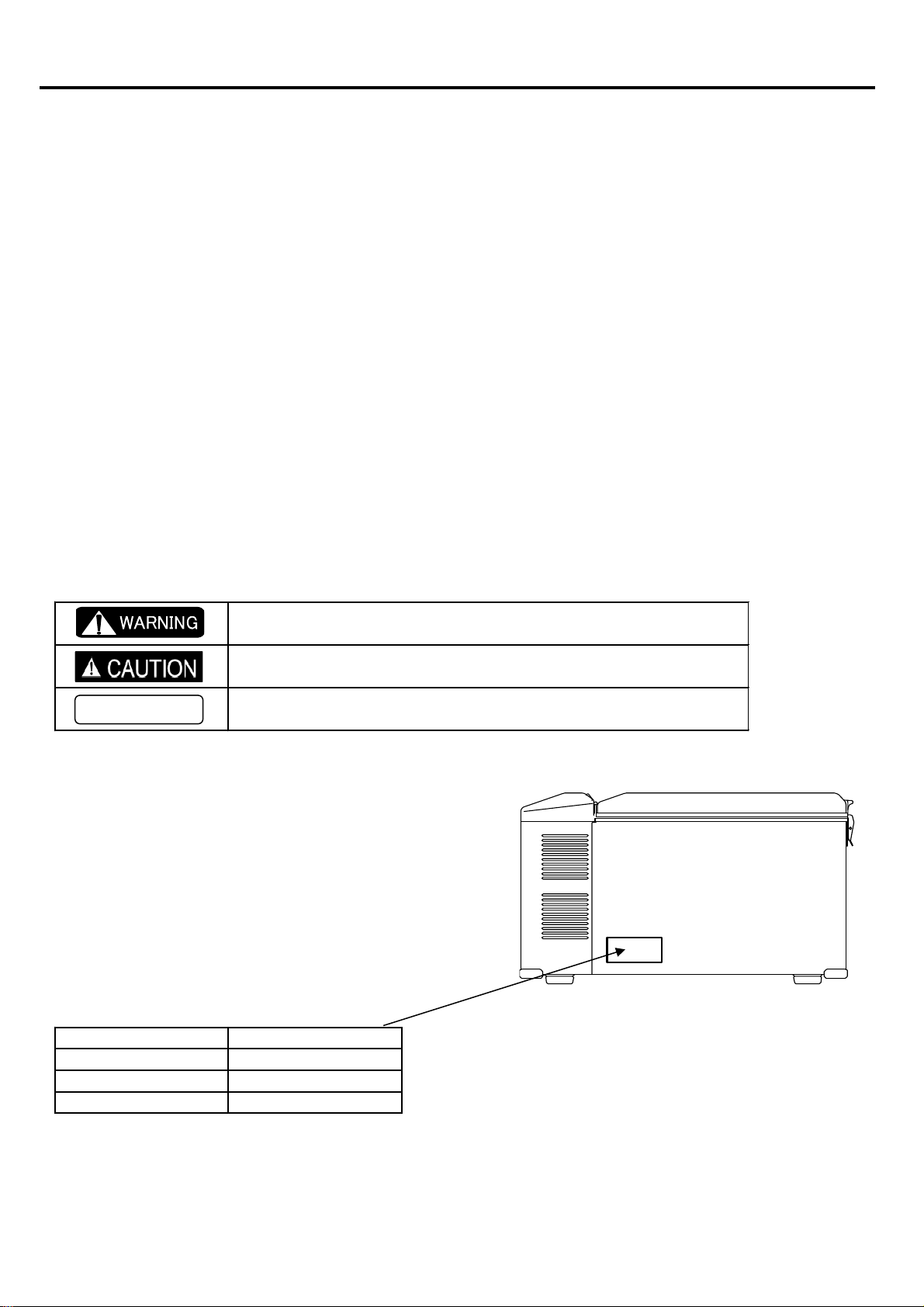

Engel MT35F-U1D-P User manual

MODEL (Digital display type) :

MT35F-U1D-P 0642 032 0310

MT45F-U1D-P 0642 042 0R40

MT45F-U1CD-P 0642 042 1R00

2020.12

#3

SERVICE MANUAL

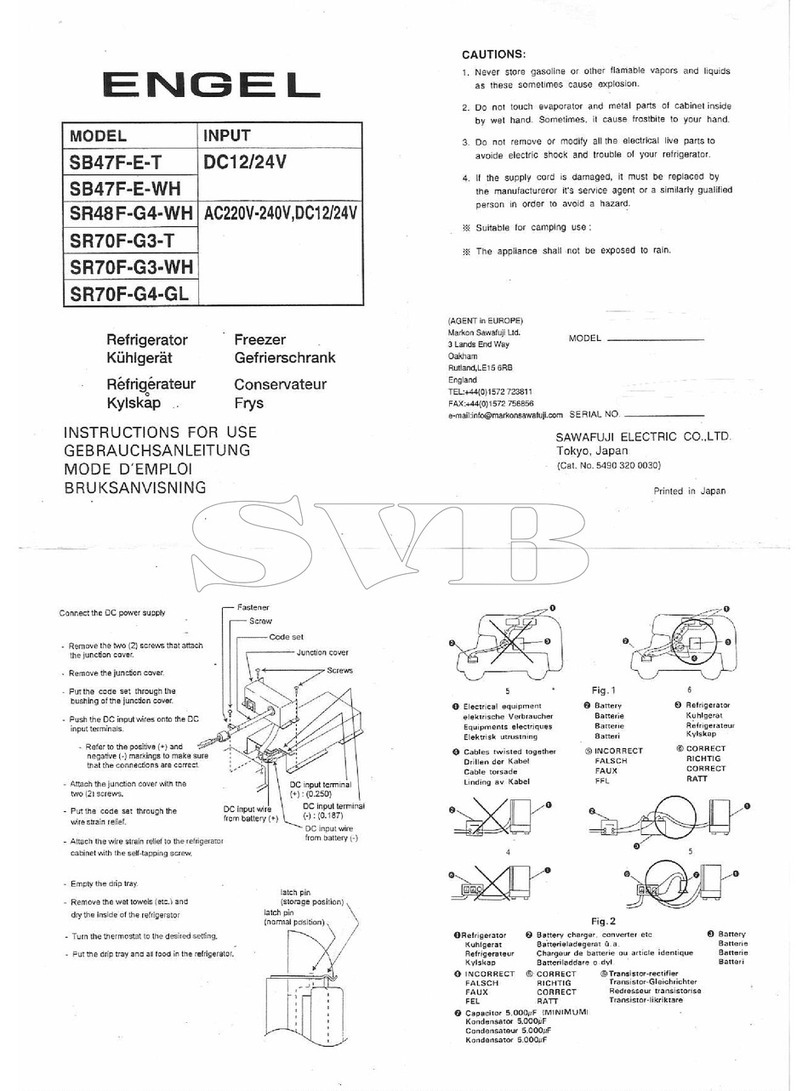

●FOR REFRIGERATOR USERS

・Failing to service properly may result in poor reliability of the refrigerator.

・Read this booklet carefully and perform servicing with great care.

・

●FOR SAFETY OF YOURSELF

・

●SAFETY SYMBOLS

・The following warning labels in this booklet indicate precautions for service work.

Comply with what each symbol indicates whenever it appears.

