ENERGY SUPPORT CORPORATION ISS-101 User manual

Manual No.3011E R5

INSTRUCTION MANUAL

FOR

DUST DENSITOMETER

MODEL ISS-101

KV-610014-J

1

1. General description

1.1 Introduction

This Dust densitometer model ISS-101 is a relative dust concentration

meter, which utilizes the light scattering method and can be used to

continuously monitor the dust concentration for an extended period of

time. The analyzer is directly connected to the flume and has a simple

sampling piping system, ensuring easy maintenance.

By supplying the clean air to the optical system, lowering of the sensitivity due to

contamination of the optical system is prevented.

Therefore, the analyzer can measure from the high concentration to low concentration

without effects of load fluctuations and does not require any maintenance for an extended

period of time.

This instruction manual describes how to install, operate, and inspect the Dust

densitometer model ISS-101. Before starting installation of this analyzer, thoroughly read

this instruction manual to fully understand its contents and operate the analyzer in correct

manner.

2

1.2 Guarantee of product

The guarantee period of this product is stated in the final document. If the

delivery drawings are not provided, the guarantee period is determined as

one year after delivery.

(1) Conditions

The product shall be stored and installed properly until the trial-run adjustment is

started. If any defect due to faulty design, defective materials, and/or poor

workmanship is found during the guarantee period, Energy Support corp. shall repair

or replace defective item free of charge.

The proper operating conditions include the following terms.

①The operating conditions and installation conditions specified in this instruction

manual shall be satisfied.

②Excessive mechanical shock and impact shall not be applied to the sampling

probe.

③The Dust densitometer shall be calibrated and consumable parts shall be

replaced periodically.

④The confirmation and maintenance of the Dust densitometer operation status

shall be performed correctly.

⑤The suction and exhaust valves shall be closed not to suck the sample gas until

the warm-up time of the transmitter has elapsed.

⑥The optical system shall be cleaned and clogging of the probe shall be inspected

and cleaned periodically.

This guarantee does not include defects arising from the following conditions

even during the guarantee period.

・Defects arising from improper handling (improper operation not stated in this

instruction manual)

・Defects arising from repair, modification, or overhaul cleaning made by

personnel other than those authorized by Energy Support corp.

・Defects arising from fire, natural disaster, or improper maintenance (storage in

a place where high temperature and high humidity exist, or mold occurs.)

Note: Replacement of consumable and/or similar parts is not included in the

guarantee coverage.

(2) Guarantee coverage

This guarantee covers only products manufactured and delivered by Energy Support

corp. Incidental and consequential damages (damage and loss caused by controlled

and recorded results by the product delivered by Energy Support corp. and damage

and loss of the equipment, in which Energy’s product is installed) resulting from

malfunction of the product manufactured by Energy Support corp. are not included.

IMPORTANT

3

(3) Remarks

①It is difficult to remove the slug dust by purging. It is absolutely necessary to

perform the maintenance and replacement work with the probe removed.

②This instrument is a Dust densitometer that utilizes the light scattering method.

When measuring the dust actually, a difference between the indication value on

the Dust densitometer and weight concentration value of the actual dust may be

produced by influences of the color, shape, and grain size of the dust.

Therefore, the customer needs to perform the manual analysis and add the

compensation value from the following weight conversion coefficient to make the

indication value on the Dust densitometer matched with the weight concentration

value.

Weight conversion coefficient =

(Actual dust weight concentration value (mg/m3N)

(Average of indication value on the Dust densitometer

(mg/m3N))

This compensation is similar to the standard gas calibration of the gas analyzer.

4

Table of contents

1. General description-------------------------------------------------------------------------------------------------------- 1

1.1 Introduction ------------------------------------------------------------------------------------------------------------- 1

1.2 Guarantee of product ------------------------------------------------------------------------------------------------ 2

1.3 Table of contents------------------------------------------------------------------------------------------------------ 4

1.4 Safety precautions---------------------------------------------------------------------------------------------------- 6

1.5 Cautions for operation ----------------------------------------------------------------------------------------------- 7

1.6 Overview of Dust densitometer------------------------------------------------------------------------------------ 8

1.7 Part names and functions------------------------------------------------------------------------------------------- 9

2. After unpacking------------------------------------------------------------------------------------------------------------11

2.1 Checking of accessories -------------------------------------------------------------------------------------------11

2.2 Temporary storage of product-------------------------------------------------------------------------------------13

3. Installation ------------------------------------------------------------------------------------------------------------------14

3.1 Installation conditions-----------------------------------------------------------------------------------------------14

3.2 Installation--------------------------------------------------------------------------------------------------------------16

3.3 Piping and wiring-----------------------------------------------------------------------------------------------------19

3.4 Inspection after installation ----------------------------------------------------------------------------------------22

