Engel MHD13F-DM User manual

MODEL :

MHD13F-DM 0642 013 4020

2020.12

#1

SERVICE MANUAL

●FOR REFRIGERATOR USERS

・

Failing to service properly may result in poor reliability of the refrigerator.

・

Read this booklet carefully and perform servicing with great care.

・

●FOR SAFETY OF YOURSELF

・

●SAFETY SYMBOLS

・

The following warning labels in this booklet indicate precautions for service work.

Comply with what each symbol indicates whenever it appears.

●REFRIGERATOR MODEL

・

This manual is compatible with described model in below.

Please check refrigerator model.

(Lable place as picture)

MODEL

MHD13F-DM

Lead to failure of the refrigerator set or its components if failed to comply

with this precaution

This service manual describes maintenance procedures for ENGEL refrigerator.

This manual is intended for repair engineers who are familiar with basics service skills and

knowledge for ENGEL refrigerator.

This manual does not guarantee correct maintenance when service is done by a non-skilled

worker without technical knowledge.

Note that the content of this booklet including product specifications is subject to change for

improvement without notice.

Always comply with the procedures, directions, and work tips in this booklet when servicing the

refrigerator.

To secure safe and correct servicing, read this manual thoroughly in advance and check if there

are protective equipment and appropriate tools and service parts ready as well as technical skills

necessary to perform servicing.

May lead to death or serious injury if failed to comply with this precaution

May lead to injury if failed to comply with this precaution

WORK TIPS

CONTENTS

1. SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

■ Specifications Table ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

■ Dimensions ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2

2. INSTALLING A REFRIGERATOR ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3

■ Installation ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 3

■ Temperature Setting ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4

3. PARTS NAME ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5

4. CONNECTING DIAGRAM ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6

■ Block Diagrams ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6

■ Wiring Diagrams ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6

5. TROUBLE SHOOTING ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7

■ Error Code (digital display) ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7

■ Does not get Cold ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

8

■ Cooling is Weak ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9

■ Refrigerator is too Cold. (Can not be temperature adjustment) ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10

■ It will not get Hot ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10

■ Typical Problem ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11

■ Technical Data ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11

6. CHECK POINT&CHECK METHOD ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

【Check 1】 Special Fuse. ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

【Check 2】 Output Voltage of the Power Supply. ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

【Check 3】 Input Voltage of the Compressor. ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

【Check 4】 Resistance of the Compressor. ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13

【Check 5】 Resistance of the EVA. Thermistor. ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13

【Check 6】 Resistance of the Heater Assy. ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13

【Check 7】 Fan Motor Assy. ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

14

【Check 8】 Compressor Rated Current. ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

14

7. REPLACING PARTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

15

【How to Replace Cooling System】 ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

15

【How to Replace Power Supply】 ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

16

【How to Replace Fan Motor】 ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

16

【How to Replace Control Assy】 ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

17

■ Specifications Table

L

in

mm

in

mm

Material

Heat

insulator

Material

Heat

insulator

V

Refrigerator

(With fan)

A

Warm

(The fan motor stop)

A

LBS.

Kg

※ Tolerance is omitted

1. SPECIFICATIONS

MODEL

MODEL CODE

STORAGE VOLUME

13

EXTERIOR DIMENSIONS

W×D×H

17.4×11.2×14.6 ※

442×284×372 ※

MHD13F-DM

0642 013 4020

INTERIOR DIMENSIONS

W×D×H

13.7×7.5×7.5 ※

348×190×190 ※

DOOR

Polypropylene resin

Foamed polyurethane

CABINET

Polypropylene resin

Foamed polyurethane

INPUT VOLTAGE

DC 12/24

INPUT CURRENT

DC12V/3.0A DC24V/1.5A

DC12V/2.8A DC24V/1.4A

COMPRESSOR RATING

AC 15V, 27W

REFRIGERANT

Dichlorodifluoromethane (HFC-134a)

TEMPERATURE RANGE

−18℃ to 45℃

(Ambient of 25℃ at no load )

TEMPERATURE CONTROL

Automatic temperature control by dial setting

(Electronic thermostat control type)

WEIGHT

25.3

11.5

1

■ Dimensions

※ Tolerance is omitted

(mm)

1. SPECIFICATIONS

2

284

190

442

372

348

190

■ Installation

①

②

③

④Install refrigerator away from each wall at least 150mm or more. (Fig 2)

⑤Avoid installing your fridge close to a kitchen sink or faucet. (water)

⑥Clean the interior with a cloth moistened in warm water and wipe with a dry cloth.

