Enconnex AC6000 User manual

Enconnex AC6000 UPS

USER MANUAL

Legal Disclaimer

This document is meant for instructional purposes only. This publication is not meant to

be a substitute for a detailed operational and site-specific development plan. Therefore,

Enconnex assumes no liability for damages, violations of codes, improper installation,

system failures, or any other problems that could arise based on the use of this

publication.

This publication has been compiled in good faith by Enconnex. However, no

representation is made, or warranty given, either expressed or implied, as to the

completeness or accuracy of the information this publication contains.

Enconnex reserves the right to make changes or updates with respect to or in the content

of the publication or the format thereof at any time without notice. Copyright, intellectual,

and all other proprietary rights in the content (including but not limited to software, audio,

video, text, and photographs) rests with Enconnex or its licensors. All rights in the content

not expressly granted herein are reserved. No rights of any kind are licensed or assigned

or shall otherwise pass to persons accessing this information.

This publication shall not be for resale in whole or in part

Table of Contents

Legal Disclaimer 1

Table of Contents 2

Figures 4

Tables 5

AC6000 Safety Information 6

Handling and Electrical Safety Information 6

Disclaimers 7

Life Support Applications 7

Product Introduction 9

Overview 9

AC6000 Features 10

Advanced Battery Management System 10

Automated Software Interface 10

User Interface - Front Panel with Bezel 11

Connectors and Controls - Rear Panel 12

Enconnex AC6000 Technical Specifications 13

AC6000 Installation Procedure 16

About this Procedure 17

AC6000 Mount Example 16

Materials Needed 17

Box Contents 17

Slide Rail Assembly (optional) 17

Instal the Inner Slide Rails on the AC6000 17

Installing the Outer Slide Rails 19

Field Wiring 19

Power-up and Shutdown Procedure 21

About This Procedure 21

Powering Up the AC6000 21

Visual Verification 29

Modes of operation 23

5.4.1 Standby Mode 23

5.4.2 NormalUPS Mode 23

Communicating with the AC6000 29

Webpage (HTTP) Configuration 24

SNMP Configuration 29

AC6000 Display 30

LCD Display Icons 30

Default Screen 30

Navigation 31

Main Menu 31

Reset to Factory Default Settings 35

Faults and Alerts 35

AC6000 Website 38

Home Page 38

Network Configuration 38

UPS Configuration 38

Control 38

System Status 38

DB9 and REPO Port Pin-Outs 39

REPO Connector 39

Serial Communication 39

Troubleshooting 40

Appendix 45

Safety Symbols and Definitions 45

Figures

Figure 2.1-1: AC6000 Drawing

Figure 2.1-2: AC6000 System Overview

Figure 2.5-1: AC6000 Front Panel Callouts

Figure 2.6-1: AC6000 Rear Panel

Figure 4.1-1: AC6000 Example Installation

Figure 4.4-1: Enconnex Adjustable Mounting Rails

Figure 4.4-2: Enconnex Adjustable Mounting Rails

Figure 4.4-3: Slide Rail Mounting.

Figure 4.4-4: AC600 Enclosure with optional Enconnex slide rails attached.

Figure 4.5-1: Hard-wiring inspection and assembly.

Figure 5.2-1: AC6000 Rear Panel

Figure 5.2-2: AC6000 Power Button Location

Figure 5.5-1: AC6000 Rear-Panel Communication Ports for Troubleshooting

Figure 6.3-1: AC6000 User Input Controls

Figure 6.4-1: AC6000 Front Panel Menu

Figure 8-1: Expansion Communication Ports and REPO Connector

Figure 8.1-1: REPO Connector Pin-Out

Figure 8.2-1: Serial and Ethernet Pin-Outs

Tables

Table 2.5-1: User Interface and Controls

Table 2.6-1: AC6000 Rear Panel Detail

Table 3-1: AC6000 Technical Specifications

Table 4.2-1: Materials Needed

Table 4.5-1: Field Wiring Table

Table 5.3-1: Icons and Descriptions

Table 5.5-1: Webpage Default Username and Password.