4. Operation -------------------------------------------------------------------------------------------------------------------23

4.1 Preparations for operation-----------------------------------------------------------------------------------------23

4.2 Key operation ---------------------------------------------------------------------------------------------------------26

4.3 List of functions-------------------------------------------------------------------------------------------------------31

4.4.1 List of system data (user data)------------------------------------------------------------------------------33

4.4.2 List of system data (manufacturer data)------------------------------------------------------------------35

4.5 Starting operation----------------------------------------------------------------------------------------------------37

4.6 Stopping operation---------------------------------------------------------------------------------------------------38

4.7 Operation while analyzer is running-----------------------------------------------------------------------------39

4.7.1 Measuring range change operation------------------------------------------------------------------------39

4.7.2 Calibration operation-------------------------------------------------------------------------------------------40

4.7.3 Purge and bypass operation---------------------------------------------------------------------------------47

4.7.4 O2 conversion/weight conversion operation-------------------------------------------------------------49

4.7.5 Output signal calculation/hold/output adjustment ------------------------------------------------------51

5

5. Maintenance ---------------------------------------------------------------------------------------------------------------54

5.1Cautions for maintenance ----------------------------------------------------------------------------------------54

5.2 Maintenance and inspection items ------------------------------------------------------------------------------55

5.3 Maintenance and inspection --------------------------------------------------------------------------------------56

5.4 Error display-----------------------------------------------------------------------------------------------------------66

5.5 Troubleshooting ------------------------------------------------------------------------------------------------------68

5.6 Replacement parts---------------------------------------------------------------------------------------------------75

5.7 Replacement of parts -----------------------------------------------------------------------------------------------77

5.8About transmitter-----------------------------------------------------------------------------------------------------78

6. References -----------------------------------------------------------------------------------------------------------------79

6.1 Construction of unit--------------------------------------------------------------------------------------------------79

6.2 Outside view and dimensional drawing-------------------------------------------------------------------------80

6.3 Standard specifications---------------------------------------------------------------------------------------------83

6

1.4 Safety precautions

WARNING

1. Before starting the wiring work to the terminal block, always

shut-down the power. Failure to do so may cause an electrical

shock. Additionally, before starting the maintenance work of electrical

parts, always shut-down the power.

2. To prevent an electrical shock accident, connect the grounding cable to the

grounding terminal firmly.

CAUTION

1. To prevent dew condensation, the transmitter main body becomes hot.

Before starting the cleaning and maintenance work of the piping in the optical

system, trap, and ejector, always wear heat-resistant gloves.

2. Before attaching and detaching the cap to/from the span port, always wear

heat-resistant gloves since the span port is hot.

3. If the suction and exhaust valves are not closed fully when starting the

maintenance work while the furnace is being operated, the sample gas may spout

out.To prevent such troubles, always close the suction and exhaust valves fully.

4. Before installing or removing the Dust densitometer, make sure that the furnace

operation is stopped completely.

If it is strongly required to install or remove the Dust densitometer while the furnace

is being operated, pay special attention to the following cautions.

(1) Since the part close to the mounting seat is hot, always wear heat-resistant

gloves.

(2) If the positive pressure exists inside the furnace, the sample gas may spout

out

from the opening. Never get access to the opening.

(3) Additionally, the dust and soot in the sample gas may also spout out.Always

wear dust-proof glasses to prevent dust and soot from entering your eyes.

IMPORTANT

7

1.5 Cautions for operation

CAUTION

The following cautions must be strictly observed to prevent corrosion

and clogging of dust caused by dew condensation. Always operate

the Dust densitometer correctly while carefully referring to the following

operations.

1. Close the suction and exhaust valves if the HEAT lamp on the controller does not

flash or if the warm-up operation is not performed for 60 min.

2. If the power to the transmitter is shut-down due to power failure, immediately close

the suction and exhaust valves.

3. Perform the heat retention (heat insulation) work on the sample gas flowing pipes

between the furnace wall (guide pipe) and transmitter.

4. The dust concentration inside the furnace becomes high during a period of

approximately 2 hrs.After stopping or starting the furnace operation, causing the

optical system of the Dust densitometer to be contaminated. Therefore, close the

suction and exhaust valves for approximately 2 hrs. after stopping or starting the

furnace operation in order to prevent the dust from entering the analyzer.

5. Open and close the suction and exhaust valves periodically (once a month). If the

valves are not operated for an extended period of time, dust may stick to the valves,

causing the valves not to be opened or closed.