⑦Never use the ENGEL refrigerator inside a freezer container car or refrigerator container car.

3

2. INSTALLING A REFRIGERATOR

Your shockproof fridge should be installed on a level and solid surface although it will operate

satisfactory for long period on angles of up to 30°.

Be sure your fridge is not in direct sunlight, (Fig 1) near a gas stove, heater, or other heat-generating

appliances.

In order to get good cooling performance and less current consumption, adequate ventilation for

refrigerator is needed.

Condensation can easily occur in the interior of the refrigerator container car and freezer container car,

causing water drops to fall in the refrigerator and damage the equipment.

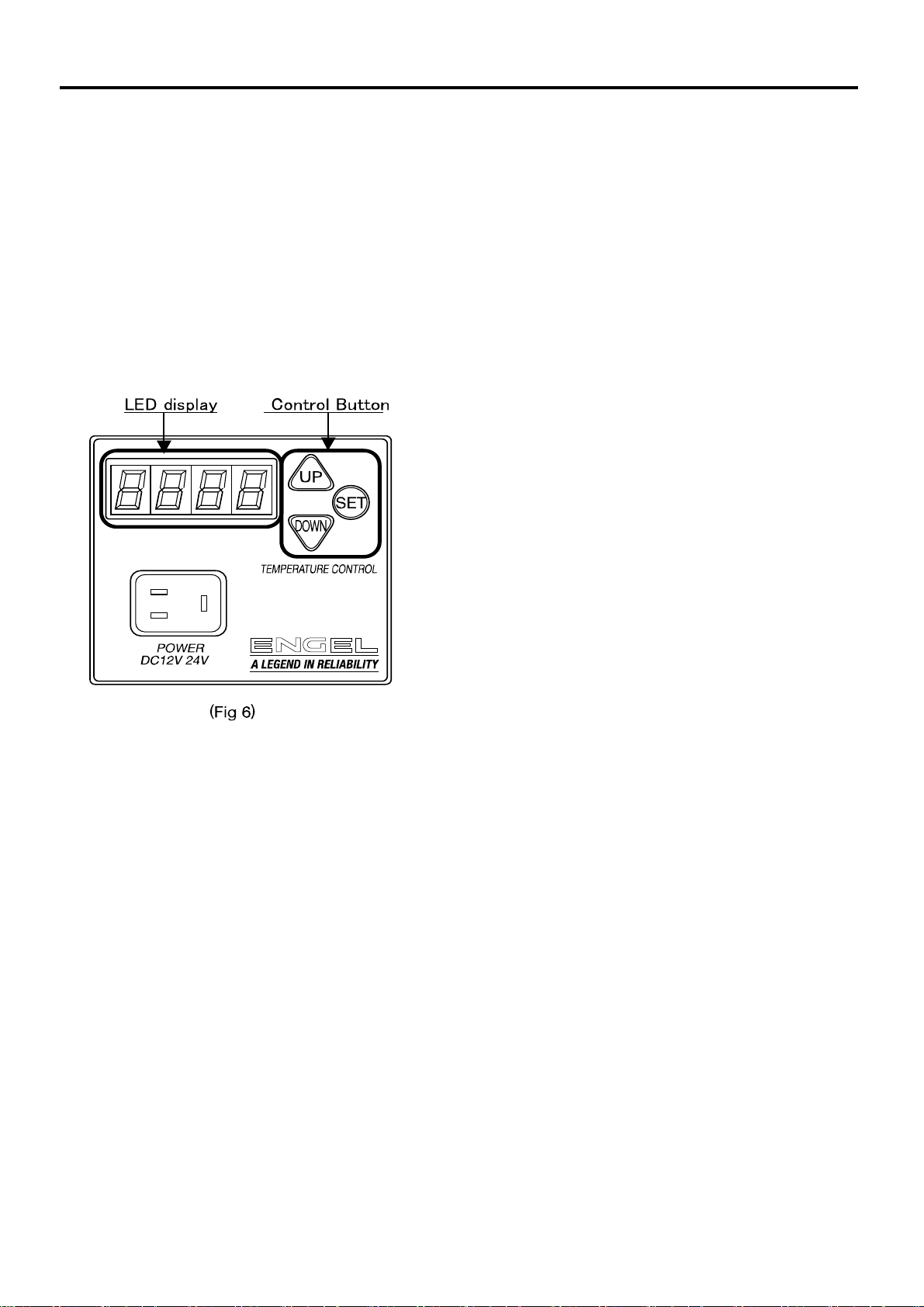

■ Temperature Setting

Set the cabinet inside air temperature range by means of the Temperature controller.

TEMPERATURE SETTING (see Fig 6)

Temperature range – Achievable temperature from -18 ~ 55℃ ( 0 ~ 131°F ) at Ambient of 25°C (77°F).

The preset temperature is displayed when the LED starts blinking.

The approximate interior temperature of the cabinet will be displayed once the LED lights up.

When the “SET” button is depressed for 3 seconds (long push), the LED display will blink.

During this mode, the cabinet temperature can be selected by pressing the “UP” and ”DOWN” button.

Pressing/holding onto the “UP” and ”DOWN” buttons will continuously change the range of the temperature.

SELECTING TEMPERATURES (°C or °F).

TROUBLESHOOTING

When error message is displayed, the unit will be on “standby mode”. Operations will stop.

2. INSTALLING A REFRIGERATOR

After pre-setting the temperature, the LED display will

stop blinking (after a few seconds), indicating the

