Energy Recovery 8500 Series Instruction manual

Energy Recovery, Inc. ERI Document Number 80020-01-2

ENERGY RECOVERY

,

INC.

441144

INSTALLATION, OPERATION, & MAINTENANCE

MANUAL

Series 8500-2400 PX Booster Pumps

Energy Recovery, Inc.

1908 Doolittle Drive, San Leandro, CA 94577 USA

Tel: +1 510 483 7370 / Fax: +1 510 483 7371

© Energy Recovery, Inc., 2001-2005

Energy Recovery, Inc. ERI Document Number 80020-01-2

Installation, Operation, & Maintenance Manual

Series 8500-2400 PX Booster Pumps

TABLE OF CONTENTS

1.0 INTRODUCTION 3

2.0 MATERIALS OF CONSTRUCTION AND QUALITY 3

3.0 SAFETY, ARRIVAL AND INSPECTION 3

4.0 PRINCIPLE OF OPERATION 4

5.0 INSTALLATION 6

6.0 OPERATION 7

6.1 SPECIFICATIONS 7

6.1.1 SYSTEM PERFORMANCE SPECIFICATIONS 8

6.1.2 PRECAUTIONS AND CONDITIONS 8

6.1.4 PHYSICAL CHARACTERISTICS 8

6.1.5 UTILITY REQUIREMENTS 9

6.1.6 SPARE PARTS 9

6.2 STARTUP PROCEDURE 9

6.3 MAINTENANCE AND STARTUP LOG 10

7.0 MAINTENANCE INSTRUCTIONS 10

7.1 GENERAL 10

7.2 LUBRICATE BOOSTER PUMP MOTOR 11

7.3 MECHANICAL SEAL MAINTENANCE 11

7.3.1 REMOVE THE OLD MECHANICAL SEAL 12

7.3.2 INSTALL THE NEW MECHANICAL SEAL 15

7.4 DISASSEMBLY OF WET END 21

7.5 ASSEMBLY OF WET END 22

7.6 MOTOR BEARING SERVICE 28

8.0 TROUBLE SHOOTING 32

9.0 ERI FIELD COMMISSIONING 37

10.0 WARRANTY AND LIABILITY 38

11.0 REVISION LOG 39

12.0 DRAWINGS AND DATA 39

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. ERI Document Number 80020-01-2

1.0 INTRODUCTION

This manual contains instructions for the installation, operation, and maintenance of the

Energy Recovery, Inc.(ERI) PX Booster Pumps for energy recovery in Sea Water Reverse

Osmosis (SWRO) systems in conjunction with ERI’s Pressure Exchanger(PX) technology.

The PX Booster Pump boosts the pressure in the high pressure portion of an SWRO system to

make up the small pressure losses that occur through the SWRO membranes, the PX units and

the associated piping. The PX Booster Pump is designed to withstand a high inlet pressure in a

corrosive seawater environment.

Please read this manual thoroughly before installation or operation and keep it for future

reference. The instructions in this manual are intended for personnel with general training and

experience in the operation and maintenance of fluid handling systems. PX and PX Booster

Pump maintenance personnel are strongly encouraged to attend Factory Training courses

offered by Energy Recovery, Inc. Energy Recovery, Inc. technical service personnel are

available for assistance by telephone during the regular business hours of 08:00 to 17:00

Pacific Standard Time. Field service and system commissioning assistance are available.

Further information about PX Booster Pumps or other Energy Recovery, Inc. products or

service can be found by contacting Energy Recovery, Inc. at:

Energy Recovery, Inc.

1908 Doolittle Drive, San Leandro, CA 94577 USA

Tel: +1 510 483 7370 / Fax: +1 510 483 7371

2.0 MATERIALS OF CONSTRUCTION AND QUALITY

ERI’s commitment to quality starts with the fabrication and procurement of top quality

materials made to extremely tight clearances. Every part is checked to ensure it meets all

dimensional specifications during and after each stage of the manufacturing process. All wetted

metal components in PX Booster Pumps are AL6XNor equivalent stainless steel. Impellers

and diffusers are fiber reinforced polymer. The mechanical seal has carbide contact/sealing

faces. Seals are ethylene propylene (EPDM).

Assembled PX Booster Pump units are subjected to extensive testing in our wet test facility.

Each PX Booster Pump is tested for efficiency, operating pressures, and flow rates. Each unit

is tracked with a serial number and the testing records are maintained.

3.0 SAFETY, ARRIVAL AND INSPECTION

The PX Booster Pump has been designed to provide safe and reliable service. However, it is

both a pressure vessel and a piece of industrial rotating machinery. Therefore, operations and

Energy Recovery, Inc., ERI, PX, Pressure Exchanger, and PX Pressure Exchanger

are trademarks of Energy Recovery, Inc.

Trademark of Allegheny Ludlum Corp.

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 4 ERI Document Number 80020-01-2

maintenance personnel must exercise good judgment and proper safety practices to avoid

damage to the equipment, to avoid damage to surrounding areas, and to prevent injury. It must

be understood that the information contained in this manual does not relieve operation and

maintenance personnel of the responsibility of exercising normal good judgment in the

operation and care of this product and its components. The safety officer at the location where

this equipment is installed must establish a safety program based on a thorough analysis of

local industrial hazards. Proper installation and care of shutdown devices and over-pressure

and over-flow protection equipment must be an essential part of any such program. In general,

all personnel must be guided by all the basic rules of safety associated with high-pressure

equipment and processes. Operation under conditions outside of those stated in Table 6-1 can

result in damage to the PX Booster Pump and will void the warranty.

The flags shown and defined below are used throughout this manual. They should be given

special attention when they appear in the text.

Each PX Booster Pump should be inspected immediately upon arrival and any irregularities

due to shipment should be reported to the carrier. PX Booster Pump units are securely packed

with plugs in the fittings to protect the unit from damage during transportation. Care must be

taken during unpacking and handling to avoid damage to the PX Booster Pump.

4.0 PRINCIPLE OF OPERATION

The PX Booster Pump is designed to be used in SWRO systems in conjunction with ERI’s PX

technology. The PX Booster Pump is a horizontal multistage centrifugal pump driven by a

Totally Enclosed Fan Cooled (TEFC) motor. The PX Booster Pump boosts the pressure in the

When handling and installing a PX Booster Pump, care

should be taken to avoid dropping the unit or putting undue

strain on the port fittings to avoid internal damage. Do not lift

or support the PX Booster Pump by the port fittings.

CAUTION

Energy Recovery Inc. will not be liable for any project delay, damage

or injury caused by the failure to comply with the procedures in this

manual. This product must never be operated at flow rates,

pressures or temperatures outside of those stated in Table 6-1, or

used with liquids not approved by Energy Recovery, Inc.

