Table of contents

4

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . 5

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Installation, commissioning and operation . . . . . . . . 5

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.5 Notes on safety conventions and icons . . . . . . . . . . 6

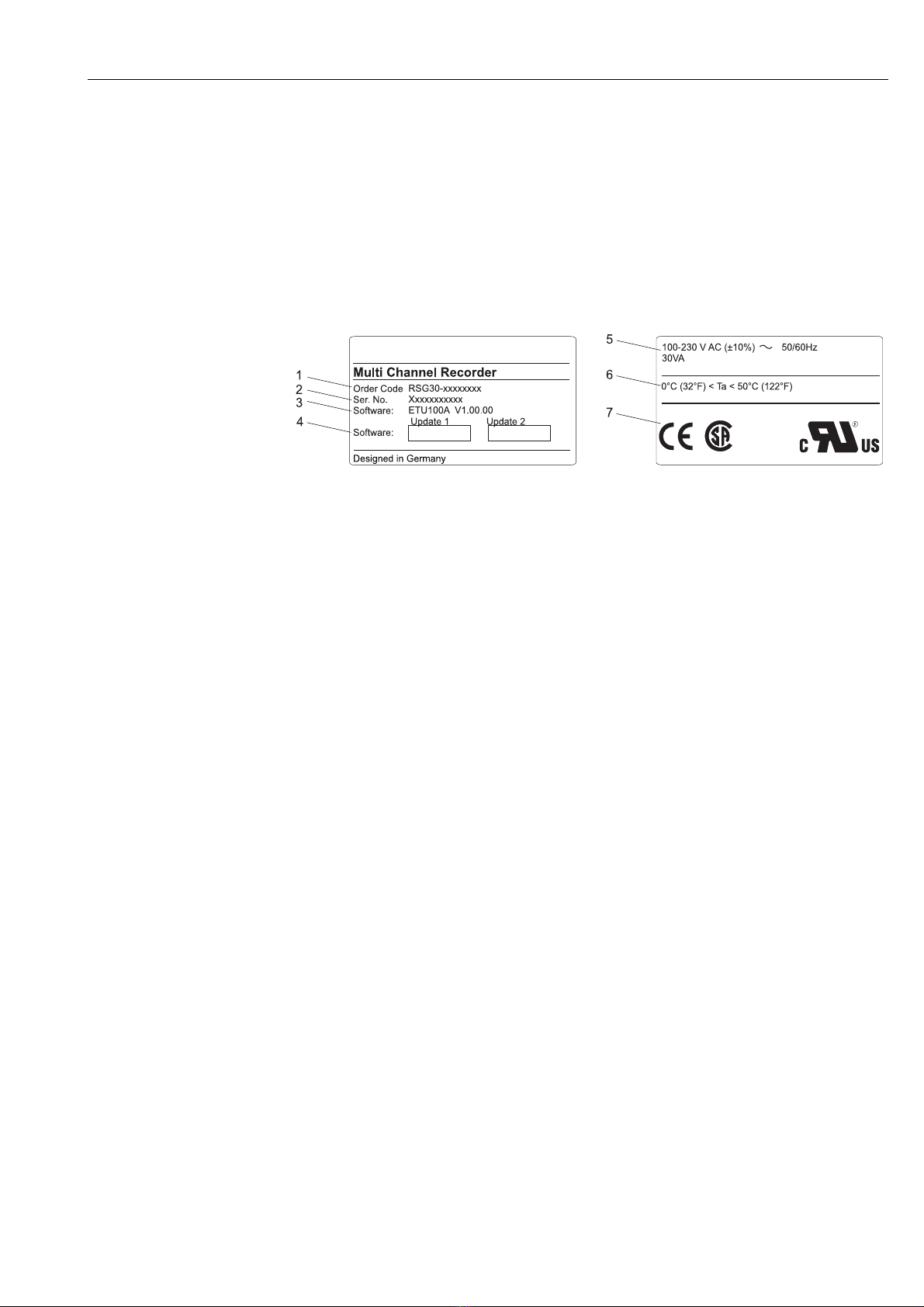

2 Identification . . . . . . . . . . . . . . . . . . . . 7

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 7

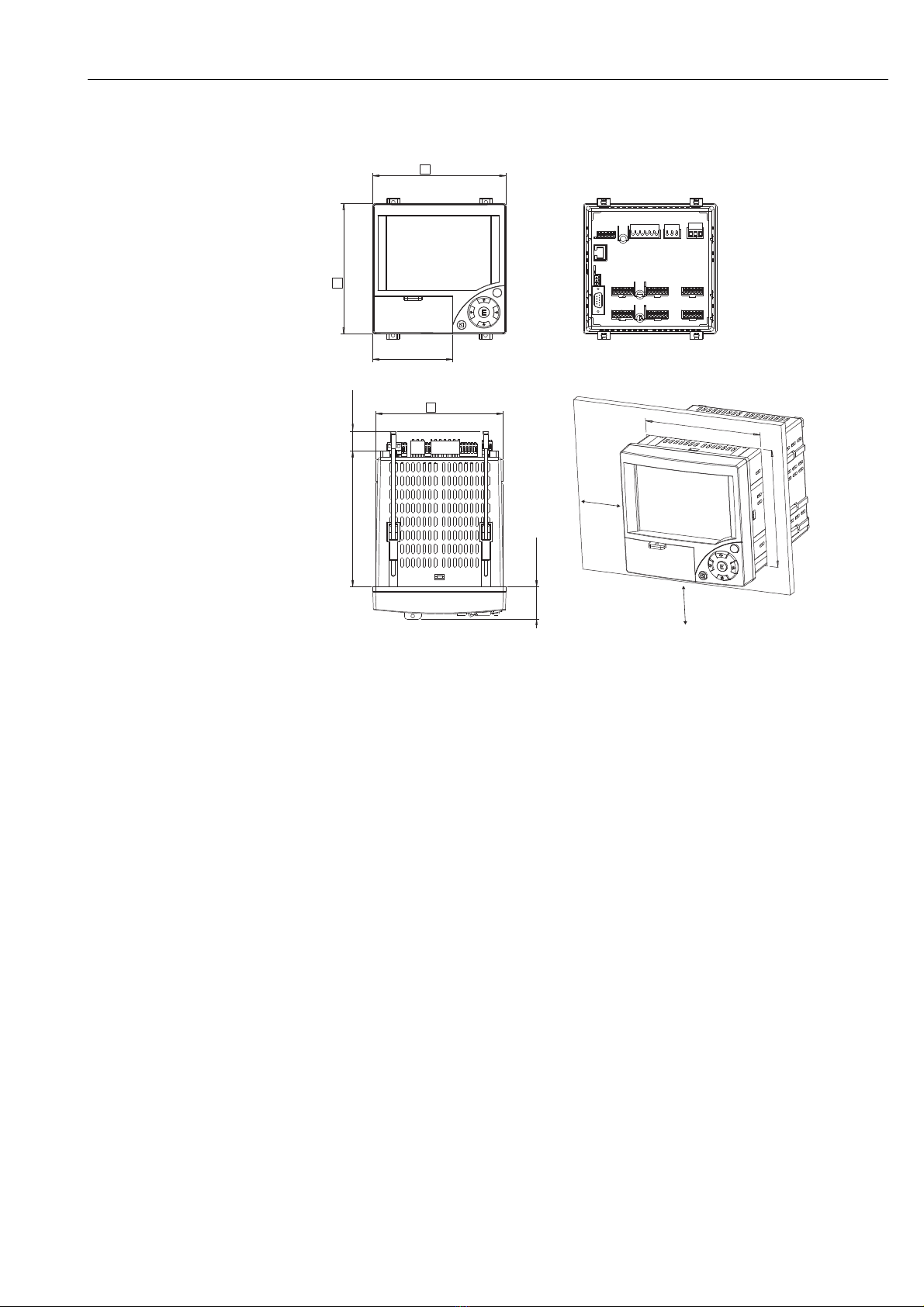

3 Installation . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Incoming acceptance, transport, storage . . . . . . . . . 8

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Mechanical locking . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Post-installation check . . . . . . . . . . . . . . . . . . . . . 10

4 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Terminal assignment . . . . . . . . . . . . . . . . . . . . . . 14

4.3 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Post-connection check . . . . . . . . . . . . . . . . . . . . . 18

5 Operation . . . . . . . . . . . . . . . . . . . . . . 19

5.1 Quick operating guide . . . . . . . . . . . . . . . . . . . . . 19

5.2 Display and operating elements . . . . . . . . . . . . . . . 20

5.3 Entering text and numbers . . . . . . . . . . . . . . . . . . 21

5.4 Overview of the symbols used . . . . . . . . . . . . . . . 21

5.5 Confirming error messages . . . . . . . . . . . . . . . . . . 22

5.6 Communication; PC software installation . . . . . . . 22

6 Commissioning. . . . . . . . . . . . . . . . . . 26

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2 Switching on the unit . . . . . . . . . . . . . . . . . . . . . . 26

6.3 Unit Set up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4 The set up window (at main menu) . . . . . . . . . . . 30

