6

Notes:

• Air or electric powered pumps only: Once the blade has

stopped cutting at 1000 psi [69 bar], the pressure should be

gradually increased using the pressure regulator on the pump.

Allow adequate time for the blade to cut before increasing

pressure.

• If pressure is increased too quickly, blade damage may result.

Excessive pressure may also cause the nut splitter's internal

relief valve to open, resulting in oil leakage from the oil bleed

hole located on the underside of the blade holder.

• On larger nuts, it may be helpful to periodically retract and re-

lubricate the blade. This will reduce friction and increase blade

efficiency.

11. Continue to apply hydraulic pressure until the nut is

completely severed. As the nut splits, a loud “crack” will be

heard, indicating that the nut has been severed.

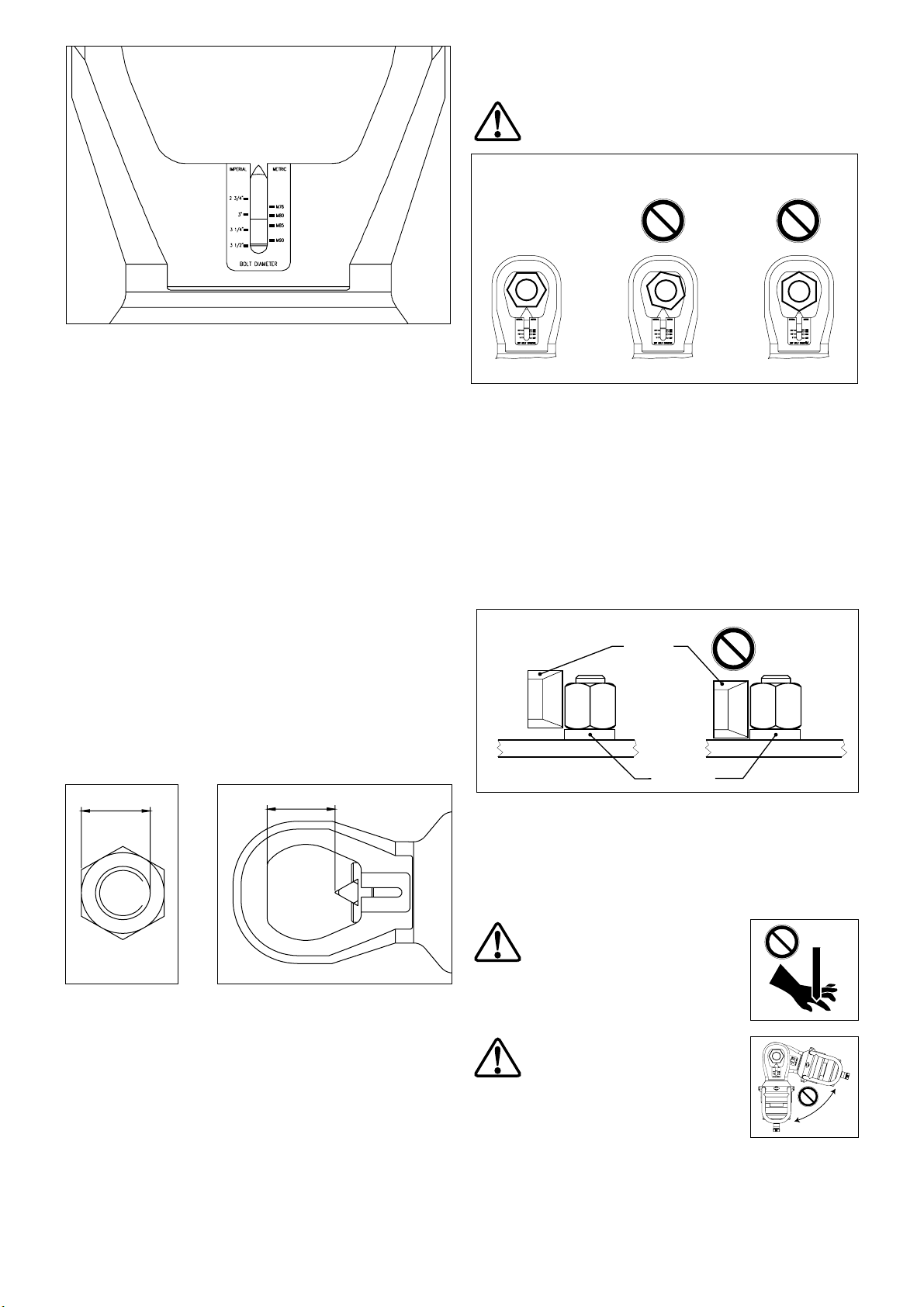

12. If necessary, a second cut

may be applied, at 180° to

the first, completely severing

the nut in half. See Figure

10.

