ENERGY SUPPORT CORPORATION LP-30H User manual

Manual No.3022E R2

INSTRUCTION MANUAL

MODEL LP-30H

OXYGEN ANALYZER

(Probe Transmitter)

Read the operation Manual

!

ENERGY SUPPORT CORPORATION

Contents

Handling Precautions・・・・・・・ P0

1.General・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P1

2.Principle of Measurement ・・・・・・・・・・・・・・・・・・・・・・・・・・・ P2

3.Components and their Functions

3-1 Probe transmitter・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P3

4.Mounting

4-1 Selection of the sampling position・・・・・・・・・・・・・・・・・・・・ P4

4-2 Selection of the mounting position of the panel・・・・・・・・・・・・・・ P4

4-3 Mounting of guide pipe・・・・・・・・・・・・・・・・・・・・・・・・・・ P5

4-4 Mounting of Probe Transmitter ・・・・・・・・・・・・・・・・・・・・・・ P7

5.Oxygen analyzer diagram・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P9

6.Inspection and Maintenance

6-1 Precautions for Inspection and Maintenance・・・・・・・・・・・・・・・・ P10

6-2 Daily inspection・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P10

6-3 Calibration of indication (about once a month) ・・・・・・・・・・・・・ P11

6-4 Treatment at the stop of boiler and furnace・・・・・・・・・・・・・・・・ P11

6-5 Periodic inspection (once a year. Or according to circumstances・・・・・・ P13

6-6 About heater unit・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ P13

7.Exchange (removal) of filter unit

7-1 Replacing Filter Unit・・・・・・・・・・・・・・・・・・・・・・・・・・・ P14

7-2 Sensor Unit Replacement・・・・・・・・・・・・・・・・・・・・・・・・・・ P15

- 0 -

Warning

(1) When installing wiring around the terminal section of the analyzer or performing

Maintenance inside the analyzer, take care to avoid electric shock.

Turn the power off without fail when performing maintenance of electrical parts.

(2) Be sure to connect the grounding cable to the grounding terminal to reduce the possibility

of electric shock.

The electric shock caution mark on the left is attached to the terminal area that may

cause electric shock.

When wiring or checking, be careful not to get an electric shock.

「Caution」

(1) Stop the plant when removing or installing the probe transmitter. If it is unavoidable

to remove or install the probe transmitter during plant operation, use sufficient care

for the following points.

① Wear heart resistant gloves because the installation section and its periphery are

very hot.

② Hot sample gas will blow out from a furnace at a positive pressure; never reach or

approach openings.

③ Dust in the sample gas will also blow out; wear protective glasses to protect your

eyes from dust.

④ The gas inside the furnace may blow out from piping parts of reference and calibration

gases; plug the piping ports when removing or installing the probe transmitter. After

the probe transmitter has been inserted, return the piping in its original state

promptly.

(2) Install the probe transmitter during stoppage of the plant. Turn the heater on one hour

before plant operation. If the probe is not sufficiently heated, the detector cell or

probe itself may be worn due to corrosive gases or the like.

Handling Precautions

!

!

- 1 -

1. General

The Oxygen Analyzer LP-30H is a device with a sensor (sensor cell),fitted at the tip of a

probe, heated to a high temperature by a heater, and inserted in the of a boiler or various

types of furnace, to measure automatically the oxygen partial pressure in combustion exhaust

gas. This analyzer has no gas sampling part common in old types, needs minimal maintenance,

has quick response, and is able to make stable measurement for a long time. Therefore, we

are quite confident that the LP-30H Oxygen analyzer is the most suitable instrument for

automatic control of low oxygen combustion aiming at energy conservation and NOx reduction.

- 2 -

2. Principle of Measurement

Cubic system solid solution composed of zirconia (ZrO₂) combined with calcium oxide (CaO)

and yttrium oxide (Y₂O₃)becomes solid electrolyte which conducts oxygen ion (O⁻⁻)at a high

temperature. When a couple of electrodes (Porous) are faced to this solid electrolyte, and

gases which have different oxygen partial pressure are supplied to each electrode, oxygen

ion conduction will occur and the following electromotive force between the electrodes will

generated.

(A)

Po

(S)

Po

ln

4F

RT

E

2

2

Where E :Electromotive force generated between the electrodes(V)

R :Gas constant(8.314 J・mol-1・K-1)

T :Absolute temperature of the (Normal 923・K)

F :Faraday constant(9.649×104 C・mol-1)

Po2(A) :Oxygen partial pressure in the standard gas(air)

(concentration 20.6 vol %)

Po2(S) :Oxygen partial pressure in the sample gas

(concentration is indicated by vol %)

Substituting the numerical values of constants in the above equation, we obtain.

