EnergAir metacentre DX Box User manual

MANY0739A.GB – Metacentre DX Box User Manual

TM

DX Box

bar

Metacentre DX Box

Page 1

Index

1.0 Introduction

1.1 Management System Connectivity

1.2 Basic Function

1.3 Operation

2.0 Operation

2.1 User Interface

2.2 Display

2.3 Status Symbols

2.4 Indications

2.5 Compressor Identification

2.6 Operation

2.7 Power Failure Auto-Restart

2.8 Failure Modes

2.9 Compressor Fault

2.10 DX Box Fault

2.11 Pressure Sensor Fault

3.0 Parts List

4.0 Technical Data

5.0 Wiring Connection Diagram

Refere to Section Indicated

Note

Important or Caution, Safety

Health and Safety

Refer to Metacentre Safety Manual

User Manual

Page 2

1. INTRODUCTION

The DX Box is designed to connect two

load/unload air compressors to a system

management unit, using a 2-wire RS485 data

cable up to 500m (1650ft) in length.

The DX Box is designed specifically to ‘group’

two compressors together as a single

coherent unit. The system management unit

will detect and manipulate the two

compressors as a single multiple step or

variable output compressor unit.

The DX Box is able to manipulate two identical

capacity compressors to form a single ‘group’

that will act in an identical manner as a 3-step

compressor. The DX Box is also able to

manipulate two differential capacity

compressors providing demand matched

control and sequence to form a single ‘group’

that will act in an identical manner as a

variable stepping output, compressor.

This functionality provides the ability to:

a) Group two adjacent air compressors

together as a single coherent unit.

b) Combine two similar capacity

compressors together to form a three-

step variable output group acting as a

single coherent variable output unit.

c) Take advantage of a small or minimal

capacity compressor, grouped

together with a medium or higher

capacity compressor, to form a high

capacity, variable output, group acting

as a single variable output ‘top-up’

compressor.

d) Exceed the maximum compressor

control capability of a system

management unit by combining

compressors together as one.

Two single pressure switch control type air

compressors can be connected to the DX Box

using a 6-wire cable and a compressor

interface PCB (i-PCB). The ‘i-PCB’

connections are identical to an system

management unit.

The DX Box also provides optional ‘local

pressure sensor’ connections. The

compressor delivery pressures, local system

pressure and air treatment differential

pressures can be displayed. The monitored

local pressure is available on the system

network and can be utilised by an system

management unit for advanced pressure

related functions.

Any number of DX Boxes can be connected to

an system management unit as long as the

total number of single compressors and/or

groups does not exceed the total number of

compressors for the system management unit

model.

1.1 Management System Connectivity

12 #1

DX Box

3#2

The DX Box connects to an ystem

management unit using an industrial two wire

RS485 data network (Multi485).

1.2 Basic Function

The DX Box is a ‘Duel unit eXtension’ to a

system management unit providing the ability

to group two individual air compressors

together in to one duel ‘group’ acting as a

single coherent unit.

The DX Box provides additional ‘i-PCB’

connectivity.

The DX Box can also be used to provide ‘i-

PCB’ connectivity at a remote location beyond

the maximum distance specification of direct

system management unit connection.

1.3 Operation

2.3.1 Timer Rotation Mode (Tr)

#1 #2

50% 50% = 100%

1AB

2BA

AB

Timer Rotation should be used when the two

compressors have the same (50:50), or very

similar, output capacity. The DX Box will

assign one compressor as ‘Duty’ and the other

as ‘Standby’. The duty compressor will always

be loaded first and the standby used as and

when required to meet demand. The duty and

standby assignment will be changed at every

‘Interval Time’ (adjustable).

Metacentre DX Box

Page 3

1.3.2 Automatic Mode (Ar)

#1 #2

65% 35% = 100%

0% - -

35% - B

65% A -

100% A B

AB

Automatic mode can be used when the

compressor capacities are different. The DX

Box will utilise each compressor as required to

match output to demand. This mode enables

the compressor ‘group’ to behave in the same

manner as a single (multiple step) variable

output unit.