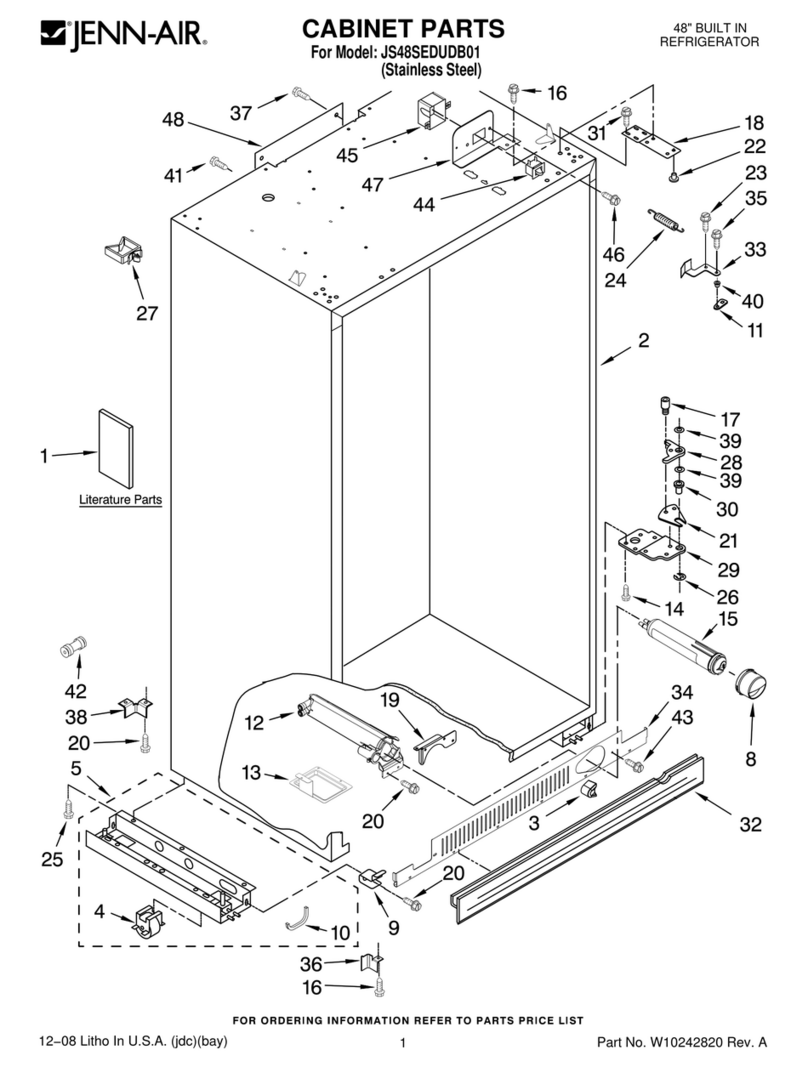

●REFRIGERATOR CODE NUMBERS

・This manual is compatible with described model in below.

Please check refrigerator model name and number in lable .

(Lable place as picture)

NUMBER MODEL NAME

0642 032 0310 MT35F-U1D-P

0642 042 0R40 MT45F-U1D-P

0642 042 1R00 MT45F-U1CD-P

To secure safe and correct servicing, read this manual thoroughly in advance and check

if there are protective equipment and appropriate tools and service parts ready as well

as technical skills necessary to perform servicing.

May lead to death or serious injury if failed to comply with this

precaution

May lead to injury if failed to comply with this precaution

Lead to failure of the refrigerator set or its components if failed

to comply with this precaution

This service manual describes maintenance procedures for ENGEL refrigerator.

This manual is intended for repair engineers who are familiar with basics service skills and

knowledge for ENGEL refrigerator.

This manual does not guarantee correct maintenance when service is done by a non-skilled

worker without technical knowledge.

Note that the content of this booklet including product specifications is subject to change for

improvement without notice.

Always comply with the procedures, directions, and work tips in this booklet when

servicing the refrigerator.

WORK TIPS

1.

SPECIFICATIONS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

■ Specifications Table ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

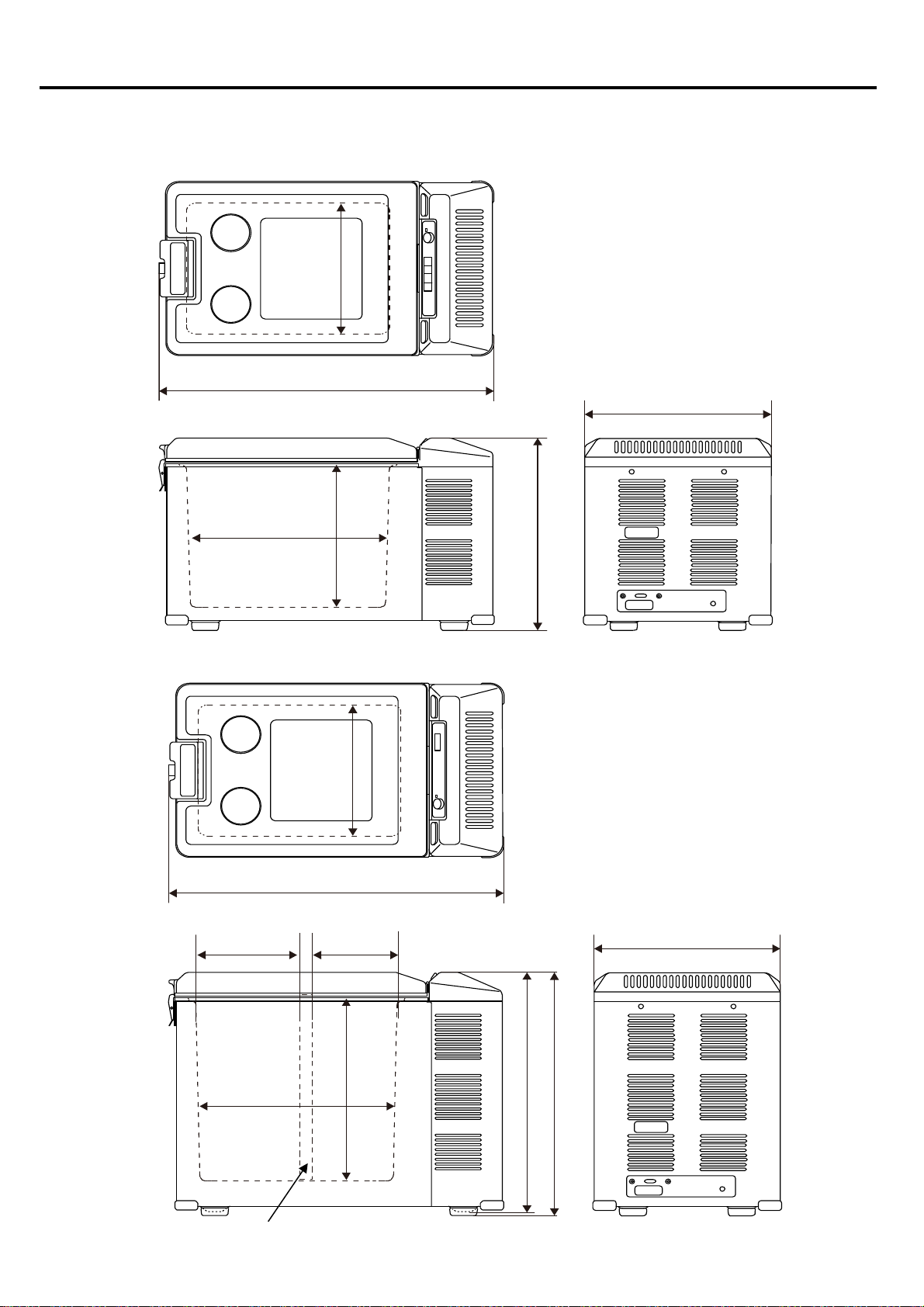

■ Exterior / Interior Dimensions ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2

2.

INSTALLATION A REFRIGERATOR ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3

■ How to Install the Refrigerator ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3

■ About digital displays・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4

3.

PART NAME ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5

■ MT35F / MT45F (Non Combi type)・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5

■ MT45F (Combi type)・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6

4.

CONNECTING DIAGRAM ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7

■ MT35F / MT45F (Non Combi type)・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7

■ MT45F (Combi type)・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

8

5.

TROUBLE SHOOTING ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9

■ Error Message (Digital display of temperature controller)・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9

■ Trouble flowchart ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10

・Does not get Cold ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10

・Cooling is Weak ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11

・Refrigerator is too Cold ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11

■ Technical Data ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

6.

CHECK POINT & CHECK METHOD ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13

【Check 1】 Special Fuse & Blade Fuse ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13

【Check 2】 AC output voltage from power supply to compressor ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13

【Check 3】 Check the Resistance at the Coil if Compressor ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

13

【Check 4】 Resistance of Thermistor ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

14

【Check 5】 Output DC voltage measurement from control assembly to power supply ・・・・・・・・・・・・・・・・・・・・・・・

14

【Check 6】 Output DC voltage measurement from power supply to control assembly ・・・・・・・・・・・・・・・・・・・・・・・

14

【Check 7】 Compressor Rated Current ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

15

【Check 8】 Resistance of Fan motor ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

15

7.

REPLACING PARTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

16

【How to Replace Cooling Unit 】 ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

16

【How to Replace Fan Motor】 ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

19

【How to Replace Power Supply】 ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

20

【How to Replacement of Temperature controller】・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

20

CONTENTS

■ Specifications Table

STORAGE VOLUME ℓ (liter)

in

mm

in

mm

CABINET

DOOR

CABINET

DOOR

DOOR

CABINET

AC

DC

DC12V

DC24V

AC

Fridge side 5℃

Freezer side −15 ℃ or lower

LBS.