Table 5.5-2: Parameter Table

Table 6.4-1: Front Panel Menu

Table 6.6-1: AC6000 Beep Codes

Table 6.6-2: Beep Control Mode

Table 6.6-3: Fault Messages and Descriptions

Table 6.6-4: Display Messages and Descriptions

Table 9-1: Troubleshooting: Problems and Solutions

Table 9-2: Error Codes, Messages and Descriptions

1. AC6000 Safety Information

1.1. Handling and Electrical Safety Information

IMPORTANT SAFETY INSTRUCTIONS — SAVE THESE INSTRUCTIONS

This document contains important information and direction that should be followed

during installation, maintenance, and usage of this product. Before installing or operating

this equipment, please read all instructions, warnings and cautions. Save this manual for

future reference.

- DANGER

This UPS contains LETHAL VOLTAGES. All repairs and service should be performed only

by an Enconnex-AUTHORIZED SERVICE PERSONNEL.

Fuses are permanently installed. There are NO SERVICEABLE PARTS inside this product.

- WARNING

● Personnel should be knowledgeable of the processes before attempting to install,

configure or replace this equipment.

● It is important to note that this UPS contains its own energy source (lithium-ion cells).

Its output may produce high voltages and currents even when it is not connected to

AC mains.

● This system contains live batteries that may present a shock hazard even when

disconnected. Output safeguards such as disconnect switches, interlocks, etc. must

be provided by user.

● Connect only to a mains provided with branch circuit overcurrent protection. This

must be performed in accordance with the National Electrical Code® (NEC)

ANSI/NFPA 70 and applicable codes of local jurisdictions.

● Leakage current of this UPS and all connected equipment must not have an earth

leakage current greater than 3.5 milliamperes per international standards and wiring

regulations.

● For 230V/50Hz models, cables should not exceed ten meters in length.

● Lithium ion is a Class 9 hazardous material and must be shipped in accordance with

CFR 49. Please contact your Enconnex representative when shipping a unit for return

or other purposes.

● Contact Enconnex agent for service, recycling, and disposal instructions. Also visit

earth911.com for instructions on disposal.

● Damage will occur if the input or output AC terminals are shorted. Enconnex is not

responsible for damages to the UPS incurred in this manner.

- CAUTION

● Install this UPS in a clean, temperature- and humidity-controlled indoor location in

order to reduce the risk of fire or electric shock. Ambient temperature must not be

above 40°C (104°F) or below 0°C (32°F). Do not locate near water or excessive

humidity (95% maximum).

● It is advisable to not bring superfluous conductors into the installation area. Before

beginning maintenance or installation, please remove jewelry (e.g. watches, rings and

necklaces). Metal conductors have the potential to short between power terminals

(power and ground, commonly) and nearly instantly heat to very high temperatures

when connected between them. This can cause serious burns and/or weld a metal

object to the terminals.

● This system is cooled through forced air convection. Do not block air flow of fans and

allow adequate space on the front and rear of the unit for proper ventilation.

● This equipment has been tested and found to comply with the limits for a Class-A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference

that the user must correct, including the expense of all corrective modifications.

● This system is suitable for IT (impedance-grounded) systems.

1.2 Disclaimers

Modification or changes to the AC6000 not performed or expressly approved by

Enconnex may void the unit's warranty.

The integral battery is not field-replaceable. There are no user-replaceable fuses within.

Contact Enconnex Customer Support for assistance.

The AC6000 is designed for installation in temperature-controlled, indoor areas free of

conductive contaminants. See Technical Specifications for more information.

1.3 Life Support Applications

The Enconnex AC6000 is not for use in life support applications where failure or

malfunctions of the unit can be reasonably expected to cause failure of the life support

device or to significantly affect its safety or effectiveness. The Enconnex AC6000 is not

for direct patient care.

Enconnex will not knowingly sell its products for use in such applications unless it

receives in writing assurances satisfactory to Enconnex.

The AC6000 does not meet medical standard requirements for use in direct patient care.

2. Product Introduction

2.1 Overview

The Enconnex AC6000 is a highly integrated line-interactive uninterruptible power

system (UPS). Integrating the electronics and a battery capable of supplying 6kWs of

power for 6 minutes contained within a small 2RU form factor, this system is designed

to protect servers in the back office and data center environments.