The set ‘Interval Time’ is ignored in this mode,

the DX Box will continuously evaluated

utilisation to match demand.

For example:

If demand can be satisfied by the smaller of

the two compressors (demand < 36%) the DX

Box will utilise the lower capacity compressor

(B). If demand increases above the output

capacity of the smaller compressor, but within

the capacity of the larger capacity compressor,

the DX Box will utilise the larger capacity

compressor (A). If demand exceeds to

capacity of the larger capacity compressor the

DX Box will load the larger compressor

continuously and utilise the smaller capacity

compressor to regulate as required.

1.3.3 Management System Integration

When integrated with a system management

unit the DX Box compressor ‘group’ will

respond in ‘Top-Up’ mode or ‘Base-Load’

mode as dictated by the management unit.

The assigned mode of response will change

from time-to-time dependant on the set

sequencing mode of the management unit.

In Top-Up’ mode the DX Box will allow

variable capacity control (as described above)

dependant on demand.

In ‘Base-Load’ mode the DX Box will fully load

both compressors to provide full base-load

capacity output.

The DX Box ‘group’ unit should be set as a

variable output unit on the management

system. The management system will fully

utilise the variable output capacity capability of

the DX Box ‘group’ and report the percentage

of utilisation of the ‘group’ in the same manner

as a single variable output compressor.

1.3.4 Percentage Capacity

The capacity of each compressor is

expressed, and set, as a percentage of the

combined output capacity of both

compressors.

For example:

If the larger compressor #1 (A) has an output

capacity of 13.0m3/min, and the smaller #2 (B)

compressor an output capacity of 7.0m3/min,

the total combined output of the DX Box

‘group’ equates to 20.0m3/min.

Total Capacity (20.0m3/min.) = 100%

Compressor #1 (A) = 65%

Compressor #2 (B) = 35%

1.3.5 Compressor Failure Mode

If one compressor in the DX Box ‘group’

suffers a shutdown failure, or is manually

stopped, the DX Box will indicate an ‘Alarm’

condition. The remaining compressor will

continue to function and the DX Box will

continue to operate at reduced capacity.

If both compressors suffer a shutdown failure,

or are manually stopped, the DX Box will

indicate a shutdown ‘Trip’ condition.

User Manual

Page 4

2. OPERATION

1

2

3

4

10

5

6

7

8

9

BAR

2.1 User Interface

1) LCD Display

2) No function (unit always ON)

3) No function

4) No function

5) ESCAPE Button

6) UP, PLUS Button

7) DOWN, MINUS Button

8) ENTER Button

9) DX Box Active Indicator

10) FAULT Indicator

2.2 Display

The upper display will continuously show the

The detected ‘System’ pressure and the lower

display will show the percentage load of the

DX Box ‘group’.

Press UP and DOWN to view the status,

‘Delivery’ pressure (if enabled) and

‘Differential’ pressure (if applicable) for each

compressor in the ‘group’.

When viewing the status or pressure

information for a compressor the ‘network

address’ and DX Box identification will be

show on the upper display (for example,

“C.03.1” indicates that the compressor is

connected to the DX Box as compressor #1

and the DX Box is represented on the system

management unit as compressor number

“03”). The status of the compressor will also

be show using the ‘Run’ and ‘Load’ symbols.

If the ‘Delivery’ pressure sensor option for a

compressor has not been enabled the lower

display line will not be shown and the

‘differential’ pressure item will not be available.

User Menu Iems:

P.-C>: ‘System’ Pressure. and % Output

C#1-P>: ‘Delivery’ pressure compressor #1

C#1- P: ‘Differential’ Pressure #1

C#2-P>: ‘Delivery’ pressure compressor #2

C#2- P: ‘Differential’ Pressure #2

2.3 Status Symbols

DX Box Status (C>):

Power Failure Auto Restart (always on)

Communicating with the System

Management Controller (Remote Mode)

Flashing - No Communications with the

System Management Controller (Local

Mode)

One, or both, Compressors are Loaded

One, or both, compressors are switched

to ‘Service Maintenance’ mode.

