indicated or below the unit at any

distance

•Installation position shall not prevent access to disconnection means.

•If indoor mounted,

i. a fire alarm is required to be installed in the same room as the Elektrobank 14

ii. The room should have at minimum one external wall vent

0.6m

minimum

0.3m minimum

1.5m

minimum

0.9m minimum

0.6m minimum

Figure 2 - Clearance around unit

Version 5.0

Page 12 of 33

7.1 Wall Mount:

1. Conform to AS 5139 requirements and conduct risk assessment on mounting method

2. Ensure the wall is vertical and flat across the full width and height of the Elektrobank 14

3. Ensure the wall is structurally sound to take the weight of the Elektrobank 14

4. Remove external packaging and remove wall mount bracket from packaging.

7.1.1 Install wall bracket

Determine mounting method from below or equivalent minimum total Working Load Limit (WLL)

6kN, minimum 6 fasteners (12 into wood).

Wall material

Anchor type

Product Example

Quantity

Solid brick or concrete, with no

risk of internal voids

AnkaScrew

8x100 mm

Ramset Australia AS08100WGM

At least 6 per

system

Brick or concrete with internal

voids

M8 glue in

studs with

sleeves

Ramset Australia CS08110GH

Ramset Australia ISS08

Ramset Australia

Chemset 101 PLUS (Curing time

is around 50 minutes)

At least 6 per

system

Timber

Coach screws

M8x100mm

Zenith M8 x 100mm Stainless Steel

Hex Head Coach Screw | Bunnings

Warehouse

At least 12

per system

5. Mount wall bracket on wall

•Use spirit level to ensure bracket is level

•If fixing into a timber framed wall, the wall bracket must be secured into two different

studs, and has been designed to span the usual spacing of 600mm.

Figure 3 - Wall Mount Bracket Fixing Locations

Version 5.0

Page 13 of 33

7.1.2 Mount unit on wall bracket

6. Using a two-man lift, place the Elektrobank 14 onto the wall bracket.

7. Fix the small top fixing bracket with the 2x supplied M6 bolts

Figure 4 - Top Fixing Bracket

7.2 Floor Mount

1. Floor Mounting is suitable when the wall is considered not completely structurally sound to

mount the unit, this could be the case for many types of wooden structures or walls with

plastic/wooden cladding.

2. Floor Mounting is only viable when there is a suitable vertical structural member or wall to fix

the top of the unit to. The unit cannot be mounted freestanding.

3. Floor mounting can only take place on a flat concrete base. A separate risk assessment shall be

carried out to ensure the platform is structurally sound to mount the unit to.

4. Fit the base unit to the unit using the provided M6 bolts and washers.

5. Place the unit next to the wall with the wall bracket and mark the height that the wall bracket

should be fitted at to still provide support to stop the unit from toppling forwards.

6. Fit the wall bracket ensuring level

7. Lift the unit onto the wall bracket and adjust the feet until the feet begin to take the weight of

the unit

8. Fix the small top fixing bracket with the 2x supplied M6 bolts as per Figure 4 - Top Fixing Bracket

Version 5.0

Page 14 of 33

7.3 Battery Installation

1. Before starting, ensure the enclosure is securely fixed (wall mounted or floor mounted) as per

above instructions.

2. Ensure all internal covers are still attached

3. Ensure all Circuit breakers are off, and the unit is completely isolated from mains and PV

4. Specifically, ensure that the integrated battery circuit breaker is turned OFF to ensure isolation.

Figure 5: Unit before installing batteries

5. Fit the battery modules in the below order, ensuring not to trap any wires behind each module

and to fix the module before fitting the next module, using the long M6 bolts provided, tighten

