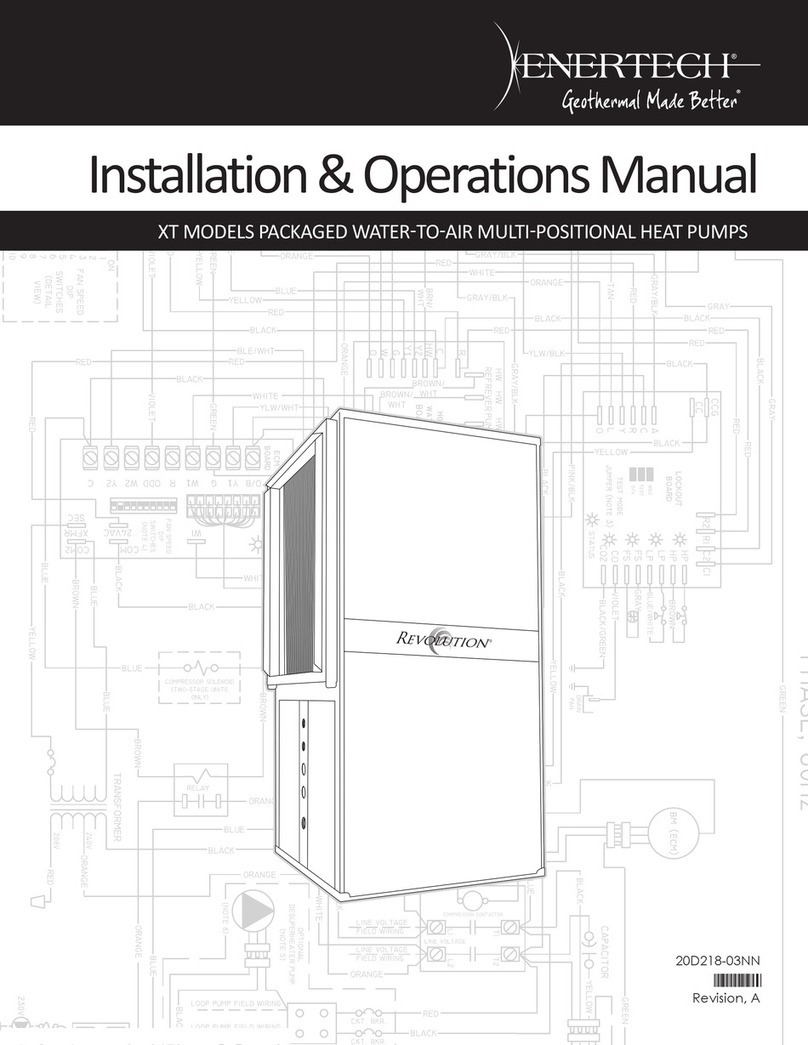

Enertech Global, LLC 13 AV : MD/ME - Rev. A Models

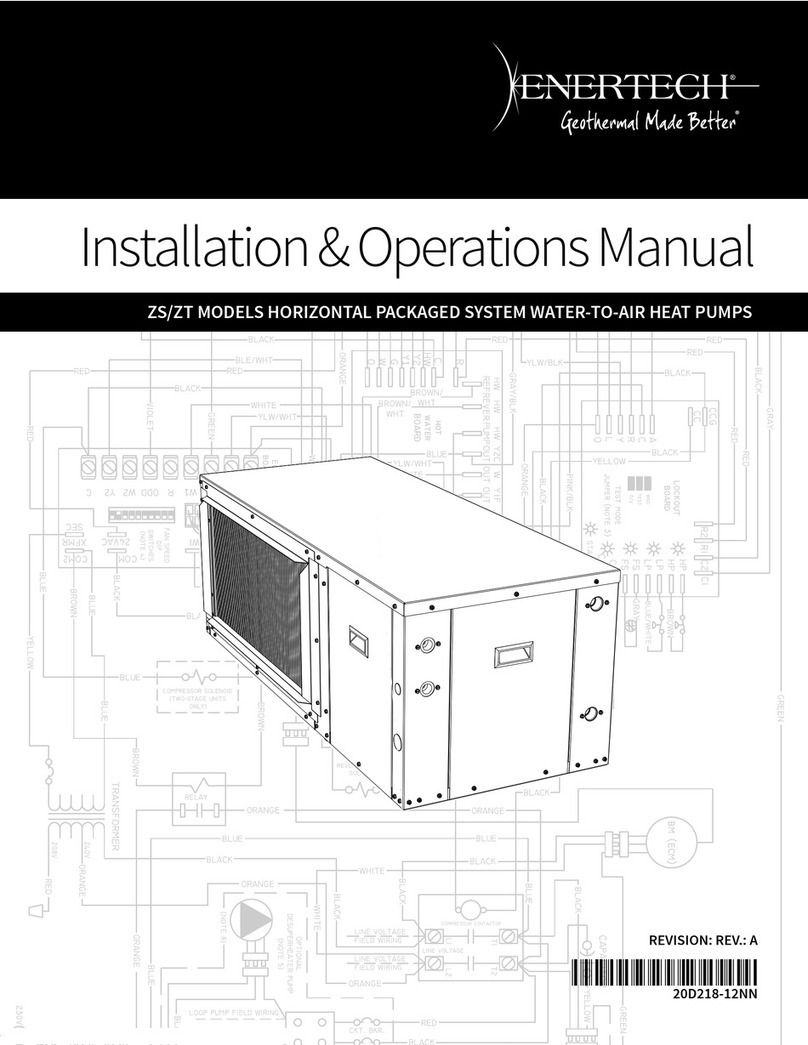

Installaon and Operaons Manual

A New Era with Advantage

Enertech’s Advantage system was painstakingly engineered to

funcon awlessly between space condioning and domesc

hot water. Our indoor module has truly set the bar with the

rst turnkey total comfort soluon. With its integrated electric

or dual fuel opon, each backing up heang and DHW, you’ll

never be le out in the cold!