One, or both, compressors have

exceeded the set Pressure Limit

1: Compressor Alarm

2: Auxiliary Alarm input active

3: Delivery Pressure Sensor fault

(display “- - - -“)

1: Compressor Not Available

2: Auxiliary Trip input active

Metacentre DX Box

Page 5

Compressor Status:

Compressor Running

Compressor On Load

Flashing - Not Responding, Compressor

Not Running When required to load.

Service Maintenance function active

Pressure Limit Exceeded

1: Compressor Alarm

2: Auxiliary Alarm input active

3: Pressure Sensor fault (display “- - - -

“)

1: Compressor Not Available

2: Auxiliary Trip input active

2.2 Indicators

Run Indicator (Green LED)

OFF DX Box Fault condition

ON Active

Fault Indicator (Red LED)

OFF – No fault

Slow Flash:

1: Compressor Alarm

2: Pressure Sensor fault (display “- - - -

“)

Fast Flash:

1: Compressor Not Available

2.3 Compressor Identification

Each compressor connected to the DX Box

will have an assigned compressor

identification number #1 or #2.

12 #1

DX Box

3#2

The DX Box ‘group’ will also have a single

unique system address identification and will

be represented on the system management

unit as a single entity using the ‘address’

identification number. The identification

number will be unique for the system.

For example, “C.03.1” indicates that the

compressor is connected to the DX Box as

compressor #1 and the DX Box is represented

on the system management unit as

compressor number “03”.

2.4 Operation

The DX Box is always active (started) and

cannot be stopped. The DX Box will

automatically switch between ‘Remote’, when

under system management unit control, or

‘Local’ mode.

2.5 Power Failure Auto-Restart

The DX Box will always automatically start

when power is re-applied after a power supply

disruption or failure.

2.6 Failure Modes

If communications with the system

management unit is disrupted, the DX Box will

switch to ‘Local’ mode and pressure regulation

control is maintained using the set pressure

set points.

The DX Box will automatically switch back to

‘Remote’ mode when communications with the

system management unit are re-established,

or the DX Box fault is reset.

If a fault occurs with the DX Box, or power to

the DX Box is disrupted, pressure regulation

control is automatically transferred back to

each compressor. The compressor(s) will

continue to operate using the pressure

settings programmed or set in the individual

compressor controller(s).

The design of some air compressor control

systems may inhibit automatic transfer of

pressure regulation control to local operation

mode. In this instance the compressor will not

continue production of compressed air –

consult the air compressor manual or your air

compressor supplier / specialist for details

before installing the DX Box unit.

2.7 Compressor Fault

If a compressor fault condition is detected the

‘status’ display will show an ‘Alarm’ condition.

The ‘status’ display associated with the

compressor will also indicate a fault condition

(see Status Symbols). The DX Box ‘Fault’

indicator (10) will flash to attract attention.

Compressor fault conditions will also be

communicated to the system management unit

controller.

User Manual

Page 6

2.10 DX Box Fault

The DX Box has two ‘shutdown’ fault

conditions:

E:0821

Short Circuit Condition Detected,

check all DX Box controller inputs and outputs.

E:0135

BAR

System Pressure Sensor Fault.

If one of these fault conditions occur the DX

Box will switch ‘off. The ‘Run Indicator’ (9) will

also switch off and the ‘Fault Indicator’ (10) will

fast flash.

2.11 Pressure Sensor Fault (Option)

E:0115

BAR

Delivery #1 Pressure Sensor Fault.

E:0125

BAR

Delivery #2 Pressure Sensor Fault.