IMPORTANT

8

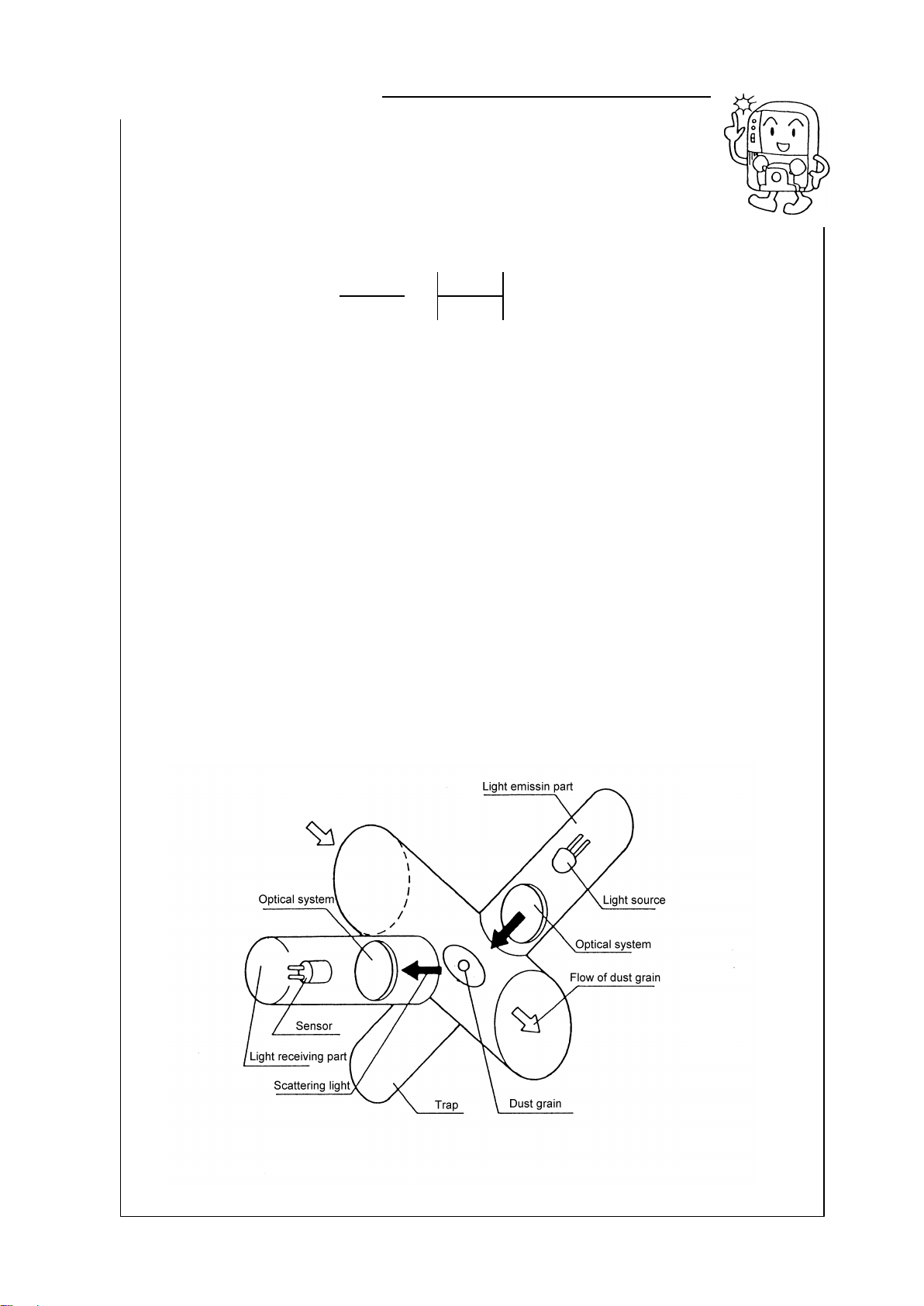

1.6 Overview of Dust densitometer

[Measuring principle]

This Energy’s Dust densitometer is a light scattering type Dust

densitometer that utilizes the correlation between the dust weight

concentration and scattering intensity.

The light scattering intensity (I

) is expressed by the following formula.

I=

2

6

m2–1

2

(1 + cos2)

822

m2+ 1

: Scattering angle,

: Wavelength,

: Grain diameter parameter (2

a/

), a: Radius of

grain, R: Distance from grain, m: Index of refraction of light in grain/Index of refraction of

light in medium

When the physical property of the grain (shape, size, composition, color, etc.) is almost

constant, the scattering intensity is parallel to the dust weight concentration.

An infrared ray LED lamp with an emission light waveform of 875 nm is used as light

source.

When this light is intermittently emitted to the dust passing through the detection area of

the detector, the scattering light occurs at any angle to the dust.

A light receiving sensor is located at 70

forward to the light axis between the light source

and trap. This sensor receives the infrared ray coming from the light source and

converts it into the electrical signals.

These electrical signals are processed to measure the relative dust concentration at

real-time.

Using the standard grain, scales are put on this Dust densitometer. When measuring the

exhaust gas, it is possible to perform the continuous measurement by calculating the

weight conversion coefficient based on the measurement in conformity with JIS Z 8808.

