ENGINDOT GSH01B User manual

User Manual

Gas Pressure Washer

Model:GSH01B

ID:QX2121-65F32

HIGH PRESSURE WASHER OPERATOR MANUAL

Please read and comply with

these original instructions prior to

the initial operation of your appli-

ance and store them for later use

or subsequent owners.

Contents

Model Overview

Safety Instructions

Assembly Instructions

Preparation

Operating Instruction

Using the Accessories

Working with Detergents

Taking a Break

Shutting Down & Clean Up

Winterizing & Long Term

Storage

Maintenance Instructions

Cleaning Tips

Troubleshooting

EN-2

EN-3

EN-6

EN-7

EN-8

EN-9

EN-10

EN-10

EN-11

EN-11

EN-11

EN-12

EN-14

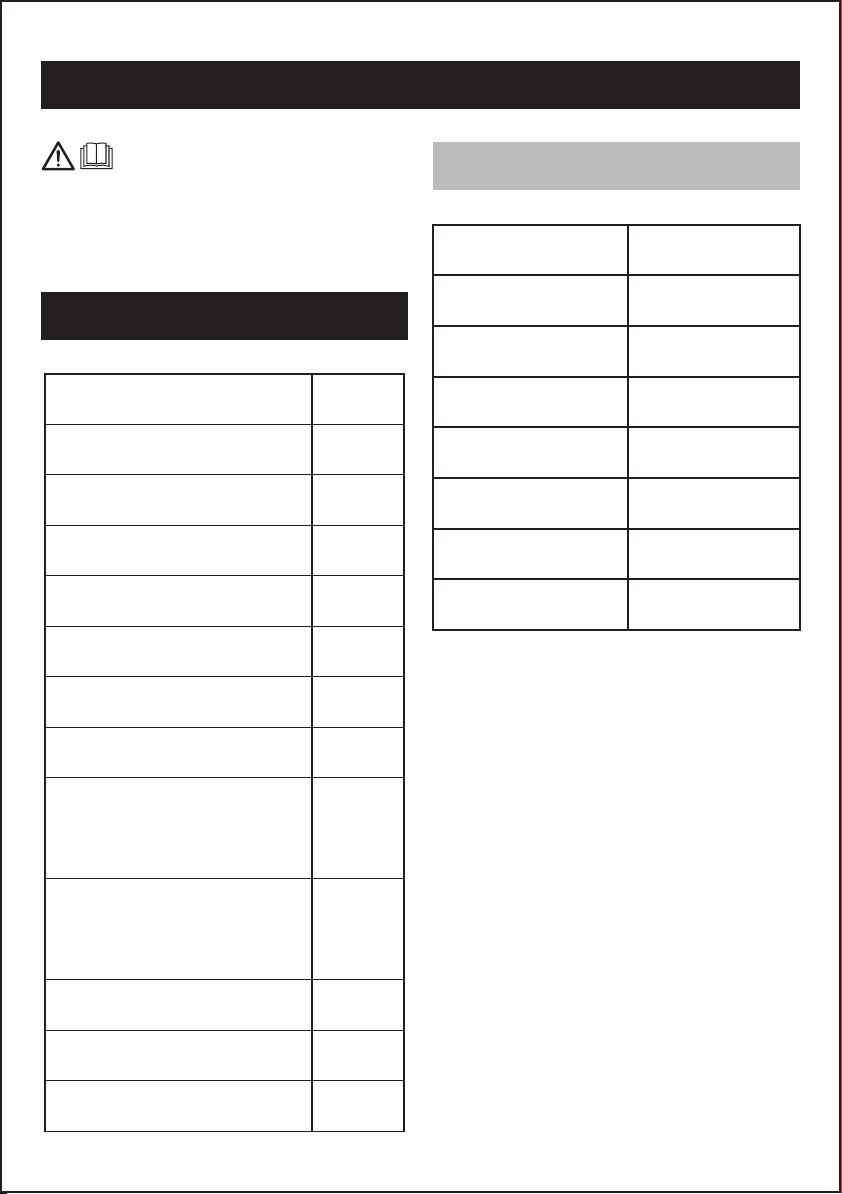

Specifications

Operating Pressure

Water Volume

Engine

Fuel Type

Fuel Tank Size

Engine Oil Type

Engine Oil Capacity

Model Numbe

3200 PSI

540 l/h

Rato 209cc

R210-S

2.6L

SAE 10W-30

GSH01B

1

0.6L

1

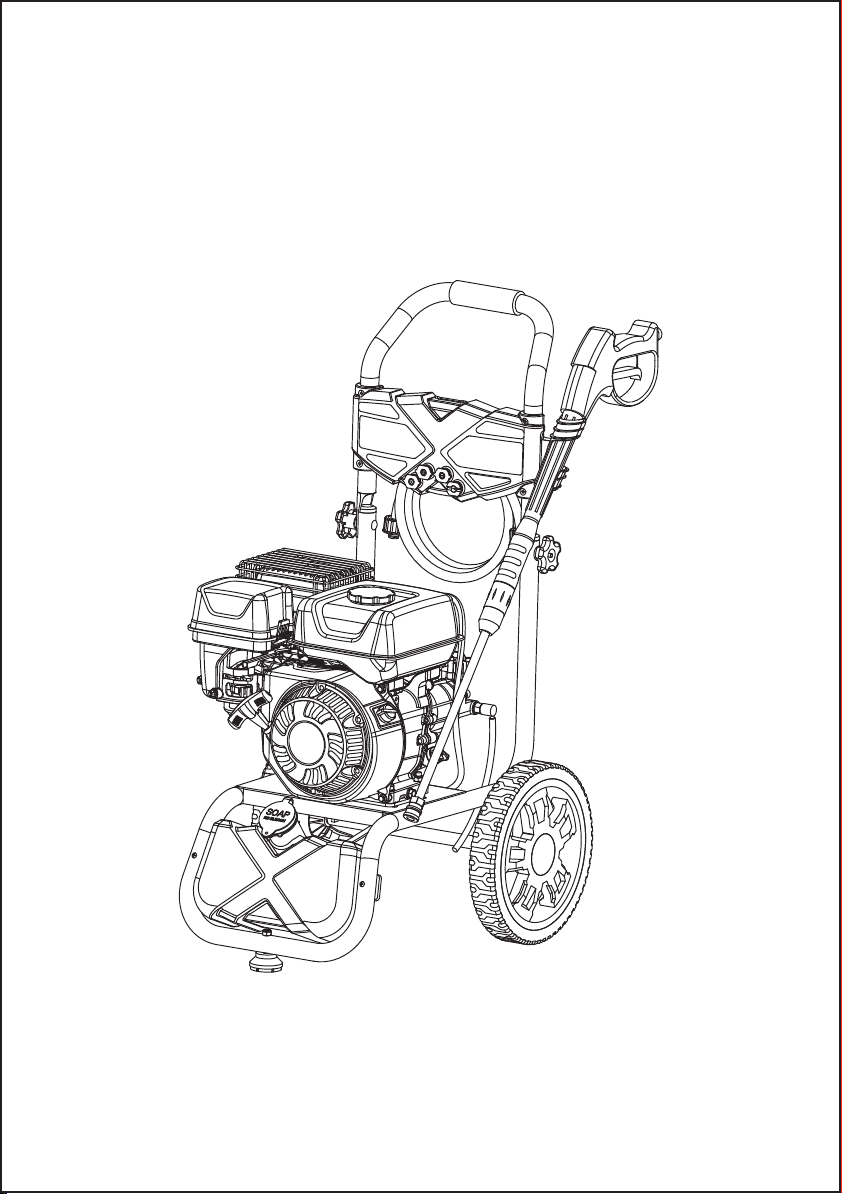

2

3

4

5

6

7

8

AIR CLEANER

FUELTANK

FUEL TANKCAP

MUFFLER

HAND CORD

ENGINE STWICH

OIL DISTICK

1. Spray Gun

3. Pressure Hose

Thermal Relieve

Valve

2. Nozzles

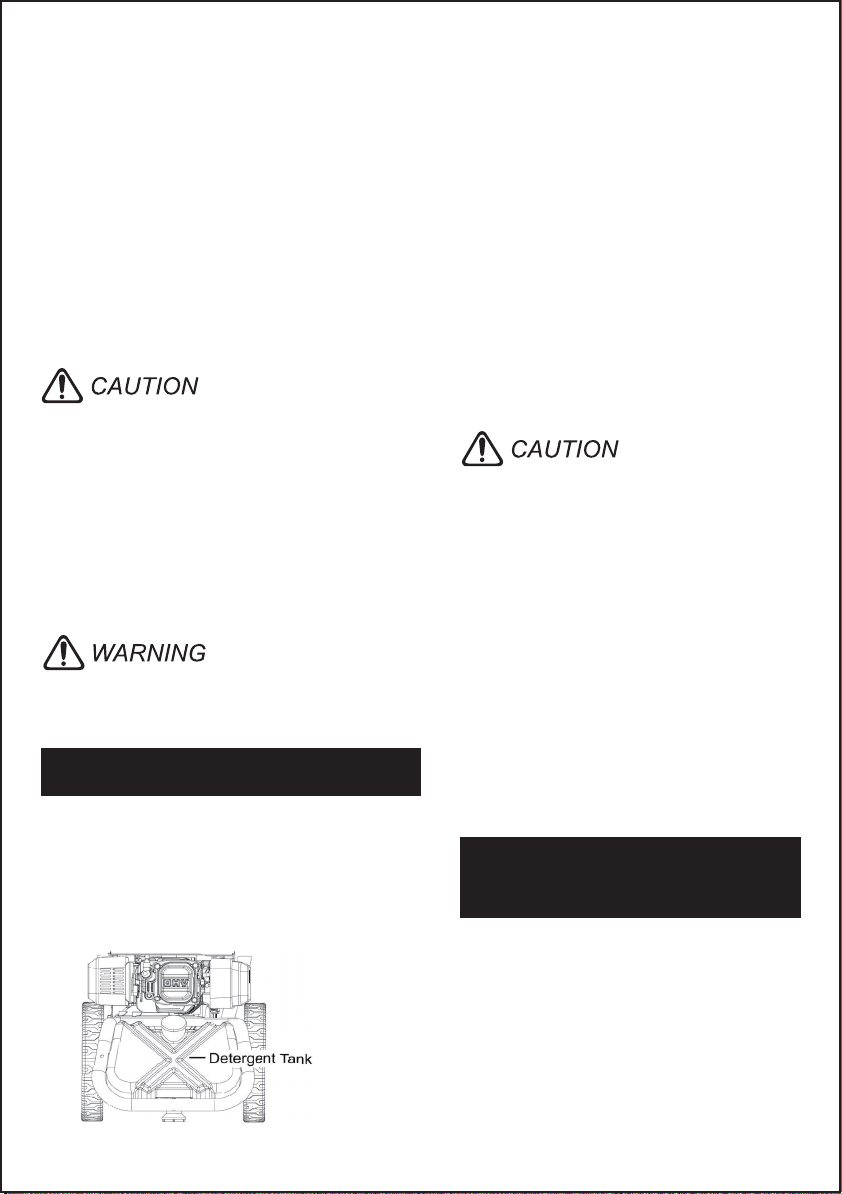

7.Detergent Tank

Model Overview

GSH01B

2

5. Pump

4. Engine

6.Wheels

8. Rubber Foot

Pump Inlet

Pump Outlet

Hazard Levels

Safety Instructions

Indicates “an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.”

Indicates “a potentially hazardous

situation which, if not avoided, could

result in death or injury.”

Indicates “a potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury or in

property damage incidents.”

When using this product, basic

precautions should always be

followed, including the following:

▬

▬

▬

▬

▬

▬

▬

▬

▬

▬

▬

▬

▬

▬

Read the operating instructions of

the engine manufacturer before

