5Ideal airtherm - Air Source Heat Pump - Installation

GENERAL

INTRODUCTION

This installation manual is accompanied by a user guide (see

reverse of this book), a commissioning record sheet and a

warranty registration card, all of which should be left with the

householder. The user guide explains how the system works,

how it is controlled and what to do in the event of a problem.

The commissioning record sheet must be completed as its

production will be required in the event of a warranty claim.

HEATING WITH A HEAT PUMP

The Ideal heat pump is designed to operate up to 65oC water

temperature for the domestic hot water delivery, and negates

the need for direct electrical heating in the form of an electrical

emersion heater. The unit also provides space heating

temperatures variable from 35oC to 55oC.

Heat pumps for domestic heating are a fully proven technology

which will give many years of trouble-free service. Ideal Heat

Pumps which are MCS approved have been specifically

designed for optimum operation in the UK’s climate.

However, unlike an oil or gas boiler which may be oversized for

the heating demand of the property and therefore regularly

cycles on and off, a heat pump is closely matched to the heat

demand and is designed to run for long periods without

switching on/off.

The following steps must therefore always be taken to ensure

a successful installation. Major problems can occur if they are

not taken and failure to comply will invalidate the warranty.

a. SAP or equivalent heat loss calculations must be

established with the results recorded on the

commissioning sheet.

b. The heat pump must be correctly sized in relation to the

calculated heat losses.

c. The space heating system must be capable of satisfying

the heat demand at the water flow temperature set for the

heat pump. This is particularly important where retro-fitting

a heat pump to a radiator system designed originally for a

Delta T of 60oC, as the heat pump will run at a Delta T of

30oC. In this situation, you will normally need to fit larger

radiators.

d. The electrical supply must be adequate to meet the start

current demand.

e. The heat pump and the associated heating system must be

commissioned in accordance with the procedures laid

down in this manual.

A heat pump may be fitted on a stand-alone basis (monovalent

system) to satisfy the full heating and hot water demand of the

property or in parallel with an existing boiler (bivalent system).

In the case of a bivalent installation the heat pump is sized to

provide a variable proportion of the annual heating requirement

(say 85%) with the existing boiler integrated to deliver the

balance on the coldest days. In bivalent systems, the heat

pump is sometimes only linked to the space heating system

which eliminates the requirement to fit a new DHW cylinder.

Standard designs for several different configurations, including

plumbing and electrical circuits, are included in this manual.

REGULATIONS

The Ideal airtherm models confirm

• BS EN60335-1:2002 &2-40:2003, and therefore comply with

the Low Voltage Electrical Equipment Directive 73/23/

EEC;93/68/EC.

• BS EN ISO 12100-1:2003, BS EN ISO 12100-2:2003, BS

EN ISO13857:2008: BS EN ISO 13850:2006, and therefore

comply with the Supply of Machinery (Safety) Directive 98/

37/EC.

• BS EN55014-1:2000+A1:2001+ A2:2002, 14-

2:1997+A1:2001, EN61000-3-2:2000, -3-3:1995 + A1:2001,

-4-2:1995, -4-3:1996, -4-4:1995, -4-5:1995, -4-6:1996, -4-

11:1995.

and therefore comply with the Electromagnetic

Compatibility Directive 2004/108/EC.

• Comply with the Pressure Equipment Directive 97/23/EC,

Fluid Group 2,Category 1.

