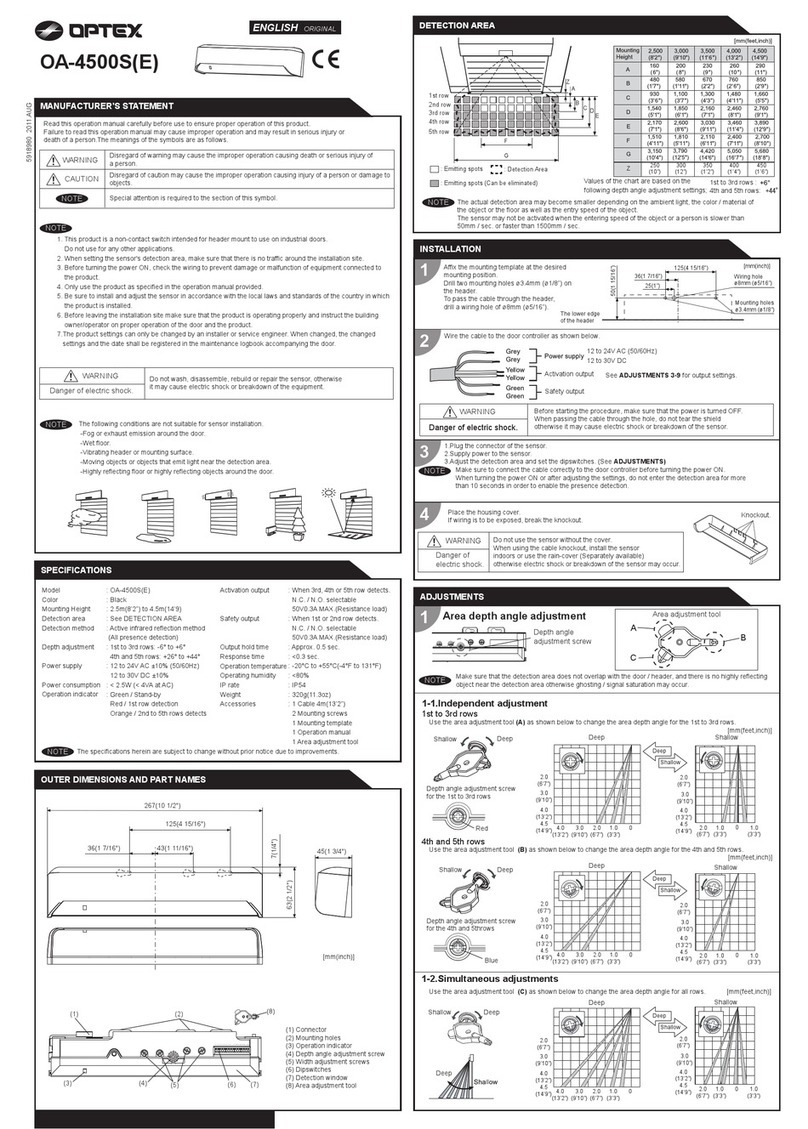

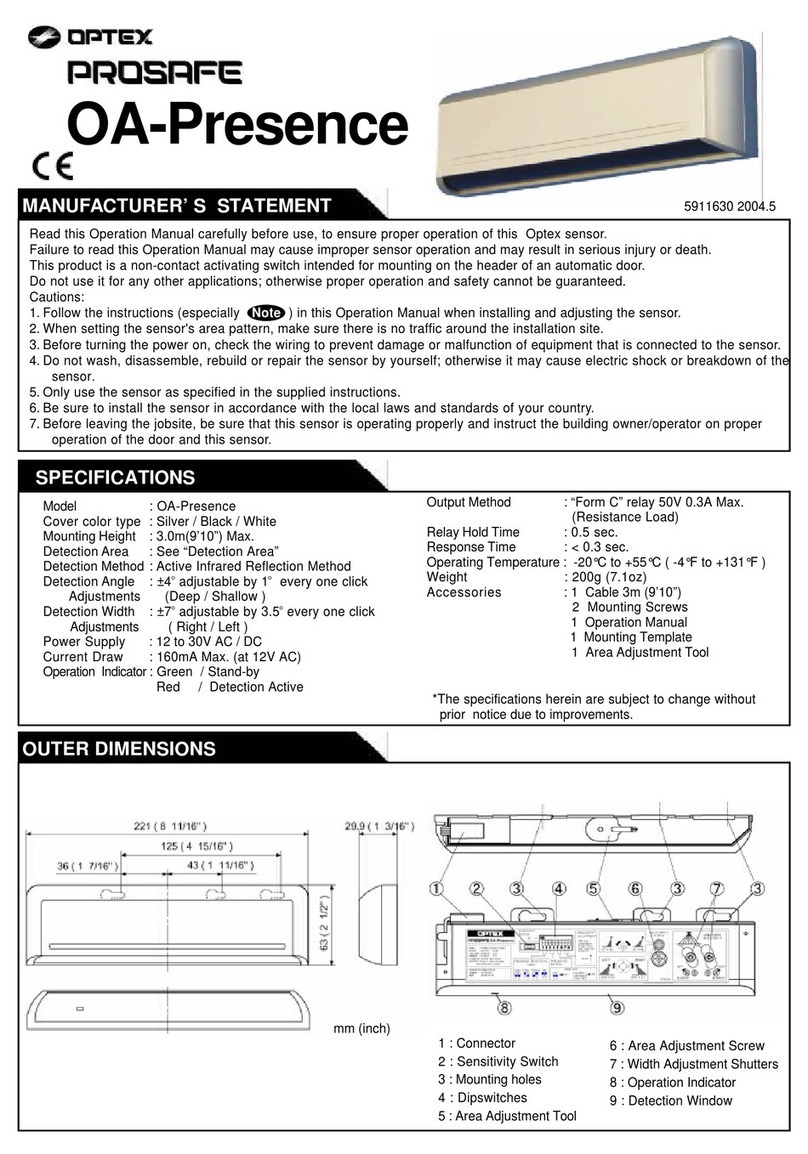

4th and 5th rows

1st to 3rd rows

Use the area adjustment tool (B) as shown above to

change the area depth angle for the 4th and 5th rows.

Depth angle adjustment screw for the 4th and 5th rows.

Use the area adjustment tool (A) as shown above to

change the area depth angle for the 1st to 3rd rows.

For the simultaneous adjustment of the 1st to 5th rows, use the adjustment tool (C).

When adjusting the width adjustment screws,

make sure to turn until it clicks otherwise the proper

operation may not be obtained.

Adjustments

When adjusting the 1st row close to the door,

see Table 1 dipswitch 16 for the easier adjustment.

Make sure that the detection area

does not overlap with the door/header,

and there is no highly reflecting object

near the detection area otherwise

ghosting/signal saturation may occur.

Area adjustment tool

A

B

1. Area depth angle adjustment

NOTE

a. Independent adjustment

b. Simultaneous adjustment

Depth angle adjustment screw for the 1st to 3rd rows.

Shallow Deep

Red

Shallow Deep

Blue

2. Area width adjustment

NOTE

C

2.0 (6′7")

3.0 (9′10")

ShallowDeep

02.0

(6′7")

[m(feet,inch)]

1.0

(3′3")

-1.0

(3′3")

02.0

(6′7")

1.0

(3′3")

-1.0

(3′3")

0

[m(feet,inch)]

3.0

(9′10")

2.0

(6′7")

1.0

(3′3")

03.0

(9′10")

2.0

(6′7")

1.0

(3′3")

ShallowDeep

2.0 (6′7")

3.0 (9′10")

Reference

INFRARED FINDER

Detection area

Detection area

1. Turn the depth angle adjustment screw to the right (Deep) to place the detection area most away from the door.

2. Set INFRARED FINDER sensitivity to "H" (High) and place it on the floor as shown below.

3. Turn the depth angle adjustment screw to the left (Shallow) until the emitting area is placed at the position where

INFRARED FINDER is in the low detection status. (Slow Red blinking)

Area depth adjustment with INFRARED FINDER (Separately available)

