Engineered air DJ Series User manual

A

May 12 R2

INSTALLATION, OPERATION

AND MAINTENANCE MANUAL

FOR

DJ(E,S) & DG SERIES

INDIRECT GAS OR OIL FIRED HEATING UNITS

INDOOR AND OUTDOOR MODELS

UNIT MODEL NO. _________________

UNIT SERIAL NO. _________________

SERVICED BY: ___________________

TEL. NO: ________________________

CANADIAN

HEAD OFFICE

AND FACTORY

USA

HEAD OFFICE

AND FACTORY

CANADIAN

EASTERN FACTORY

1401 HASTINGS CRES. SE

CALGARY, ALBERTA

T2G 4C8

Ph: (403) 287-4774

Fx: 888-364-2727

32050 W. 83rd STREET

DESOTO, KANSAS

66018

Ph: (913) 583-3181

Fx: (913) 583-1406

1175 TWINNEY DRIVE

NEWMARKET, ONTARIO

L3Y 5V7

Ph: (905) 898-1114

Fx: (905) 898-7244

SALES OFFICES ACROSS CANADA AND USA

Retain instructions with unit and maintain in a legible condition.

Please give model number and serial number when contacting

factory for information and/or parts.

www.engineeredair.com

ADJ & DG MANUAL

2 of 34 May 12 R2

TABLE OF CONTENTS

YOU HAVE RESPONSIBILITIES TOO............................................................................................................................................... 3

INTRODUCTION................................................................................................................................................................................ 3

SAFETY PRECAUTIONS................................................................................................................................................................... 3

WARRANTY....................................................................................................................................................................................... 4

PARTS................................................................................................................................................................................................ 5

RECEIVING........................................................................................................................................................................................ 5

TEMPORARY STORAGE .................................................................................................................................................................. 5

INSTALLATION..................................................................................................................................................................................6

CODES............................................................................................................................................................................................... 6

MINIMUM CLEARANCE TO COMBUSTIBLES AND FOR SERVICE IN INCHES (mm).................................................................... 7

LIFTING.............................................................................................................................................................................................. 8

MOUNTING........................................................................................................................................................................................ 8

SHIPPING MATERIALS..................................................................................................................................................................... 9

ASSEMBLY ........................................................................................................................................................................................ 9

PIPING, ELECTRICAL OR CONTROL SERVICE CONNECTIONS.................................................................................................10

NATURAL GAS AND PROPANE INSTALLATION:.......................................................................................................................... 10

GAS LINE TESTING (EXTERNAL TO THE UNIT)........................................................................................................................... 11

OIL INSTALLATION ......................................................................................................................................................................... 11

HEAT EXCHANGER CONDENSATE DRAIN ON INDOOR UNITS.................................................................................................11

VENTING PRODUCTS OF COMBUSTION ..................................................................................................................................... 12

DUCT FURNACE INSTALLATION................................................................................................................................................... 13

PIPING, ELECTRICAL OR CONTROL SERVICE CONNECTIONS.................................................................................................13

ELECTRICAL INSTALLATION......................................................................................................................................................... 13

Recommended 24V Field Wiring Size:.............................................................................................................................................14

DUCT MOUNTED TE-6000-EA3 TEMPERATURE SENSOR.......................................................................................................... 15

COIL CONNECTIONS...................................................................................................................................................................... 15

DRAIN TRAPS.................................................................................................................................................................................. 16

FLUSHING AND DEGREASING OF WATER AND GLYCOL COILS............................................................................................... 16

HEAT TRANSFER FLUIDS.............................................................................................................................................................. 17

BEFORE START-UP........................................................................................................................................................................17

START-UP CHECK LIST..................................................................................................................................................................17

OPERATION ....................................................................................................................................................................................19

SAFETY SHUTOFF VALVE LEAK TEST:........................................................................................................................................ 20

GAS MANIFOLD............................................................................................................................................................................... 20