Figure 2.1-1: AC6000 Drawing

The line-interactive approach captures the best features of UPS topologies: Its

electronics are mostly inactive, but always “armed”. They’re at the ready for the next

power interruption. Switchover to UPS Mode occurs within ¼to ½cycle of the 60 Hz

mains.

This translates to full power available with an interruption of 4 to 8 thousandths of a

second. Most, if not all, IT equipment is designed to never notice this very high-speed

handoff.

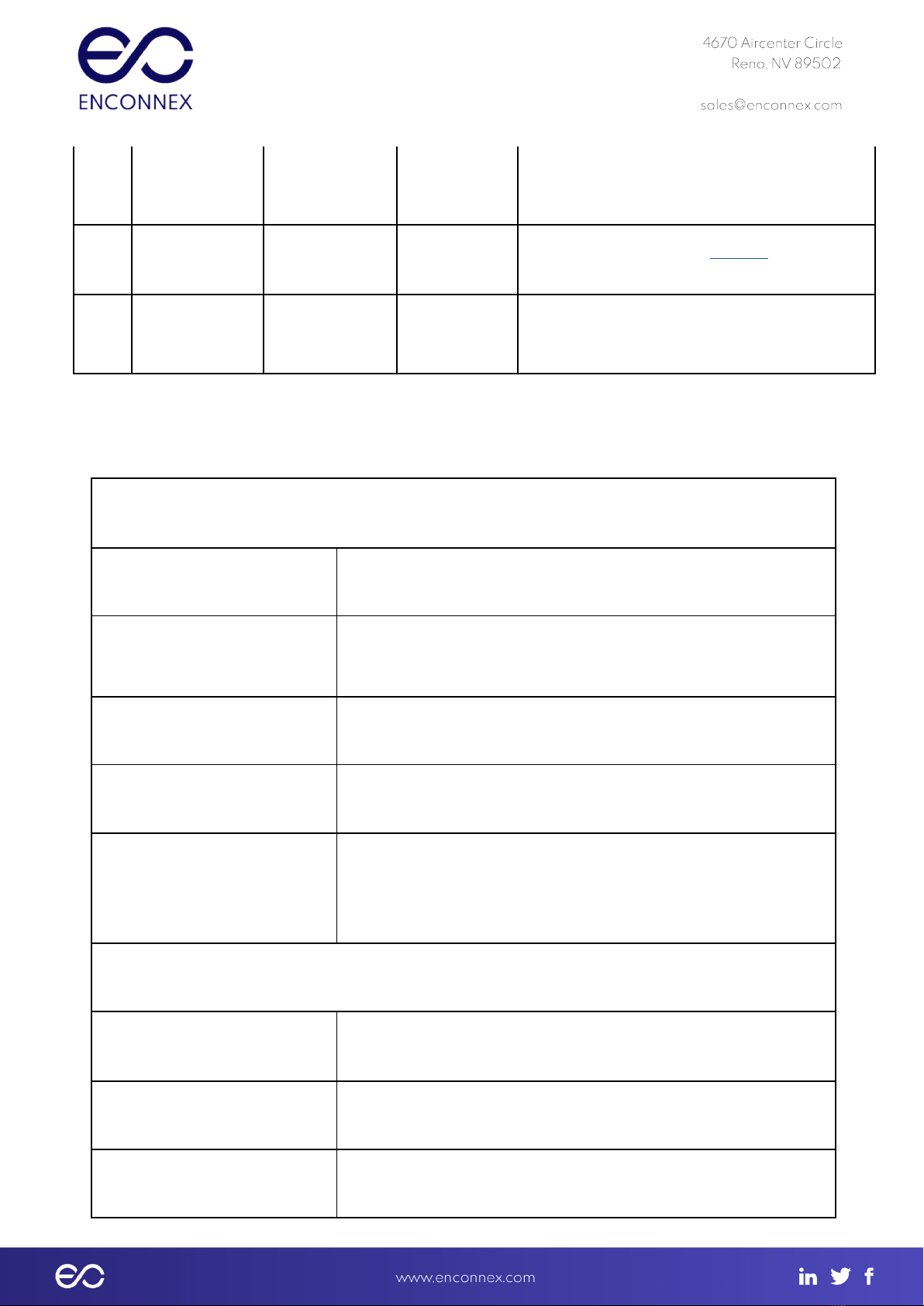

Figure 2.1-2: AC6000 System Overview

The AC6000 is versatile and extensible. It can serve to supplement mains power

during peak energy consumption times using unique peak shaving technology. This

highly efficient unit operates with an input and output of 208, 230, or 240 VAC. It is