temperature has been set (lock).

It is not necessary to reset the temperature again as the

temperature has been stored.

The product will now operate at the selected

temperature.

It is possible to select between Celsius or Fahrenheit with product.

When the “SET” button is depressed for 3 seconds, the LED display will blink. Pressing the “SET”

button during this mode will display the °C →°F →°C →°F change.

After pre-setting the temperature, the LED display will stop blinking (after a few seconds), indicating the

temperature has been set (lock).

Error message will be displayed if the voltage of the battery is low or in the event of any malfunctions –

(See page 9 ).

4

3. PARTS NAME

5

SHOULDER STRAP

CONTROL ASSY

(TEMPERATURE

CONTROLLER)

FAN MOTOR

POWER SUPPLY

COOLING SYSTEM

LATCH ASSY

DIAL

DOOR ASSY

CASE BOTTOM

TERMINAL BLOCK

DC CORD

HINGE

SPECIAL FUSE

HOLDER ASSY

COMPRESSOR

EVAPOLATOR

THERMISTOR (EVA. THERMISTOR)

(It is inside the insulation)

WIRE

CONDENSER

HEATER ASSY

■ Block Diagrams

■ Wiring Diagrams

4. CONNECTING DIAGRAM

6

■Error Code (digital display)

Error message will be displayed if the voltage of the battery is low or in the event of any malfunctions – (see table below).

When error message is displayed, the unit will be on “standby mode”. Operations will stop.

※DEFAULT VALUES FOR BATTERY PROTECTION

5. TROUBLE SHOOTING

7

An error is displayed

on the digital display.

※(MHD13F-DM Only)

Normal

Yes

No

No

Yes

Yes

No No

Yes

No

※1 Ambient temp 25℃

※2 Ambient temp 25℃ to -16℃ ※4 Replacement of only the thermistor can not.

※3 Use tester: Digital multimeter It will be the exchange of the cooling system.

5. TROUBLE SHOOTING

8

Yes

■Does not get Cold.