OPERATIONAL CHECK FOR ALL GAS FIRED DJ & DG UNITS.................................................................................................... 21

OPERATIONAL CHECK FOR ALL OIL FIRED DJ & DG UNITS ..................................................................................................... 22

COMBUSTION AND FINAL UNIT CHECK FOR UNITS WITHOUT TRAC CONTROLS.................................................................23

ELECTRODE DETAIL...................................................................................................................................................................... 24

UNIT SHUT-DOWN INSTRUCTIONS.............................................................................................................................................. 24

Service Shut Down...........................................................................................................................................................................24

Emergency Shut Down.....................................................................................................................................................................25

Start-Up After Extended Shut-Down Period......................................................................................................................................25

CONTROL SETTINGS ..................................................................................................................................................................... 25

MAINTENANCE................................................................................................................................................................................25

ELECTRICAL ................................................................................................................................................................................... 26

BELT ADJUSTMENT........................................................................................................................................................................ 26

SET SCREWS.................................................................................................................................................................................. 27

BEARING SETSCREW TORQUES.................................................................................................................................................. 27

LUBRICATION OF FAN BEARINGS................................................................................................................................................ 27

LUBRICATION OF DODGE FAN BEARINGS.................................................................................................................................. 28

MOTOR LUBRICATION ................................................................................................................................................................... 29

GAS MANIFOLD............................................................................................................................................................................... 30

GAS BURNERS................................................................................................................................................................................ 30

OIL BURNERS ................................................................................................................................................................................. 30

VENT TERMINALS........................................................................................................................................................................... 30

FILTERS........................................................................................................................................................................................... 30

CONTROLS...................................................................................................................................................................................... 31

CONTROL ENCLOSURE VENTILATION ........................................................................................................................................ 31

OUTDOOR AIR INTAKES, MIXING SECTIONS AND DAMPERS................................................................................................... 31

COILS............................................................................................................................................................................................... 31

© Airtex Manufacturing Partnership. All rights reserved.

ADJ & DG MANUAL

3 of 34 May 12 R2

YOU HAVE RESPONSIBILITIES TOO

This installation, operation and maintenance manual can not cover every possibility, situation or

eventuality. Regular service, cleaning and maintaining the equipment is necessary. If you are not capable

of performing these tasks, hire a qualified service specialist. Failure to perform these duties can cause

property damage and/or harm to the building occupants and will void the manufacturers’ warranty.

INTRODUCTION

Engineered Air units are high quality products designed and manufactured to provide many years of

trouble-free operation. We recommend that this manual be read thoroughly to ensure proper installation,

efficient operation and proper maintenance of this equipment. The submittal record is considered to be

part of the Installation, Operation and Maintenance Manual. Please report any omissions to the national

service manager.

SAFETY PRECAUTIONS

Read, understand and follow the complete manual before beginning the installation, including all safety

precautions and warnings.

mhgWARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death or property

damage.

Be sure to read and understand the installation, operation and service instructions in this

manual.

Improper installation, adjustment, alteration, service or maintenance can cause serious

injury, death or property damage.

—Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

—WHAT TO DO IF YOU SMELL GAS

·Do not try to light any appliance.

·Do not touch any electrical switch; do not use any phone in your building.

·Leave the building immediately.

·Immediately call your gas supplier from a phone remote from the building. Follow

the gas supplier’s instructions.

·If you cannot reach your gas supplier, call the fire department.

—Installation and service must be performed by a qualified installer, service agency or the

gas supplier.

ADJ & DG MANUAL

4 of 34 May 12 R2

Warning:

m

Pool, laundry and common cleaning products often contain fluorine or

chlorine compounds. When these chemicals pass through the heater,

they can form strong acids. The acid can eat through the heat

exchanger wall, causing serious damage and presenting a possible

threat of flue gas spillage into the building.