These flags denote items that, if not strictly observed, can

result in serious injury to personnel.

These flags denote items that, if not strictly observed, can

result in damage or destruction to equipment.

These flags denote highlighted items.

CAUTION

NOTE

NOTE

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 5 ERI Document Number 80020-01-2

high pressure portion of an SWRO system to make up the small pressure losses that occur

through the SWRO membrane, the PX units and the associated piping. The PX Booster Pump

is designed to withstand a high inlet pressure in a corrosive seawater environment.

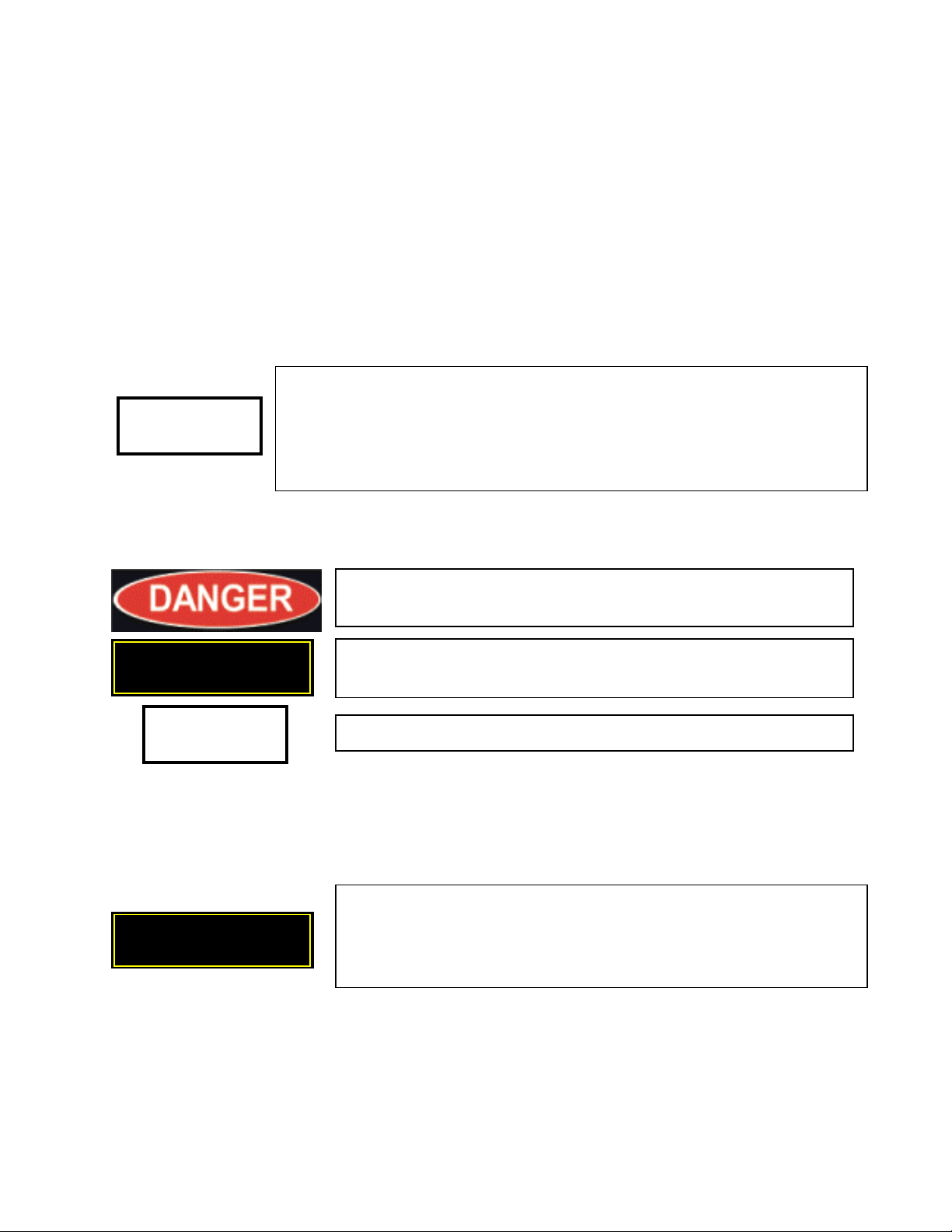

Figure 4-1 shows the flow path of a PX Booster Pump installed in a typical SWRO system

equipped with PX technology. The reject brine from the SWRO membranes (G) passes through

the PX unit(s) where its pressure is transferred directly to a portion of the incoming raw

seawater at up to 95% efficiency. This pressurized seawater stream (D), which is nearly equal

in volume and pressure to the reject stream, passes through the PX Booster Pump (not the

main high-pressure pump) to add the small amount of pressure lost to friction in the PX unit(s),

the membranes, and the associated piping. The PX Booster Pump is specially designed to

handle high operating pressures while consuming minimal energy to provide a small boost to

the high-pressure flow. The PX Booster Pump also serves to drive the flow of the high-

pressure stream through the PX unit(s) (G and D). Fully pressurized seawater then merges

with the main seawater to the SWRO system after the main high-pressure pump. Example flow

rates and pressures are listed in Table 4.1.

Figure 4-2. Typical SWRO System with PX Unit(s) and PX Booster Pump

Table 4-1 - Example Flow Rates and Pressures

STREAM DESCRIPTION FLOW RATE PRESSURE PSI / BAR

A Seawater supply 330 29 / 2.0

B PX LP Inlet/ Seawater 195 29 / 2.0

C Main HP Pump outlet 135 1000 / 69

D PX HP Outlet/ Seawater 195 957 / 66

E Booster Pump Outlet/ Seawater 195 1000 / 69

F SWRO Feed Stream 330 1000 / 69

G PX HP Inlet/ Reject 200 971 / 67

H PX LP Outlet/ Reject 200 15 / 1.0

I SWRO Product Water 130 5 / 0.3

B

PX Booster Pum

p

Main High

Pressure Pump

Seawater Supply

Pum

p

Permeate

Pressure

Exchanger(s)

F

H

G

I

E

A

C

D

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 6 ERI Document Number 80020-01-2

In an SWRO system equipped with PX technology, the main pump is sized to equal the SWRO

permeate flow plus a small amount of bearing lubrication flow, not the full SWRO feed flow.

Therefore, PX technology significantly reduces flow through the main pump. This point is

significant because a reduction in the size of the main pump results in lower operating costs. In

a typical SWRO system equipped with PX technology, the main pump will provide 41% of the

energy, the booster will provide 2% and the PX unit(s) will provide the remaining 57%. Since

the PX energy recovery device uses no external power, the total power savings is 57%

compared to a system with no energy recovery.