Kg

※1 We took the largest mesurement ( including latch and handles)

※2 At an ambient temperature of 30℃ with the refrigerator door closed

1. SPECIFICATIONS

MODEL

MODEL CODE

EXTERIOR

DIMENSIONS

W×D×H ※1

MT45F-U1D-P

0642 042 0R04

40

32

0642 032 0310

MT35F-U1D-P

INTERIOR

DIMENSIONS

W×D×H ※1

OUTER

ENCLOSURE

INNER ENCLOSURE

390×275×398

Painted steel plate

A.B.S.Resin

HEAT INSULATOR

INPUT VOLTAGE

RATED AMPERAGE

2.6A

1.4A

0.71A

Foamed Polyurethane (Cyclopentane)

REFRIGERANT

AVERAGE INNER

TEMPERATURE ※2

8℃±3℃

by Thermostat control NOTCH 1

TEMPERATURE CONTROL

NOTCH 5 OR FREEZE ※2

−18 ℃ or lower

TEMPERATURE CONTROL

HFC-134a

-

1

25.5×14.3×16.1

648×364×408

15.4×10.8×11.7

390×275×298

46.3

WEIGHT

COMPRESSOR MODEL

COMPRESSOR RATING

SK511P (K3)

MT45F-U1CD-P

0642 042 1R00

40

25.5×14.3×20

648×364×508

15.4×10.8×15.7

24

Automatic temperature control by dial setting (Electronic thermostat control type)

120V

12/24V

2.7A

1.5A

0.76A

AC 15V, 1.8A, 27W

21

52.9

■ Exterior / Interior Dimensions

※ Tolerance is omitted

Unit (mm)

・MT35F

・MT45F

1. SPECIFICATIONS

2

298

408

648

364

390

275

648

364

508

398

390

275

DIVIDER (Combi type only)

215 160

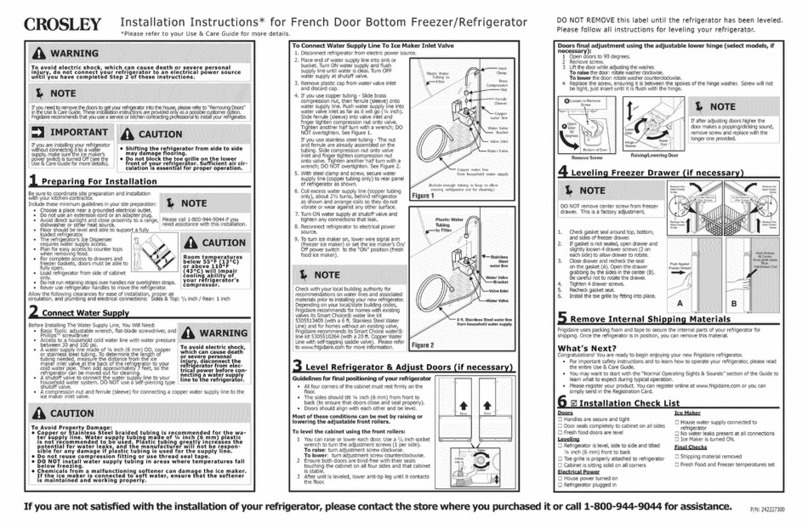

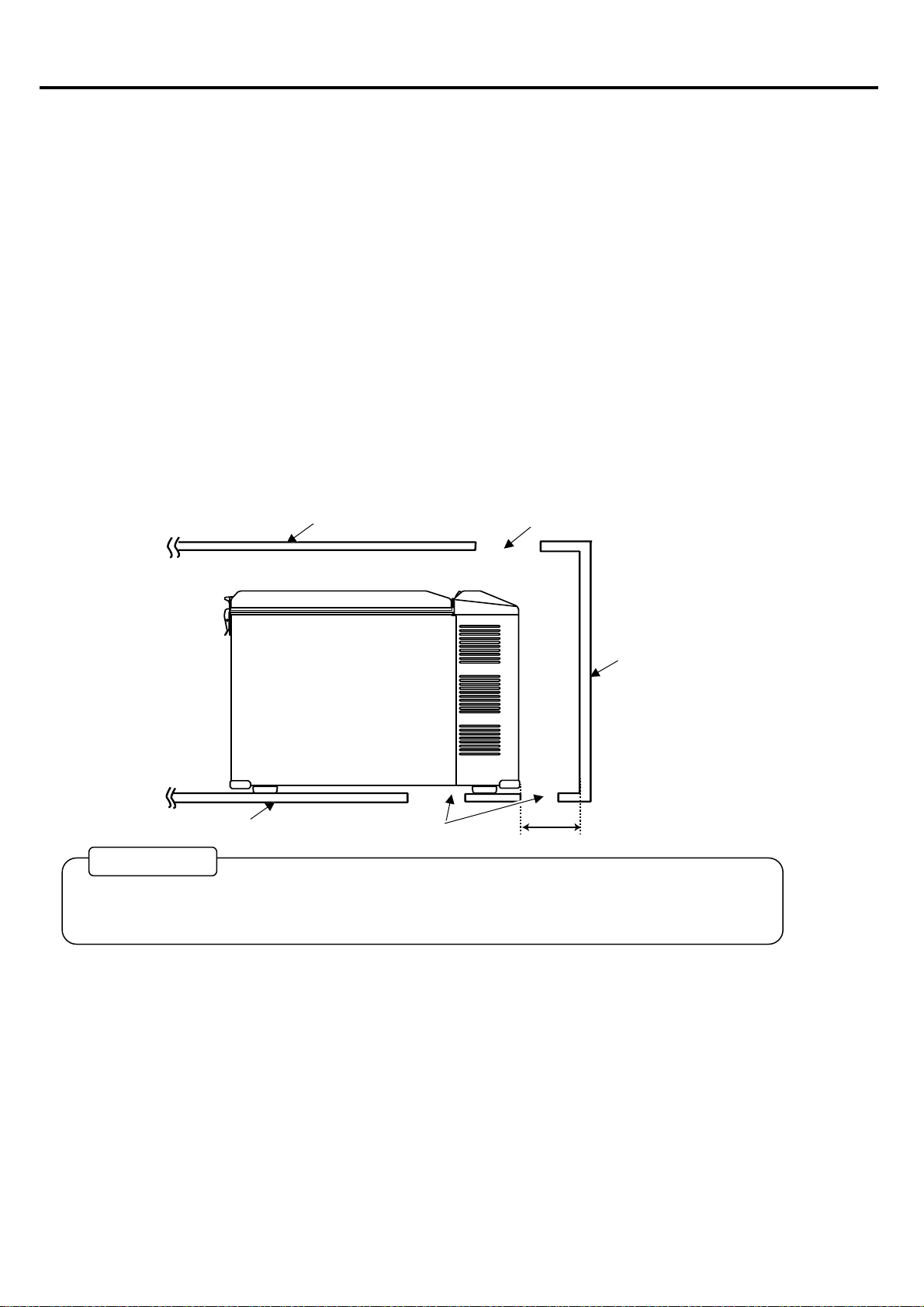

■ How to Install the Refrigerator.

(1) Your shockproof fridge is best installed on a solid surface.

(2) Be sure your fridge is not placed near a gas stove, heater or other

heat-generating appliances.

(3) Adequate ventilation and suitable distance from each wall (at least 150mm or more)

is necessary for the maximum cooling efficiency and minimum electric current consumption for

"free standing use"( see Fig.1 shown below).

(4) Avoid installing your fridge close to kitchen sink or faucet.

(5) If you use the fridge under the counter or in the fixing box, please note the

following air ventilation conditions.

① Make vent opening both under fridge or bottom and above fridge top cover.

2. INSTALLATION A REFRIGERATOR

3

② Vent opening size must be larger than 160㎠ for each opening ( the more air circulation over the

condenser, the more efficiently fridge will operate).

Failure to provide the necessary venting will result in poor refrigeration, continuous compressor

operation, accelerated battery discharge and sometimes shorten the life of fridge.