4th and 5th rows1st to 3rd rows

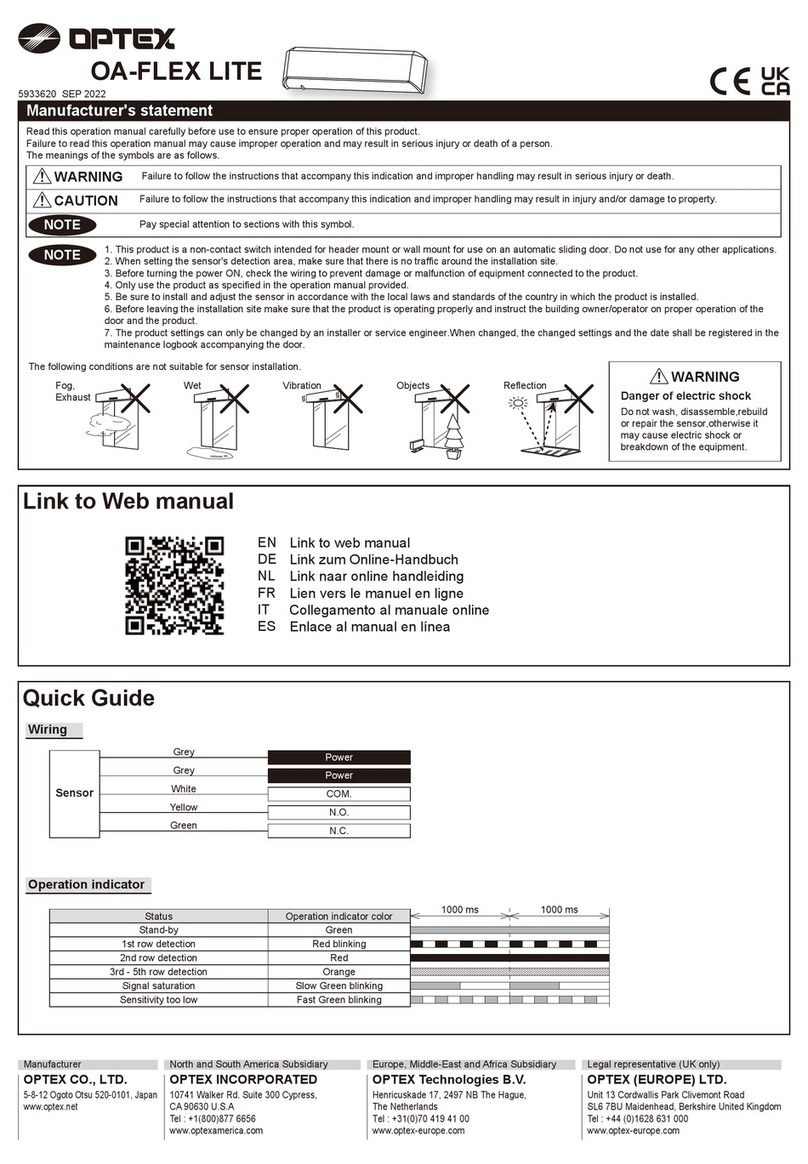

Width adjustment

screws (Right)

Width adjustment

screws (Left)

Narrow

Wide

Eliminated

Eliminated

123

Narrow

Wide

10 11 12

Eliminated

Eliminated

1 2 3 10 11 12

Front view

0

[m(feet,inch)]

123 10 11 12

4 5 6 7 8 9

2.0

(6′7")

3.0

(9′10") 01.0

(3′3")

1.0

(3′3")

2.0

(6′7")

2.0

(6′7")

1 2 3 cannot be eliminated separately, neither can 101112 .

Push 2 s

After changing the dipswitch settings, make sure to push the function switch for 2 s.