capable of supporting equipment drawing up to 6kW. This power-dense 2RU unit

contains highly efficient power electronics and a safe, high-performance lithium-ion

battery pack.

2.2 AC6000 Features

● Supplies up to 6000 watts of power for 6 minutes.

● Uses compact, safe lithium-ion technology for energy storage.

● Rapid recharge.

● Peak shaving capability to supplement power supply during high demand.

2.3 Advanced Battery Management System

● Leverages years of automotive research.

● Maintains battery cell power balance.

● Highly efficient power management with low quiescent draw.

● Integrated safety electronics.

● Provides active thermal management of cells.

2.4 Automated Software Interface

● Supports serial or SNMP communication

● Reports critical performance metrics

● Allows for firmware updates of internal microprocessors

● Provides for network communication configuration.

Alerts are generated for indicating low remaining power, announcing operational modes and

notification of performance-related issues.

2.5 User Interface - Front Panel with Bezel

Figure 2.5-1: AC6000 Front Panel Callouts

No.

Item

Type

Name

Description

1

Knob

Fastener

Knob Screw

Screw with molded knob/thumb screw.

2

Display

LCD

User

Interface

Screen

LCD screen which shows status, battery,

power, and alert/fault conditions and allows

unit configuration.

3

Button

Momentary

Power

Used to change the operating state of the

unit.

4

Button

Momentary

Left

Navigation button to move selection on

display left.

5

Button

Momentary

Up

Navigation button to move selection on

display up.

6

Button

Momentary

Down

Navigation button to move selection on

display down.

7

Button

Momentary

Right

Navigation button to move selection on

display right.

8

Button

Momentary

Menu

Navigation button to display the Main Menu.

Table 2.5-1: User Interface and Controls

2.6 Connectors and Controls - Rear Panel

Figure 2.6-1: AC6000 Rear Panel

The AC6000 comes equipped with forced air convection cooling multiple standard

configurations, and is Ethernet or serial compatible.

No.

Item

Type

Name

Description

1

Fan

Ventilation

Cooling Fan

Extracts air from the AC6000 enclosure.

Speed controlled by internal temperature

regulation. Air flows from the enclosure

bezel cold side.

2

Connectors

DB9

RS485.CAN

DB-9 female connector reserved for future

use.

3

Connector

Phoenix

REPO

(Remote

Power-Off)

Depending on user preference, the REPO

feature can be configured in three ways::

1. not used

2. normally open (top two positions)

3. normally closed (bottom two positions)

The default configuration is normally closed.

4

Switch

Circuit

Breakers

Power

Switch

Provides Input over-current protection as

well as a means to disconnect the input

power from the AC6000

5

Connector

RJ45

RS232

Serial

RS232 console for configuration and

monitoring.

6

Rail/Mountin

g Brackets

Slide

Rail/Mounting

Brackets

Left & Right

Slide Rails

and

Attaches device to slide rails a allows the

AC6000 to be extracted from the

enclosure for service.

Mounting

Brackets

7

Connector

RJ45

Ethernet

port

Ethernet port provides network connectivity.

8

Cable

Management

Compression

Clamps

Input /

Output

Secures the power cable connections for

power I/O.

Table 2.6-1: AC6000 Rear Panel Detail

3. Enconnex AC6000 Technical Specifications

System Specifications

Efficiency

93%

Power Protection

Mechanical Circuit Breaker (MCB), electronic monitoring and

control, fusing, fuse links

System Power Factor

>0.9

Battery Protection

Discharge, Overcharge, Overcurrent, Thermal

6000 W, max.

6 minutes

Environmental

Operating Temperature

Range

0°C to +40°C

Storage Temperature Range

-20°C to +60°C

Humidity

0% to 95%, Non-Condensing

Cooling Method

Integrated Forced Air

Physical Specifications

Case Material

Steel

Dimensions, Inches

2U: 3.5 H x 19.0 W x 32.0 D

Weight

approx. 90 lbs.