REFERENCE

9

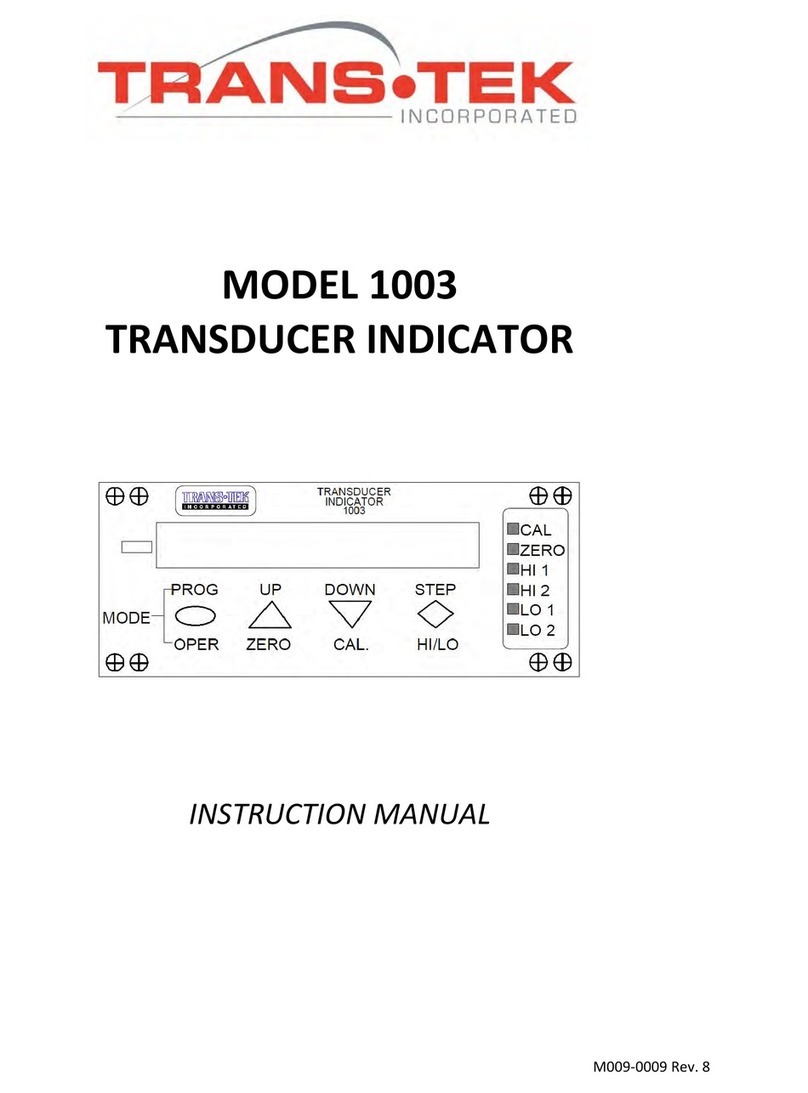

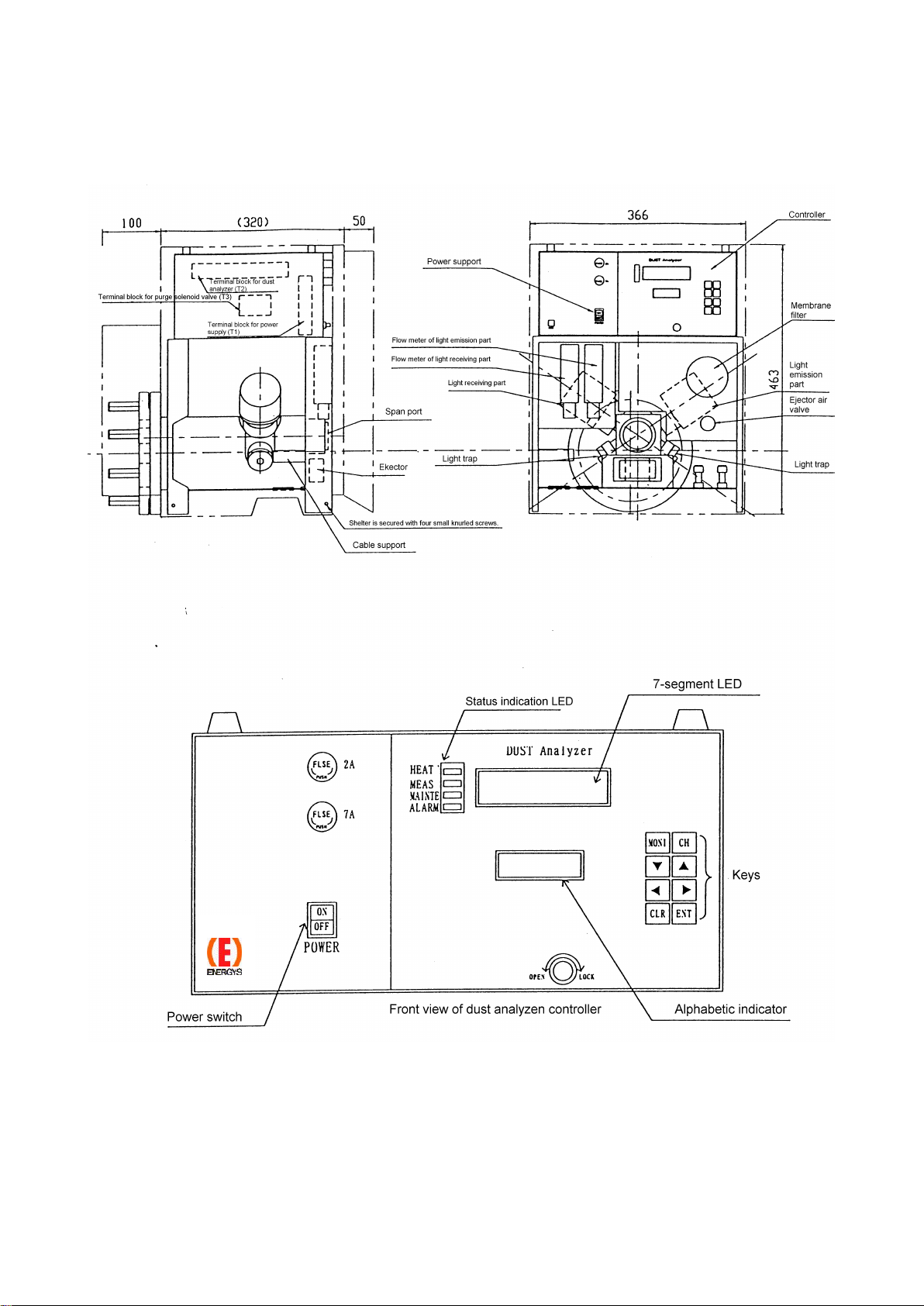

1.7 Part names and functions

1) Outside view of Dust densitometer

10

2) Part names and functions of Dust densitometer

No.

Name

Function

1

Controller

Processes the signals inside the Dust densitometer.

2

Power switch

ON/OFF switch for the power to the Dust densitometer

3

HEAT LED

Pilot lamp of the heater for the Dust densitometer.

Lit during temperature rise and flashes during control.

4

MEAS LED

Lit during measurement.

5

MAINTE LED

Lit during measurement.

6

ALARM LED

Lights up if a fault occurs.

7

7-segment LED

Indicates the dust concentration and error No.

8

Alphabetic indicator

Indicates the measuring range and status, such as CAL or

PURGE.

9

Fuse 2A

Fuse for the electronics circuit.

Fuse 7A

Fuse for the heater of the Dust densitometer

10

Flow meter of light emission

part

Flow meter for clean air of the light emission part

11

Flow meter of light receiving

part

Flow meter for clean air of the light receiving part

12

Ejector air valve

Flow regulation valve for driving of the ejector

13

Span port

Span rod is inserted into this port for span calibration.

Cleaning port for cleaning of the suction side

14

Ejector

Ejector nozzle for suction of the sample gas

When cleaning the exhaust side, remove this ejector and clean

it.

15

Filter membrane

Filter for clean air

16

Light emission part

Infrared LED light source built-in unit

17

Light receiving part

Light sensor and amplifier built-in unit used to detect the

scattering light.

18

Light trap

Absorbs the stray light.

19

Suction/exhaust nozzle

Nozzle used to suck/exhaust the sample gas.

20

Suction/exhaust valve

Valve used to shut-down the sample gas during calibration.

21

Terminal block for power

supply (T1)

Terminal block for power supply to the Dust densitometer

22

Terminal block for Dust

densitometer (T2)

Terminal block for signals to the Dust densitometer

23

Terminal block for purge

solenoid valve (T3)