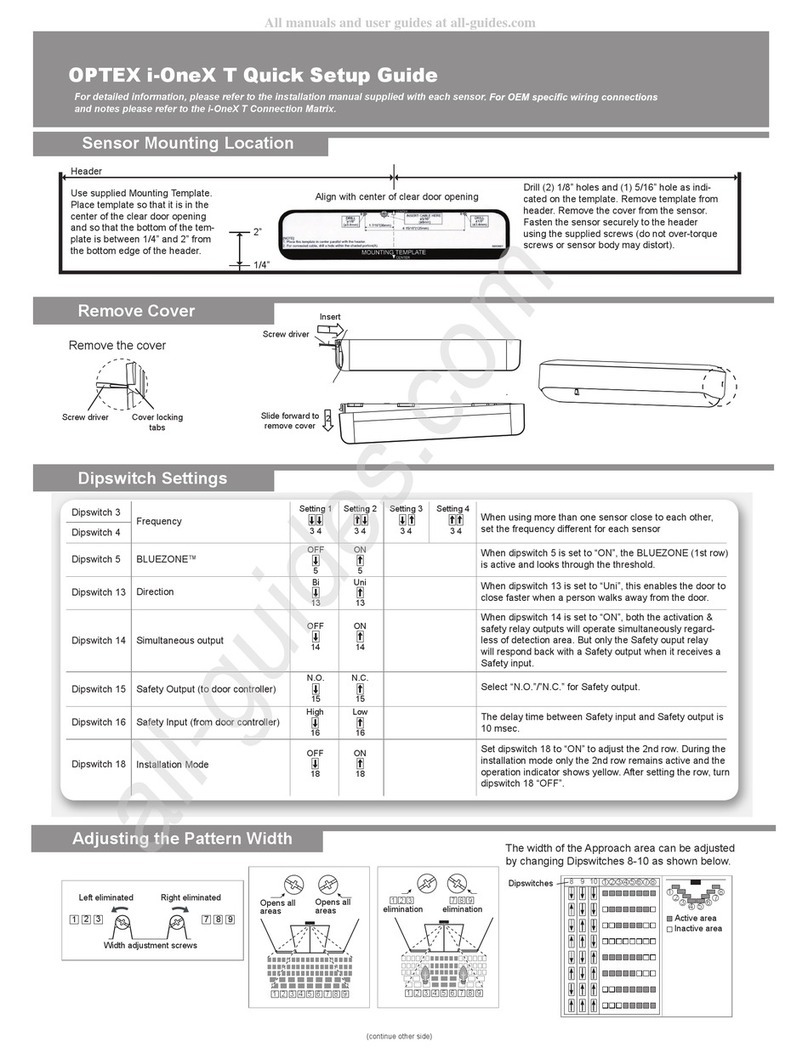

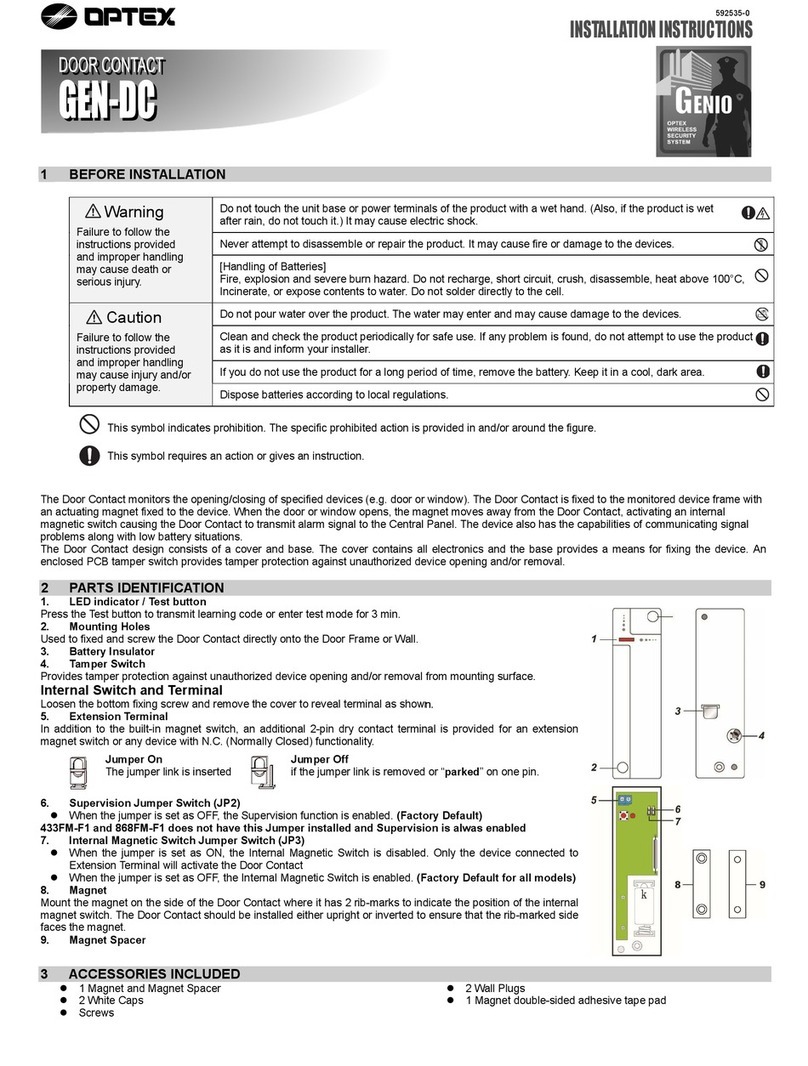

3. Dipswitch settings

CommentSettingFunction

Dip

switch

No.

Special attention to the setting is required

when the door is used often by the elderly or

children. Please adjust the sensitivity and the

presence detection timer according to your

risk assessment.

21

Low

21

Middle

21

High

21

S-High

1

Sensitivity

2

Table 1

CommentSettingFunction

Dip

switch

No.

Service mode

-

During the "Service mode", 1st row and 3rd to 5th row are transmitting. The operation indicator shows Yellow & Green blinking.

- After installation, be sure to turn to the "Operation mode" because it does not comply with EN 16005.

- The sensor automatically returns to "Operation mode" after 15 min from the transition.

To Service mode

Keep pushing function switch for 5 s until the operation indicator starts to blink after off.

Keep pushing function switch until the operation indicator goes off.

To Operation mode

Set dipswitch 16 to "ON" to adjust the 1st row.

During the Installation mode only the 1st row

remains active and the operation indicator

shows yellow.

After setting the row set dipswitch 16 "OFF".

16

OFF

16

ON

Installation mode

16

When dipswitch 15 is set to "Uni", this setting

enables the door to close faster when a

person walks away from the door.

Uni-directional function is disabled in case the

detection at 1st and/or 2nd row continues

for more than 5 s.

Bi

15

Uni

15

Direction

15

* No EN 16005 compliance.