Battery Capacity

1000 Watt-Hours

Electrical Power Connectors

Standard:

Input: NEMA L6-30R (24A input)

Output: NEMA L6-30P

Optional:

For 6kW output on 50A service:

Option 1 – CS8265/4

Option 2 – Hardwire I/O

(Intended for loads in excess of 5kW to

accommodate full power at low line conditions.)

Option 3 – For Europe, 24A input using 332C6/P6.

Note: User must include upstream branch protection. For

standard configuration and option 3, branch protection must

not exceed 30 A. For Options 1 & 2, branch protection must

not exceed 50 A.

Table 3-1: AC6000 Technical Specifications

4. AC6000 Installation Procedure

4.1. About this Procedure

This procedure covers the installation of the AC6000 UPS unit into a standard 19-inch

rack enclosure.

4.1.1 AC6000 Mount Example

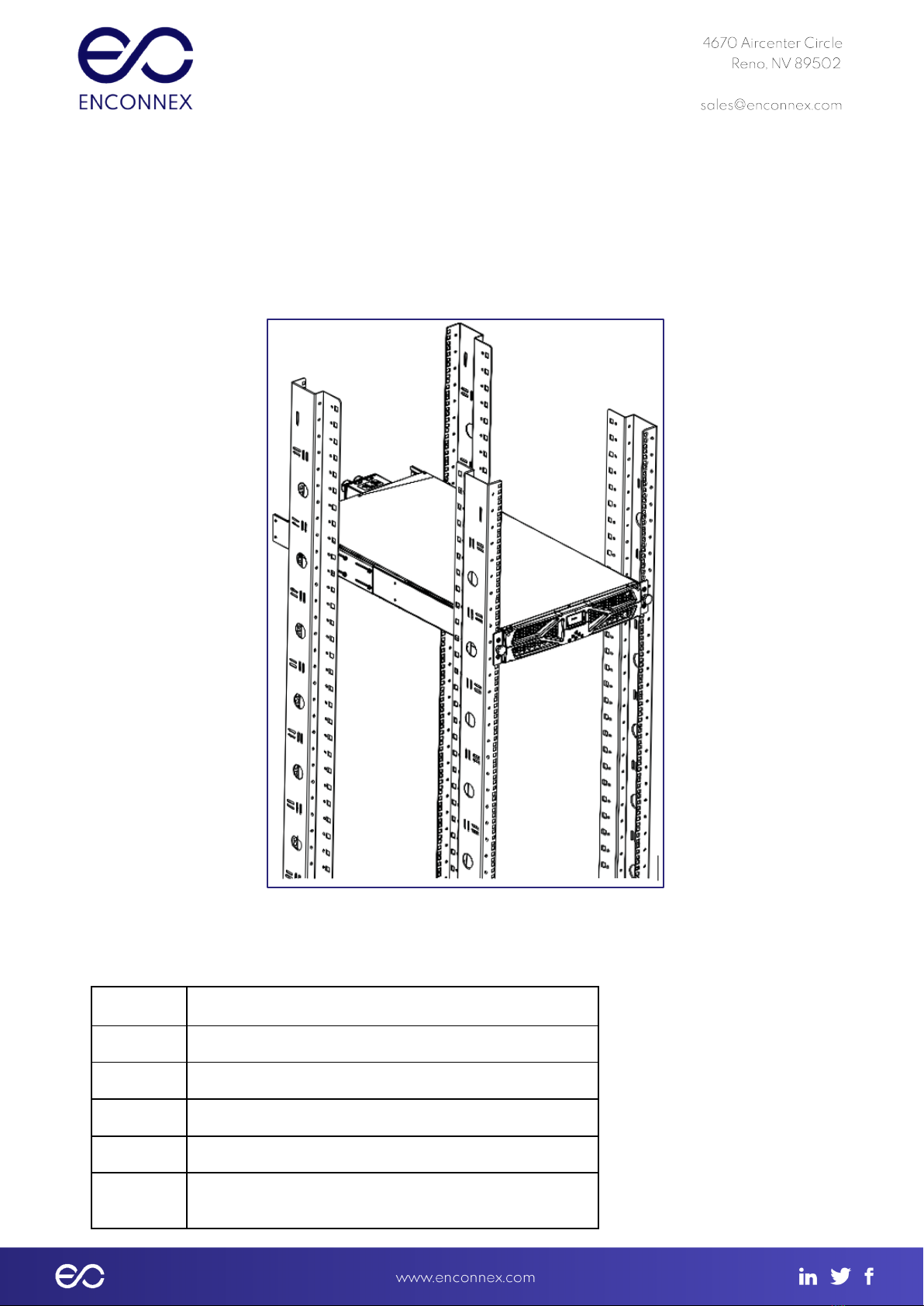

Figure 4.1-1: AC6000 Example Installation

4.2. Materials Needed

Qty.

Material

1

Set of AC6000 UPS and Hardware

2

Slide Rails

8

M3x8 Phillips Head Screws (Not supplied)

12

#12-24 Cage Nuts (Supplied with Rails)

12

#12-24 x ⅝” Pilot Point Machine Screw (Supplied with

Rails)

4

#12-24 x 1” Machine Screw

Table 4.2-1: Materials Needed

4.3. Box Contents

The AC6000 container should have the following items:

● User Manual

● AC6000 with input and output power cables

● Mounting rails with hardware (optional)