6.5 The main menu . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.6 Saving measured values . . . . . . . . . . . . . . . . . . . . 61

6.7 Important functions of the provided PC software . 62

7 Maintenance. . . . . . . . . . . . . . . . . . . . 64

7.1 Software update via the provided PC software . . . . 64

7.2 Instruction for releasing a software option e.g.

"Integration + Analysis + Maths" . . . . . . . . . . . . . 64

8 Accessories. . . . . . . . . . . . . . . . . . . . . 65

8.1 Accessory parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9 Troubleshooting. . . . . . . . . . . . . . . . . . 66

9.1 Diagnostic/unit information . . . . . . . . . . . . . . . . . 66

9.2 Troubleshooting instructions . . . . . . . . . . . . . . . . . 67

9.3 System error messages . . . . . . . . . . . . . . . . . . . . . 68

9.4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

9.7 Software history . . . . . . . . . . . . . . . . . . . . . . . . . . 71

10 Technical data . . . . . . . . . . . . . . . . . . . 72

10.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.2 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.3 Power supply/terminal diagram . . . . . . . . . . . . . . 75

10.4 Performance characteristics . . . . . . . . . . . . . . . . . . 76

10.5 Installation conditions . . . . . . . . . . . . . . . . . . . . . . 76

10.6 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

10.7 Mechanical construction . . . . . . . . . . . . . . . . . . . . 78

10.8 Human interface . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.9 Certificates and approvals . . . . . . . . . . . . . . . . . . . 81

10.10 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.11 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82