start-up and follow the safety

instructions carefully.

Read all instructions before using

product.

To reduce the risk of injury, close

supervision is necessary when the

product is used near children.

Know how to stop the product and

bleed pressures quickly. Be

thoroughly familiar with the

controls.

Stay alert - watch what you are

doing.

Do not operate when fatigued or

under the influence of alcohol or

drugs.

Keep operating area clear of all

persons.

Do not overreach or stand on

unstable support. Keep good

footing and balance at all times.

Wear safety goggles and ear

protection.

Follow the maintenance instruc-

tions specified in the manual.

To avoid risks, all repairs and

replacement of spare parts should

only be carried out by trained

personnel.

Tire pressure should not exceed

max. 25 psi.

Risk of injection or injury – Do not

direct discharge stream at

persons.

High pressure jets can be danger-

ous if misused. The jet must not

be directed at persons, animals,

electrical devices, or the unit itself.

Do not spray electrical connec-

tions, electrical outlets or fixtures.

Do not use acids, solvents, or any

alkaline or flammable material in

this product. These products can

cause physical injuries to the

operator and irreversible damage

to the machine.

3

▬

▬

▬

▬

▬

▬

▬

▬

▬

▬

▬

▬

Water Supply

(Cold Water Only)

Gun kicks back – Hold with both hands

The trigger gun safety lock prevents

the trigger from accidentally being

engaged. This safety feature must be

engaged when replacing nozzles or

not in use.

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Operation of this equipment may

create sparks that can start fires

around dry vegetation. A spark arrestor

may be required. Operator should

contact local fire agencies for laws or

regulations.