Table 4.3-1: Box Contents

4.4 Slide Rail Assembly (optional)

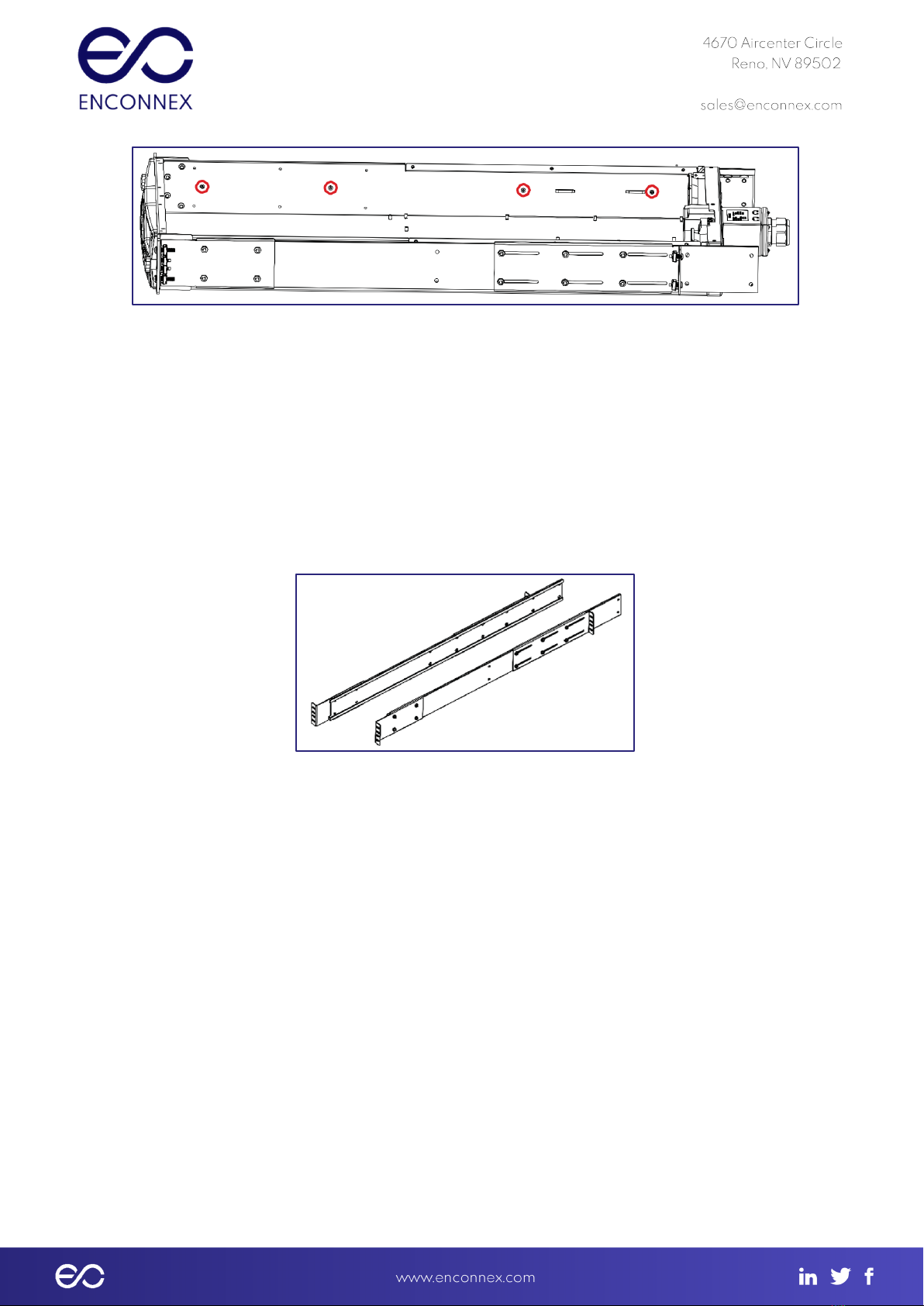

Figures 4.4-1 & 4.4-2: Enconnex Adjustable Mounting Rails.

Slide rail assemblies are recommended for mounting the AC6000 UPS.

4.4.1 Install the Inner Slide Rails on the AC6000

Materials Needed:

● M3x8 Phillips Head Screws (qty. 8)

● Inner Slide Rails (qty. 1 set)

Figure: 4.4-3: Inner Slide Rails

Tools Required:

● Phillips Head Screwdriver

● Cage Nut Compressor Tool

The optional inner slide rails attach to the left and right sides of the AC6000 enclosure (The rails

are marked with “Left” and “Right” for reference. They are fastened to the enclosure with

screws into the supplied PEM nuts. The illustration below shows the interior of the AC6000.

PEM rivet nut locations circled in red.

Figure 4.4-4: Slide Rail Mounting.

Step 1: Remove the slide rail assembly from it’s packing materials.

Step 2: Remove the inner rails and extract them from the outer rail channels

Step 3: Fasten the inner rails to the AC6000 enclosure.

4.4.2 Installing the Outer Slide Rails

Materials Needed:

● #12-24 x ⅝” Pilot Point Machine Screw (qty. 8)

● Cage Nuts (qty. 12)

● Outer Slide Rails (qty. 1 set)

Figure 4.4-5: Outer slide rails

Tools Required:

● Phillips Head Screwdriver

● Cage Nut Compressor Tool

Step 1: Select installation height on the rack posts where you will mount left and right