It is important to note that the PX unit(s) and associated boost pump are sized for 100% of the

reject flow. The role and size of the main high-pressure pump is reduced to that of a “make-up

pump” to compensate for the water that is exiting the SWRO system as permeate.

5.0 INSTALLATION

The PX Booster Pump should be installed in a dry, sheltered location. Some type of drainage

should be provided beneath the pump to allow standing water to drain when performing

maintenance or repair. See installation drawings in Section 13.0 for pump dimensions,

interface locations and minimum maintenance envelope requirements.

1. Place the PX Booster Pump in an appropriate location and mount the motor securely;

making sure that the base of the unit is permanently supported.

2. Connect the inlet and outlet of the pump to the appropriate points. Proper piping, piping

support, and motor mounts must be implemented to minimize external stresses on all piping

fittings. Flexible couplings should be used for joining fittings and piping. See Section 13.0

for appropriate connection dimensions and specifications. PX Booster Pumps are shipped

with the inlet oriented vertically upward. The inlet housing can be rotated either left or right

to a horizontal orientation. Remove the four (4) bolts that connect the inlet housing to the

yellow bell housing, rotate the pump head and replace the bolts. Torque bolts to 12 ft-lbs

(16 N-m) as shown in Figure 7-4 below.

3. Connect the pump motor to a suitable electrical supply. See the motor plate or the inside

cover of the motor electrical junction box for high and low voltage wiring diagrams. If no

wiring diagram is evident on the motor, refer to Table 5-1. Connect a suitable ground to the

pump motor.

The PX Booster Pump is constructed from AL6XN or

equivalent stainless steel. Inlet and discharge

interconnecting lines should be constructed of suitable

materials to avoid galvanic corrosion.

ERI encourages plant designers and engineers to submit P&IDs to ERI

for engineering review, especially for large or complex SWRO systems.

CAUTION

NOTE

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 7 ERI Document Number 80020-01-2

4. The SWRO-PX system must include pressure gauges upstream and downstream of the PX

Booster Pump and a high-pressure flow meter in the high-pressure circuit.

Table 5-1 – Motor Wiring

MOTOR

MANUFACTURER L1 L2 L3 JOIN

High Voltage 1 2 3 4+7, 5+8, 6+9

General Electric Low Voltage 1+7 2+8 3+9 4+5+6

High Voltage 1+12 2+10 3+11 4+7, 5+8, 6+9

Leeson Low Voltage 1+6+7+12 2+4+8+10 3+5+9+11 —

6.0 OPERATION

6.1 Specifications

The successful use of the PX Booster Pump depends on observing some basic operating

conditions and precautions. The PX Booster Pump must be installed, operated and maintained

in accordance with this manual and good industrial practice to assure safe operation and a long

service life. Failure to observe these conditions and precautions can result in violation of the

warranty, damage to the equipment, and/or harm to personnel.

Disconnect electrical supply before installing and/or

servicing the pump. Failure to do so can cause serious

injury or death to personnel.

Strictly observe all applicable electrical codes and

regulations governing the installation and wiring of electrical

equipment.

The power supply should always be of a greater service rating than

the requirements of the pump. Never connect the pump to a line

that services another electrical device. The pump should have

dedicated power circuit with proper fuse or breaker protection.

The PX Booster Pump is designed to be used in conjunction with a

variable frequency drive and high-pressure flow meter.

Check for proper motor rotation upon start up.

CAUTION

NOTE

NOTE

NOTE

Piping must be independently supported. Do not allow

piping to place a load on the PX Booster Pump.

CAUTION

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 8 ERI Document Number 80020-01-2

6.1.1 System Performance Specifications

Table 6-1 provides a summary of system performance specifications. See Section 12.0 for flow

and pressure curves.

Table 6-1 - System Performance Specifications

Parameter Specification

Raw Water Tem

p

erature Ran

g

e: 33-113°F

(

1-43°C

)

Maximum Outlet Pressure: 1200 psi / 83 bar

Minimum Inlet Pressure: 15 psi / 1.0 bar

Design Flow Range: *

HP-8503 30-110 gpm (7 – 25 m3/hr)

HP-8504 30-110 gpm (7 – 25 m3/hr)

HP-1253 40-190 gpm (9 – 43 m3/hr)

HP-1254 40-190 gpm (9 – 43 m3/hr)

HP-2402 80-300 gpm (18 – 68 m3/hr)

HP-2403 80-300 gpm (18 – 68 m3/hr)

* 60 Hz / 3450 rpm

6.1.2 Precautions and Conditions

The following precautions / conditions apply:

Piping connections to the pump must be designed so as not to induce stress on the pump or

motor.

Ensure that all flexible connections are secure and tight before operating pump.

Under no circumstances shall the inlet pressure or outlet pressure exceed 1,200 psig (83

bar).

Ensure sufficient feed water supply. The PX Booster Pump should be thoroughly purged of

air before startup. Operating the PX Booster Pump with feed pressures less than 15 psi may

result in damage to PX Booster Pumps internal components. Never run pump dry.

6.1.4 Physical Characteristics

See Section 13.0 for weights and dimensions. Connections dimensions and requirements are

provided in Table 6-2.

Do not allow the high-pressure reject and/or seawater to

exceed 1,200 psi (83 bar). If necessary, install a pressure

switch and/or safety valve in the high-pressure line(s) to

ensure the s

y

stem does not exceed 1,200 psi

(

83 bar

)

.

CAUTION Allowable operating ranges for individual PX Booster

Pumps are listed in Table 6-1. PX Booster Pumps are not

designed to operate outside of these ranges.

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 9 ERI Document Number 80020-01-2

Table 6-2 - Connection Dimensions and Requirements

Utility Connection Maximum Pressure (psi / bar)

Inlet 3” Flexible Coupling 1,200 / 83

Discharge 3” Flexible Coupling 1,200 / 83

6.1.5 Utility Requirements

Power requirements are provided on the nameplate on the top of all PX Booster Pump motors.

Horsepower requirements are provided in Table 6-3.