Checking

Is fuse blown?

Are wirings and couplers

connected?

Power check on the

vehicle side

Replace the fuse

See page 12

【Check 1】

Test result

Judge

Fixing

Connected repair.

Resistance of the compressor.

Approx. 1.6Ω ※1, ※3

Compressor coil is

disconnection.

Replace the

cooling system.

0Ω

Compressor coil is

shorted.

∞Ω

Resistance of the thermistor.

Approx. 2kΩ -10kΩ※2

Thermistor is broken.

∞Ω

Power supply output voltage.

Approx. AC11V - 18V ※1

AC 0V

Power supply is

broken.

Replace the

power supply.

Lower than AC11VOutput

maladjustment.

See page 13

【Check 5】

Normal

Normal

Normal

Power supply output voltage.

Approx. AC11V - 18V ※1

Lower than AC11V

Replace the

power supply.

Output

maladjustment

See page 13

【Check 4】

See page 12

【Check 2】

DC

cord

lamp

lit?

Is compressor

running?

Replace the

cooling system.

※4

The compressor is locked, or

contaminated.

Replace the

cooling system.

A

See page 12

【Check 2】

Higher than 2.0A

The compressor is locked, or

contaminated.

Lower than 1.7A Gas is leaking.

Compressor rated current.

Approx. 1.7A - 2.0A

Replace the

cooling system.

See page 14

【Check 8】

Is cont

rol assy

digital display lit

?

Replace the

control assy

※1 Ambient temp 25℃

9

5. TROUBLE SHOOTING

■Cooling is Weak

Checking

Test result

Judge

Fixing

Battery voltage is lower than 10V

Voltage is too low.Voltage of battery 10V - 13V?

Charge the bettery

Is the machine part ventilated enough?

Make at least 150mm

room between unit and

wall.

YES

NO

Normal

Please keep the ambient

temperature below 30℃.

Ambient temperature is

too high.

Ambient temparature is higher than 30℃

NO

YES

There are too many things in the refrigerator.

Make some room

for cool air.

YES

Power supply output voltage.

Approx. AC11V - 18V ※1

Lower than AC11V

Replace the power supply.

Output maladjustment

Is the fan motor running?

NO

Fan motor is broken.

Replace the fan motor.

YES

Higher than 2.0A

The compressor is locked, or

contaminated.

Lower than 1.7A Gas is leaking.

Compressor rated current.

Approx. 1.7A - 2.0A

Replace the

cooling system.

NO

Normal

See page 13

【Check 5】

See page 13

【Check 6】

Insufficient ventilation.

Cool air does not spread.

See page 14

【Check 7】

See page 14

【Check 8】

Normal

※2 Ambient temp 25℃ to -16℃

※4 Replacement of only the thermistor can not.

It will be the exchange of the cooling system.

Normal

5. TROUBLE SHOOTING

10

■Refrigerator is too Cold.

(Can not be temperature adjustment)

Checking

Test result

Judge

Fixing

Resistance of the thermistor.

Approx. 2kΩ -10kΩ ※2

Thermistor is short.

0Ω

0Ω

Heater assy is shorted.

∞Ω

Replace the

heater assy

.

Heater assy is broken.

See page 13

【Check 5】

Replace the

cooling system.

※4

Replace the

control assy

■It will not get Hot.

(Can not be temperature adjustment)

Replace the

control assy

Resistance of the heater assy.

Approx. 4.4Ω - 5.1kΩ

See page 13

【Check 6】

※1 Ambient temp 25℃

■ Typical Problem ※2 Ambient temp 25℃ to -16℃ ※4 Replacement of only the thermistor can not.

※3 Use tester: Digital multimeter It will be the exchange of the cooling system.