to approximately 1N.m

a. ASYH006 - bottom left

b. ASYH007 –bottom right

c. ASYH004 –middle left

d. ASYH005 –middle right

e. ASYH002 –top left

f. ASYH003 –top right

6. Tighten all the 24 mounting bolts to 5N.m +/- 1N.m

7. Connect the fuel gauge temperature sensor from battery 6 to the master BMS as shown below

Version 5.0

Page 15 of 33

8. Connect all the modules together, starting at the bottom Left Hand blue connector and working

up

Figure 6 - Module Connections

8. Next, connect the 6x BMS connectors, ensuring to connect the right size into the correct

receptacle and again working from the bottom up

Version 5.0

Page 16 of 33

Figure 7 - BMS Connections

9. Finally connect the battery stack connections, the black connector at the bottom and then the

red connector at the top

Figure 8 - Battery Stack Connections

7.4 Close and fasten door

These should be done following the following process to ensure the correct seating and loading of the

environmental seals

Version 5.0

Page 17 of 33

1. Bolts shall be seated and loaded to 0.5Nm int the following pattern, starting from the middle bolt

2. The bolts shall then be tightened to 1Nm in the same pattern

8Wiring

In addition to all requirements in this document, ensure all wiring conforms to AS/NZS 3000 and AS/NZS

4777.1 for Australia.

Connection Summary:

Connection Name

Connection Type

DVC Class

PV

4 Sunclix External Connectors

DVC-C

Grid

2 x 6mm2minimum Live and Neutral into terminal block

DVC-C

Backup

2 x 4mm2minimum Live and Neutral into terminal block

DVC-C

Earth

Either a) or b) below

a) Single earth cable made of copper and 10mm2or greater

(but less than 16mm2), into ‘Grid’ terminal

b) One 6mm2minimum earth cable into ‘Grid’ terminal

block and a second earth cable into ‘Backup’ terminal

block, of the same cross sectional area

DVC-A

LAN

RJ45

DVC-A

DRM0

2 wires into terminal block

DVC-A

Meter RS485

2 wire twisted pair into terminal block

DVC-A

Table 1 - Connection Summary

8.1 External Isolation Device Requirements

The following isolation devices are required

1. 40A single pole circuit breaker for grid port, connected to active conductor only

Version 5.0

Page 18 of 33

a. Never put a circuit breaker/RCD on the supply/grid side neutral conductor otherwise it

may disrupt the continuity of the neutral to the backup circuits.

2. A double pole solar PV isolator (suitably rated and certified) for each MPPT

3. If backup circuits are connected then this product requires

a. A 20A circuit breaker on the output of the backup port to protect the inverter

b. an external RCD Type A 30mA to be installed on every subcircuit that is backed up.

8.2 Port Locations

Version 5.0

Page 19 of 33

8.3 Ferrite Attachments

1. Grid Active and Neutral Cables Only –2 turns of Wurth Part Number 74271211

2. Backup (if used) Active and Neutral Cables Only - 2 turns of Wurth Part Number 742700790

3. Ethernet Cable –2 turns of Wurth Part Number 74271112

8.4 Grid Port Including Protective Earthing

1. Cable used for protective earth shall conform to option a) or b) below

a. made of copper and 10mm2or greater (but less than 16mm2)

b. One 6mm2minimum earth cable into ‘Grid’ terminal block and a second earth cable

into ‘Backup’ terminal block, of the same cross sectional area

2. Use minimum 6mm2cable for the grid port active and neutral connections.

3. Only Copper wire is suitable for use

4. Make sure all grid/earth cabling is rated for outdoor use as per local standards. Recommend

running all external cabling in conduit. Connect cable as in the below image, live (L), neutral (N)

and earth (earth symbol) to terminal block as marked

5. Ensure the main >10mm2minimum earth wire is longer than the live and neutral wire so that if

the cable pulls out the earth wire is the last to be disconnected, It shall be connected to one of

the Grid connector Earth points. The spare Earth port can be used for a second earth that may be

present in the twin core and earth cable used.

6. The wires shall be stripped to 18mm and the connections are push fit spring connections.

a. Insert, push until no copper can be seen and then do an approximately 1kg pull test and

confirm no copper can be seen.

7. At this stage confirm all grid cables, especially earth is well connected mechanically and confirm

with multimeter that the enclosure has continuity to earth.