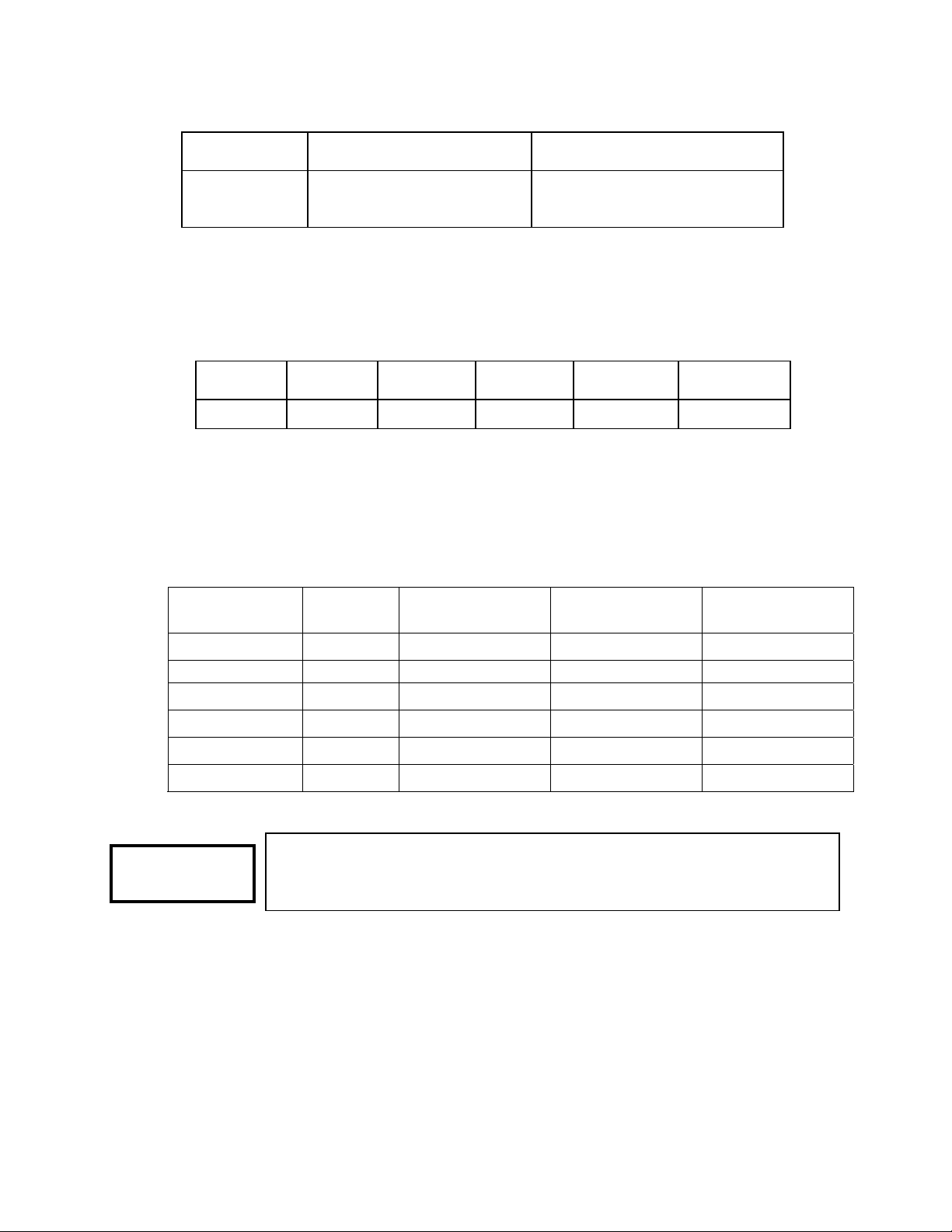

Table 6-3 – Motor Horsepower Requirements

HP-8503 HP-8504 HP-1253 HP-1254 HP-2402 HP-2403

5 7.5 10 15 15 20

6.1.6 Spare Parts

A listing of recommended ERI spare parts is provided in Table 6-4. O-ring kits are

recommended for disassembly and inspection. Rebuilt kits provide impellers, stage assemblies

and O-rings.

Table 6-4 - Recommended Spare Parts

DESCRIPTION QTY

O-RING KIT

PART NUMBER

REBUILD KIT

PART NUMBER

MECHANICAL

SEAL KIT

HP-8503 1 20005-02 20005-01* 20004-01

HP-8504 1 20006-02 20006-01* 20004-01

HP-1253 1 20007-02 20007-01* 20004-01

HP-1254 1 20008-02 20008-01* 20004-01

HP-2402 1 20009-02 20009-01* 20004-01

HP-2403 1 20010-02 20010-01* 20004-01

* Includes Impellers, Stage Assemblies and O-rings

6.2 Startup Procedure

Refer to the PX Operations and Maintenance manual for detailed startup and shutdown

instructions for the PX device.

1. Verify system is de-energized and un-pressurized.

2. Check tightness of all lines and fittings.

3. Supply feed water to the SWRO system and the PX unit’s low-pressure inlet.

Only genuine ERI spare parts should be used in PX Booster

Pumps. Use of parts other than those specified by ERI will void

the warranty.

NOTE

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 10 ERI Document Number 80020-01-2

4. Verify that the inlet pressure to the PX Booster Pump is at least 15 psi as seen at the inlet of

the main high-pressure pump. Verify that all air has been purged from the system. The

pump cannot be run dry for even a few seconds. Damage will occur in seconds if the pump

is started dry.

5. Jog the PX Booster Pump and verify that its rotation is correct.

6. Start the PX Booster Pump and verify that the pump is operating on the flow and pressure

curves provided in Section 12.0.

6.3 Maintenance and Startup Log

A sample operating-log has been provided in Section 8.0 of this manual and must be submitted

by fax or e-mail to Energy Recovery, Inc. in San Leandro, California upon completion of the

startup and flow balancing routines. Submittal of this form with the initial startup data within

24 hours of startup is a condition of obtaining PX Booster Pump warranty coverage. The data

must be recorded daily and maintained during the life of the warranty in order to support any

claims. Include pump serial number with all submittals.

Submittal of the maintenance and startup log to ERI within 24 hours of startup is a condition of

obtaining PX Booster Pump warranty coverage. The data must be recorded daily and

maintained during the life of the warranty in order to support any claims.

7.0 MAINTENANCE INSTRUCTIONS

7.1 General

The table below details the specific recommended pump maintenance requirements for the

ERI’s PX Booster Pump product line:

Never run the PX Booster Pump dry or with low feed flow.

Operating with feed pressures less than 15 psi (1 bar) or below

recommended the flow range can cause damage to the pump’s

internal components.

The PX Booster Pump should rotate in the clockwise direction when

facing the rear of the motor.

A sample operating-log has been provided at the end of Section 8.0

and must be submitted by fax or e-mail to Energy Recovery, Inc.

upon completion of the startup and balancing routines. Submittal of

this form with the initial startup data within 24 hours of startup is a

condition of obtaining warranty coverage. The data must be

recorded daily and maintained during the life of the warranty in

order to support any claims. Include serial number with submittal.