Warning:

m

c

This unit is connected to high voltages. Electrical shock or death could occur

if instructions are not followed. This equipment contains moving parts that

can start unexpectedly. Injury or death could occur if instructions are not

followed. All work should be performed by a qualified technician. Always

disconnect and lock out power before servicing. DO NOT bypass any

interlock or safety switches under any circumstances.

WARRANTY

LIMITED WARRANTY ENGINEERED AIR will furnish without charge, F.O.B. factory, freight collect,

replacement parts for, or repairs to products covered herein which prove defective in material or

workmanship under normal and proper use for a period of twelve (12) months from the initial start-up or

eighteen (18) months from the date of shipment, whichever expires sooner, provided the customer gives

ENGINEERED AIR written notice of such defects within such time periods and provided that inspection by

ENGINEERED AIR establishes the validity of the claim and all pertinent invoices have been paid in full.

The repairs or replacements will be made only when the complete product(s) or part(s) claimed to be

defective are returned to ENGINEERED AIR or a depot designated by ENGINEERED AIR, transportation

charges prepaid. Repairs or replacements as provided for by this paragraph shall constitute fulfillment of

all ENGINEERED AIR's obligations with respect to this warranty. The refrigerant charge is not included in

any part of this warranty. This warranty does not apply to any products or parts thereof that have been

subject to accident, misuse or unauthorized alterations, or where ENGINEERED AIR's installation and

service requirements have not been met.

The foregoing warranty is in lieu of all other warranties, express or implied. ENGINEERED AIR specifically

disclaims any implied warranty of merchantability and/or fitness for purpose. Under no circumstances shall

ENGINEERED AIR be liable to, nor be required to indemnify, Buyer or any third parties for any claims,

losses, labour, expenses or damages (including special, indirect, incidental, or consequential damages) of

any kind, resulting from the performance (or lack thereof) of this Agreement or the use of, or inability to use

the goods sold hereunder, including, but not limited to, damages for delay, temporary heating/cooling

costs, loss of goodwill, loss of profits or loss of use. Furthermore, the parties agree that the Buyer's sole

remedy under this Agreement shall be limited to the limited warranty set forth in the preceding paragraph

relating to the repair or replacement of any defective goods. Under no circumstances shall any claim or

award against ENGINEERED AIR exceed the original contract price whether awarded through arbitration,

litigation or otherwise.

ENGINEERED AIR Warranty is void if:

1. The unit is not installed in accordance with this manual.

2. The start-up and operation of the unit is not performed in accordance with this manual.

3. The unit is operated in an atmosphere containing corrosive substances.

4. The unit is allowed to operate during building construction.

5. The unit is allowed to operate in atmospheres where chlorine or chlorine compounds are present or

which contain any contaminant (silicone, aluminum oxide etc.) that adheres to the spark ignition

flame sensing probe.

ADJ & DG MANUAL

5 of 34 May 12 R2

PARTS

Warning:

mc

hg

Any replacement part must be of equivalent listing or certification and be

functionally equivalent. The replacement part must meet the original’s

specification in terms of functionality including certifications, timing, input

and output range,accuracy and operation.

Failure to replace parts or components with equivalent parts can cause

property damage, injury or death.

1. Motors:

Motor manufacturers have service centers that will repair or replace motors as required.

2. Parts Other Than Motors:

Contact the nearest Engineered Air sales office or factory. Be sure to include Model Number,

Serial Number, date of installation and nature of failure along with the description of the parts

required. Some parts may not be stocked items that must be made or ordered.

RECEIVING

Refer to the back of the packing slip for receiving unit instructions.

On receipt of the unit, check for damage. Inspect protective covers for punctures or other signs that there

may be internal damage. Remove protective covers and check for internal damage. Replace covers if the

unit is not being assembled or installed at this time. Open access doors and check for internal damage.

Close access doors when the inspection is complete.

All units are pre-tested at the factory immediately prior to shipping and are ensured to be in good operating

condition at that time. If damage is found follow the instructions on the packing slip.