1. When turning the power ON, alwayswalk-test the detection area to ensure the proper operation.

2. Do not place any objects that move oremit light in the detection area. (e.g. plant, illumination, etc.)

Inform building owner/operator of the following items

1. Always keep the detection window clean. If dirty, wipe the window with a damp cloth.

Do not use any cleaner/solvent.

2. Do not wash the sensor with water.

3. Do not disassemble, rebuild or repair the sensor yourself, otherwise an electric shock may occur.

4. When the operation indicator blinks green, contact your installer or service engineer.

5. Always contact your installer or service engineer when changing the settings.

6. Do not paint the detection window.

WARNING

NOTE

When using more than one sensor close to

each other, set the frequency different for

each sensor.

Frequency

5

6

Setting4Setting3Setting1 Setting2

65 65 65 65

3

4

The 1st and 2nd rows have the presence

detection function.

To enable the presence detection, do not

enter the detection area for 10 s after setting

the timer.

30 s

43

60 s

43

600 s

43

Presence timer

43

2 s

(Motion)*

10 ms delay time between Test input and

Safety output.

If the door controller has no Test, put Test

input to "OFF" and do not connect Black and

Red wires.

"High" or "Low" indicates the Test input signal

level from door controller.

N.C.

7

N.O.

7

Safety output

(to door controller)

7

8 8

OFF

(High) ON

(Low)

Test input

(from door controller)

8

Set the depth rows with dipswitches 9 and 10.

When "2 rows" are selected, the Activation

output is disabled.