Terminal block for driving of the purge solenoid valve for the Dust

densitometer

11

2. After unpacking

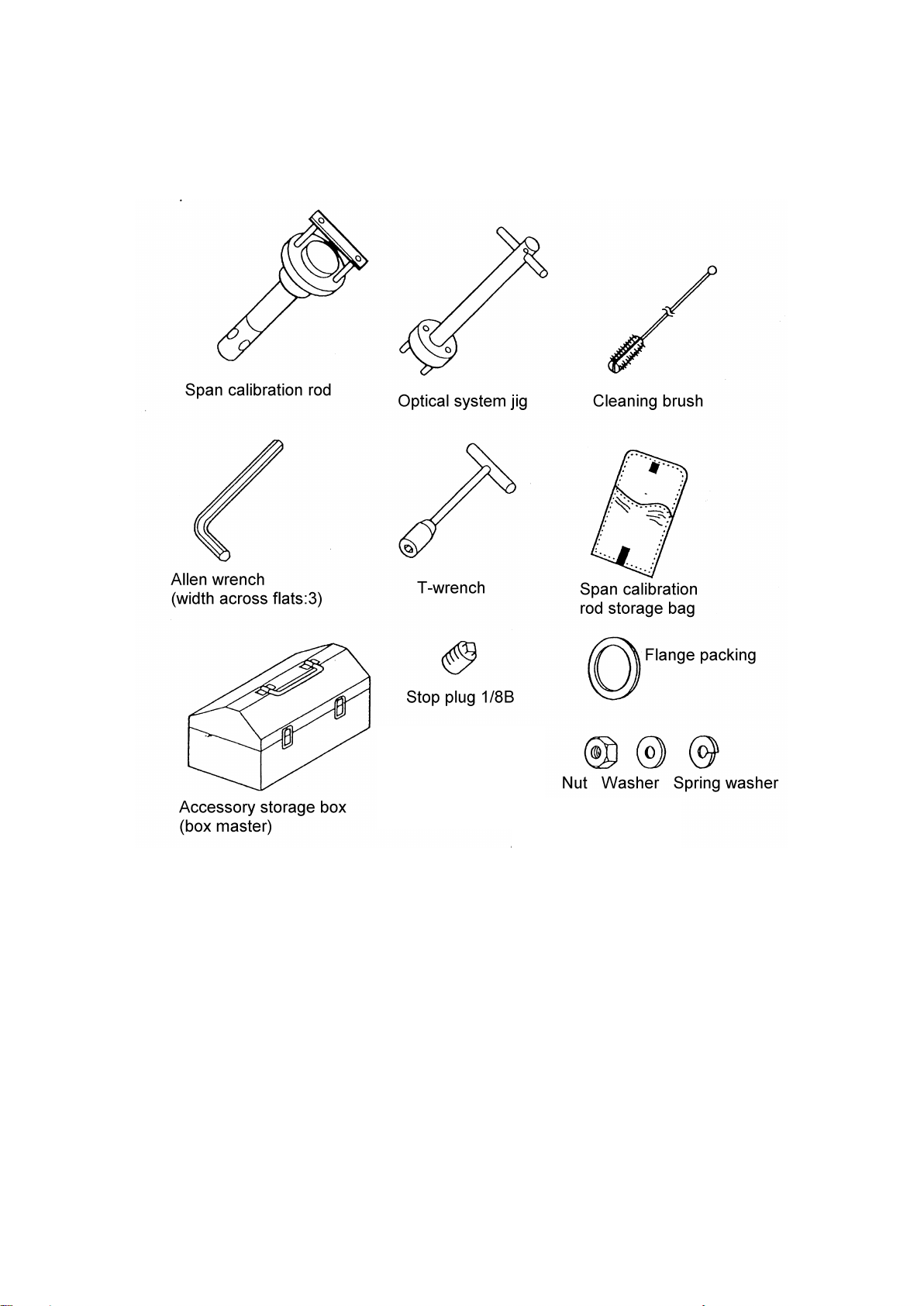

2.1 Checking of accessories

12

List of products and accessories

Name

Part No.

Q’ty

Remarks

Dust densitometer model

ISS-101

KV-610014-J

1

With case (shelter)

Suction nozzle

KV-620212-L

1

L = Specified length (mm)

Exhaust nozzle

KV-620212-L

1

L = Specified length (mm)

Span calibration rod

KV-610402-A

1

Optical system jig

KV-650105

1

Cleaning brush

KV-650106

1

T-wrench

KV-650132

1

Span calibration rod storage

bag

1

L size

Accessory storage box

1

B-54

Stop plug

PG3041/8B

1

Used to stop the air inlet of the ejector

nozzle when the ejector is not in use.

Stop plug

PG3161B

1

Supplied with the Dust densitometer

main unit

Allen wrench

1

Width across flats: 3

Nut

8

For M16

Washer

8

For M16

Spring washer

8

For M16

Flange packing

T1995K10A100RF3T

1

13

2.2 Temporary storage of product

This Dust densitometer must be stored under original packing conditions

in an indoor place (temperature: -5 –50

C, humidity: 90%RH or less) until

the installation work is started.

Do not store the Dust densitometer in an outdoor place (exposed to the rain) or a place

where high temperature or high humidity exists, or mechanical vibration exists. Doing so

may cause the Dust densitometer to malfunction.

When the Dust densitometer is installed, close the door and cure the Dust densitometer

so that rain water and dust does not enter the inside through the piping port or wiring port.

In the same manner, cure the probe and transmitter.

