- 22 -

Danger

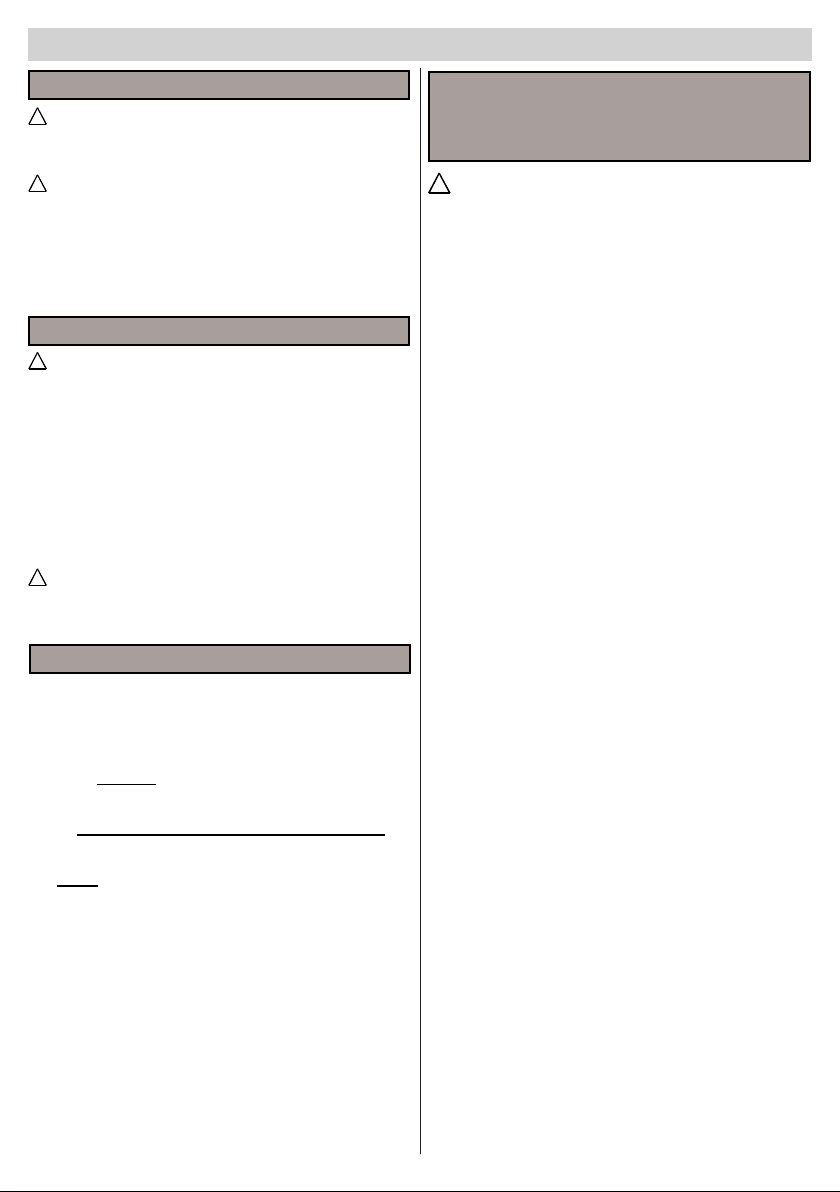

The cleaner must operate with clean water. Dirty or sandy

water, corrosive chemicals and solvents can cause severe

damage to the cleaner.

Danger

Never suck up liquids containing solvents or acids in the pure

state,forexamplepetrol,paintsolventsordiesel.Thespraymist

fromthelanceishighlyinammable,explosiveandpoisonous.

Failure to respect the above absolves the manufacturer

of all liability and represents negligent use of the product.

Information

Respect the instructions provided by the water utility

company.

Current regulations specify that the appliance may not be con-

nected to the drinking water supply unless a suitable system

separatoristted.

Use a suitable EN 12729 type BA system separator.