)

E

・(S)=

Po

2

78

.

45

(log 20.6 )10( Anti

Po₂ in the sample gas can be obtained through the above equation by substituting the measure

electromotive force. This solid electrolyte (sensor cell) is fitted at the tip of the probe

transmitter of the LP-30H Oxygen Analyzer and heated to 650℃ Sample gas flows through a

special filter, diffuses and contacts with the cell, and electromotive force, corresponding

to the O₂ partial pressure in the sample gas, is generated. This electromotive force E will

be calculated through an Antilog conversion circuit in the control unit, and indicated as

a direct readable O₂ pressure (VOL%)

- 3 -

3. Components and their Functions

3-1 Probe Transmitter

Specifications

MODEL LP-30H

Measurement principle Zirconia

Response Less than 10sec.(90%F.S)

Changing the Calibration gas

Warm-up time Approx.20min.

Reference air flow rate Approx.2 /min.

Calibration gas flow rate Approx1~3 /min.

Accessories Bolt,Nut,Washer M16,L70(S38) 4

Sets Gasket(JIS10K65A T1995 t3)1

Accessories

Name Remarks Q,ty

Bolt、Nut、W、SW M16,L70(S38) 4

Non asbestos packing JIS10K65A 1

Name :LP-30H Oxygen Analyzer

Number:KS-1630□□-□

Number LSize mm

Probe transmitter 500

AKS-1630□□-□ 1000

1500

Filter Unit

KS-185496

+ - + -

C E L L K

H E A T E R

- 4 -

4. Mounting

Mounting, plumbing and wiring of LP-30H type Oxygen Analyzer will be shown.

Wrong selection of mounting place, and inappropriate mounting work will cause unexpected

trouble, deterioration in performance of the analyzer, and also damage in the equipment later,

therefore sufficient understanding of the contents of the following articles before

undertaking the work is necessary.

In a special case in which the work is difficult to do according to the following articles,

please discuss with us beforehand.

Before delivering the analyzer, the following items shall be determined or prepared.

1) Determination of the gas sampling position (mounting position of probes)

2) Determination of the mounting place of panel (control unit)

3) Determination of the plumbing and wiring routes

4) Purchase and mounting work of the guide pipes

5) Purchase of the plumbing and wiring material

4-1 Selection of the gas sampling position

Selection of the sampling point of sample gas, that is, the mounting position of the

probe transmitter should be made normally to the position where the following conditions

are satisfied.

1) Where the gas values of the sampled gas are representative values.

2) Where there is less change in oxygen concentration.

3) Where there is less change in gas pressure and temperature

4) Where the gas temperature is less than 600℃.

5) Where a uniform laminar flow of sample gas exists.

6) Where little mechanical vibration and shock exists.(Use by 0.1G or less)

7) Where maintenance work can be done easily.

8) Where outside air temperature is less than 80℃

4-2 Selection of the mounting position of the panel (control unit)

The selection of the mounting position of the panel in which the control unit

1) Where the outside air temperature is within the range of -5℃ to less than 55℃ and

the temperature change during 24 hours is less than 15℃, which preferably as little

change as possible.

2) Where little corrosive gas exists.

3) Where little mechanical vibration or shock exists.

4) Where there is not a direct stream of steam or hot air

5) Where there is, no exposure to the direct rays of the sun.

6) Where little electromagnetic induction exists.

- 5 -

7) Where the storing temperature of the standard gas cylinder is specifically less than

35℃, and there is no exposure to the direct rays of the sun and it is well ventilated.

8) Where the distance from the transmitter is shorter than 100m.

(A shorter distance is preferable to save the cost of plumbing and wiring work and

to reduce the plumbing resistance)

9) Where the door of the panel can be opened and still allow enough space for maintenance.

- 6 -

4-3 Mounting of guide pipe

Horizontal mounting (on boiler wall, etc.)

Note)・Guide pipe and steel skin of the furnace wall shall be fixed by welding the whole

periphery.

・Mounting angle of the guide pipe shall be 5~10 degrees downward to the horizontal axis.

- 7 -

Vertical mounting (on ceiling of boiler, etc.)

- 8 -

4-4 Mounting of Probe Transmitter

The probe transmitter is mounted according to the mounting drawing but the following

conditions should be observed.

「Caution」

(1) Asbestos packing (accessories) should be mounted so as not to slip out.

(2) Bolts and nuts (accessories) should be tightened uniformly so as to prevent uneven

tightening.