IMPORTANT: Do not cut the

nut into small pieces. Use a

maximum of two cuts and always

at 180º (opposite) to the first.

Otherwise, nut metal fragments

may be released.

13. After the cut is completed:

• Single acting models: Release the pressure to retract

the nut splitter blade.

• Double acting models: Move the control valve to the

retract position to retract the nut splitter blade.

14. Stop the pump. Check that pressure gauge indicates zero

(0) psi/bar.

15. Remove nut splitter from the nut.

16. Remove the severed nut from the stud.

6.4 If Nut Does Not Split at Full Hydraulic Pressure

If the nut splitter is at full pressure, 10,000 psi [700 bar], and

the nut does not split:

WARNING

: Fully release hydraulic pressure and

disconnect hydraulic hose(s) from nut splitter cylinder

before applying lubricant to blade or performing any

other work inside the cutting zone.

1. Ensure that the blade cutting depth setting is correct. Also,

check that the cylinder is not at full stroke.

2. If the blade cutting depth setting is correct and cylinder

is not at full stroke: Release hydraulic pressure and rotate

the cylinder clockwise one full turn. This will allow the blade

to advance 1 to 2 mm further. Then, re-apply hydraulic

pressure and try again to split the nut.

3. If step 2 did not work: Release hydraulic pressure. Re-

lubricate the blade and the groove in the nut where the

blade has penetrated. Then, re-apply pressure, ensuring

that the blade is positioned back in the same nut groove.

4. If step 3 did not work: Re-lubricate the blade and the

nut groove again. Lift and position the nut splitter above

the flange surface so that the blade will penetrate the nut

approximately ²⁄³the height of the nut, and in the same

groove. Then, re-apply pressure.

5. If step 4 did not work: Install a larger cutting head (if

available) or use a larger nut splitter model. Be certain

that the nut size is within the larger equipment's operating

range.

6.5 After Using the Nut Splitter

1. Ensure that the nut splitter cylinder is fully retracted. If it

is fully or partially advanced, reconnect the cylinder to

the pump and allow time for full retraction to occur. After

ensuring that there is no pressure present in the system,

disconnect the hydraulic hose(s) from the cylinder.

2. Using a clean cloth, wipe away any debris from the nut

splitter components. Pay particular attention to the cutting

head and blade area. Remove all traces of lubricant from

the blade.

3. Reinstall dust caps and/or plugs on all hydraulic couplers.

4. If the nut splitter is to be stored in damp conditions or will

not be used for a long period of time, coat exterior surfaces

with a water-repellent spray or similar removable protective

coating.

5. Store the nut splitter subassemblies in their storage cases.

7.0 CUTTING BLADE REPLACEMENT

The blade features three separate cutting edges. If one edge

becomes damaged or severely chipped, the blade can be

removed, rotated 120 degrees, and reinstalled to provide a

new cutting edge.

IMPORTANT: After all three edges are worn, the blade should

be replaced. Do not attempt to sharpen worn or damaged

blades.