Safety Labeling and Signal Words

The signal words NOTICE, DANGER, WARNING, CAUTION, and

Note are used on product labels and throughout this manual

to idenfy levels of hazard seriousness.

“NOTICE” Nocaon of installaon, operaon or

maintenance informaon which is important, but which is

NOT hazard related.

“CAUTION” Indicates a potenally hazardous situaon or an

unsafe pracce which, if not avoided, COULD result in minor

or moderate injury, product or property damage.

“WARNING” Indicates a potenally hazardous situaon

which, if not avoided, COULD result in death or serious injury.

“DANGER” Indicates an immediate hazardous situaon

which, if not avoided, WILL result in death or serious injury.

“Note” Used to highlight suggesons which will result in

enhanced installaon, reliability, or operaon.

Upon receipt of any equipment, carefully check the shipment

against the packing slip and the freight company bill of lading.

Verify that all units and packages have been received. Inspect

the packaging of each package and each unit for damages.

Ensure that the carrier makes proper notaon of all damages

or shortage on all bill of lading papers. Concealed damage

should be reported to the freight company within 5 days.

If not led within 5 days the freight company can deny all

claims.

Note: Nofy Enertech Global, LLC shipping department of all

damages within 5 days. It is the responsibility of the purchaser

to le all necessary claims with the freight company.

Enertech units are mounted to wooden pallets for easy

handling during shipment and installaon. Units are protected

during shipment with durable cardboard corner posts, top and

air coil panels. Shrink wrap is applied covering the enre unit

and aachment to the pallet.

Upon receipt of the unit, carefully remove the shrink wrap.

Using a box cuer, slit the shrink wrap on the cardboard top

and corner posts. Use cauon to not damage the nished

surface of the unit. Keep all cardboard or other packaging

material for safe storage and transport to the job site prior to

installaon.

Remove the front service panel to locate technical documents;

manuals, bullens or instrucons and accessory items; HWG

piping kits, and strainers.

⚠CAUTION ⚠

DO NOT OPERATE THE HEAT PUMP UNIT DURING

BUILDING CONSTRUCTION PHASE

Protect units from damage and contaminaon due to

plastering (spraying), painng and all other foreign materials

that may be used at the job site. Keep all units covered on

the job site with either the original packaging or equivalent

protecve covering. Cap or recap unit connecons and all

piping unl unit is installed. Precauons must be taken to

avoid physical damage and contaminaon which may prevent

proper start-up and may result in costly equipment repair.

Storage

All units should be stored inside in the original packaging, in

an upright posion at all mes. Units should not be stacked

unless specially noted on the packaging.

Removal and Disposal

All units removed from service should have all components,

oils, anfreeze and refrigerants properly disposed of

according to local and naonal environmental recycling codes,

regulaons, standards and rules.

Before you fully install the equipment, it is recommended you

do the following:

1. Fully inspect the unit after unpacking

2. Compare the electrical data on the unit nameplate with

packing slip and ordering information to verify that the

correct unit has been shipped.

3. Inspect all electrical connections and wires. Connections

must be clean and tight at the terminals, and wires

should not touch any sharp edges or copper pipe.

4. Verify that all refrigerant tubing is free of dents and

kinks. Refrigerant tubing should not be touching other

unit components.

5. Before unit start-up, read all manuals and become

familiar with unit components and operation.

Thoroughly check the unit before operating.

6. Locate the Unit Start-Up Form from this manual and

have it available as the unit installation proceeds.

Installaon locaon should include adequate service clearance

around the unit, and be oriented in a way that piping or other

permanently installed xtures do not have to be removed

for servicing. The Indoor Module should be located in a

condioned space where the ambient temperature remains

between 55oF and 95oF with a maximum RH of 78-80%.

Secon 3: Introducon & Operaonal Consideraons

⚠ CAUTION ⚠

THE EME/EMD SERIES EQUIPMENT IS DESIGNED FOR

INSTALL THE EME/EMD MODULE OR STORE IN A

CORROSIVE ENVIRONMENT OR IN A LOCATION

WHERE TEMPERATURE AND HUMIDITY ARE SUBJECT

TO EXTREMES. EQUIPMENT IS NOT CERTIFIED FOR

OUTDOOR APPLICATIONS. SUCH INSTALLATION WILL

VOID ALL WARRANTIES.

⚠ NOTICE ⚠

WHEN REMOVING PANELS, GIVE SPECIAL ATTENTION

TO CABINET INSULATION. INTERLOCKING INSULATION

EXTENDS BEHIND THE FRONT PLASTIC FAN GRATE. IF

NEEDED, REMOVE LEFT CORNER PANEL AND FRONT

PLASTIC FAN GRATE TO REMOVE INSULATION.