(3) The insertion of the probe transmitter to the guide pipe should be made slowly to

avoid shock to the probe transmitter

(especially to the tip of transmitter).

(4) When the pressure in the furnace is positive in the case of inserting the probe

transmitter, care should be paid concerning gas explosion.

And as gas explosion may occur from the plumbing holes of standard air and calibrating

gas, blinding cocks should be inserted to the holes of plumbing.

(5) Plumbing should be connected immediately after the completion of insertion of the

probe control unit.

(or the blind stopper should be installed)

Mounting method of Probe transmitter

!

- 9 -

5. Piping and wiring

- 10 -

6. Inspection and Maintenance

6-1 Precautions for inspection and maintenance

「Caution」

(1) Remove / install the probe transmitter while the plant is shut down.

If you do remove / install the probe transmitter during plant operation, please pay

attention to the following points.

① Use gloves for heat resistance, etc. because the temperature near the mounting

seat is high.

② If the furnace has a positive pressure, high temperature sample gas will be emitted,

so be sure to keep your body away from the opening.

③ Also, because dust and dirt in the sample gas spout out, wear dust-proof glasses

etc. so that dust and dirt do not get into eyes.

④ Also, there is a blowout of furnace gas from the reference air and calibration

gas piping port. Attach a closing plug to the piping port and perform removal /

installation of the probe transmitter.

(2) When removing the filter unit and sensor unit, apply anti-seizure material (Molycoat

1000, Dow Corning) to the hexagonal socket bolt.

(3) Apply a anti-seizure material (Molycoat 1000, Dow Corning) to the hexagonal bolt when

removing / mounting the probe transmitter.

(4) The sensor unit will be damaged if it falls. Pay careful attention to the handing

when replacing the sensor unit.

(5) At the time of removal / installation of the probe transmitter, please do the removal

/ installation work slowly so that shock is not applied to the probe transmitter body

(especially the tip part).

6-2 Dairy inspection

・ Check the indicated value or recorder chart.

・ Check if the reference air flow rate is about 2ℓ/min.

!

- 11 -

6-3 Calibration of indication (about once a month)

・ Carry out calibration of indication in accordance with DGO (Control Unit) Instruction

Manual, and keep a record of (K) thermo-electromotive force and cell electromotive force

and response time for ZERO gas and AIR. By this record, the frequency of sensor cell

change can be determined.

・ Measurement method of cell electromotive force and (K) thermo-electromotive force.

This measurement is made at the time of inspection and calibration of DGO (Control Unit)

Instruction Manual.

For measurement of the cell electromotive force and (K) thermo-electromotive force, a

high input impedance instrument should be employed (e.g.digital volt meter). Either

electromotive force is DC several tens mV.

Measurement method of cell electromotive force

① Flow ZERO gas (SPAN gas) about 3ℓ/min in the calibration gas circuit.

② Measure the cell electromotive force at ZERO gas (SPAN gas) at this time between No.3(+)

and No.4(-) of the receiver terminal block CELL terminal.

* The calculated output value of cell electromotive force is attached at the end of

the instruction manual, so please refer to it.

* Since the cell EMF can be lowered somewhat at the beginning of calibration gas flow,

wait for it to stabilize and measure it.

・ Thermo-electromotive (K) EMF is measured between the thermo-electromotive (K) terminals

of the receiver terminal block.

・ How to measure response time

Measures the response time when switching between zero gas and air

① Flow zero gas into the calibration gas path approximately 3/min.

② Operate the value when the indication is stable and switch from zero gas to air.

(The air flow rate at this time is also about 3/min)

③ Measure the 90% response time to the air reading from the point when the zero gas reading

starts changing at this time.

④ Next, measure the 90% response time from air to zero gas in the same way as in Section3.

⑤ 90% response time when switching the calibration gas is about 10 seconds as a standard

value regardless of the temperature difference of the calibration gas.

e.g.)0~25vol%O2Range

- 12 -

・ Standard of exchanging time of the sensor cell

The time to exchange the sensor cell is as follows.

① When the indication and calibration with the calibration gases

② When the response time becomes too much to handle in practical purpose.

For example

・ Cell electromotive force・・・When it becomes less than -30% against the calculated output

Value. (For the calculated output value, refer to the table

of cell electromotive force at the end of the instruction

Manual)

・ Response time・・・・・・・ When the calculation gas 90% response time becomes more than

30 sec at the time of the calibration gas change over

(ZERO⇄SPAN gas)

6-4 Treatment at the stop of boiler and furnace

・ In case of a short period (within 1 week)

Same as the normal operation , except that about 3ℓ/min. or air is flown continuously

in the calibration gas circuit.