Symptoms Cause Test Result Treatment

Resistance of compressor is ∞Ω

・Normal: Approx. 1.6Ω ※1, ※3

Output voltage of power supply is AC 0V

・Normal: Approx. AC11-18V ※1

Resistance of EVA. thermistor ∞Ω

・Normal: Approx. 2kΩ-10kΩ ※2

Replace of cooling system

Replace fan motor

Charge the bettery

-

Make some room for cool air

Resistance of the heater assy is ∞Ω

・Normal: Approx. 4.4Ω - 5.1kΩ

Replace the fuse

Replace the fuse

Check the vehicle

■ Technical Data ※1 Ambient temp 25℃ ※3 Use tester: Digital multimeter

※2 Ambient temp 25℃ to -16℃

Checking Points Normal data

Current value measurement with clamp meter between

input cord terminals.

Compressor rated current

Approx. 1.7A - 2.0A

Replace power supply

Make at least 150mm room

between unit and wall

Between terminals of compressor

DC cord lamp is not lit.

Cooling is weak

Digital display is lit.

Resistance of the compressor

Special Fuse

Fuse at power supply

5. TROUBLE SHOOTING

Approx. 2KΩ - 10KΩ ※2

Between incoming cords to compressor

Gas is leaking from Cooling Unit

Fan motor is broken

Input voltage is lower than 10V

The special fuse inside DC cord is open

Replace the cooling system

Replace the cooling system

※4

EVA. thermisitor is open

Coil of the compressor is open

Compressor does not work

Power supply is broken

Inside of the fridge does

not get cold

It will not get hot.