5 rows 4 rows 3 rows 2 rows

109 109 109 109

9

10

Row adjustment

11 11

Set dipswitch 11 to "ON" when the sensor

operates by itself (Ghosting). When

dipswitch 11 is set to "ON" the actual

detection area may occur smaller.

OFF ON

Immunity

11

Dipswitch12 is for the Activation output to

door controller.

12 12

N.O. N.C.

Activation output

12

When Dipswitch 13 is set to "ON", both

Activation & Safety output will operate

simultaneously regardless of detection area.

But only Safety output will respond back with

Safety output when it receives Test input.

13

OFF

13

ON

Simultaneous

output

13

* After changing the dipswitch settings, make sure to push the function switch for 2 s.

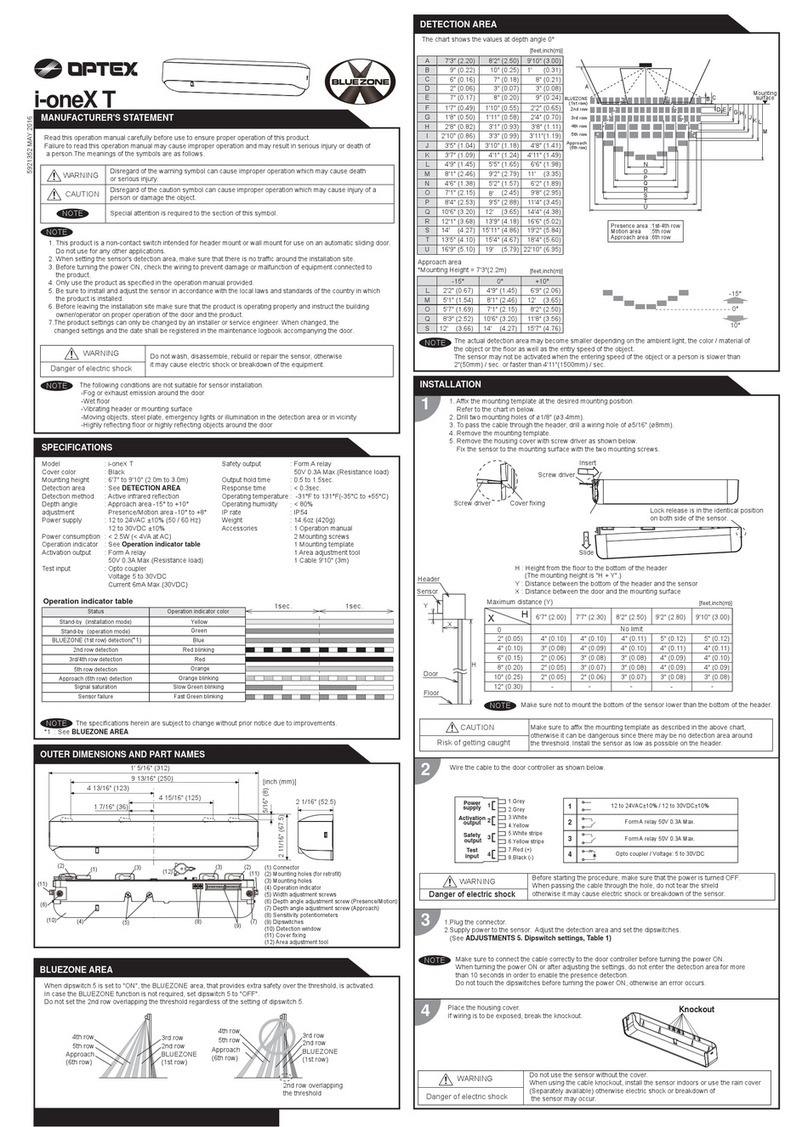

Door operation Operation

indicator Possible cause Possible countermeasures

Troubleshooting

Contact your installer or service engineer.

Check the wires and connector.

Check the wires and connector.

Wipe the detection window with a damp cloth.

Do not use any cleaner or solvent.

Set the sensitivity higher.(*)

Check Table 1 dipswtich 1 to 4. (*)

If the problem still persists, hard-reset the sensor.