Risk of asphyxiation – Use this product

only in a well ventilated area. Do not

operate indoors or in any confined

area.

Operate and fuel machine in a well

ventilated area, free of devices featur-

ing an open pilot or flame such as

boilers, water heaters, etc.

Risk of fire/explosion – Do not add fuel

when the machine is operating or still

hot.

Risk of fire/explosion -Operate only

where open flame or torch is permitted.

Do not spray flammable liquids.

Do not operate if fuel has been

spilled. Instead, move machine to

different location and avoid creat-

ing sparks.

This machine has hot surfaces

which can cause burns. Operate

in a safe environment and away

from children.

Do not touch hot surfaces or allow

accessories to contact hot surfac-

es.

Do not leave machine running

unattended.

Avoid tipping machine on its side.

When connecting to water supply

mains, local regulations of your

municipal water company must be

observed. In some areas connect-

ing directly to public drinking water

supply may require a back flow

prevention device. This is to

ensure that there is no feedback

of chemicals into the water supply.

Use a water filter to avoid potential

damage from dirt in the water

supply.

Garden hose must be at least 5/8

inch diameter.

Flow rate of water supply must not

fall below 2.6 GPM(gallons per

minute)

Flow rate can be determined by

running the water for one minute

into an empty 5-gallon container.

The water supply temperature

must not exceed 122°F/50°C.

Never use the pressure washer to

4

▬

▬

draw in water contaminated with

solvents, e.g. paint thinners, gasoline,

oil, etc.

Always prevent debris from being

drawn into the unit by using a clean

water source. Use additional water

filter.

Do not operate pressure washer

without the water turned on.