• Compliant to RoHS Directive 2002/95/EC

SAFETY PRECAUTIONS

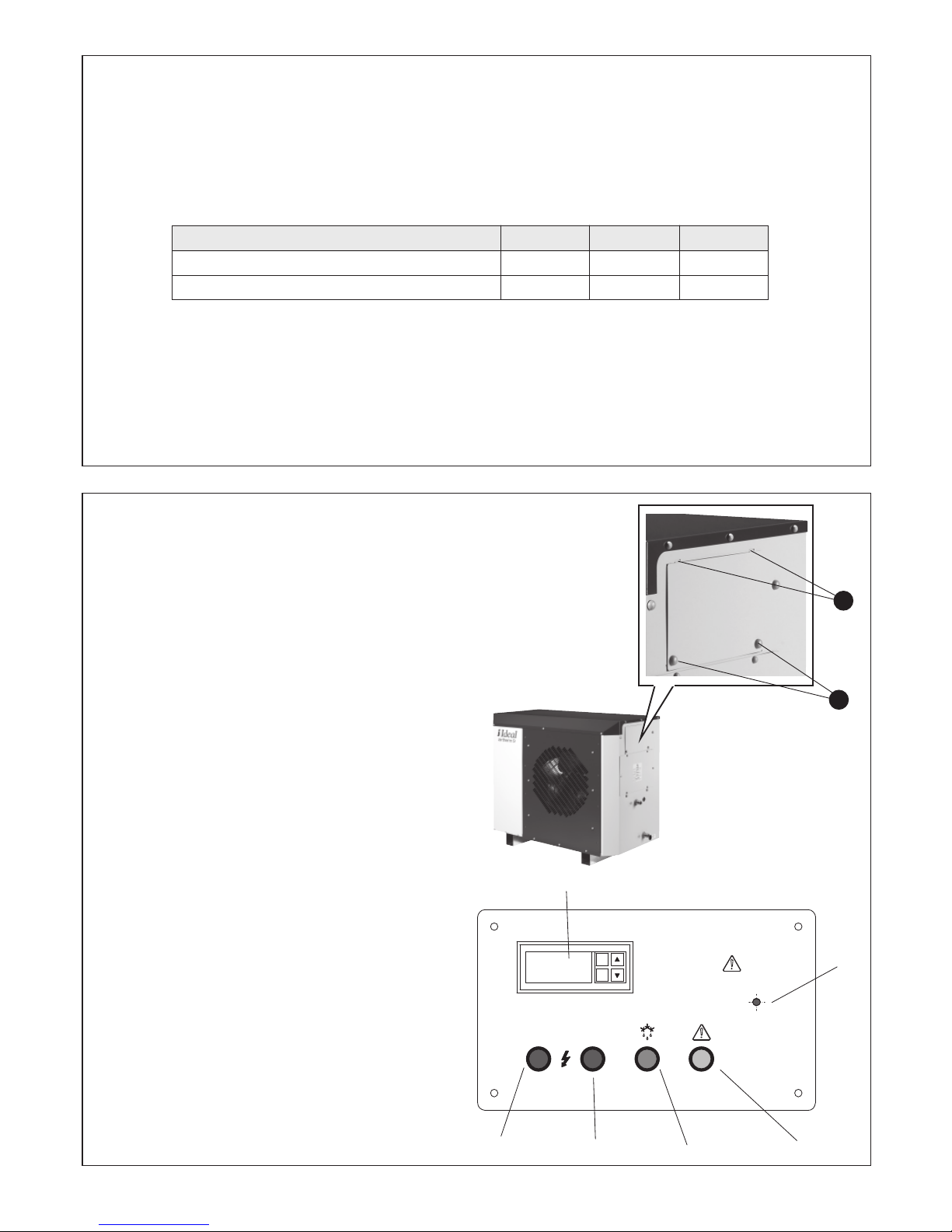

a. The unit must be securely installed on a structure that can

sustain its weight. If mounted on an unstable structure, it

may fall causing injury or damage.