CAUTION

NOTE

NOTE

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 11 ERI Document Number 80020-01-2

Table 7-1 - Periodic Maintenance Task Frequency

Weekly

3 Months

As Required

Labor Hours

(approximate)

Inspect connections 0.1

Inspect mechanical seal 0.1

Lubricate pump motor 0.2

Change mechanical seal 2.0

7.2 Lubricate PX Booster Pump Motor

Motor bearings should be checked daily for temperature and noise. Motor bearings must be

lubricated a minimum of every three months. Use a grease gun and high-quality ball bearing

grease such as Shell Dolium R or Chevron SR1 2. Refer to the motor manufacturer’s websites

for additional guidance and information.

7.3 Mechanical Seal Maintenance

A mechanical seal is used to seal the rotating shaft. This seal will require replacement

approximately every 12-18 months. An indication that maintenance is required will be a leak or

drip from the rear of the pump into the bell housing. Mechanical seal kits are available from

ERI. The kit includes the components listed in Table 7-2 and illustrated in Figure 7-1.

Table 7-2 - Mechanical Seal Kit - ERI Part Number 20004-01

PART NUMBER DESCRIPTION QUANTITY

10055-01 SHIM 2

10066-01 RETAINING RING, 3 /4” 1

10117-01 DOWEL PIN 2

10122-01 SPACER 1

10123-01 MECHANICAL SEAL 1

10124-01 FENDER WASHER 2

10128-01 ALLEN WRENCH, 3/32” 1

10134-01 THREAD LOCKER 1

10160-01 O-RING, -225 1

80027-01 MECHANICAL SEAL O&M MANUAL 1

ERI offers a tool kit (ERI Part Number 20003-01) for PX Booster Pump maintenance

operations. Alternately, a list of tools and materials recommended for maintenance of the

mechanical seal are provided in Table 7-3.

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 12 ERI Document Number 80020-01-2

Table 7-3 - Recommended Tools and Materials

Pump Model Tool Application

all 9/16-inch Wrench

Bolts between Inlet Housing

and Bell Housing

all 3/4-inch Wrench

Bolts between Bell Housing

and Motor

8500-pumps 3/16-inch Allen/Hex Wrench Coupling

1250- and 2400-pumps 1/4-inch Allen/Hex Wrench Coupling

all 3/32-inch Allen/Hex Wrench Seal Set Screws

all Anti-Seize Compound All Threads

all Water Soluble Lubricant O-Rings

The following procedure provides instructions for removing an old seal and inserting a new

one.

7.3.1 Remove the Old Mechanical Seal

1. Verify system is de-energized and un-pressurized.

2. Disconnect the flexible coupling connections from the inlet and outlet of the PX Booster

Pump and allow water to drain from system.

3. Unbolt the motor base from the floor.

4. Stand the PX Booster Pump on the motor in a vertical orientation as shown in Figure 7-2.

5. Partially loosen (1-3 turns) the eight (8) shaft coupling screws inside the bell housing.

There is an access slot for these screws at the side of the bell housing. See Figure 7-3.

6. Remove the four bolts that hold the inlet housing to the bell housing with a 9/16” wrench

as shown in Figure 7-4.

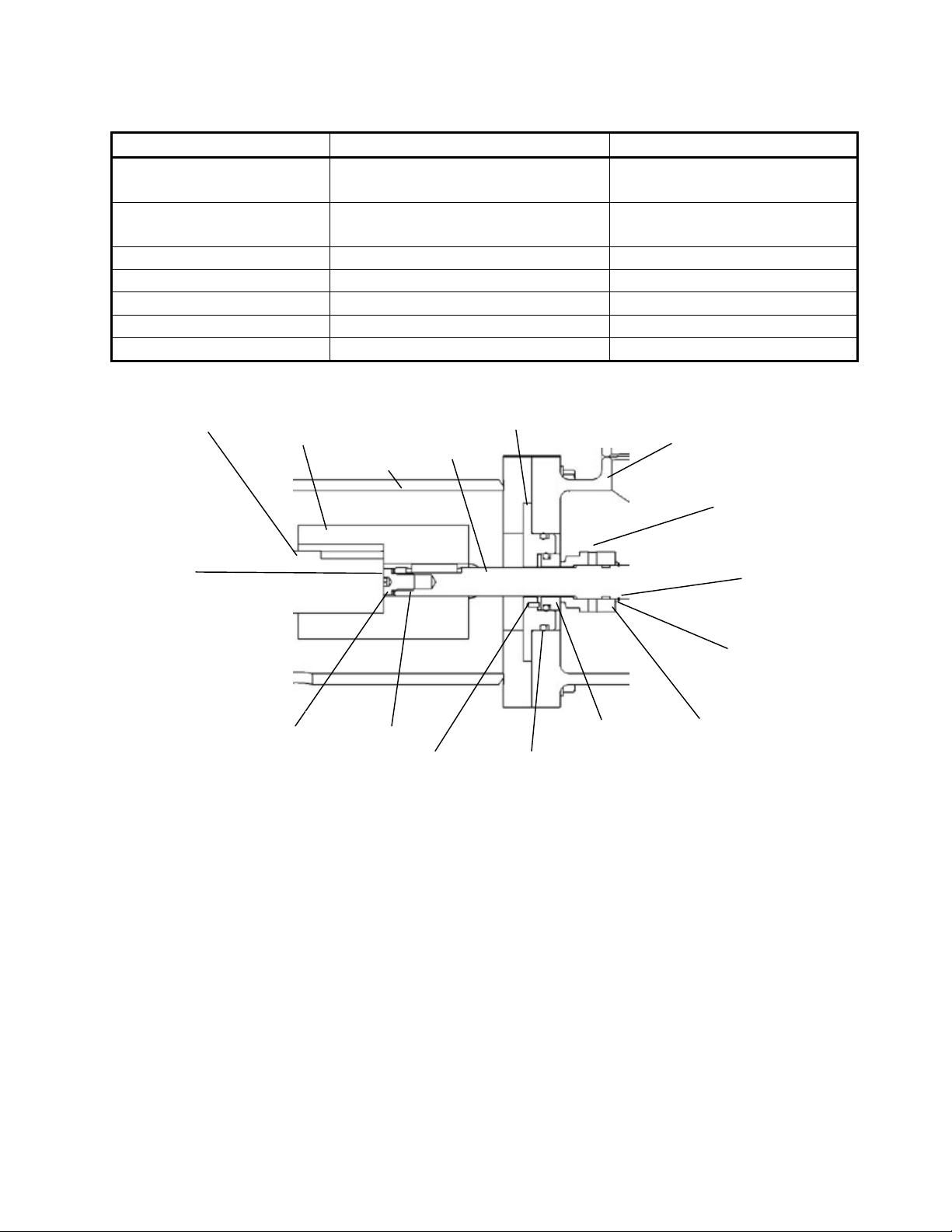

Figure 7-1 - Section View of Shaft and Seal Components

Motor

Shaft Coupling Bell

Housing Pump

Shaft Seal

Plate

Jack

Screw

Stationary

Seal Primary

Seal

Window to

check

Compression

shafts in

contact

Inlet

Housing

Pin O-Ring

Spacer

10122-01

Retaining

Rin

g

Shim

Spacer(s)