outer slide rails.

Step 2: Install 4 cage nuts in each front rail, and 2 cage nuts in each back rail as shown in the

picture.

Front Rail Rear Rail

Step 3: Adjust the rear slider plate on the Outer Sliding rails to increase or decrease the length

of the rails to properly fit the cabinet.

Step 4: Attach the Outer Sliding Rails (stationary) to the cabinet front mounting rails using 2

screws on each side of the rail. These screws will be placed in the middle two holes. The outer

two holes will be where the AC6000 is mounted.

NOTE: Do not tighten completely as they may need to be adjusted for the width of the AC6000

● AC6000 screw

● Outer Slide Rails screw

● Outer Slide Rails screw

● AC6000 screw

*Above is the order for which the screws will be installed.

Step 5: With the rails at the proper length, install 2 cage nuts and 2 screws at the rear of the

cabinet to fasten the stationary rail to the cabinet. Place the screws at the top and bottom of

the 4 holes.

Step 6: With two people, lift the AC6000 unit into the cabinet by inserting the sliding rails on the

UPS (AC6000) into the track of the stationary Outer Slide rails. Approximately ⅓of the way in

you will hear a click. This is the latch engaging which disables the rail from being completely

pulled out. When fully seated install the remaining 4 screws into the cage nuts to secure the

unit in the rack.