CAUTION

14

3. Installation

3.1 Installation conditions

This section describes how to carry out the installation, piping, and wiring

work of the Dust densitometer model ISS-101.

If the installation place is selected incorrectly or the installation work is performed

incorrectly, an unexpected trouble may occur later or the performance of the analyzer

cannot be maintained, causing damage to the units. Thoroughly read the following

description to fully understand its contents before staring the installation work.

If it is difficult to install the Dust densitometer under the conditions specified below,

contact Energy Support corp. Before installing the Dust densitometer, determine or

prepare the following items.

①Determine the gas sampling position (Dust densitometer installation position)

②Determine the storage panel (purge unit) installation place.

Cautions for installation work ( CAUTION)

1) Before installing or removing the Dust densitometer, make sure that the furnace

operation is stopped completely.

If it is strongly required to install or remove the Dust densitometer while the furnace

is being operated, pay special attention to the following cautions.

(1) Since the part close to the mounting seat is hot, always wear heat-resistant

gloves.

(2) If the positive pressure exists inside the furnace, the sample gas may spout

out from the opening. Never get access to the opening.

(3) Additionally, the dust and soot in the sample gas may also spout out. Always

wear dust-proof glasses to prevent dust and soot from entering your eyes.

2) Make sure that the suction and exhaust valves are closed fully.

If these valves are not closed fully, this may cause dust clogging or corrosion.

3) Attach the flange packing (accessory) so that it does not deviate.

4) Apply the burn prevention agent (mori-coat) to the hexagon bolts and tighten the

hexagon bolts and nuts (accessories) evenly.

IMPORTANT

15

3.1 Installation conditions

①Selection of gas sampling position

When selecting the gas sampling position, that is, Dust densitometer

installation position, always take the place satisfying the following

conditions into consideration.

1) Place where the typical dust value can be measured.

2) Place where the dust concentration does not vary rapidly.

3) Place where is close to the manual analysis seat.

4) Place where the gas temperature is 500

C or less.

5) Place where the sample gas forms an even laminar air flow.

(It is not appropriate to install the Dust densitometer at a corner where the turbulent

flow occurs easily.)

6) Place where the mechanical vibration and impact are minimized.

7) Place where the maintenance work can be carried out easily.

Keep the maintenance area satisfying the following conditions.

a. Place where is approximately 1000 mm above the center and both sides of the

mounting seat. (It is necessary to attach and detach the shelter.)

b. Place where is located 1000 mm + overall length of the nozzle after the

mounting seat.

8) Place where the outdoor temperature is –10 - 50

C.

②Selection of storage panel (purge unit) installation place

When selecting the storage panel installation place, always take the following

conditions into consideration.

1) Place where the outdoor temperature is 0 - 50

C and variation in temperature is

15

C or less during daytime.

2) Place where the corrosive gas is minimized.

3) Place where the mechanical vibration and impact are minimized.

4) Place where the Dust densitometer is not exposed to the steam or hot air.

5) Place where the Dust densitometer is not exposed to the direct sunlight.

6) Place where the electro-magnetic induction is minimized.

(Pay special attention to this caution for wiring place.)

7) Place at a distance of 50 m or less from the transmitter.

(To reduce the piping and wiring construction costs and suppress increase in

piping resistance, the above distance shall be made as short as possible.)

8) Place where maintenance space to allow opening and closing of the door of the

storage panel can be kept.

IMPORTANT

16

3.2 Installation

1) Preparations

①Wind a seal tape on the screw parts (R 3/4 male-screw) of the suction and exhaust

nozzles.

②Remove four shelter mounting screws from the Dust densitometer. Raise the shelter

to remove it. Apply the burn prevention agent (mori-coat, etc.) to eight M16 bolts

welded to the flange of the Dust densitometer.