10055-01

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 13 ERI Document Number 80020-01-2

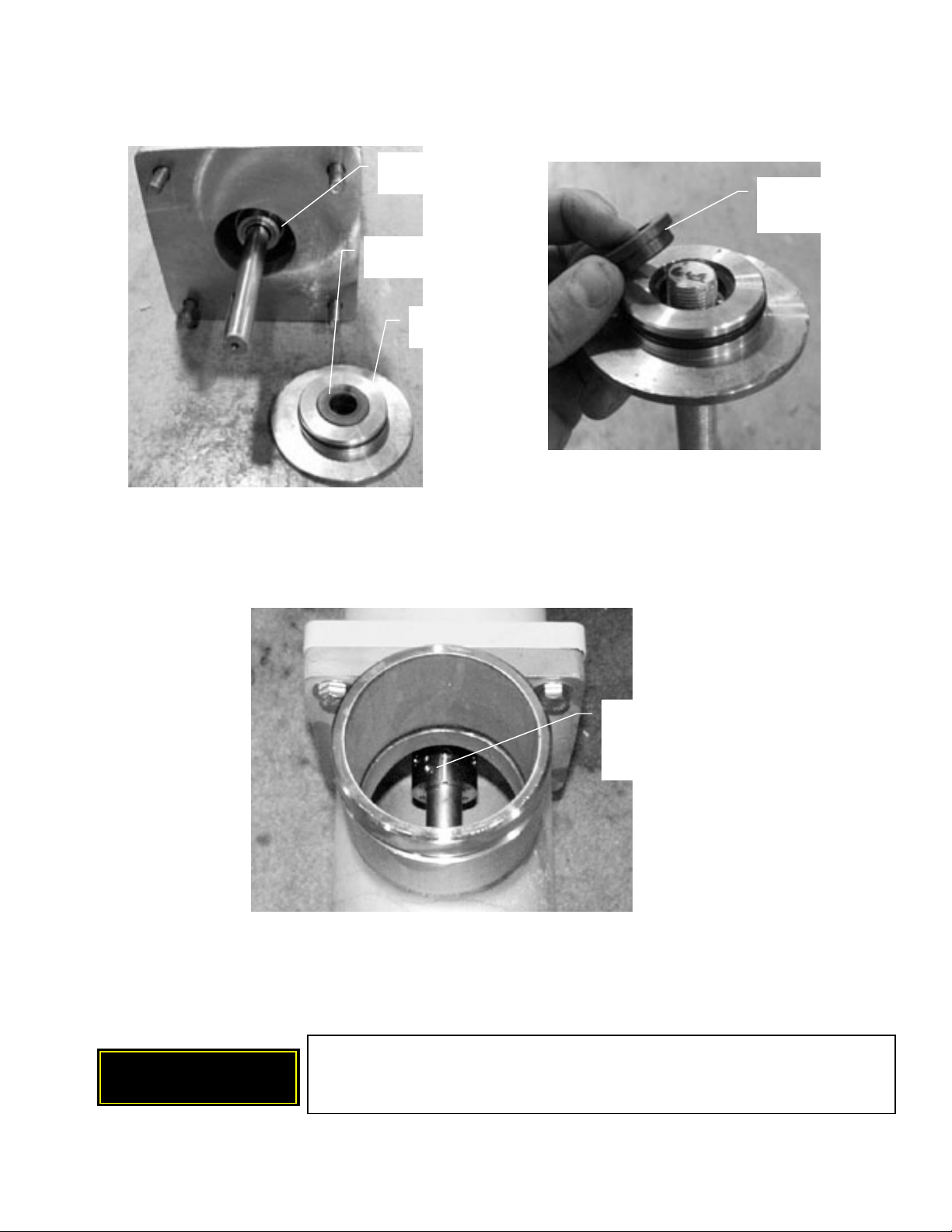

7. Pull the pump, shaft and seal out of the bell housing and away from the motor.

8. Remove the seal plate from the inlet housing as shown in Figure 7-5. It may be necessary

to pull on the pump shaft to create an initial gap between the seal plate and the inlet.

9. The mechanical seal includes the primary seal and the stationary or mating plate as shown

in Figure 7-6. Extract the stationary plate from the seal plate by pushing through the seal

plate with a rod as shown in Figure 7-7. Remove stationary plate from the seal plate.

Bell Housing

Coupling Screws (4x2)

Figure 7-3 - Loosen Coupling Screws

Access Slot

Figure 7-2 - Pump

Oriented Vertically

Figure 7-5 - Remove Seal Plate from InletFigure 7-4 - Remove Pump from Bell Housing

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 14 ERI Document Number 80020-01-2