Assembly Instructions

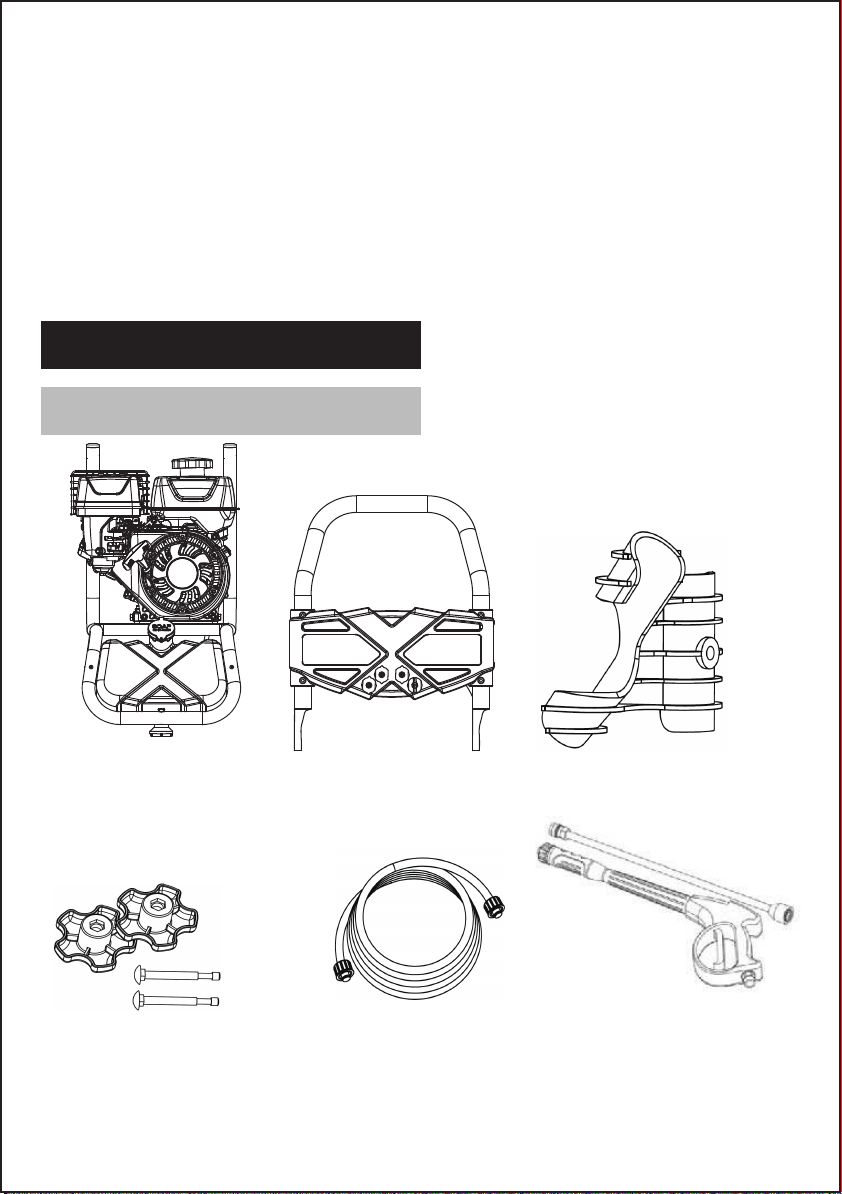

Part List

A - Main Frame C - Gun Hook

D - Knobs & Bolts E – Pressure Hose

B - Handle

5

F - Spray Gun &Wand

Assembling

G - Wheels

Parts not shown:

1 - Manual

2 - Nozzle Cleaner

3 - Spark Plug Wrench

4 - O-Ring Set

(2 for pressure hose, 1 for spray gun)