Ambient temparature is higher than 30℃

Fuse in the vehicle is open

Ventilation at mechanical part is not enough

Checking items

Output voltage of power supply

Input voltage at compressor

Too many things are put inside

Approx. AC 11V - 18V ※1

Between outgoing cords from power supply

Approx. AC 11V - 18V ※1

Socket or other DC power line in the vehicle is bad

11

Replace the heater assy

Heater assy is broken

Resistance of the heater assy

Between two pin of the coupler

Approx. 4.4Ω - 5.1kΩ

0Ω

Resistance of EVA. thermistor

Between two pin of the coupler

Approx. 1.6Ω ※1, ※3

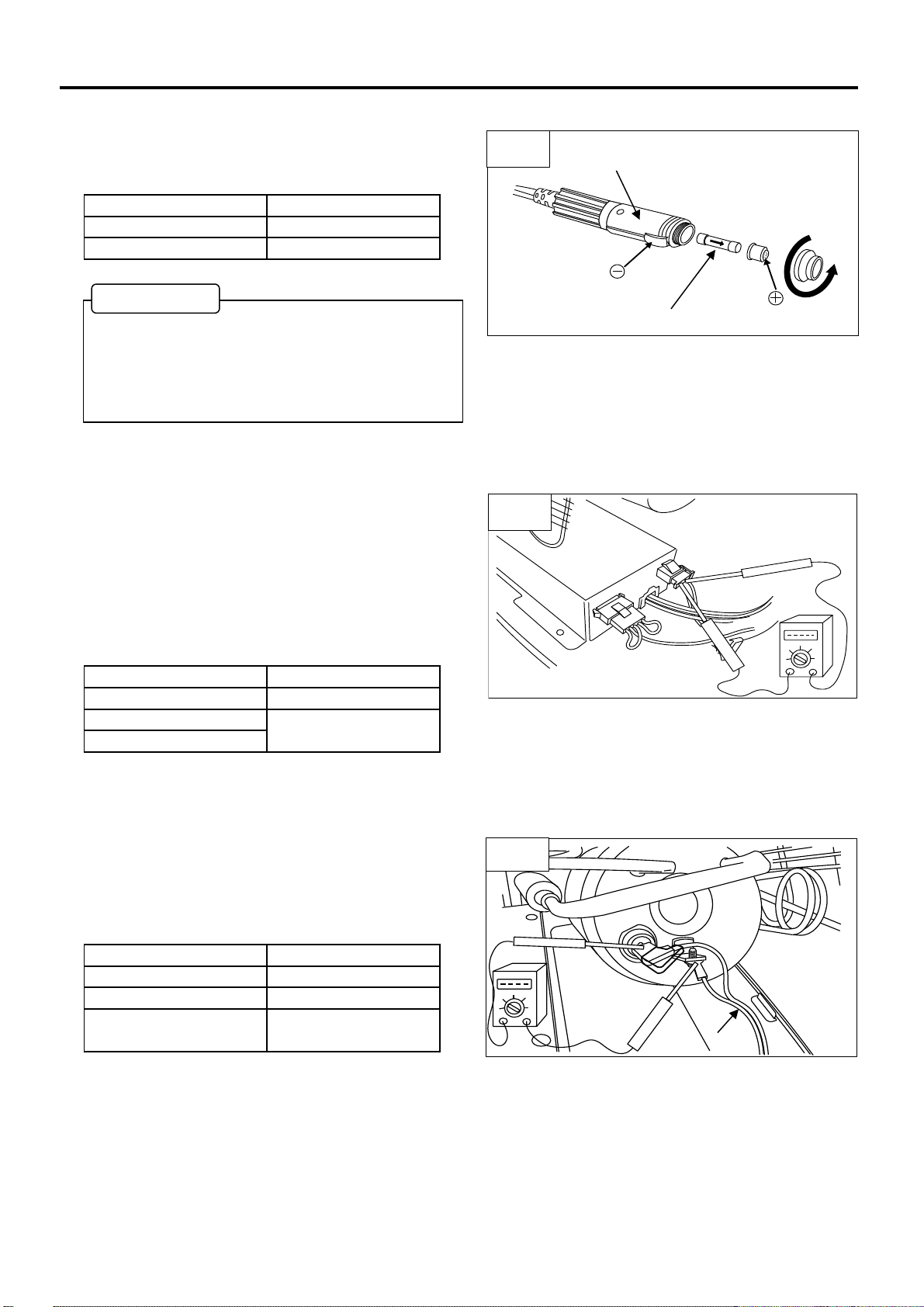

【Check 1】 Special Fuse. (Fig.1)

◇ Check the resistance of special fuse by tester.

Test result Judge

0Ω Normal

∞Ω Broken

【Check 2】 Output Voltage of the Power Supply. (Fig.2)

◇Checking point

・Check at two pin coupler of power supply

or at input terminals of the compressor.

(See 【Check 3】)

(Ambient temp 25℃)

Test result Judge

Approx. AC11V - 18V Normal

Lower than AC11V

AC 0 V

【Check 3】 Input Voltage of the Compressor. (Fig.3)

◇Checking point

Voltage measurement between terminals of input cord.

Test result Judge

Approx. AC11V - 18V Normal

Lower than AC11V Power Supply is broken

12

6. CHECK POINT&CHECK METHOD

AC 0 V

Power Supply is broken or

input cord disconnection

Power Supply is broken

Fig.1

SPECIAL FUSE

DC CORD

Fig.2

Fig.3

INPUT CORD

・Please attach attention to the special fuse of

orientation.

・It can not detect the temperature is in the wrong

special fuse orientation. (※)

WORK TIPS

※

【Check 4】 Resistance of the Compressor. (Fig.4)

◇Checking points

Remove two pin couplers at input cord, and check.

(Ambient temp 25℃)

Test result Judge

Approx. 1.6 Ω Normal

∞Ω Broken

※3 Use tester: Digital multimeter

【Check 5】 Resistance of the EVA. Thermistor. (Fig.5)

◇Checking points

Remove the two pin couplers from power supply, and

test.

(Ambient temp 25℃ to -16℃)

Test result Judge

Approx. 2 kΩ - 10 kΩ Normal

∞Ω Broken

0Ω Short Circuit

※ When short circuit, compressor runs continuously.

【Check 6】 Resistance of the Heater Assy. (Fig.6)

◇Checking points

Remove the two pin couplers from power supply, and

test.

Test result Judge

Approx. 4.4Ω - 5.1Ω Normal

∞Ω Broken

0Ω Short Circuit

13

0Ω

Coil of compressor is short

circuit

6. CHECK POINT&CHECK METHOD

Replacement of only the EVA. thermistor can not.

It will be the exchange of the cooling system.