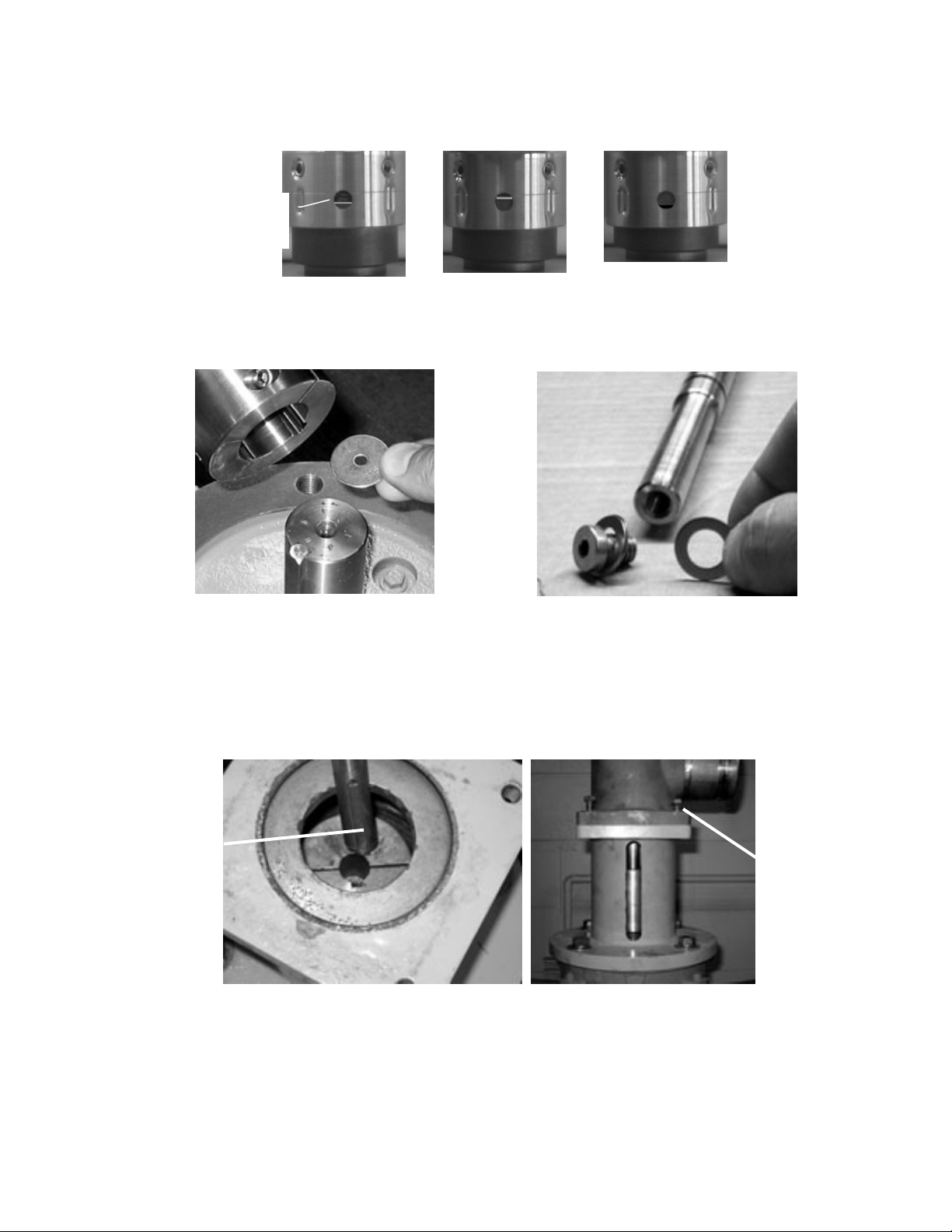

10. Loosen the four (4) set screws (3/32 inch hex) that hold the primary seal onto the shaft as

shown in Figure 7-8. Be careful not to strip the set screws. If a particular set screw is very

tight, it may be necessary to rotate the shaft and loosen a different set screw first.

11. Slide the primary seal off the shaft and out of the pump.

12. Remove the bell housing from the motor as shown in Figure 7-9.

13. Remove the coupling from the motor shaft. Disassemble the coupling as shown in Figure 7-

10. Clean the coupling and the shaft keys to remove any salt deposits or debris.

Mechanical seal set

screw, 4ea,

3/32 inch hex

Figure 7-8 - Loosen Set Screws

Primary Seal

Stationary Plate

Seal Plate

Figure 7-6 - Mechanical Seal Components

Stationary

Plate

Figure 7-7 - Extract Stationary

Plate from Seal Plate

Keep the shafts and coupling clean and free of dirt, rust and foreign

matter. Use plenty of anti-seize upon reassembly to ensure easy

disassembly the next time.

CAUTION

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 15 ERI Document Number 80020-01-2

7.3.2 Install the New Mechanical Seal

Before installing the new mechanical seal, completely remove the pump head, the bell housing

and the coupling as described above.

1. Reassemble the coupling using plenty of antiseize on the bolts and inside of the coupling.

Apply antiseize to the motor shaft.

2. Install the coupling onto the motor shaft as shown in Figure 7-11. Use plenty of antiseize.

3. Install the bell housing onto the motor as shown in Figure 7-11. Use anti-seize compound

on the bolt threads. Make sure that the drainage hole is oriented so that it will be on the

bottom of the bell housing when the PX Booster Pump is reinstalled. Torque the bolts to 40

foot-pounds (ft-lbs) / 58 N-m.

Figure 7-9 - Remove Bell Housing

Figure 7-10 - Disassemble Coupling and Clean Components

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 16 ERI Document Number 80020-01-2

Figure 7-11 – Install Coupling and Bell Housing onto Motor

4. Lubricate the o-ring in the new primary seal with a water-soluble lubricant. Install new

spacer ring and new primary seal onto the pump shaft. Slide these components onto the

shaft until they contact the retaining ring. See Figure 7-12 and 7-13 for the correct

sequence. Tighten the three set screws to 7 inch-pounds (in-lbs) / 0.79 Newton-meters (N-

m) torque using a 3/32-inch hex wrench.

5. Insert the anti-rotation pin into the seal plate as shown in Figure 7-14. Once inserted, the

pin should not protrude more than 1/16-inch (1.6 mm). Assure that there is no debris inside

the seal plate that would prevent the stationary seal from fully seating.

6. Lubricate the O-ring of the new stationary seal with a water-based lubricant such as

glycerin or soap. Insert the new stationary seal into the seal plate. Be sure to line up the

groove in the bottom of the stationary ring with the anti-rotation pin as shown in Figure 7-

15. The stationary seal must seat flat and level in the seal plate.

Shaft

Figure 7-12 - Primary Seal Sequence

Primary

Seal

Set Screw

Groove

Retaining

Ring

Spacer

Figure 7-13 - Primary Seal Assembly

Retaining

Ring

Primary

Seal

Set

Screw (4)

Spacer

Drainage Hole

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 17 ERI Document Number 80020-01-2

7. Slide the seal plate onto the shaft as shown in Figure 7-16.

Figure 7-16 – Assemble the Shaft, Seal and Seal Plate, Install into Inlet Housing

8. Align the shaft key with the slot in the coupling and install the pump onto the bell housing

as shown in Figure 7-17.

Figure 7-17 – Install Pump into Bell Housing

Figure 7-14 - Insert Anti-Rotation Pin Figure 7-15 - Stationary Seal, Line up Pin

with Groove

Groove

Pi

n

Antiseize

Key

Align shaft

key with slot

in coupling

Finger tight

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 18 ERI Document Number 80020-01-2