Water passing through a system separator is no longer classi-

edasdrinkingwater.

Warning

Do not connect the machine to a drinking water container.

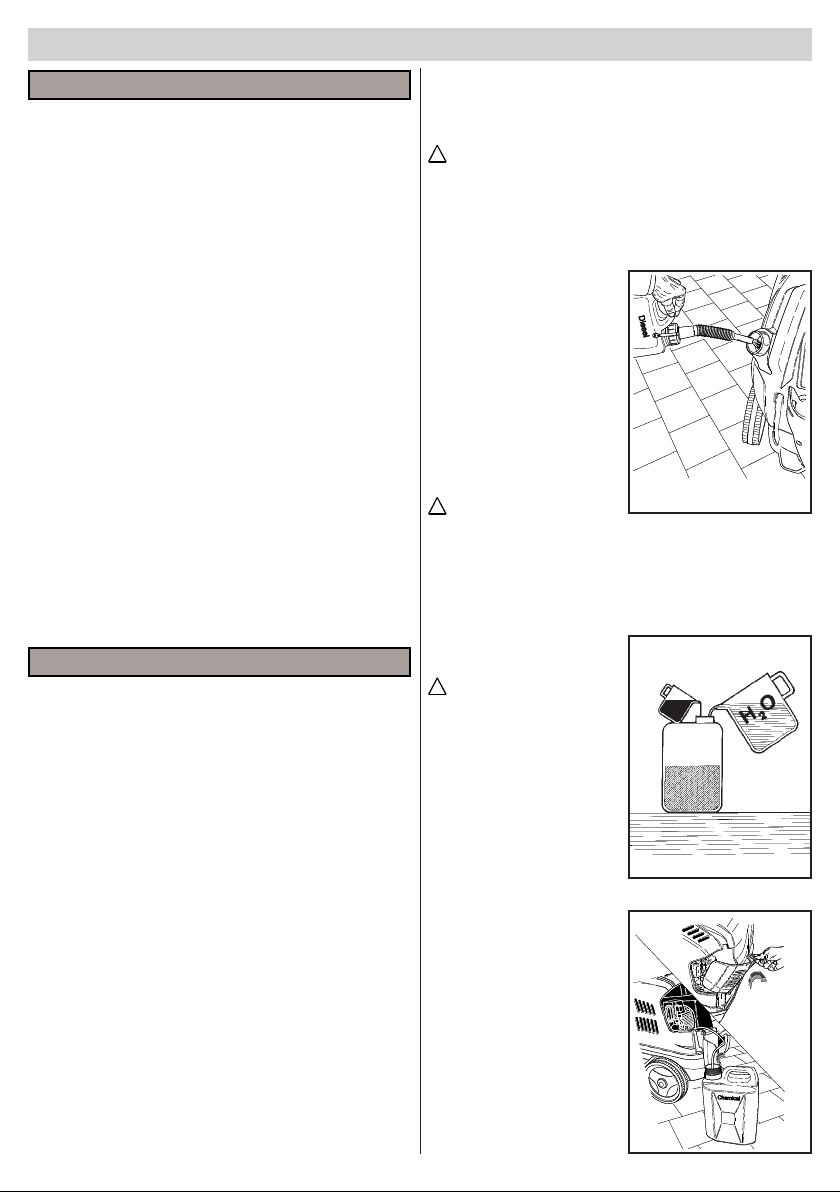

ELECTRICAL CONNECTION

The water cleaner must be connected to a mains electricity

supply conforming to current legislation and standards.

Ensure that the mains voltage available is the same as the vol-

tage at which the cleaner is supposed to work; this is indicated

ontheidenticationplate.

Danger

-Theelectriccable mustbe protectedfrom accidentalcrushing.

- Do not use the machine if the supply cable is damaged.

- The use of any electric appliance requires the respect of

some basic rules:

•Donottouchtheappliancewithwetordamphandsorfeet.