17

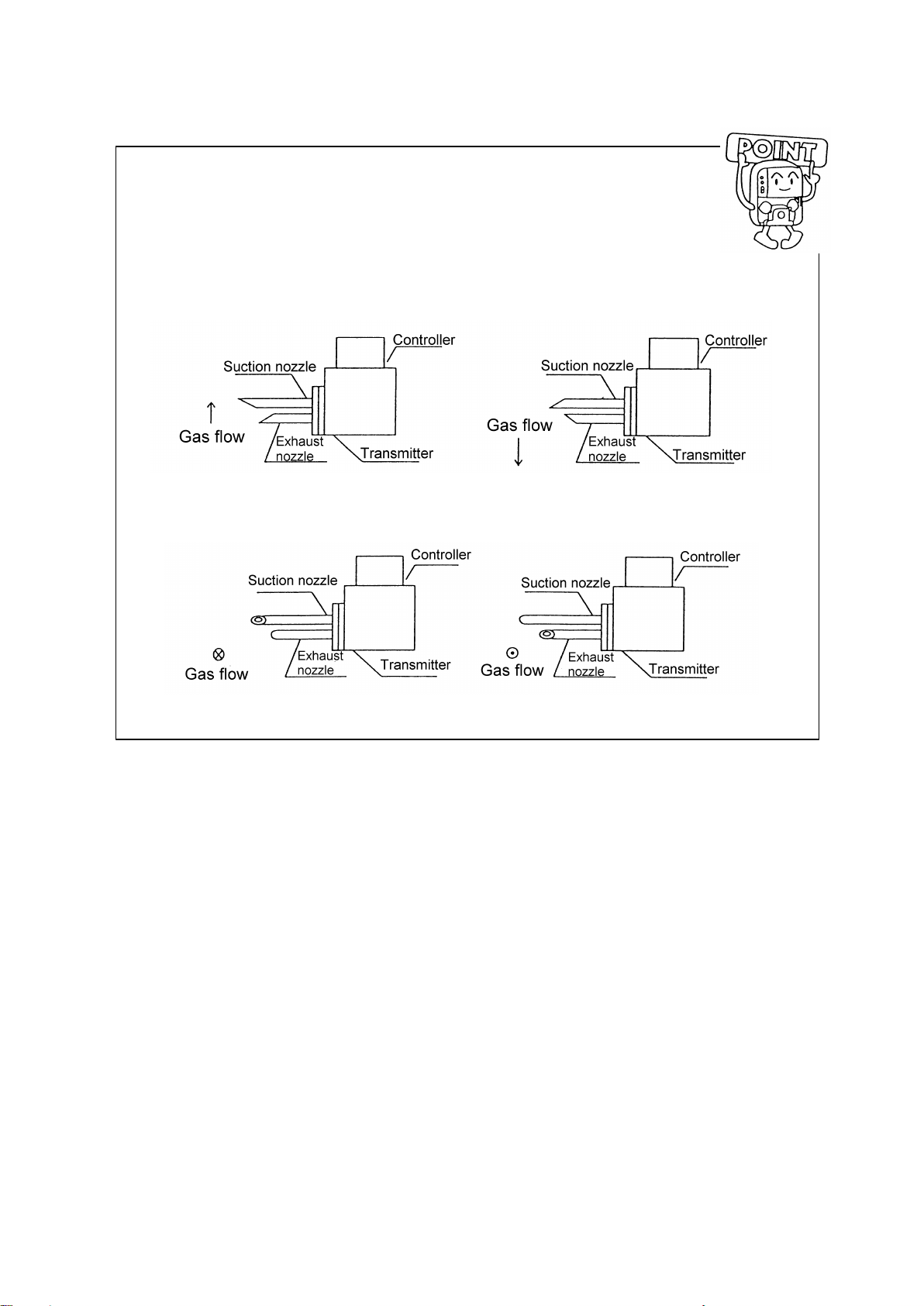

2) Procedures

①Screw the suction and exhaust nozzles into the flange.

Make the opening of the suction nozzle faced toward the gas

flow and the opening of the exhaust nozzle faced against the gas

flow as shown in the following.

a. Gas flows from the bottom to the top. b. Gas flows from the top to the bottom.

c.Gas flow fromthefrontsidetothefar side. d.Gas flow fromthefarsidetothefrontside.

To screw-in the suction and exhaust nozzles, first turn the nozzles manually, and then

retighten them with a pipe wrench.

(If the nozzles are not retightened with a pipe wrench, the nozzle may fall down

during operation.)

(If the nozzles cannot be positioned as shown in the Fig. above after the nozzles

have been screwed in, adjust the positions by increasing or decreasing the seal tape

winding amount.)

18

②Insert the M16 bolt of the Dust densitometer into the mounting seat (guide pipe),

attach the M16 washer, spring washer, and hexagon nut in that order, and then

tighten the nut.

(At this time, check that the suction and exhaust valves are closed fully.)

In the above assembly, always attach the flange packing (T1995-10K100RF3T).

Since the weight of the Dust densitometer is approximately 40 kg, always

carry out the installation work by two or more personnel.

③Carry out the heat retention work of the mounting seat (guide pipe).

Dimensions of guide pipe work (beyond delivery conditions)

(Reference)

*1 Carry out the heat retention work of the guide pipe.

CAUTION

Table of contents

Other ENERGY SUPPORT CORPORATION Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

HF Scientific

HF Scientific CLX owner's manual

Zehntner

Zehntner ZGM1130 Technical manual

ATAGO

ATAGO PAL-Easy ACID1 instruction manual

PCB Piezotronics

PCB Piezotronics HT352A21/NC Installation and operating manual

Hydrofarm

Hydrofarm Active Eye LGBQM Quantum PAR Meter instruction manual

Satimo

Satimo EME Guard user manual