Metacentre DX Box

Page 7

3.0 Parts List

DX Box

Item Part No. Description

- Y07ENER10.00 Unit, DX Box

- Y07CM14.00 Manual, User CD

1Y07CM20.00 Controller, S1 DX

2Y05CM31.00 Unit, XPM-TAC24

3KPY0617.00C PCB, Terminal EX

4Y07CM49.00 Gland, Set - Pg13.5

Required For Each Compressor:

Item Part No. Description

5Y04CM59.00 Unit, i-PCB

Optional Accessories:

Item Part No. Description

6Y04CM29.00 Sensor, Pressure

4-20mA, 0-16.0bar

7Y01ENER35.00 Module, Relay 24Vac

4.0 Technical Data

Dimensions 291mm x 241mm x 152mm

Weight 6.5kg (14lb)

Mounting wall, 4 x screw fixings

Enclosure IP54, NEMA 12

Supply 230Vac +/- 10%

115Vac +/- 10%

Power 50VA

Temperature 0°C to 46°C (32°F to 115°F)

Humidity 95% RH non-condensing

XPM-TAC24

i-PCB

4

AirMaster S1

5

2

1

3

6

A2 A1

22 12

24 14

21 11

7

User Manual

Page 8

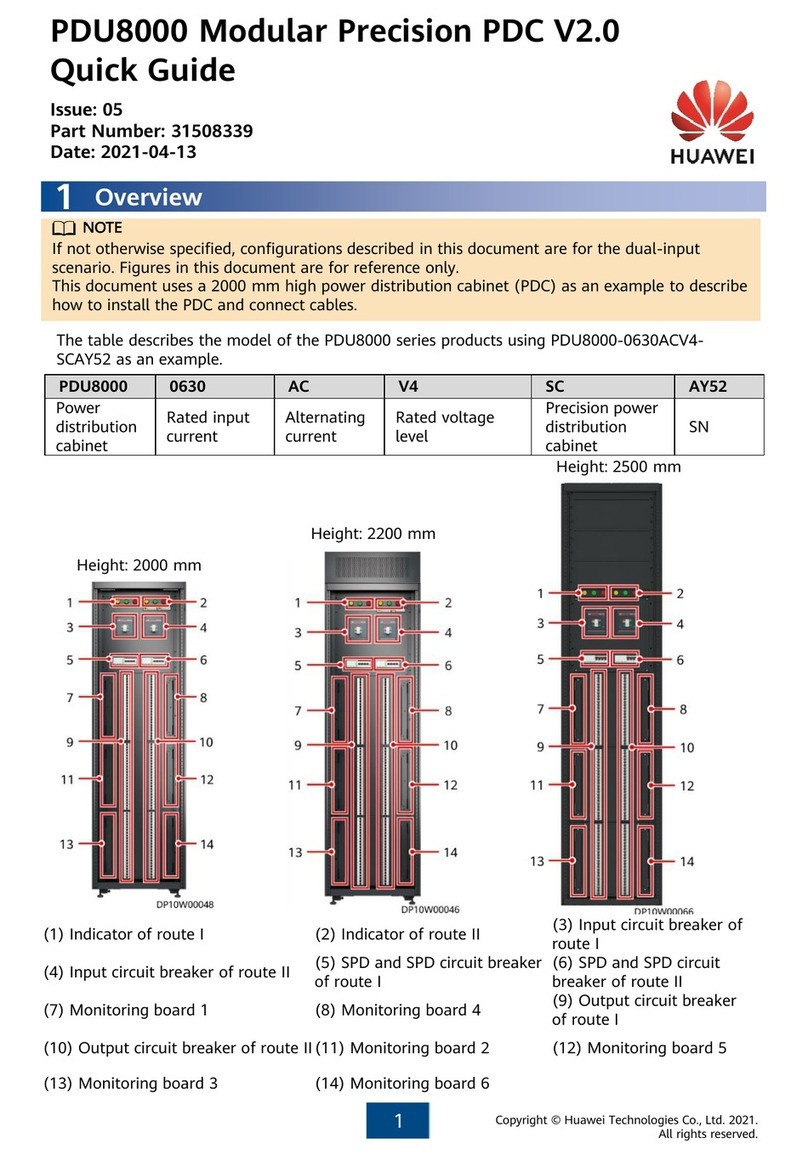

5.0 Wiring Diagram

DXBox

246

X05X06

X03

X01

5

3

1

R4

+C

+C

Di7

4-20mA

Pressure #2

R1

R2

R3

R4C+

1

2

3

4

5

6

7

8

X05

X03

X04

C001

X02

X01

Ai3

Ai2

+VDC

Ai1

+VDC

XPM-TAC24

S1-10-R4-333

Controller

24Vac

++

1

2

1

2

2

1

X03

X01

E

N

L

E

E

N

L

230Vac 10%

115Vac 10%

24Vac

0Vac

AuxFault#1

Ai2

Ai1

Di6

-

-

C002

C003

C004

C005

C006

C012

C013

C014

C015

C016

C017

C018

C019

C011

C020

C021

C022

C023

C024

C025

C032

C030

C031

4-20mA

Pressure #1

4-20mA

SystemPress.

Ai3

-

+VDC

notused