To remove the AC6000 remove the mounting screws on each side, and slide the unit out. When

the latches are exposed activate them while continuing to slide the unit out of the

4.5 Field Wiring

● To wire the unit in the field, ensure that the electrical service is properly rated for

the desired output.

Table of contents

Popular UPS manuals by other brands

Tripp Lite

Tripp Lite INTERNET OFFICE 300 Manual Del Usuario

Tripp Lite

Tripp Lite Power Suppy owner's manual

Tripp Lite

Tripp Lite SmartOnline owner's manual

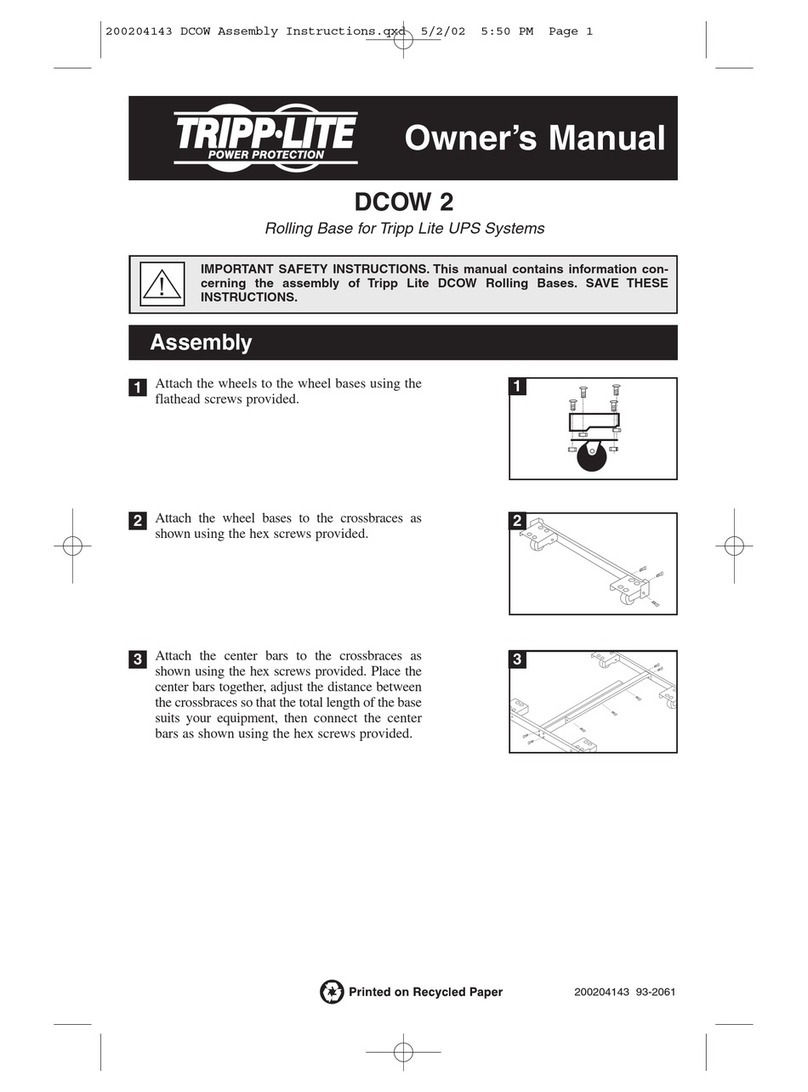

Tripp Lite

Tripp Lite DCOW 2 owner's manual

Tripp Lite

Tripp Lite SmartOnline SU40K owner's manual

Contec

Contec CONPROSYS Alpha Series Reference manual

Tripp Lite

Tripp Lite SmartPro SMART3000RMXL2U owner's manual

MetaSystem

MetaSystem MEGALINE 1250 RACK instruction manual

Tripp Lite

Tripp Lite SmartOnline AGPS5548 owner's manual

Tripp Lite

Tripp Lite BCPRO850 Features and specifications

Tripp Lite

Tripp Lite SmartPro SMART1500RM2U Specification sheet

Tripp Lite

Tripp Lite SmartOnline 3-Phase 10kVA owner's manual