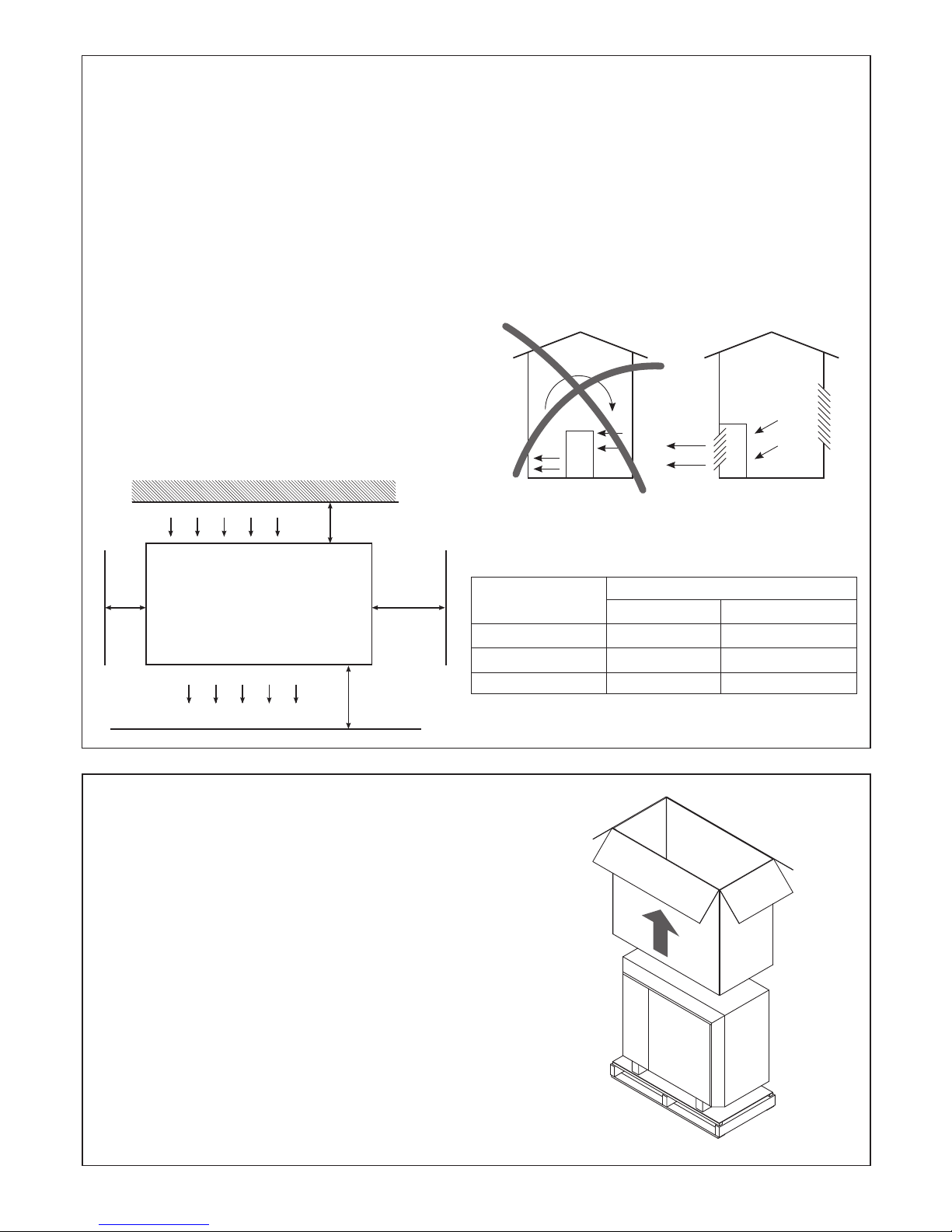

b. If the heat pump is installed in an enclosed area, sufficient

ventilation must be provided so as not to impede the air flow

through the unit and to prevent the concentration of

refrigerant gas in the room building up in the event of a leak.