Top Cover Minimum Opening

Wall or Box Case

At least 150mm

From Each Wall

Floor or Box Bottom Minimum Opening

WORK TIPS

(Fig 1)

INDICATING

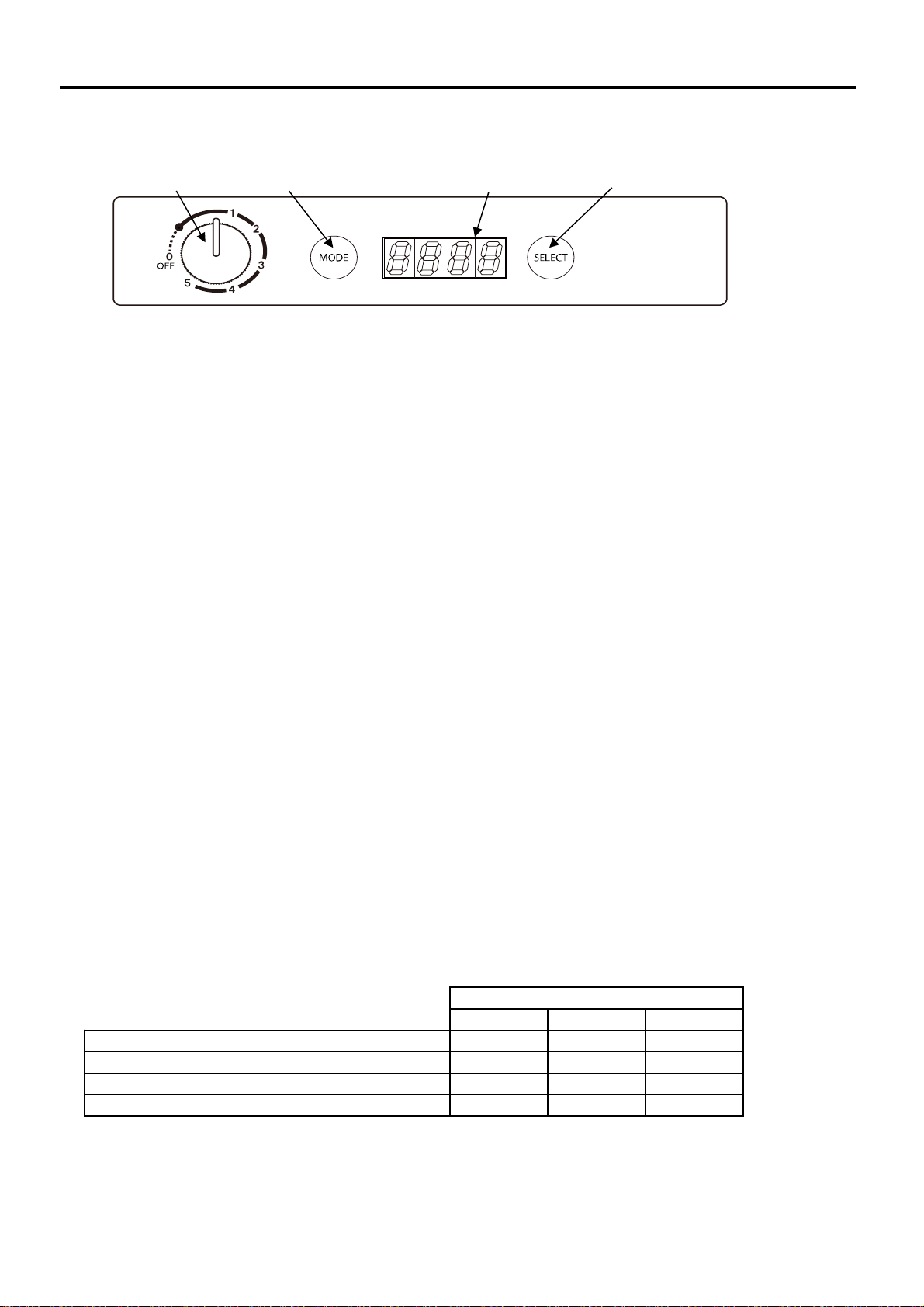

■ About digital displays

Displays the temperature inside the refrigerator, temperature setting display, error code, etc.

【How to set the temperature in the refrigerator】

Refrigerator temperature setting range is -18 ℃ to + 10 ℃

① Turn the dial to set the temperature inside the refrigerator. (-18 ° C to + 10 ° C)

② After a few seconds after you stop the dial, the temperature display changes from blinking to lit,

and the setting is confirmed.

③ After that, the LED display will show the temperature inside the refrigerator.

【How to switch between Celsius (℃) and Fahrenheit (℉)】

① Press the "MODE" button. (LED display blinks)

② Press the select button while the LED display is blinking to switch between Celsius and Fahrenheit.

③ After the setting is completed, after a few seconds, the LED will change from flashing to lit and

display Celsius or Fahrenheit.

【How to set the battery protection function】

This refrigerator has protection function for battery protection.

Set the operation stop and return of the refrigerator by the input voltage. (See table below)

① Press the mode button twice. (The current setting of the protection function is lit.)

② Every time you press the select button, the LED blinks and switches from “OFF” →“LO” → “HI”.

③ After a few seconds, the LED changes from blinking to lit and the setting is finalized.

④After that, the LED display will show the temperature inside the refrigerator.

【Error message display】

When an error message is displayed, the refrigerator goes into "standby mode" and stops operating.

To reset the error, reset the power.

At DC12V input Operation automatic return voltage

9.6V or less

23.1V

25.0V

An error message will be displayed on the LED display when the battery voltage is low or the refrigerator is

abnormal. (See page 8 for details)