►

►

6

H – Flat Gasket

I – Elastic Gasket

J – Screw

K – Screw Driver

5 - Funnel For Adding Engine Oil

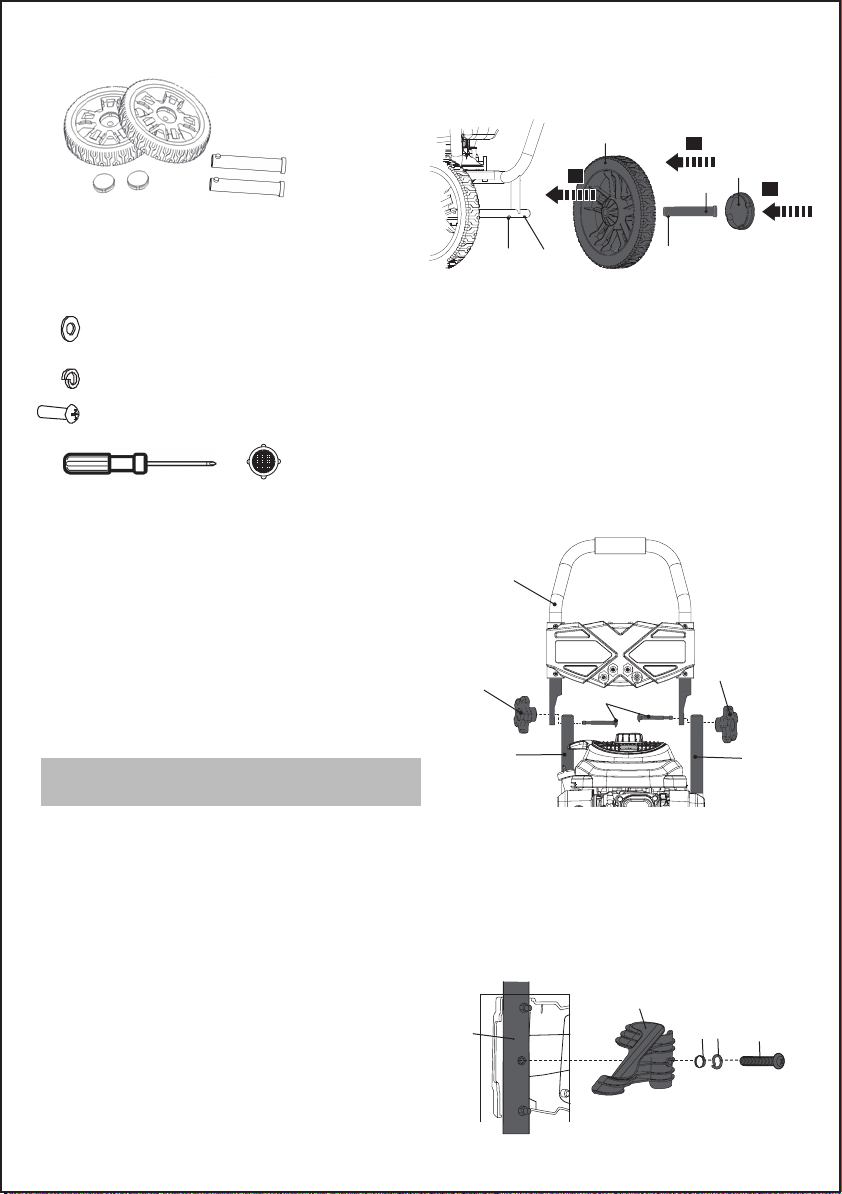

Wheel

> Squeeze the locking pin (G2) and

insert the wheel axle (G1) into the hole

of the wheel (step 1).

> Squeeze the locking pin and insert the wheel

axle into the wheel support (G5)(step 2).

Ensure the locking pin snaps in the locking

hole (G3) properly.

> Put the wheel hubcap (G4) onto the wheel.

(step 3). Ensure it snaps in place properly.

> Repeat with the other wheel.

►

1.

2. 3.

G4

G1

G5G3 G2

G

Handle

> Align the holes and attach the upper

handle bar (B) onto the lower handle

bar (A).

> Secure the connection with bolts (D2)

and knobs (D1). Ensure the

bolts (D2) are engaged into the

square hole properly.

B

D1 D1

D2

AA

> Secure the spray gun holder (C)

onto the upper hand bar (B) with

flat gasket (H), elastic gasket (I)

and screw (J) using the provided

screwdriver (K).

Gun Holder

B

C

H I J

L-Water Inlet Filter

►

►

►

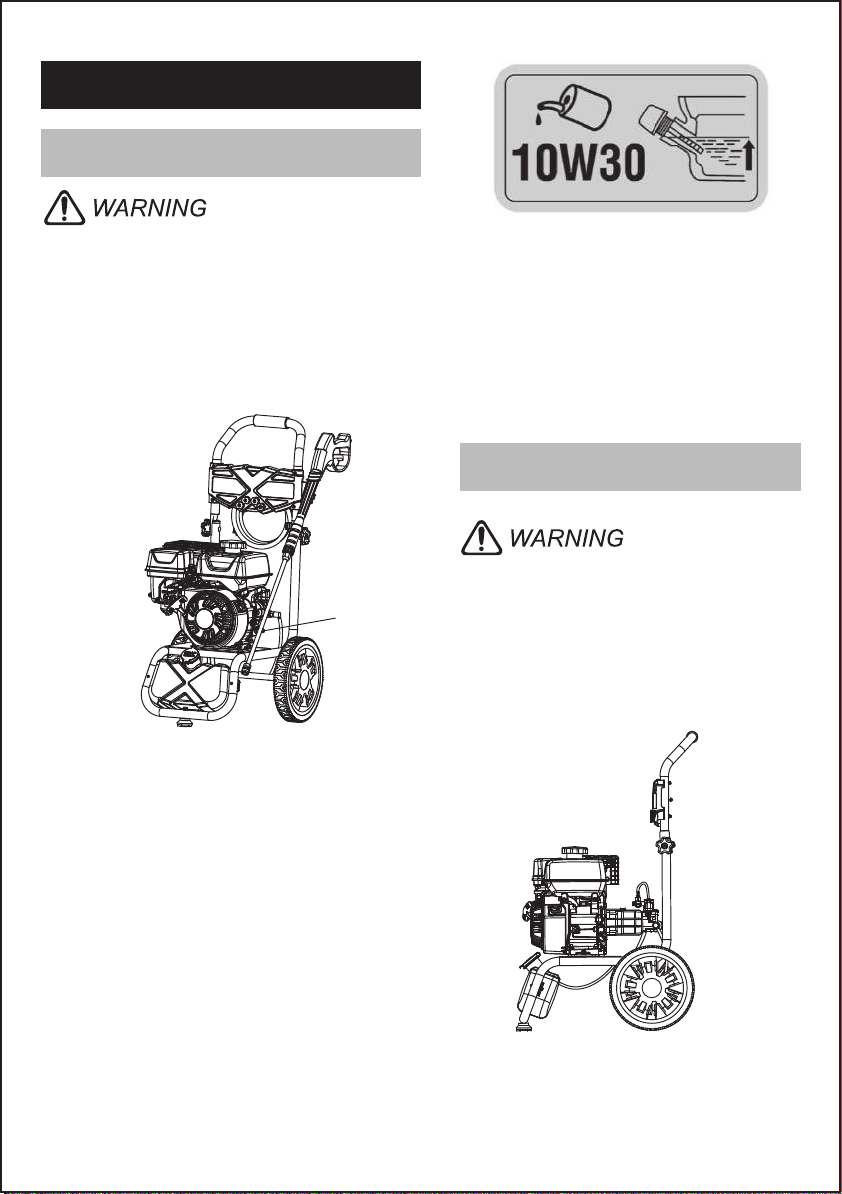

Always use SAE 10W-30 oil.

Oil crankcase capacity: 0.6L.

Reposition the oil gauge dipstick and

tighten it by turning clockwise.