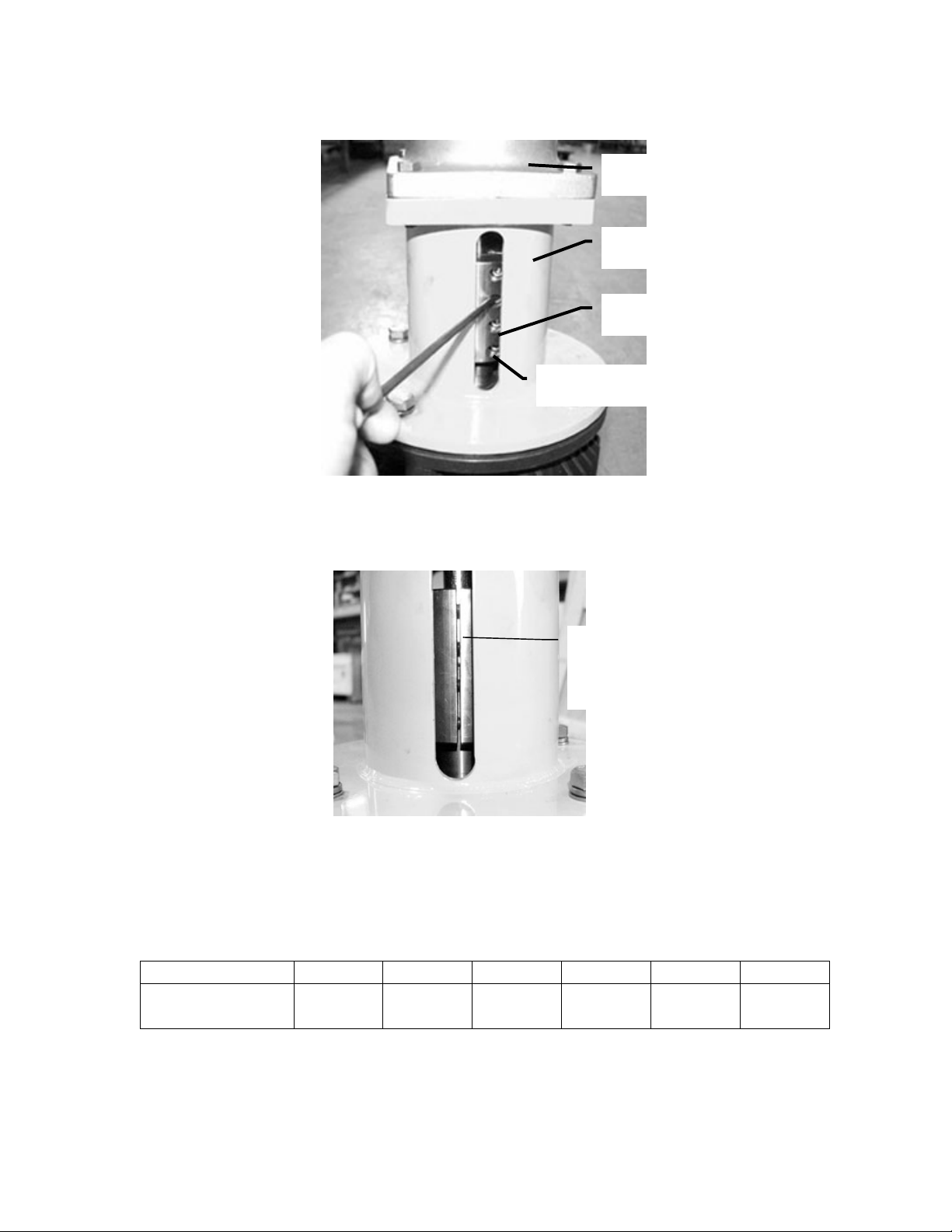

9. Assemble the seal compression tool components using a flexible coupling as shown in

Figure 7-18. Alternately, compress seal manually as shown in Figure 7-19.

Figure 7-18 – Assemble and Install Seal Compression Tool Components

10. Check the seal compression by applying downward force on the pump shaft while looking

into the inlet housing as shown in Figure 7-19.

Figure 7-19 – Install Pump onto Bell Housing

11. Inspect the mechanical seal inside the inlet housing. Check the compression of the

mechanical seal by looking into the circular window as shown in Figure 7-20. If seal is not

correctly compressed, remove the pump and install a fender washer into the shaft coupling

or a shim spacer onto the shaft as shown in Figure 7-21. Reassemble pump according to the

steps above.

Apply downward force

to top of shaft

Check seal compression

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 19 ERI Document Number 80020-01-2

12. Verify that the shaft keys are in place.

13. Line up the key of the pump shaft with the slot in the shaft coupling inside the bell housing

as shown in Figure 7-22 below.

14. Install the pump head onto the bell housing. Install the four (4) bolts between the pump to

finger tight.

Figure 7-22 – Install Pump into Bell Housing

15. With the pump and motor shafts in contact, tighten the eight (8) coupling screw as shown

in Figure 7-23. NOTE: THE PUMP AND MOTOR SHAFT MUST BE IN CONTACT.

Figure 7-21 – Add or Remove Fender Washer(s) or Shim Spacer(s) to Change Seal Compression

Figure 7-20 - Check Seal Compression

Circular Window to

Check Compression

Under

Compressed Correct

Compression Over

Compressed

Align shaft

key with slot

in coupling

Finger tight

SERIES 8500-2400 PX BOOSTER PUMPS

Energy Recovery, Inc. 20 ERI Document Number 80020-01-2

16. Tighten both halves of the coupling evenly making sure that the gap between the two halves

is equal as shown in Figure 7-24.

17. Torque the coupling screws according to the requirements listed in Table 7-4. Make sure

the gap between the two halves of the coupling is even on both sides as shown in Figure 7-

24. The coupling must be tightened evenly and fully to prevent an out of balance condition,

excessive vibration and premature motor bearing failure.

Table 7-4 - Shaft Coupling Torque Requirements

HP-8503 HP-8504 HP-1253 HP-1254 HP-2402 HP-2403

Coupling Screw

Torque

8 ft-lb /

11 N-m

8 ft-lb /

11 N-m

8 ft-lb /

11 N-m

8 ft-lb /

11 N-m

12 ft-lb /

16 N-m

12 ft-lb /

16 N-m

Figure 7-24 - Check Gap Between Coupling Halves

Gap – Both

sides equal

gap

Bell Housing

Coupling Screws (4x2)

Figure 7-23 – Tighten Coupling onto Shafts

Access Slot

Inlet Housing

This manual suits for next models

7

Table of contents

Popular Water Pump manuals by other brands

Rosenbauer

Rosenbauer R600 Operation manual

Fuelab

Fuelab 42401-c Operating and installation instructions

Barmesa Pumps

Barmesa Pumps BSP-CCE Series Installation, operation & maintenance manual

Fimco

Fimco High-Flo HFP-45060-113 owner's manual

CAT Pumps

CAT Pumps 2530 Service manual

AquaScape

AquaScape AquaJet 600 Instruction and maintenance

Crane

Crane BARNES SP33HTX Series installation manual

Dover

Dover PSG ALL-FLO MAX-PASS S Series Installation, Operation & Maintenance Instruction Manual

Walrus

Walrus TPK Series Replacing

T.I.P.

T.I.P. GPK 46/42 operating instructions

Lavor

Lavor EDP 5000 Translation of the original instructions

Oase

Oase AquaMax Eco Expert 21000 Commissioning