(Caution) ・Do not turn off the electric power source of the O₂ analyazer.

・Please make the standard air flow about 2 / min continuously.

・Turn MEAS switch OFF.

・ In case of long period (more than 1 week and less than a month)

Follow the same procedure as above (in the case of a short time) until the atmosphere

in the flue becomes air atmosphere, but after that turn off the 0₂ meter power supply.

However, air venting to the calibration gas line and reference air should flow

continuously.

Before starting the boiler / furnace operation, turn on the O₂ meter power supply a few

hours ago.

・ In case of stopping more than 1 month due to periodic inspection and other reasons.

Same treatment as the above (in case of an extended period) but to check the probe

transmitter, draw it out after waiting until the temperature in the flue goes down to

normal temperature.

(In drawing the probe, sufficient care shall be paid in that treatment)

- 13 -

6-5 Periodic inspection(once a year, or according to circumstances)

・ Inspection and cleaning of filter unit (according to circumstances)

When the movement of O₂ indication in the recorder chart becomes dull compared with the

previous movement, it is probable that the filter unit will get clogged, so check the

filter unit.

If the amount of dust in exhaust gas is about 500mg/Nm³,it will be used continuously

for about one year Yes, but if the amount of dust is 500mg/Nm³ or more, the frequency

of inspection (replacement) is May be short

・ Cleaning of filter

The filter can be re-used through purge of compressed air or pressurized water, depending

on the adhering condition of the filter.

The following illustrate the method.

1) The purge pressure should be about 0.5kg/cm² in either method.

2) The time required to purge is about 10min.

3) When the purge is made through pressurized water, dry it sufficiently before

re-installation.

4) Where dust is accumulated, remove it with a wire brush etc.

(Note)When dust has penetrated inside the filter, and a remarkable quantity of dust

is found in the filter, the filter unit should be replaced .

Before mounting to the probe transmitter, sintering preventing agent (DOW

CORNING C.MOLYKOTE 1000)

・ Visual check of probe transmitter (once a year)

Pull out probe transmitter from the guide pipe and perform a visual inspection.

At this time, check the stage of corrosion and deformation of the probe transmitter main

body SUS part.

In particular, areas located near the furnace wall proceed with corrosion, and it is

often seen that soot etc. solidify.

Please remove those that are solidified such as soot. If the SUS part is cracked and

there is an abnormal deformation, the probe transmitter body will be replaced.

・ Insulating resistance check of the wire cable (once a year)

Check whether there is any ground or insulation loss in the wire cable.

6-6 About heater unit

Since ISOWOOL blanket is used for the heater unit of this product, the safety data sheet

of ISOWOOL blanket is attached to the product. If you lose the safety data sheet, please

contact our agent or our sales office.

- 14 -

7. Exchange (removal) of filter unit

Filter unit & sensor unit external view

・ Probe transmitter main body and filter unit are connected with screw joint.

・ Since the screw joint is tightened with a hex socket head bolt, use a hex wrench to remove

it.

7-1 Replacing Filter Unit

The filter unit consists of ④,⑤,⑥,⑦,⑧,⑨ in the figure

1) Remove hexagon socket head bolt ⑨ with hexagon wrench (for M3)

2) Remove filter fixing bracket ⑧ and filter fixing net ⑥ ceramic filter ⑤

from Pt lead ⑩

3) Remove hexagon socket head bolt ⑦ with hexagon wrench (for M5) and remove

calibration gas attachment ④

4) Install the replacement filter unit in the reverse order of 2) and 3)

- 15 -

5) Fix the unit with hexagon socket head bolt ⑨. At this time, wrap and fix the

tip of PT lead ⑩ on one of the bolts.

Probe tip external view

7-2 Sensor Unit Replacement

1) Remove the filter unit according to paragraph 1.

2) Remove sensor unit ③ and metal O-Ring ②.

3) Insert the sensor unit for replacement and metal O-Ring.

4) Fix the filter unit in the reverse order of 1).

(Note)Anti-seizure agent (Molycoat1000, Dow Corning) on the screw part.

Please apply

- 16 -

Measures when the boiler is stopped

When the boiler is stopped, if you clean the inside of the boiler, or if there

is a risk that a large amount of dust may fall during cleaning and inspection,

product the probe transmitter according to the following procedure.

(1) Turn off the O2 meter power supply.

(2) Remove the probe transmitter and terminate the wiring and piping.

(3) Bring the probe transmitter into the instrument room etc. and perform the

following maintenance.