Engine oil should be changed after the

first 5 hours, then every 50 hours.

Make sure there is enough fuel in the

fuel tank before operating.This is a

4-cycle engine and does not require a

gas/oil mixture. There is a separate

reservoir for gas and a separate reser-

voir for oil.

If it is necessary to add fuel, first make

sure the engine is OFF, and then

►

►

►

Preparation

Oil Level

Fuel Level

Engine shipped without oil in crank-

case. Before starting engine, fill with

oil with funnel provided..

Do not over-fill. Do not run the

engine with a high or low oil level as

this can cause engine damage.

Turn the oil gauge dipstick counter

clockwise; remove it and clean it with a

clean cloth.

Fully reinsert the oil gauge dipstick and

pull it out to check the oil level.

If the oil level is halfway up the dipstick

or below, refill with SAE

10W -30 oil through the dipstick hole

until the oil level reaches 3/4 up the

dipstick or until it reaches the bottom

lip of the dipstick hole as shown.

7

OIL DISTICK

►

►

►

►

►

►

Operating Instructions

Air Filter

remove the fuel cap by turning it count-

er clockwise.

When refueling, make sure the fuel

filter is in place and keep in mind all

safety precautions.

Use clean unleaded gasoline with a

minimum of 87 octane. DO NOT use

old gas. DO NOT mix oil with gasoline.

Fuel tank capacity: .2.6L

Press the two clips on the top of the air

filter cover to remove the cover.

Starting Procedure:

Connect pressure hose onto pump

outlet (step 3).

Connect spray gun and

pressure hose.

8

►

3.

1.

►

Connect garden hose onto pump

intlet (step 2).

►

Spark Plug

2.

►Insert the water inlet filter(L) into

pump intlet (step 1).

►Open water source.

►

1.

2.

3.

4.

5.

NOTE: If unable to start the engine, repeat

the above operation one or two times.

Cleaning Procedure:

►

Using the Accessories

Quick Connect Nozzles

Start the Engine

Turn the engine switch to "ON"

position.

Pull the choke lever towards the

CLOSE position

Pull trigger on spray gun to release

pressure.

Locate recoil cord and pull slowly until

resistance is felt. At this point, pull

rapidly to start engine.

Pull the choke lever towards the OPEN

position

Position the tip of the wand 6-8”

(15-20 cm) away from the surface to

clean at a 45°angle.

The color-coded quick connect

nozzles provide a wide array of spray

widths from 0° to 40° and are easily

accessible when placed in the conve-

nient nozzle holder.

0° spray angle = Red nozzle

For particularly stubborn accumulation

of grime. Not recommended for soft

materials like sidings, decks, painted

surfaces, cars.

15° spray angle = Yellow nozzle For

dirt accumulation over a surface.

9

ON/OFF

SWITCH

CHOKE LEVER

CHOKE LEVER

►

►

►

►

►

▬

▬

▬

▬

▬

►

►

▬

▬

►

►

Working with Detergents

Taking a Break

five minutes or more

For dirt accumulation over a large

surface.

40° spray angle = White nozzle

For

moderate

dirt

accumulation

over

a

large surface.

Soap = Black nozzle

For

operating

with

detergents or

clean

-

ing with low pressure.

High pressure in nozzle area. Risk of

injury caused by improperly locked

nozzle.

Make sure you hear the "click" when

inserting the nozzle tip into the quick

connection.

Pull the nozzle to make sure it is

seated properly before operating your

unit.

To avoid serious injury never point

spray nozzle at yourself, other persons

or animals.

Detergents can only be applied with

the black detergent nozzle.

Install the black detergent nozzle for

detergent application at low pressure.

Fill the detergent tank with Detergent.

With the engine running, pull trigger to

operate unit.

Liquid detergent is drawn into the unit

and mixed with water.

Apply detergent to work area.

Do not allow detergent to dry on

surface.

Always flush the detergent tank with

fresh water when the cleaning job is

done, to rinse/flush any remaining

detergents from the injection system.

NOTE: For best results see Cleaning

Tips for specific information on how to

clean different surfaces.

Never use:

Bleach, chlorine products or other

corrosive chemicals.

Liquids containing solvents (i.e., paint

thinners, gasoline, oils.)

Tri-sodium phosphate products.

Ammonia products.

Acid-based products.

These chemicals will harm the unit and

will damage the surface being

cleaned.

Use of these items will void the warran-

ty.

Move the engine stop switch to the

OFF position.

Release trigger and engage safety

lock.

10

25° spray angle = Green nozzle

For moderate dirt accumulation over

large surface.

-

►

► ►

►

►

►

►

►

►

►

►

►

►

►

►

►

►

Shutting Down

&Clean Up

Winterizing &

Long-Term Storage

Maintenance Instructions

If detergents have been used, insert 1

gallon of fresh water into Detergent

Tank. Siphon water at low pressure for

one minute to clear the line of residual

detergent.

Move the engine stop switch to the

OFF position. Close the fuel valve.

Turn off the water source.

Press trigger to release water pres-

sure.

Release trigger and engage gun safety

lock.

Disconnect the garden hose from the

water inlet on the unit.

Disconnect the high pressure hose

from the high pressure outlet. Store

the high pressure hose in the gun

holder assembly.

It is highly recommended to use a

small amount of antifreeze before

winter storage and during the cleaning

season to protect the pump from freez-

ing and premature wear.

Turn engine switch to the OFF position

Disconnect all hoses.