•Do not use the appliance bare-footed or with unsuitable

clothing.

• D o n o t p u l l t h e s u p p l y c a b l e o r t h e a p p l i a n c e i t s e l f i n o r d e r

to disconnect the plug from the electric supply.

(Forwatercleanersratedatlessthan3kWttedwithplug).

As for the protection against electric shock, the H.P.cleaner

belongs to CLASS I.

Failure to observe the above warning frees the manufac-

turer from all responsibility and constitutes negligent use

of the product.

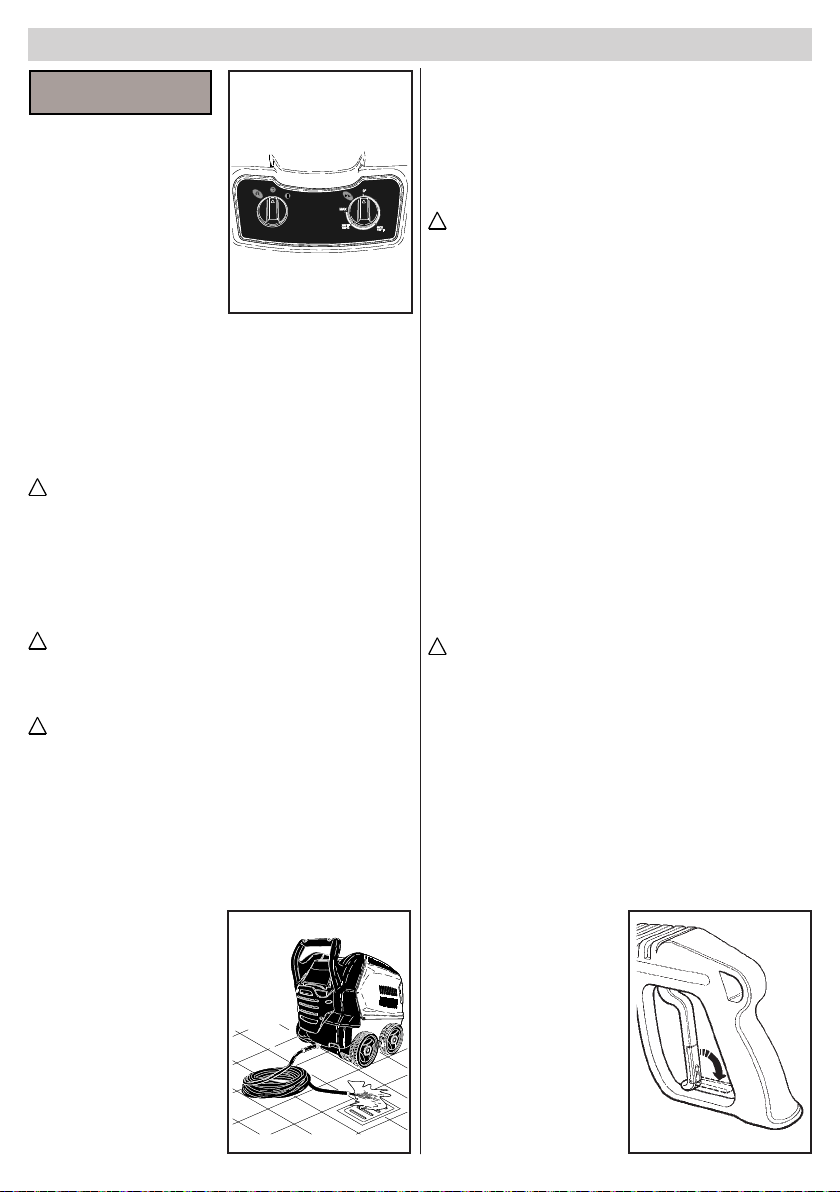

COMMAND AND CONTROL DEVICES

Warning

Before connecting the machine to the water supply and to the

powermains, it is essentialto know the function ofthe cleaner's

command and control devices.