Aux Fault #2

Aux Output

V181012

X02

11

9

7

V2

C028

C029

C026

C027

X04

notused

C015

C025

C024

10k

10k

C016

C023

C013

C014

C022

C027

C029

C031

C021

X07

C019

C018

C017

C011

C008

C007

C001

C002

C003

C004

C005

C006

C010

C009 Multi485

L2

L1

Multi485

L2

L1

C011

1428

222426

1327

212325

161820

1517193032

2931

SEQ

i-PCB1

R1

LOAD

GND

Ready/Run

Alarm/Serv.

+20VDC

R2

Di2

Di3

-

6

5

4

3

2

1

SEQ

i-PCB2

R1

LOAD

GND

Ready/Run

Alarm/Serv.

+20VDC

R3

Di4

Di5

-

6

5

4

3

2

1

Ao

X06

RS485

A-GND

C007

C008

L1

C009

C010

L2

X07

Metacentre DX Box

Page 9

XPM-TAC24

230V

115V

24Vac/1

isolated

24Vac/2

earthed

EE

L

N

N L E

BLUE

BROWN

RED

GREEN VIOLET

WHITE

ORANGE

BLACK

FH1

FH2FH3

FH4

FH5

1

VOLTAGE SELECT

2 3 4 X04

212

X03 X02 X01

T3.15A T1.6A T1.6A T1.0A

T1.0A

1 2 3 4

115V +-10%

230V +-10%

1 2 3 4

IEC

5x20mm

Other manuals for metacentre DX Box

1

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

CAME

CAME ZL170N Original-spare parts

Panasonic

Panasonic BMED500 - CAMERA CONTROL UNIT operating instructions

Hitachi

Hitachi RIO3-Y Series user manual

Schlumberger

Schlumberger CAMERON AOP D2 Series Installation, operation and maintenance manual

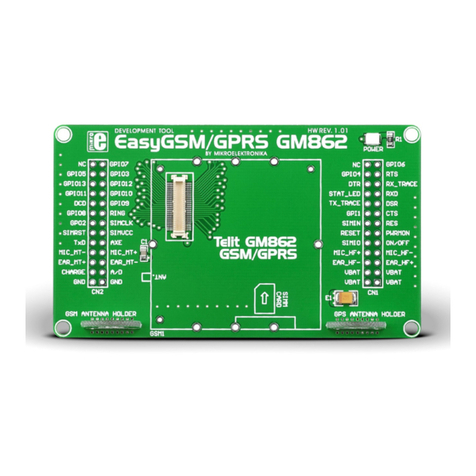

Telit Wireless Solutions

Telit Wireless Solutions GM862PYT Series Product description

Cavli Wireless

Cavli Wireless C16QS Hardware manual