Unscrew cap from Pump Guard bottle.

Remove internal seal.

Reattach cap to Pump Guard bottle

and remove black protective cap.

Screw bottle into water inlet on pres-

sure washer pump and squeeze.

With ignition OFF, pull starter rope until

fluid starts to exit.

Unscrew bottle. Store or dispose prop-

erly.

If Guard is unavailable, perform the

following:

Disconnect all water connections.

Turn on the machine for a few

seconds, until the water which

remained in the pump exits. Turn off

engine immediately.

Failure to follow the above directions

may result in damage to the pump

assembly and accessories and void

the warranty.

Do not allow high pressure hose to

become kinked.

Store machine and accessories in a

room which does not reach freezing

temperatures. DO NOT store near

furnace or other sources of heat as it

may dry out the pump seals.

Pump Inspection

You should routinely make a visual

inspection of the pressure washer’s

pump.

Pump

11

Cleaning Tips

Engine

Deck Cleaning

House Siding

Cement Patios, Brick &

Stone

Cars, Boats& Motorcycles

Carry out maintenance tasks for the

engine according to the specifications

provided in the operating instructions

provided by engine manufacturer.

With or Without Detergent

Pre-rinse deck and surrounding area

with fresh water. For best results, limit

your work area to smaller sections of

approximately 25 square feet. Allow

Deck Wash to remain on surface 1-3

minutes. Do not allow detergent to dry

on surface. Rinse at high pressure in a

long sweeping motion keeping the

spray nozzle approximately 3-6 inches

from the cleaning surface. Always

clean from top to bottom and from left

to right. When moving on to a new

section of the cleaning surface, be

sure to overlap the previous section to

eliminate stop marks and ensure a

more even cleaning result.

With or Without Detergent

Pre-rinse vehicle with fresh water. For

best results, clean one side of vehicle

at a time and always apply detergent

from bottom to top, do not allow deter-

gent to dry on surface. If needed, use

special wash brush attachment (not

included) to remove stubborn dirt.

Rinse at high pressure

in a sweeping motion keeping the

spray nozzle approximately 6-8 inches

from the cleaning surface (distance

should increase when rinsing pin-strip-

ing or other sensitive surfaces).

Always clean from top to bottom and

from left to right. For best results, wipe

surface dry with a chamois or soft dry

cloth.

With or Without Detergent

Pre-rinse cleaning surface with fresh

water.For best results, limit your work

area to sections of approximately 6

feet and always apply detergent

from bottom to top). Allow detergent to

remain on surface 1-3 minutes. Do not

allow detergent to dry on surface, if

surface appears to be drying, simply

wet down surface with fresh water. If

needed, use special wash brush

attachment (not included) to remove

stubborn dirt. Rinse at high pressure-

from top to bottom in an even

sweeping motion keeping the spray

nozzle approximately 6 inches from

the cleaning surface.

With or Without Detergent

Pre-rinse cleaning surface with fresh

water. For best results, limit your work

area to smaller sections of approxi-

12

▬

▬

▬

▬

▬

Barbecue Grills, Outdoor

Power Equipment &

Gardening Tools

Patio & Lawn Furniture

Recommendations

Optional Accessories

mately 25 square feet. Allow Pressure

Wash or Degreaser to remain on

surface 1-3 minutes. Do not allow

detergent to dry on surface. Rinse at

high pressure in a sweeping motion

keeping the spray nozzle approximate-

ly 3-6 inches from the cleaning

surface. Always clean from top to

bottom and from left to right. For

removing extremely stubborn stains,

use a DirtBlaster® Spray Nozzle (sold

separately).

With or Without Detergent

Pre-rinse cleaning surface with fresh

water. Allow Pressure Wash to remain

on surface 1-3 minutes. Do not allow

detergent to dry on surface. Rinse at

high pressure keeping the spray

nozzle approximately 3-6 inches from

the cleaning surface. For removing

extremely stubborn dirt, it may be

necessary to move the spray nozzle

even closer to the surface for greater

dirt cutting action.

With or Without Detergent

Pre-rinse furniture and surrounding

area with fresh water. If using Pressure

Wash, apply to surface at low pres-

sure. Allow Pressure Wash to remain

on surface 1-3 minutes. Do not allow

detergent to dry on surface. If needed

use special Wash Brush Attachment

(not included) to remove stubborn dirt.

Rinse at high pressure in a sweeping

motion keeping the spray nozzle

approximately 3-6 inches from the

cleaning surface. For best results,

clean from top to bottom and from left

to right.

Before cleaning any surface, an incon-

spicuous area should be cleaned to

test spray pattern and distance for

maximum cleaning results.

If painted surfaces are peeling or

chipping, use extreme caution as pres-

sure washer may remove the loose

paint from the surface.

When using on surfaces which might

come in contact with food, flush surfac-

es with plenty of drinking water.

Optional accessories are available to

further enhance your cleaning

capabilities. These accessories are

accurate as of the printing date of this

manual.

Extension Hose

DirtBlaster® Spray Nozzle

Universal Wash Brush Kit

13

Troubleshooting

Remove the spark plug cable to pre-

vent accidental ignition of the engine

before making any repair.

Symptom

Engine Will Not

Start

Unit Does Not

Reach High

Pressure

Output Pres-

sure Varies

High And Low

Cause

Diameter of garden

hose is too small.

Replace with a 5/8 inch or larger garden

hose.