SAFETY DEVICES

The safety devices protect the user and the appliance. They

must not be tampered with or used for other than their desi-

gnated purpose.

Safety valve: protects the high pressure hydraulic circuit in

the event of a by-pass valve malfunction or if the hydraulic

circuit is blocked.

The safety valve is calibrated by the Manufacturer and sealed.

FIG. 6

FIG. 5

Operations involving the safe-

tyvalve must be performed by

atechnicalservicecentreonly.

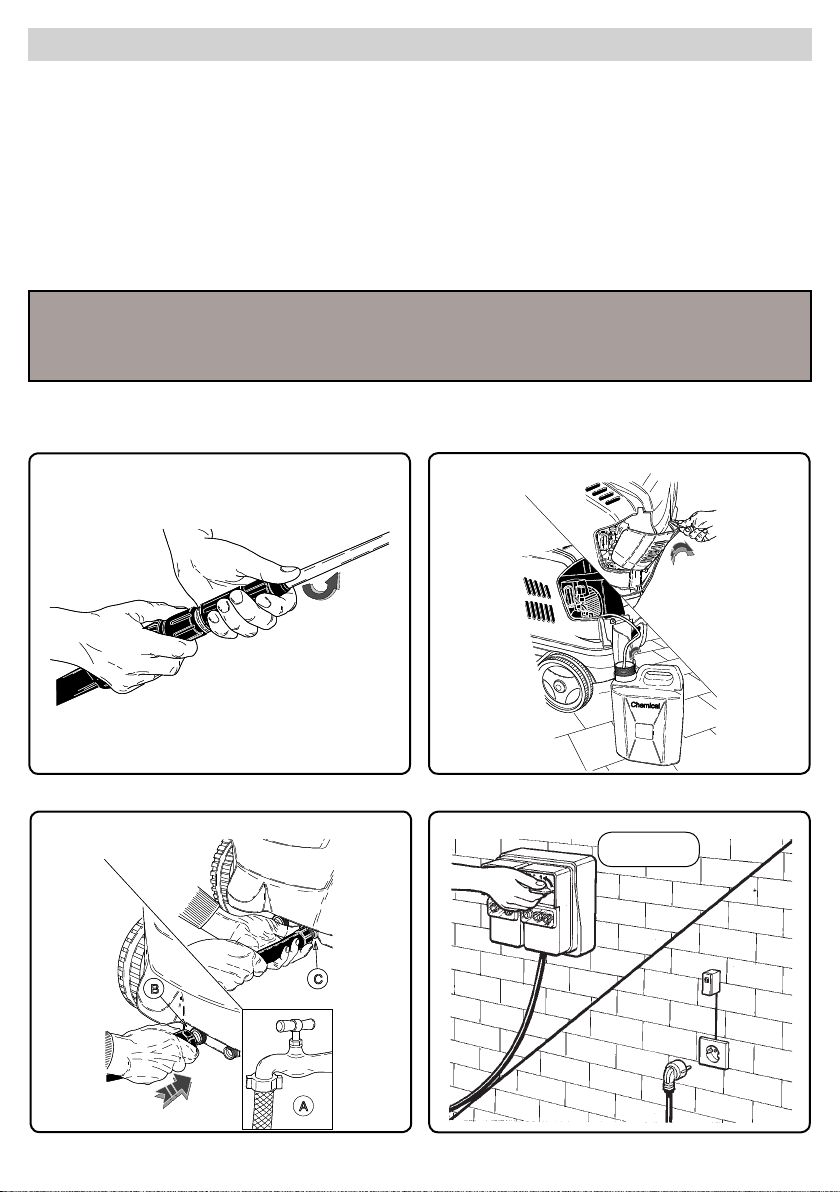

Safety device on lance

handgrip: Prevents the trig-

geronthehandgripfrombeing

operated accidentally.

Thermal cutout: stops the

high pressure washer if the

electric motor overheats.