(Turn the power OFF and ON again.)

Remove highly reflecting objects from the

detection area. Or lower the sensitivity. (*)

Or change the area depth angle for 1st to 3rd rows.

Check ADJUSTMENTS 1, 2, 3. (*)

Set the sensitivity higher. (*)

Set the presence timer longer. (*)

Check Table 1 dipswtich 7, 8, 12. (*)

Wipe the detection window with a damp cloth.

Do not use any cleaner or solvent.

Check Table 1 dipswtich 5, 6. (*)

Remove the objects.

Set dipswitch 16 to "OFF".(*)

Remove highly reflecting objects from the detection

area. Or lower the sensitivity. (*)

Or change the area depth angle.

After changing the dipswitch settings, make sure

to push the function switch for 2 s.

Use the rain-cover. (Separately available)

Or wipe the detection window with a damp cloth.

Do not use any cleaner or solvent.

Or install in a place keeping the waterdrops off.

Door opens

when no one

is in the

detection area.

(Ghosting)

Door remains

open

Door does not

open when a

person enters

the detection

area.

Proper

operation

Set to the stated voltage.

Check the wires and connector.

Set dipswitch 11 to "ON". (*)

Adjust the detection area to "Deep" (Outside).

Set the sensitivity lower. (*)

Adjust the detection area to "Deep" (Outside).

Switch to the Operation mode that keep pushing

function switch until the operation indicator goes

off.

Fast

Green

Blinking

Unstable

Slow

Green

Blinking

Red &

Green

Blinking

Unstable

Proper

Proper

Yellow

Slow

Green

Blinking

Proper

None

Yellow &

Green

blinking

Sensitivity too low or sensor failure.

Wrong wiring or connection failure.

Wrong wiring or connection failure.

Signal saturation. (1st or 2nd row)

Dirty detection window.

Sensitivity is too low.

Sudden change in the detection area.

Setting error.

Wrong detection area positioning.

Sensitivity is too low.

Short presence timer.

Wrong setting of dipswitches.

Dirty detection window.

Waterdrops on the detection window.

The detection area overlaps with that

of another sensor.

Objects that move or emit light in the

detection area.

Installation mode is set to "ON".

Signal saturation. (3rd, 4th or 5th row)

Wrong power supply voltage.

Wrong wiring or connection failure.

Others

Sensitivity is too high.

The detection area overlaps with the

door/header.

The detection area overlaps with the

door/header.

Service mode is enabled.

: Narrow

: Wide

112

–

4 9

–

Safety settings Activation settings Other settings Factory default settings

Depth angle

adjustment

screw

When the door remains open and the operation

indicator shows Fast/Slow Green blinking, refer

to Troubleshooting. If the door still remains

open, set dipswitch 14 to "OFF".

ON

14

OFF*

14

Self monitoring

14

Check the operation in the operation mode according to the chart below.

Checking

* : During warm-up, Safety output is constantly active.

Entry Entry into

3rd to 5th row

Entry into

2nd row

Entry into

1st row

Status Motion

detection

Motion/Presence

detection

Operation indicator

Outside of

detection area

Stand-by

Green Orange Red Red blinking

Activation

output

Safety

output

ON

OFF

13

ON

OFF

13

N.C.

7

N.O.

N.C.

7

N.O.

12

N.C.

12

N.O.

N.C.

N.O.

*

Power

OFF

-

None

Dipswitch 8

Test input

OFF

(High)

ON

(Low) 0 V

0 V

Test

Test

EMEA Subsidiary

OPTEX Technologies B.V.

Henricuskade 17, 2497 NB The Hague, The Netherlands

Tel : +31(0)70 419 41 00

www.optex.eu

Manufacturer

5-8-12 Ogoto Otsu 520-0101, Japan

Tel : +81(0)77 579 8700

www.optex.net

OPTEX CO., LTD.

2.0 to 2.2 m

(*High refrection)

2.0 to 2.5 m 2.5 to 3.0 m 2.5 to 3.0 m

(*Low refrection)

*Floor condition