・ Clean the outer cylinder

・ Remove the filter unit, wash the fittings with water and dry.

(The ceramic filter is replaced with a new one.)

・ Remove the detection cell unit and perform air purge to remove dirt

on the surface.

(If there is a drop in cell output or a delay in response time and it

is considered that the cell is degraded, replace the detection cell

unit.)

・ Replace the metal O-ring with a new one and assemble it.

(4) Attach a probe transmitter before boiler operation, and use it after

instructed calibration.

Dismantling method of hex. socket head bolt

(1) Remove dust around hex. socket head bolt with wire brush.

(2) Spray a small amount of CRC (oil) on the bolt hole enclosure.

(3) Insert a hexagonal rod spanner into the bolt and hit with a hammer as shown

in the figure. (lightly)

(4) Loosen the bolt。

(5) Disassemble the bolt, so that SO2

minutes and so on, after washing with hot water,

dry, then put a small amount of anti-seizure (Molycoat1000 Dow corning)and

assemble it.

Table of contents

Other ENERGY SUPPORT CORPORATION Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Prosonic Flow 90 operating instructions

HYDAC FILTER SYSTEMS

HYDAC FILTER SYSTEMS CMP 1321 Operating and maintenance instructions

Badger Meter

Badger Meter Oval Gear LM OG-AM Series user manual

EFEN

EFEN E3-LE-03MQ CT manual

Narvitech

Narvitech NS110 quick guide

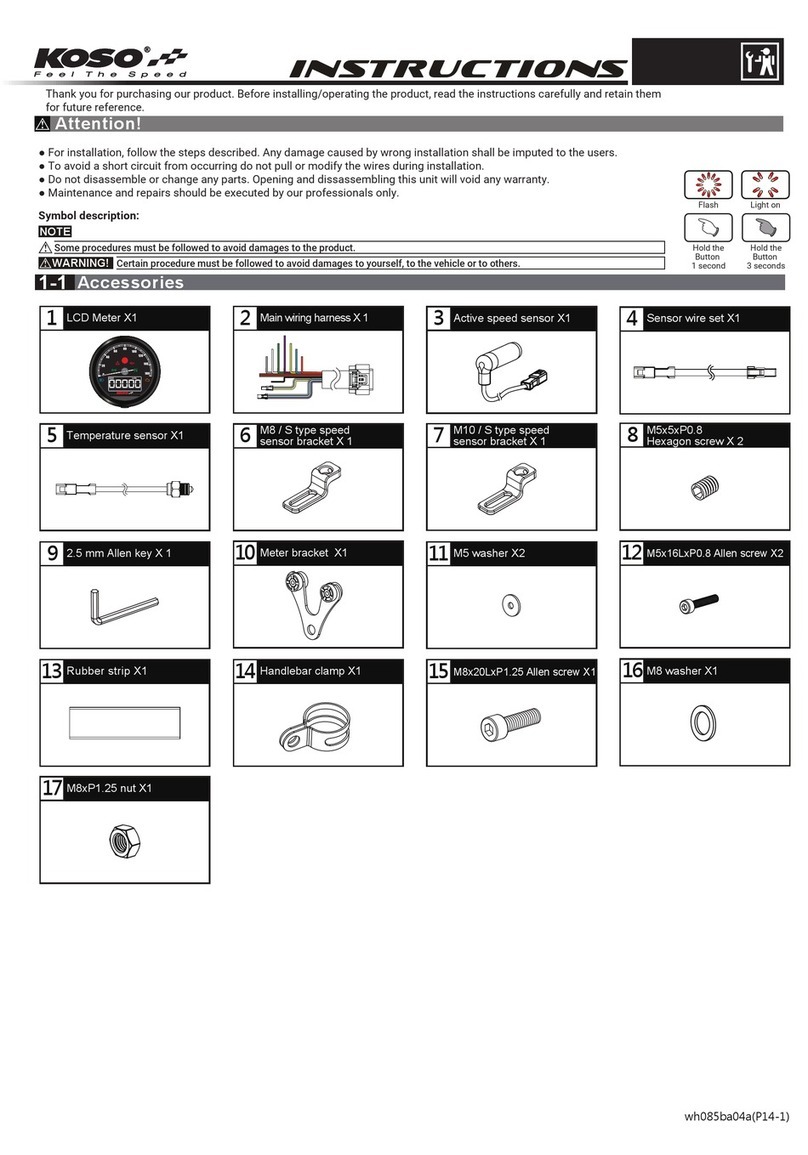

Koso

Koso TNT-05S D60 instructions