WATER CIRCUIT CONNEC-

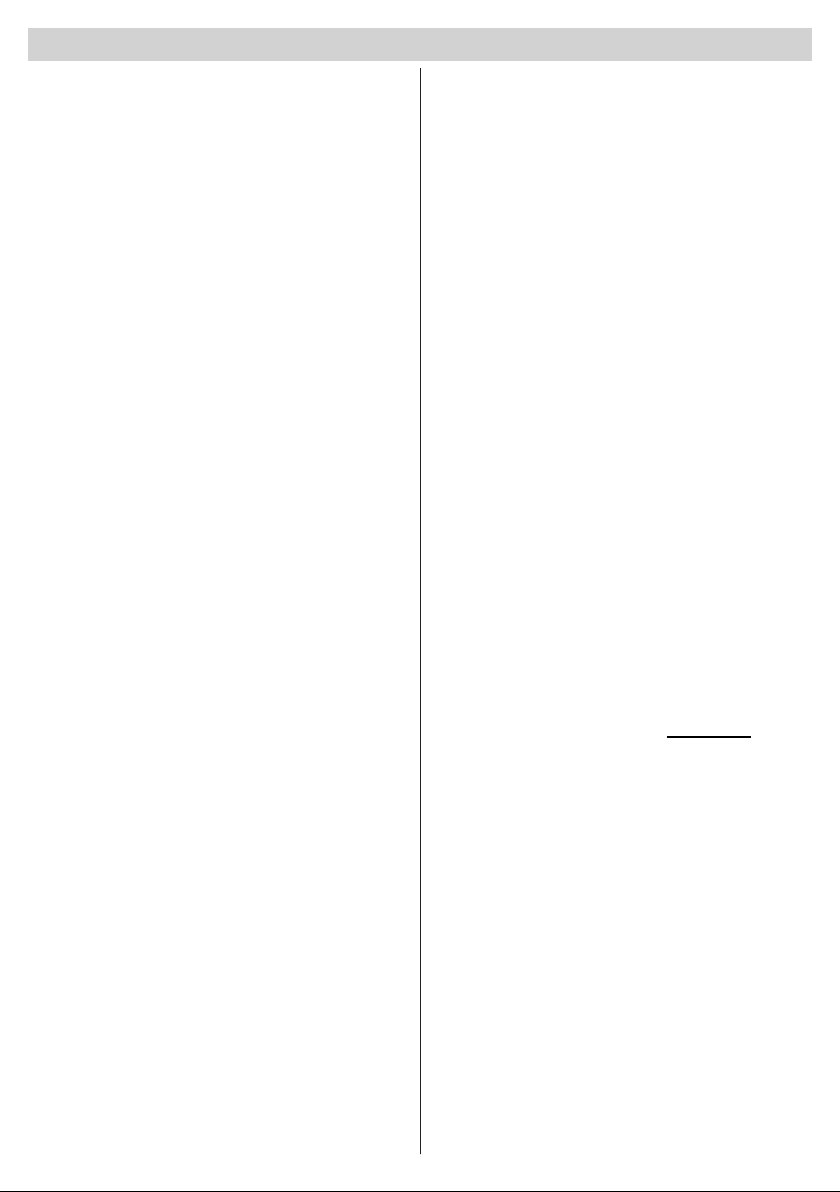

TION

Connect the feed hose to the

mains(g.5A)andtotheho-

setailonthecleaner(g.5B).

Check that the pressure and

quantity of the water supplied

bythemainsaresufcientfor

the cleaner to work properly:

200to800kPa(29to116PSI).

Maximum temperature of

feeding water 50°C (122°F).

Connect the high pressure

hose to the cleaner (g. 5C)

andtothelance(g.6).

FIG. 4

TRANSPORTING

To move the machine, di-

sconnect it from the mains

electricity and water supplies,

release the parking brake on

the side of the machine and

push it by the handle.

B

A

C

B

A

C