WORK TIPS

Fig.4

※3

INPUT CORD

Fig.5

BROWN

Fig.6

BROWN

Replacement of only the heater assy can not.

It will be the exchange of the cooling system.

WORK TIPS

【Check 7】 Fan motor Assy. (Fig.7)

◇Checking point

If the refrigerator of the switch is ON, the fan motor will start.

Please make sure that the wind has come out by hand.(Fig.7)

If the wind does not come out (fan is not moving),

the failure of the fan motor or, will be the code breaking.

◇Checking point

If want to check the start-up of the fan motor directly,

can check by connecting the DC12V directly. (Fig.8)

【Check 8】 Compressor rated current (Fig.7)

◇Checking point

Test result Judge

Approx. 1.7 - 2.0A Normal

Lower than 1.7A Gas is leaking.

14

Compressor is locked, or

contaminated.

Higher than 2.0A

Current value measurement with clamp meter

between input cord terminals.

6. CHECK POINT&CHECK METHOD

・Please be careful not to mistake the polarity of the

power supply.

・When connect with DC24V or wrong polarity,

fan motor will fail.

・Please use such as support coupler so as not to

short-circuit power.

Fig.7

Fig.8

CLAMP METER

To measure the rated current of the compressor,

please measure after 10 minutes or more after

starting the refrigerator.

Fig.9

WORK TIPS

INPUT CORD

SUPPORT COUPLER

【How to Replace Cooling System】

1. Remove four screw (Fig.1-①), remove the door assy.

2. Remove screw (Fig.1-②), remove the latch

3. Remove four screw, remove the bottom case.(Fig.2-①)

4. Remove two screws that stop the wire condensor. (Fig3‐①)

5. Remove two screws, remove the holderassy. (Fig3-②)

6. Remove two pin coupler of EVA. thermistor. (Fig4-①)

7. Remove two pin coupler of heater assy. (Fig4-②)

7. REPLACING PARTS

15

LATCH

Fig.1

②

①

DOOR

ASSY

①

Fig.2

CASE BOTTOM

Fig.4

①

In the case of power supply only exchange,

WORK TIPS

Fig.3

①

②

During assembly, please tighten the screws in

the same position as the removed screw

position. (See below; "Screws position")

WORK TIPS

1st

9th

10th

7th

6th

1st

7th

6th

1st

1st

7th

8th

Screws position

POWER SUPPLY

HOLDER ASSY

WIRE CONDENSER

SCREW

WORK TIPS

②

8.

9.

【How to Replace Power Supply】

1.

2. The fastener is cut by two places.(Fig.7-①)

3. Remove two flag terminals. (Fig.7-②)

【How to Replace Fan Motor】

1.

2. Remove two screws. (Fig.8‐①)

3. Remove the coupler. (Fig.8‐②)

7. REPLACING PARTS

16

Remove two screws (Fig.5-①) and remove the

two couplers.(Fig.5-②)

Pull out the power supply and holder assy from

the main body. (Fig.5-③)

Remove the input cord from the compressor.

(Fig.6-①、②)

Perform the procedure of how to replace the

cooling system. (Page 17 Step 3~8)

Perform the procedure of how to replace the

cooling system. (Page 17 Step 3~5)

Fig.5

②

Fig.6

①

②

②

Fig.7

②

POWER SUPPLY

Fig.8

①

③

①

POWER SUPPLY

③

HOLDER ASSY

INPUT CORD

In the case of power supply only exchange,

the holder assembly is not removed.