8. Ensure gland is tightened to IP66 (note –do not replace gland that is provided with the unit)

Figure 9 - Grid Connections

Version 5.0

Page 20 of 33

8.5 Backup Port

1. Use minimum 4mm2cable for the backup and connect to the terminals as shown in Figure 9

below.

a. Insert, push until no copper can be seen and then do an approximately 1kg pull test and

confirm no copper can be seen.

2. The stripping length is 15mm and the connections are push fit spring connections

3. Outside the Elektrobank 14 the backup wiring should wire directly to a single pole Circuit breaker

with 20A tripping current.

4. After the Circuit breaker, each backed up house circuit should have a separate Type A 30mA

RCD/RCBO

Figure 10 - Backup Connections

Voltage Backfeed Warning Label, similar to Figure 11 - Voltage Backfeed Warning Label) shall be provided

on the UPS input and on all primary power isolators installed remotely from the UPS (for example the

circuit breaker in the backup circuit board) and on any external access points between the isolators and

the UPS

Figure 11 - Voltage Backfeed Warning Label

Table of contents

Popular Accessories manuals by other brands

Optex

Optex OA-AXIS T quick start guide

iOptron

iOptron SkyGuider instruction manual

Middle Atlantic Products

Middle Atlantic Products Rackmount Light LT1R Specifications

PCB Piezotronics

PCB Piezotronics 353B34 Installation and operating manual

ROSE DISPLAYS

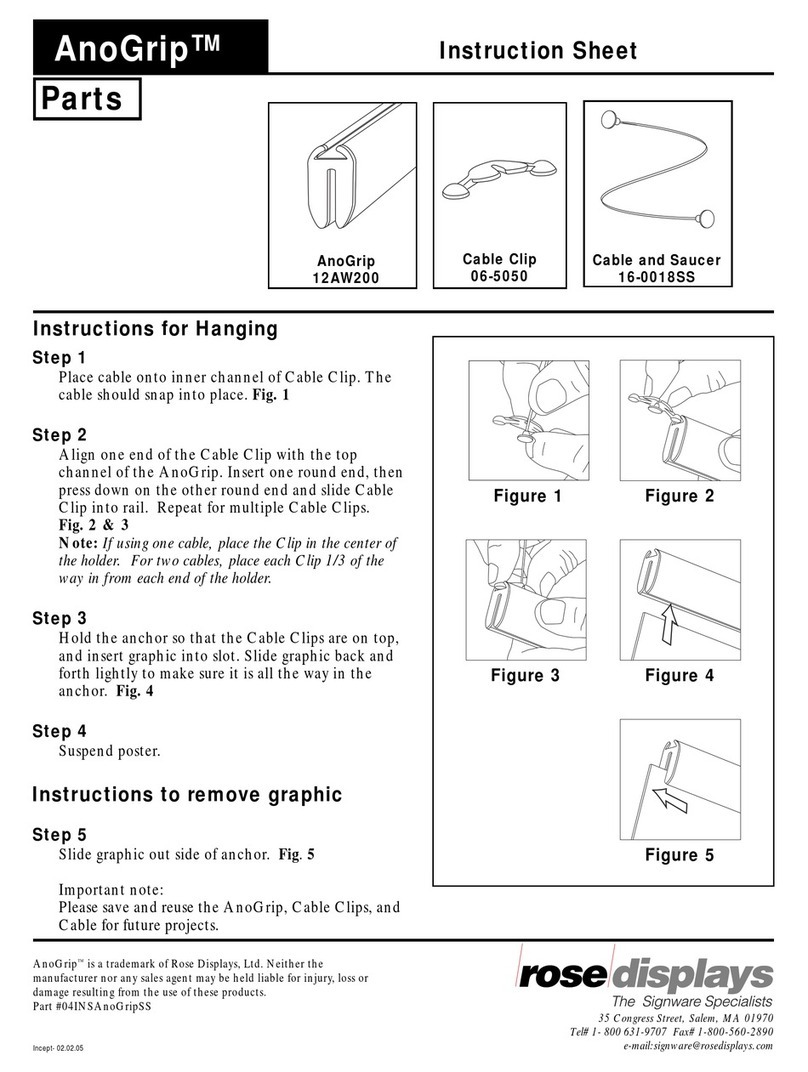

ROSE DISPLAYS ANOGRIP WITH CABLE CLIPS manual

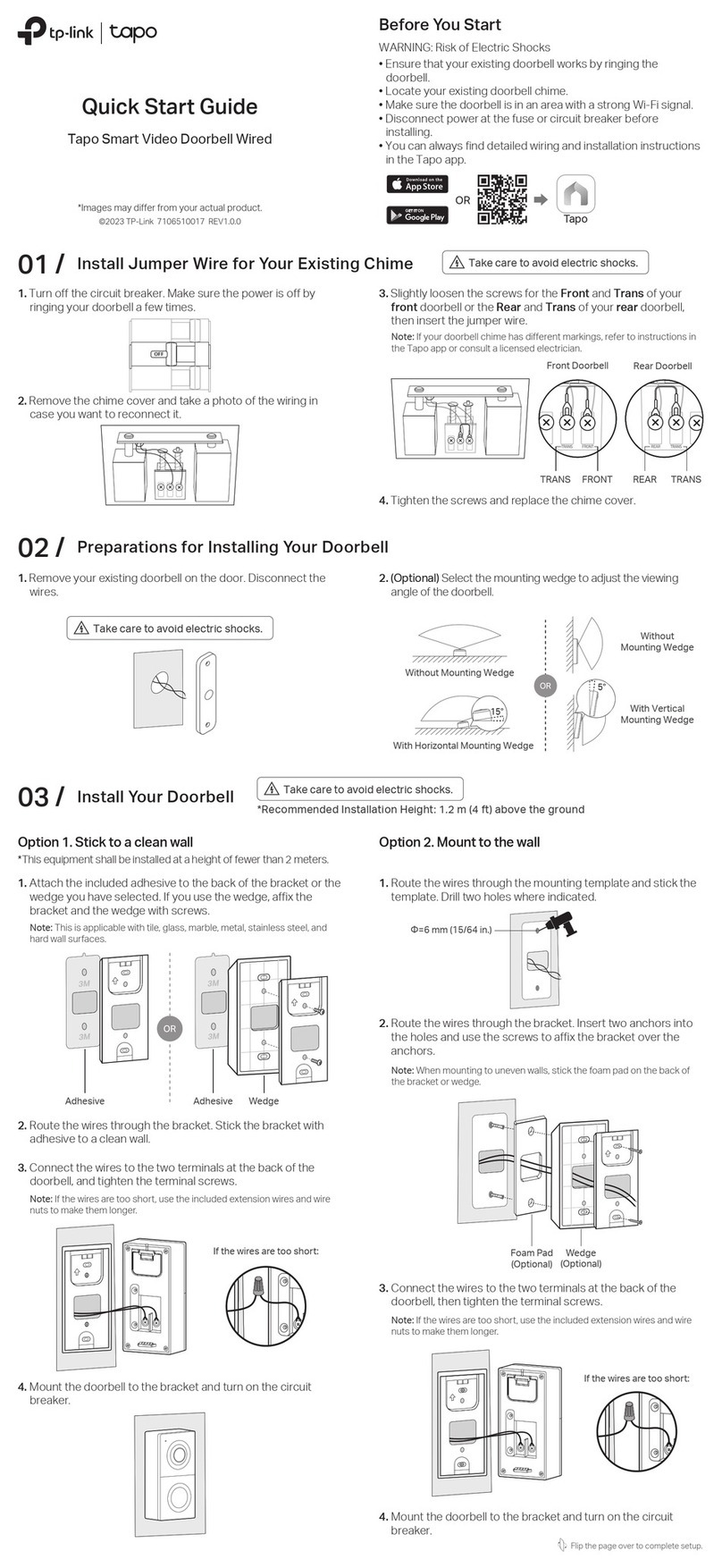

TP-Link

TP-Link Tapo Camera quick start guide