4

10.5V

11.5V

9.6V or less

11.5V

12.5V

7.9V or less

21.0V

23.1V

* Operates when the voltage value continues for 10

seconds

At DC12V input Operation stop voltage

At DC24V input Operation stop voltage

At DC24V input Operation automatic return voltage

2. INSTALLATION A REFRIGERATOR

Battery protection settings

OFF

LO

HI

7.9V or less

LED display

"MODE"button "SELECT"button

DIAL

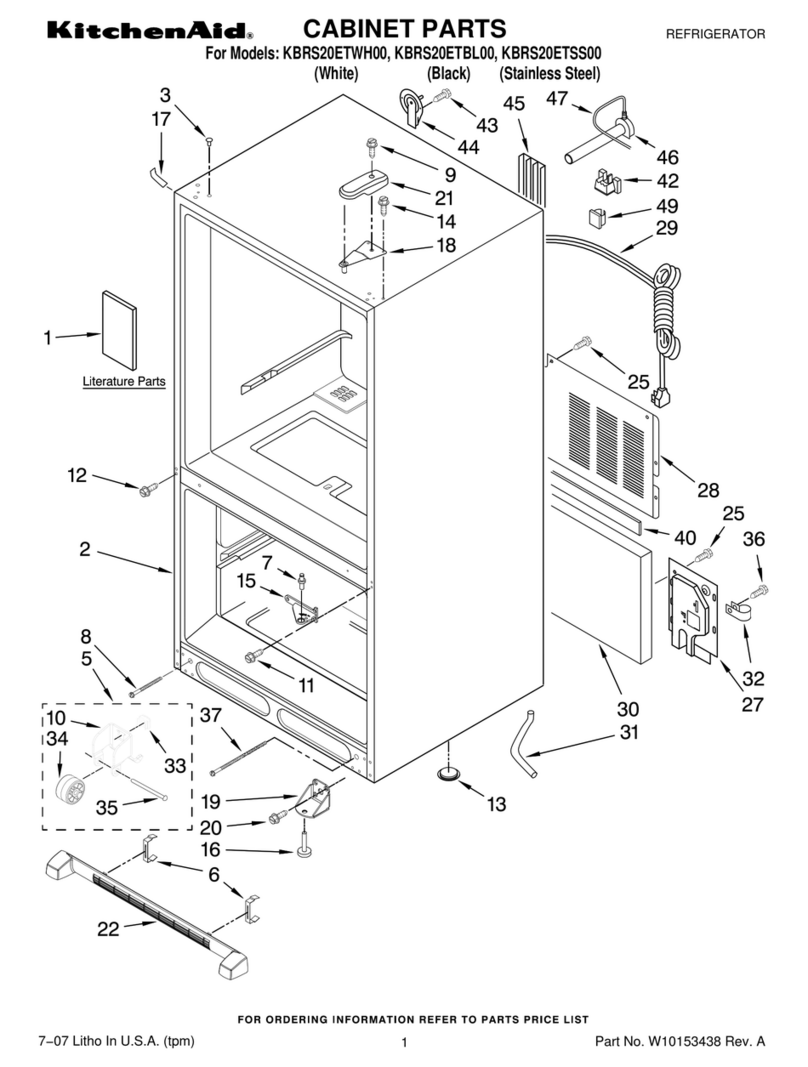

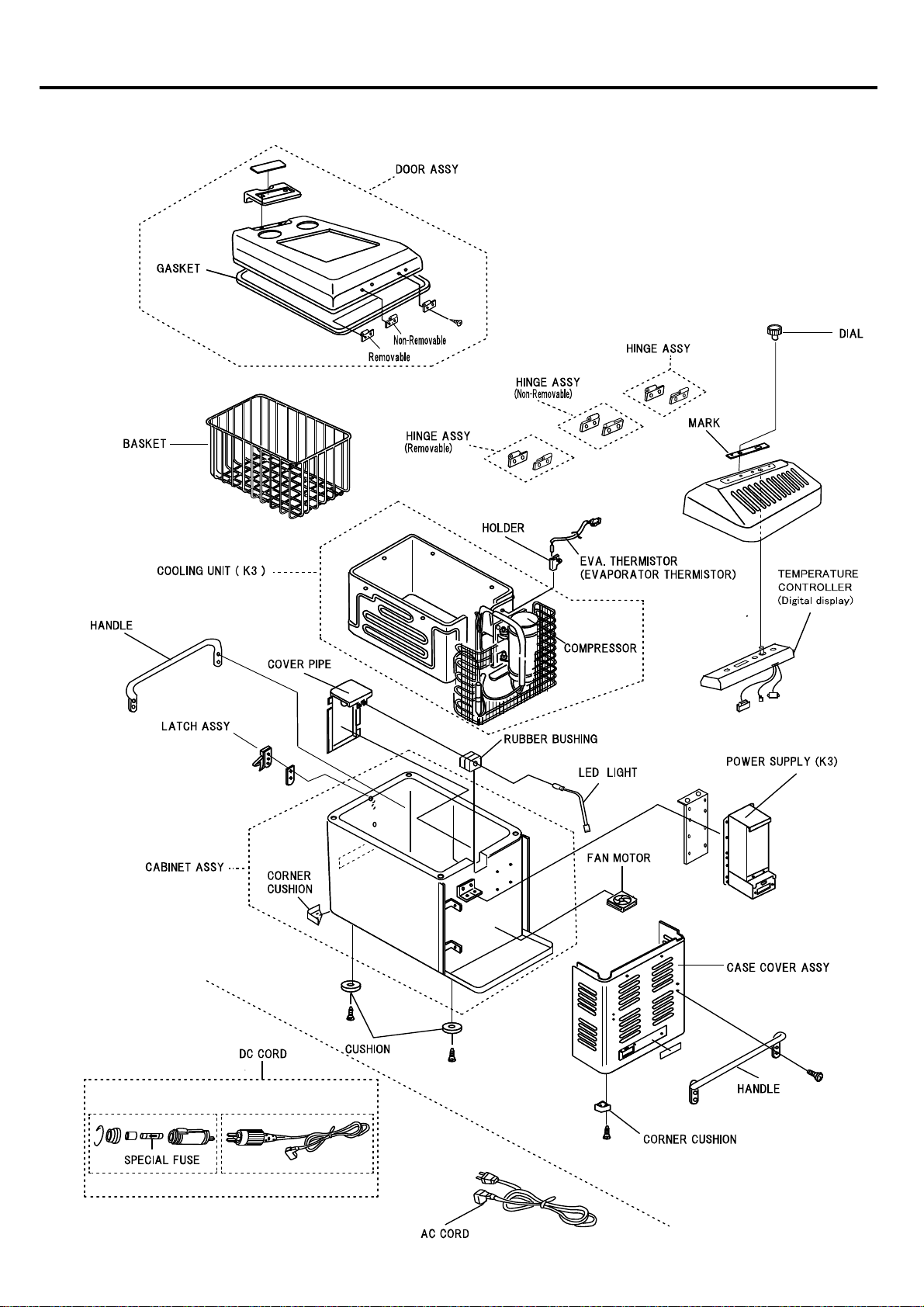

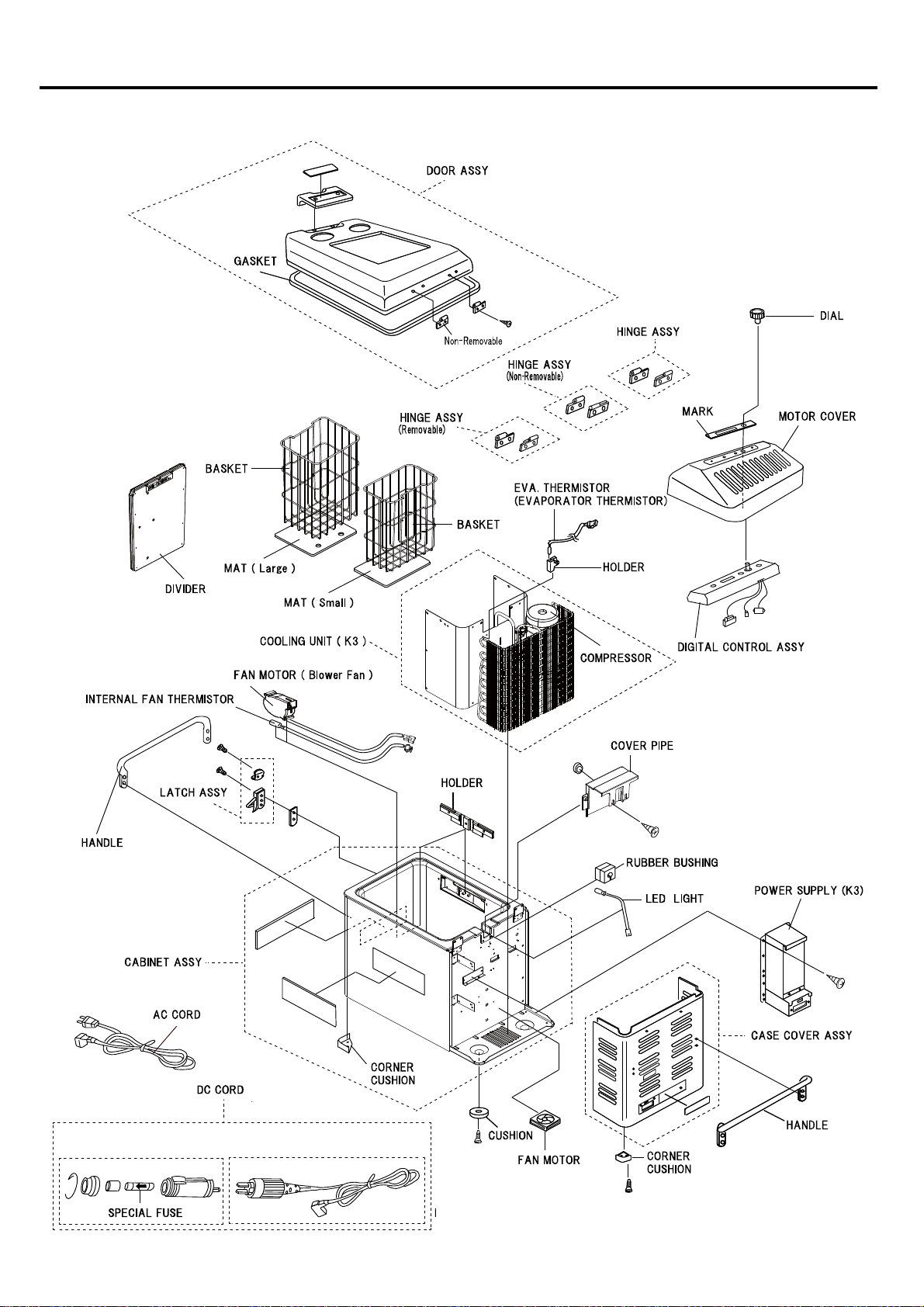

■ MT35F / MT45F (Non Combi type)

3. PART NAME

5

■ MT45F (Combi type)

3. PART NAME

6

■ MT35F / MT45F (Non Combi type)

● Block Diagrams

● Wiring Diagrams

7

4. CONNECTING DIAGRAM

■ MT45F (Combi type)

● Block Diagrams

● Wiring Diagrams

4. CONNECTING DIAGRAM

8

■ Error Message (Digital display of temperature controller)

Error message will be displayed if the voltage of the battery is low or in the event of any troubles - (see table below).

To reset the error, reset the power

Error message

※1 The voltage detection position is the terminal block of the refrigerator. (The voltages at the battery and terminal block are different to include the wiring drop.)

※2 No error is displayed if the fan is disconnected during operation. An error will occur at startup when the refrigerator is disconnected while the refrigerator is off.

■ About the battery protection function

This refrigerator has a battery protection function for battery protection.

(The above error code <.>)

If the battery voltage is low, the refrigerator stops as shown in the table on the right.

The refrigerator automatically returns when the battery voltage returns to normal voltage.

(Refer to page 8 for setting method)

At DC12V input Operation automatic return voltage

At DC24V input Operation stop voltage

At DC24V input Operation automatic return voltage

5. TROUBLE SHOOTING

9

9.6V or less

23.1V

25.0V

Battery protection settings

At DC12V input Operation stop voltage

HI

7.9V or less

10.5V

11.5V

9.6V or less

11.5V

12.5V

7.9V or less

21.0V

23.1V

E-5

Internal thermistor inspection

-

○

-

32.0V≦voltage(※1)≦35.0V (10s continuous)

Voltage(※1)≧45.0V (10s continuous)

E-4

○

○

E-8

14

Voltage(※1)≦ 9.6V (10s continuous)

17.0V ≦ voltage(※ 1)≦ 20.4V (10s continuous)

Voltage(※1)≦ 10.6V (10s continuous)

17.0V ≦ voltage(※ 1)≦ 22.5V (10s continuous)

14

SEE

PAGE

no display

The dot <.>

Flashes

○

○

○

Return condition

Battery

Protection

9.6V or more

-

E-9

E-10

ERROR

CODE

Other than

combi type

Combi type

Error code existence

CAUSE

Judgment criteria

SOLUTIONS

E-6

Power reset

Power reset

Power reset

Power reset

Increase ambient temperature or

move to a warmer place.