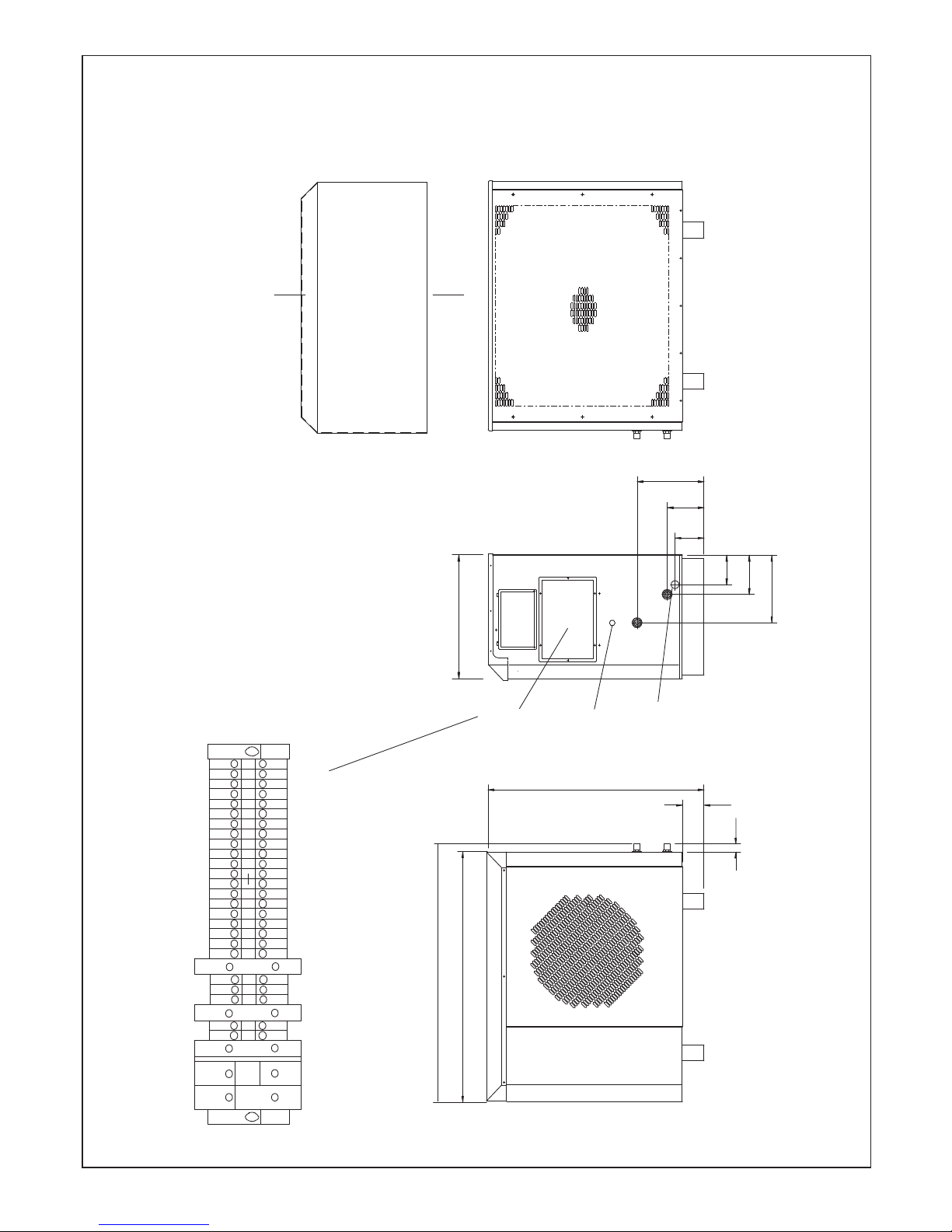

(See diagram - page 6)

c. All electrical work must be performed by a qualified

technician and comply with the latest I.E.E (17th) Regulations.

The machine should be installed in accordance with EMC

2004/108/EC.

d. Electricity to the unit must be supplied through dedicated

power lines and the correct voltage and circuit breakers must

be used. Power lines with insufficient capacity or incorrect

electrical work may result in electric shock or fire. The

electrical ratings of Ideal heat pumps are included in the

datasheet on page 16 of this manual.