WORK TIPS

①

②

FAN MOTOR

【How to Replace Control Assy】

1. Perform the procedure of how to replace the

cooling system. (Page 17 Step 3~5)

2. Remove the five coupler. (Fig.9‐①)

3. Remove the screws. (Fig.9‐②)

4. Remove the screws. (Fig.10‐①)

17

7. REPLACING PARTS

Fig.9

②

①

①

①

Fig.10

Other manuals for MHD13F-DM

1

This manual suits for next models

1

Table of contents

Other Engel Refrigerator manuals

Engel

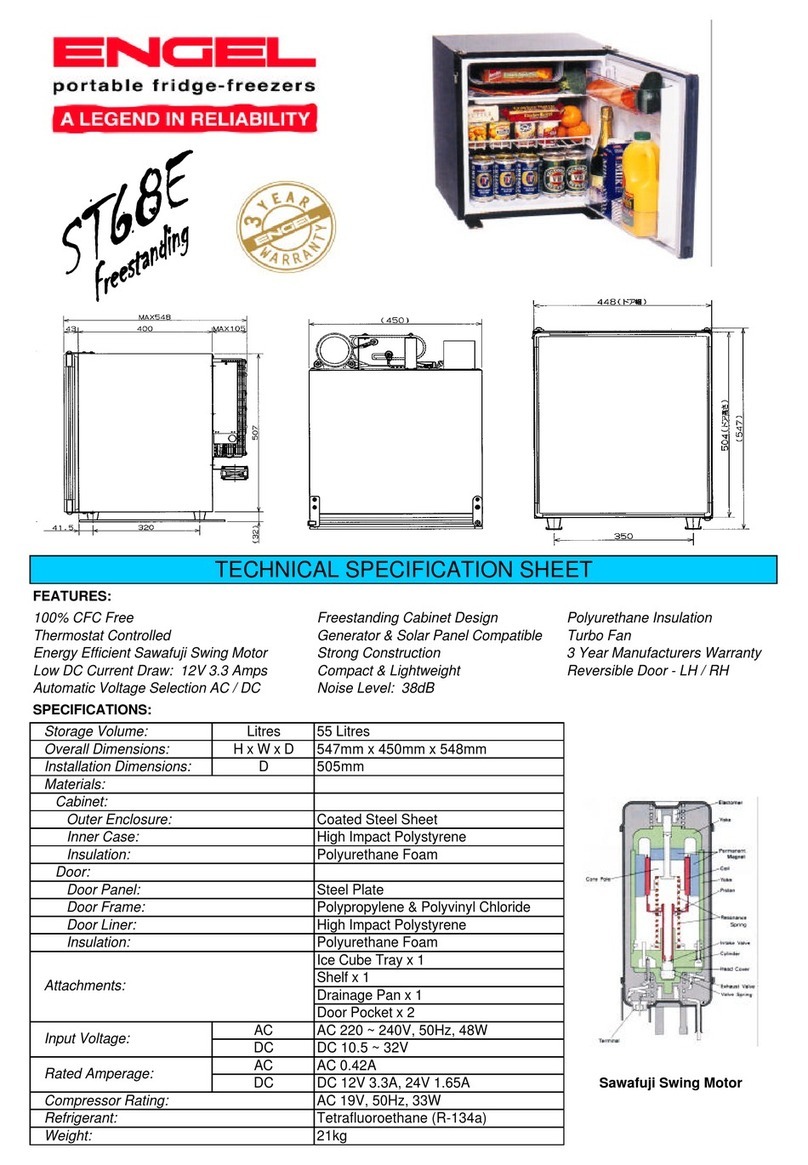

Engel ST68E User manual

Engel

Engel MT35F-G3ND-V User manual

Engel

Engel MT80F-G4-S User manual

Engel

Engel MR040F-G3 User manual

Engel

Engel SB30G User manual

Engel

Engel SR48F User manual

Engel

Engel SR70F-G4-GL User manual

Engel

Engel MT45F-S User manual

Engel

Engel MT35F-G4ND-V User manual

Engel

Engel MT35F-U1D-P User manual

Engel

Engel MT15E User manual

Engel

Engel F Series User manual

Engel

Engel MRBD030 User manual

Engel

Engel SR48F User manual

Engel

Engel Eclipse MR40F-G4 User manual

Engel

Engel MT17F-G3 User manual

Engel

Engel MD14E Manual

Engel

Engel MD14F User manual

Engel

Engel MT60F-U1 User manual

Engel

Engel MT35F-U1D-P User manual