EVA.Thermistor inspection

EVA.Thermistor inspection

Check battery

E-7

○

○

○

○

○

○

○

-

○

Ambient temperature is too low

(Substrate ambient temperature)

Thermistor short or Internal temperature

overheating abnormality

Thermistor disconnection or internal

temperature drop abnormal

Abnormal input DC voltage (too

high)

Internal thermistor short or internal

temperature overheating

Internal thermistor disconnection or

internal temperature drop abnormal

Internal fan motor disconnection

※2, FAN voltage ≦ 1V or less (5s continuous)

LO

Power reset

Power reset

Power reset

Internal thermistor inspection

OFF

Temperature ≦ -40 ℃ (5s continuous)

○

Abnormal input

DC voltage

Voltage(※1)≦ 7.9V (10s continuous)

Temperature ≧ 75 ℃ (5s continuous)

Temperature ≦ -40 ℃ (5s continuous)

Temperature ≧ 75 ℃ (5s continuous)

OFF

LO

HI

14

14

Inspection of internal fan motor

15

* Operates when the voltage value

continues for 10 seconds

Check battery

-

-

See the table below

(battery protection

settings)

Temperature ≦ -20 ℃ (5s continuous)

※1 Ambient temp 25℃

※2 Ambient temp 25℃~-16℃

5. TROUBLE SHOOTING

10

Is the output voltage from the power

supply to the compressor normal?

Approx. AC13V - 18V ※1

■Does not get Cold

(Temperature setting -18℃

)

Is compressor

running?

Lower than AC13V

Checking

Is the special

fuse of the DC

cord or the

blade fuse of

the power

supply blown?

Are wirings and couplers

connected?

Replace the

power supply.

Replace the fuse

See page 13

【Check 1】

See page 13

【Check 2】

Test result

Judge

Fixing

Connected repair.

Replace the

power supply.

See page15

【Check 7】

Power supply is

broken

Normal

Yes

Yes No

Normal

Normal

No

Yes

No

Out of standard Gas leak, clogging, etc.

Measurement of rated

current of refrigerator or

compressor

Replace the

cooling unit.

See page 15

【Check 7】

Is temperature

controller (digital

display) lit

?

Is the output voltage from the control

assembly to the power supply normal?

Normal

Abnormal

See page 14

【Check 5】

teperature controller

is broken.

Replace the

teperature

controller.

Replace the

power supply.

Lower than AC13V Power supply is

broken

Is the output voltage from the power

supply to the compressor normal?

Approx. AC13V - 18V ※1

See page 13

【Check 2】

Abnormal

Out of standard

Abnormal

Abnormal

Replace the

cooling unit.

Compressor lock etc.

Measurement of rated

current of refrigerator or

compressor

Compressor resistance

About 1.7Ω (at 25 ℃)

※Using analog tester

0Ω

∞Ω

Out of standard

Normal

Coil disconnection

Coil short circuit

Is the output voltage from the power

supply to the control assembly normal?

Out of standard Power supply is

broken

teperature controller

is broken.

Normal Replace the

teperature

controller.

See page 14

【Check 6】

Abnormal

Abnormal

Abnormal

※1 Ambient temp 25℃

※2 Ambient temp 25℃~-16℃

5. TROUBLE SHOOTING

11

■Cooling is Weak

Checking

Test result

Judge

Fixing

Battery voltage is lower than 11V

Voltage is too low.Voltage of battery 12V?

Charge the bettery

Is the machine part ventilated enough?

Make at least 150mm

room between unit and

wall.

YES

NO

Normal

Please keep the ambient

temperature below 30℃.

Ambient temperature is

too high.

Ambient temparature is higher than 30℃

NO

YES

There are too many things in the refrigerator.

Make some room for

cool air.

YES

Lower than AC13V

Replace the power supply.

Power supply is broken

Is the fan motor running?

NO

Fan motor is broken.

Replace the fan motor.

YES

The compressor is locked, or

contaminated.

Below reference value

Gas is leaking.

Replace the

cooling system.

NO

Normal

Insufficient ventilation.

Cool air does not spread.

See page 15

【Check 8】

Power supply &

Temperature

controller is

broken.

Replace the

power

supply &

Temperature

controller .

Resistance of the thermistor.

(Power supply, temperature controller side)

Approx. 2kΩ-10kΩ ※2

0Ω

Replace the

thermistor.

Normal

■Refrigerator is too cold.

(Can not be temperature adjustment)

See page 14

【Check 4】

Thermistor is

shorted.

NO

Power supply is broken

Replace the power supply.

Power is not coming to the

fan motor

Power is coming but fan

motor does not work

Above reference value

Measurement of rated

current of refrigerator or

compressor

See page 15

【Check 7】

Is the output voltage from the power

supply to the compressor normal?

Approx. AC13V - 18V ※1

See page 13

【Check 2】

Abnormal

■ Technical Data ※1 Ambient temp 25℃

※2 Ambient temp 25 to -16℃

Checking Points Normal data See page

Use DC12V → DC12V

Use DC24V → DC24V

Use AC100V → DC40V

Use DC12V → DC12V

Use DC24V → DC24V

Use AC100V → DC40V

See page 15 【Check 7】

See page 13 【Check 1】

Resistance of thermistor

Between two pin of the coupler

Approx. 2KΩ - 10KΩ ※2

Rated current of compressor

Measure the motor input code with a clamp meter.

See page 15 【Check 8】

See page 14 【Check 6】

See page 14 【Check 5】

Approx. 1.7Ω(K3) ※1

See page 13 【Check 3】

See page 14 【Check 4】

Approx. AC 13V - 18V ※1

Special fuse

Special fuse of DC cord

0Ω

Resistance of the compressor

Between incoming cords to compressor

(by detaching from terminal of compressor)

Output voltage from power supply to fan motor

Red (+) terminal and black (-) terminal of 2P fan power

coupler

DC18V

2.1A-2.3A ※1

5. TROUBLE SHOOTING

See page 13 【Check 2】

Checking items

12

Output voltage from power supply to

temperature controller

Output voltage from temperature controller to

power supply

Red (+) terminal and black (-) terminal of 6P coupler

terminal

6P coupler terminal orange (+) terminal and black (-)

terminal

Output voltage from power supply to

compressor

Between outgoing cords from power supply

(by ditaching from terminal of compressor)