Remove filter and rinse out in warm

water.

Remove black detergent nozzle and

attach high pressure nozzle.

Turn water on full force. Check garden

hose for kinks, leaks or blockage.

Check garden hose for kinks, leaks and

blockage.

Turn water on full force. Check garden

hose for kinks, leaks or blockage.

Water supply is

restricted.

Not enough inlet

water supply.

Water inlet filter is

clogged.

Not enough inlet

water supply.

Black detergent

nozzle is attached.

No Gasoline. Fill Gas Tank.

Slide lever out to closed position.

Turn Ignition switch on

Squeeze the trigger to release the

pressure.

Choke is not in the

correct position.

Ignition switch is

not in the correct position.

Water pressure built

up in the machine.

Solution

14

Symptom

Output

Pressure

Varies Between

High And Low

No Detergent

Garden Hose

Connection

Leaks

Loose fittings.

Missing/worn

rubber washer.

Pump is sucking air.

Detergent suction

tube not properly

connected to the

machine.

Detergent is too

thick.

Filter on detergent

suction tube is

clogged.

Damaged or

clogged detergent

suction tube.

A high pressure

nozzle is attached.

Spray nozzle is

obstructed.

Check connection.

Dilute detergent

Run warm water through filter to remove

debris.

Remove obstruction or replace detergent

suction tube.

Replace with black detergent nozzle.

Blow out or remove debris with fine

needle.

Tighten fittings.

Insert new washer.

Water inlet filter is

clogged.

Spray nozzle is

obstructed.

Calcified gun, hose

or spray wand.

Check that hoses and fittings are air

tight. Turn off machine and purge pump

by squeezing trigger gun until a steady

flow of water emerges through the

nozzle

Remove filter and rinse out in warm

water.

Blow out or remove debris with a fine

needle.

Run distilled vinegar through detergent

tank.

Cause Solution

15

High Pressure Washers

Limited 24 month warranty

Cold water gas pressure washers

This product is warranted by to be free of defects in workmanship and materials

under normal use.

Specific warranty applies to:

Spray Wand

Leaks

Pump Is Noisy

Water Leaks

From Pump

(Up To 10 Drop

Per Minute Is

Permissible)

Not enough gas or

engine oil.

Loose fittings.

Thermal protection

device is activated.

Thermal protection device will auto reset.

Do not run pump for more than 5 minutes

without spraying.

Spray wand not

properly attached.

Turn the swivel nut of the gun clockwise

until connection is tight.

Check that hoses and fittings are air

tight. Turn off machine and purge pump

by squeezing trigger gun until a steady

flow of water emerges through the

nozzle.

Check fittings.

Symptom Cause Solution

16

•

•

•

•

•

The warranty period is calculated from the date of purchase by the end user and covers

cost for replacement parts / equipment and warranty labor per-formed. A copy of the

original purchase receipt or gift receipt from the original retailer must also accompany

the war-ranty claim.

This warranty does not cover:

•

•

Rato 209cc engines are warranted for two (2) years on parts and labor.

Pumps and engines are warranted for two (2) years on parts and labor.

Frames, handles and detergent tanks, as well as other structural components,

carry a one (1) year parts and labor warranty.

Standard accessories and attachments are warranted for a ninety (90) day period.

Any commercial, industrial or rental use of this equipment will reduce the warranty

to ninety (90) days.

Merchandise sold as reconditioned, used, demonstration or floor models.

Merchandise purchased on eBay and other online auction web sites.

Your Service Includes

24-Month Coverage

Within 24 months of purchase, we will provide timely and effective online after-sales service.We will

repair or replace any defective product (due to manufacturing fault) within the service period.

How to Return Your ENGINDOT Product

We will issue you a return label for your return.

Tear off the “Return Details” page and fill in the details. Include this inside your return package.

We will issue your replacement/refund on receiving the return package.

Return Details

In order to process your return as quickly as possible, we require the following information.

Please fill out this form and include it in your return package.

*If your purchase was fulfilled by Amazon, please use Amazon’s 30-day return service.

Purchase Name:

Order Number:

Date of Purchase:

Your Email Address:

Place of Purchase:

516-896-6611 Mon-Fri 9AM-5PM(ET)

www.engindotools.com

support@engindotools.com

Shenzhen Houqianding Trading Co., Ltd.

Room 504D, Block B, Sunshine Hotel, No.2003, Jiabin Road,

Jianan Community, Nanhu Street, Luohu District, Shenzhen

Table of contents

Other ENGINDOT Pressure Washer manuals

Popular Pressure Washer manuals by other brands

Coleman

Coleman PW0912201 manual

benza

benza BZ 170 Use and maintenance manual

Simpson

Simpson CLEAN MACHINE CM60976 use and care manual

Alto

Alto 30HA STANDARD I/MASTER I instruction manual

Dibo

Dibo JMB-E Series Original instruction manual

Pacific hydrostar

Pacific hydrostar Pacific Hydrostar 212cc Gasoline Powered Clear Water... Owner's manual & safety instructions

Kärcher

Kärcher HDS 3.9/20 Ea Cage Operator's manual

Kerrick

Kerrick I 1308A M Safety and operating manual

Meec tools

Meec tools 009874 operating instructions

Black & Decker

Black & Decker BEPW1300H Original instructions

Bosch

Bosch AQUATAK 10 operating instructions

Kärcher

Kärcher K 2.91 MD operating instructions