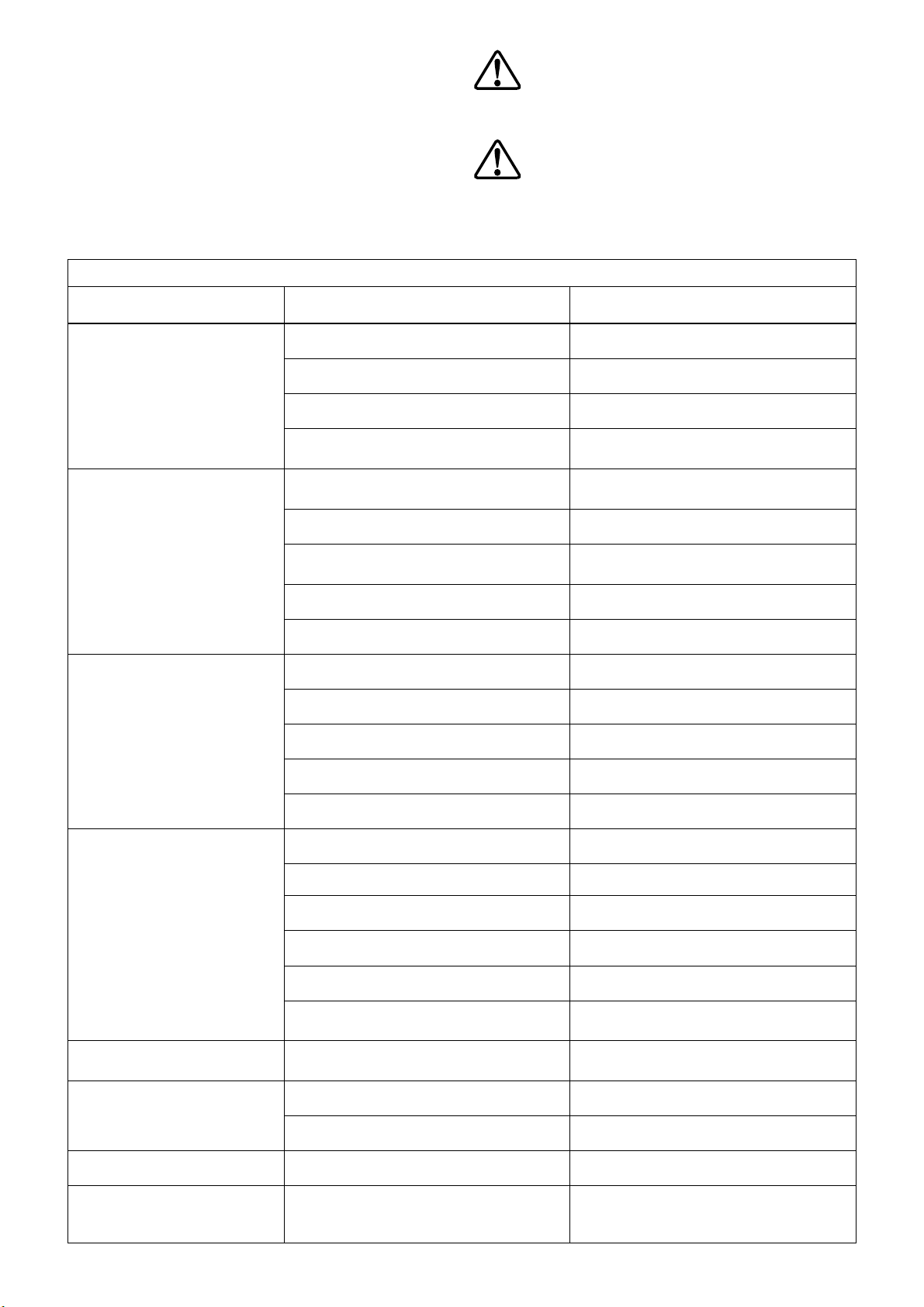

Replace the blade as described in the following steps. See

Figure 11.

1. Be sure that nut splitter cylinder is fully retracted and that

pressure gauge indicates zero (0) psi/bar. Disconnect

hydraulic hose(s) from cylinder coupler(s).

2. Slide the blade from the holder and out through the

underside of the head. If the blade is tight, a light tap on the

top surface of the blade should free it from the ball detent

mechanism.

C

AUTION: Be careful when handling blades. Fractured

edges can be sharp. Wear appropriate hand protection

when removing and installing blades.

3. Determine if the old blade has any reusable edges. If a new

blade is to be installed, refer to Section 3.1 for replacement

blade part numbers. Be sure to use the proper blade for the

cutting head used on your nut splitter model.

Ball Detent

Blade

(removed)

Blade

(installed)

Figure 11, Cutting Blade Replacement

Fig. 10, Making Two Cuts