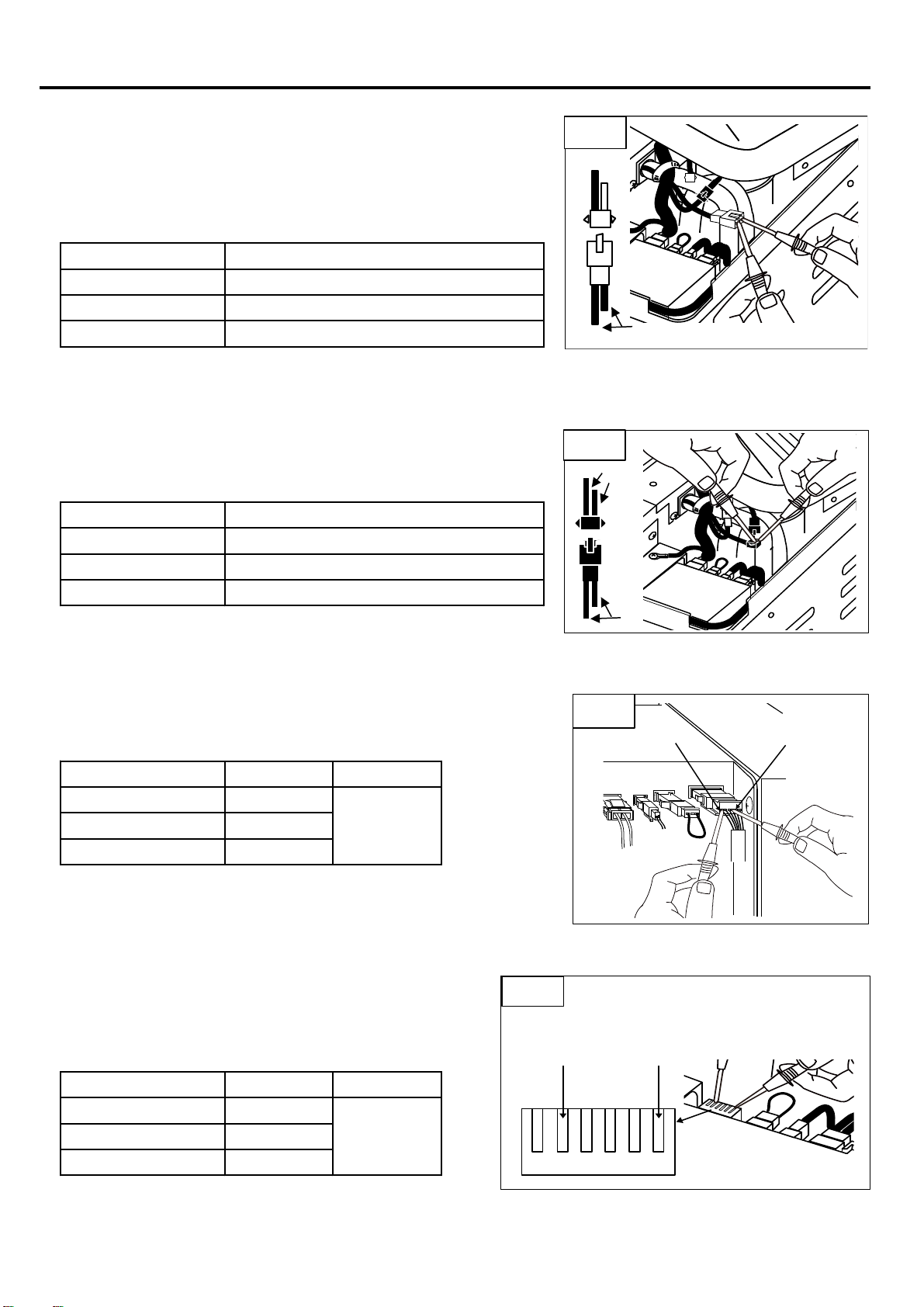

【Check 1】 Special Fuse & Blade Fuse. (Fig.1)

◇ Check the resistance of special fuse by tester.

Test result Judge

0Ω Normal

∞Ω Broken

◇ Check the blade fuse.

The blade fuse is in the power supply.

To remove the blade fuse, please remove the power supply.

【Check 2】 AC output voltage from power supply to compressor. (Fig.2)

◇ Checking point

Check at two pin coupler of power supply. (Fig.2)

Test result Judge

Approx. AC14 - 18V Normal

AC 0 V

Approx. AC14V or lower

【Check 3】 Check the Resistance at the Coil if Compressor.(Fig.3)

◇ Checking points

Remove two pin coupler at motor cord, and check.

(at25℃)

Test result Judge

Approx. 1.7 Ω Normal

∞Ω Disconnection of compressor coil

0Ω Coil of compressor is short circuit

Power Supply is broken

6. CHECK POINT &CHECK METHOD

13

・Please attach attention to the special fuse of

orientation.

・It can not detect the temperature is in the wrong

special fuse orientation. (※)

Fig.2

POWER SUPPLY

Fig.3

POWER SUPPLY

WORK TIPS

Fig.1

DC CORD

SPECIAL FUSE

BLADE FUSE (10A)

6. CHECK POINT &CHECK METHOD

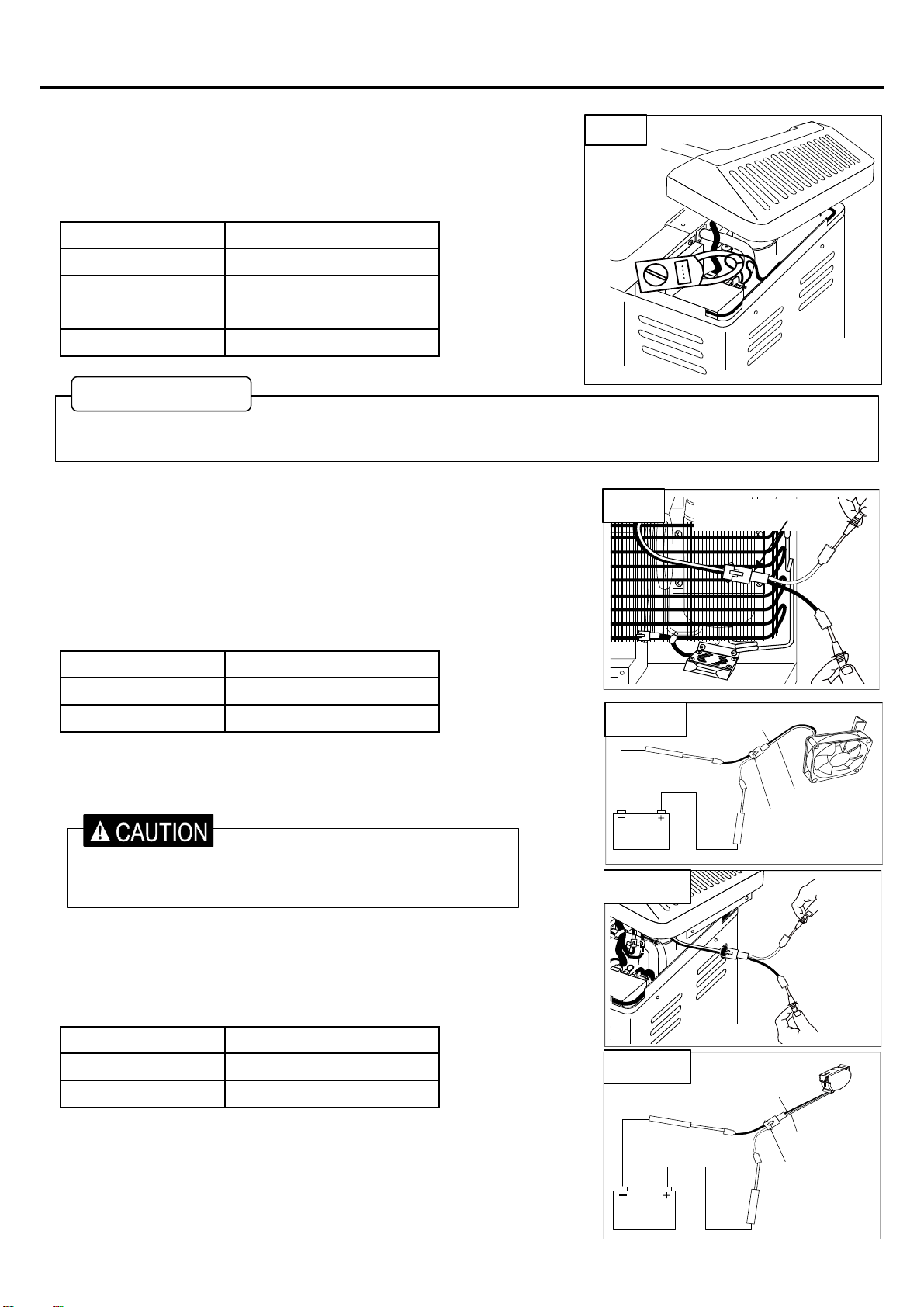

【Check 4】 Resistance of Thermistor. (Fig.4)

<EVA.Thermistor resistance measurement>

(at25℃ ~ -16℃)

Test result

2 kΩ - 10 kΩ ※1

0Ω

∞Ω

※1 The resistance increases when the thermistor body is cold.

<Internal thermistor resistance measurement> (Combi type only)

(at25℃ ~ -16℃)

Test result

2 kΩ - 10 kΩ ※1

0Ω

∞Ω

※1 The resistance increases when the thermistor body is cold.

【Check 5】 Output DC voltage measurement from control assembly to power supply

Power supply used Test result Judge

DC12V DC11-14V

DC24V DC23-26V

AC100V

DC39-41V

【Check 6】 Output DC voltage measurement from power supply to control assembly

Power supply used Test result Judge

DC12V DC11-14V

DC24V DC23-26V

AC100V

DC39-41V

Thermistor disconnection (error display E-09)

14

Normal

Remove the power supply 6P coupler and

measure the DC voltage between the black (-)

wiring section and the red (+) wiring section on

the power supply side 6P coupler section (Fig.

7)

Normal

Remove the EVA / thermistor coupler (white) and measure the

resistance between the terminals. (Fig4)

Thermistor short (Error display E-05)

Normal

Judge

Thermistor disconnection (error display E-06)

DC voltage is measured between the black (-) terminal and

the orange (+) terminal of the power supply 6P coupler (Fig.

6)

Remove the coupler (black) of the internal fan thermistor

and measure the resistance between the terminals. (Fig5)

Judge

Normal

Thermistor short (Error display E-08)

Fig.5

Fig.4

Fig.6

Orange(+)Black(-)

Black

(-)

Red

(+)

Fig.7

Black

Black

Black

Black

Blue

【Check 7】 Compressor Rated Current. (Fig.8)

◇Checking point

Test result Judge

2.1 - 2.3A Normal

Lower than 2.1A Gas is leaking. ※

【Check 8】 Resistance of Fan motor.

<Compressor-side fan motor>

Check DC voltage from power supply to fan motor

Test result Judge

DC18V Normal

0V Power supply failure

When directly checking the operation of the fan motor

<Inside fan motor> (combi type only)

DC voltage confirmation from the control ASSY to the internal fan motor

Test result Judge

DC12V Normal

0V Control ASSY failure

When directly checking the operation of the fan motor

6. CHECK POINT &CHECK METHOD

15

Current value measurement with clamp meter between

input cord terminals.

Higher than 2.3A

Compressor is locked, or

contaminated. ※

※If the refrigerator does not cool down, or if the coldness is weak

◇Remove the fan motor coupler (white) on the compressor

side and measure the DC voltage between the coupler

terminals on the power supply side (Fig. 9)

◇You can check by directly connecting 18V to 24V DC, but

follow the precautions (Fig. 10)

◇Remove the internal fan motor coupler (black) and measure the DC

voltage between the control ASSY side coupler terminals (Fig. 11)

◇You can check by directly connecting 12V DC, but follow

the precautions (Fig. 12)

・Prepare a support coupler and perform measurement.

・Be careful not to mistake the polarity.

To measure the rated current of the compressor, please measure after 15 minutes or more after starting the

WORK TIPS

Fig.8

Fig.10

Fig.9

Support coupler

Fig.12

Black(-)

Red(+)

Black(-)

Red(+)

Red(+)

Black(-)

Red(+)

Black(-)

Fig.11

Support

coupler

Support

coupler

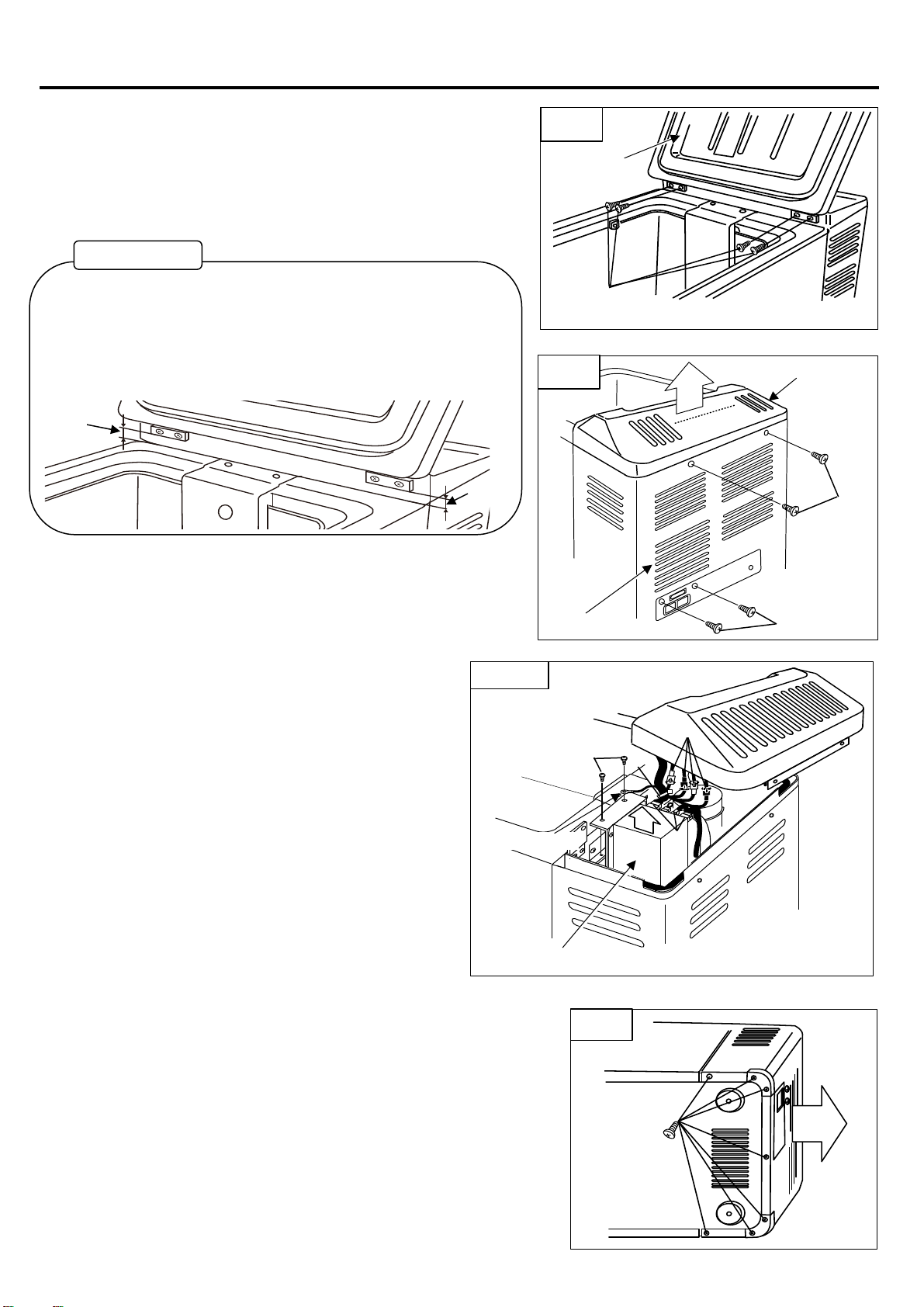

【How to Replace Cooling Unit】

1. Remove the door.

・Open the door and take out the basket.

・Remove the Divider. (Combi type only)

・Remove four screws which hold hinges. (Fig.1-①)

2. Remove the motor cover.

・Remove two screws of motor cover. (Fig.2-①)

・Remove two screws of case cover assy. (Fig.2-②)

・Remove the motor cover from the main unit. (Fig. 2-③)

3. Take out the power supply.

・Cut the fastener. (Fig.3-①)

・Remove two screws of power supply. (Fig.3-②)

・Take out the power supply. (Fig.3-④)

4. Remove the case cover assy.

Remove seven screws of case cover assy. (Fig.4-①)

Remove case cover assy. (Fig.4-②)

7. REPLACING PARTS

16

・Lift the power supply and remove the three

couplers. (Fig. 3-③)

・Remove all couplers of temperature control

assembly. (Fig. 3-⑤) (4 couplers for combi type,

3 couplers for non-combi type)

・Remove the temperature control assembly from

the main unit.

Fig.2

②

①

①

③

DOOR

Fig.1

14mm

14mm

WORK TIPS

When re-installing for door and hinges, please be care with placing position

of hinge height. Position must be 14mm from the cabinet.

(Please see reference picture in below)

After installation of door, please make sure for interior light not leak from

side of door.

If it's possible to see the light, please adjust height of hinges. MOTOR COVER

CASE COVER ASSY

Fig.3

④

⑤

①

POWER SUPPLY

GROUND CORD

②

③

Fig.4

①②

5. Remove screws of evaporator.

<For non combi type>

・Remove the 3 screws (Fig. 5-①)

<For combi type>

・Remove the 4 screws (Fig. 6-①)

6. Remove the cover pipe.

<For non combi type>

・Remove two screws of cover pipe. (Fig.7-①)

・Remove two fasteners of cover pipe. (Fig.7-②)

・Remove the cover pipe. (Fig.7-③)

・Remove the rubber bushing. (Fig.7-④)

・Remove LED light. (Fig.7-⑤)

<For combi type>

・Remove two screws of cover pipe. (Fig.8-①)

・Remove the cover pipe. (Fig.8-②)

・Remove the rubber bushing. (Fig.8-③)

・Remove LED light. (Fig.8-④)

7. REPLACING PARTS

17

Fig.5

①

EVAPORATOR

③

Fig.7

②

④

①

COVER PIPE

FASTENER

RUBBER

BUSHING

⑤

LED LIGHT

Fig.6

①

EVAPORATOR

①

①

Fig.8

①

④③

②COVER PIPE

LED LIGHT RUBBER

BUSHING

Other manuals for MT35F-U1D-P

1

This manual suits for next models

5

Table of contents

Other Engel Refrigerator manuals

Engel

Engel MT17F-G3 User manual

Engel

Engel MT15E User manual

Engel

Engel Eclipse MR40F-G4 User manual

Engel

Engel F Series User manual

Engel

Engel MT35F-G4ND-V User manual

Engel

Engel MT35F-U1D-P User manual

Engel

Engel MHD13F-DM User manual

Engel

Engel MR040F-U1 User manual

Engel

Engel MRBD030 User manual

Engel

Engel SB47F-E-T User manual