On receipt of the unit, check electrical characteristics (see rating plate) to make sure the unit voltage is

compatible with that available for the unit. All parts for field installation are listed on the shipping order form.

TEMPORARY STORAGE

If a unit is to be stored prior to installation the following precautions are required:

• Store in a well drained area that will not accumulate surface water.

• Store in an area where the unit will not get damaged.

• The entire perimeter and any full height cross members of the unit must be supported by a level

surface and the supporting surface must be adequate for supporting the entire weight of the unit.

• All protective coverings that were provided for shipping must be in place.

• Protect indoor units from rain and snow.

ADJ & DG MANUAL

6 of 34 May 12 R2

INSTALLATION

Warning:

mg

Only equipment bearing a CSA C22.2 No. 213 or UL 1604 rating plate (label)

with an accompanying CSA Certification mark is suitable for installation in

a hazardous location. The hazardous location must conform with the Class,

Division, Group and temperature code (if shown) displayed on the rating

plate (label).

If not marked as noted above, the unit is not rated for hazardous locations

and should not be installed in areas requiring any hazardous location

rating.

Caution:

m All wiring, piping and fuel line installation must be completed by qualified

persons in accordance with all federal, state, provincial and/or local codes.

Note: Installation shall be in accordance with this manual and all other associated component and

control Installation, Operation and Maintenance Manuals.

CODES

In Canada:

1. The installation of this unit shall be in accordance with the latest edition of the Canadian Electrical

Code, Part 1 –C.S.A. Standard C22.1, Provincial and Local Codes, and in accordance with the

local authorities having jurisdiction.

2. This unit shall be electrically grounded in accordance with the latest edition of the Canadian

Electrical Code, Part 1 –C.S.A. Standard C22.1, Provincial and Local Codes, and in accordance

with the local authorities having jurisdiction.

3. The installation of this unit shall be in accordance with the latest edition of the Canadian Natural

Gas and Propane Installation Code, C.S.A. Standard B149.1, Provincial and Local Codes, and in

accordance with the local authorities having jurisdiction.

4. In accordance with local authorities having jurisdiction or CSA. Standard B149.1 a readily

accessible approved manual shut-off valve shall be installed in either the drop or riser as close as

possible to the valve train (gas manifold).

5. The installation of this unit shall be in accordance with the latest edition of the National Plumbing

Code of Canada, Provincial and Local Codes, and in accordance with the local authorities having

jurisdiction.

6. The installation of this unit shall be in accordance with all other National, Provincial and Local

Codes, and in accordance with the local authorities having jurisdiction.

In USA:

1. The installation of this unit shall be in accordance with the latest edition of the National Electrical

Code (ANSI/NFPA 70), State and Local Codes and in accordance with the local authorities having

jurisdiction.

ADJ & DG MANUAL

7 of 34 May 12 R2

2. This unit shall be electrically grounded in accordance with the latest edition of the National

Electrical Code (ANSI/NFPA 70), State and Local Codes and in accordance with the local

authorities having jurisdiction.

3. If the unit has not been provided with an electric disconnect switch, one of adequate ampacity shall

be installed in accordance with Article 430 of the National Electrical Code (ANSI/NFPA 70).

4. The installation of this unit shall be in accordance with the latest edition of the National Fuel Gas

Code ANSI/Z223.1/NFPA 54, State and Local Codes and in accordance with the local authorities

having jurisdiction.

5. In accordance with local authorities having jurisdiction or NFPA 54 an accessible approved manual

shutoff valve shall be installed within 6 ft (1.8 m) of the valve train (gas manifold).

6. The installation of this unit shall be in accordance with the latest edition of the National Standard

Plumbing Code (NSPC), State and Local Codes and in accordance with the local authorities having

jurisdiction.

7. The installation of this unit shall be in accordance with all other National, State and Local

Codes, and in accordance with the local authorities having jurisdiction.

MINIMUM CLEARANCE TO COMBUSTIBLES AND FOR SERVICE IN INCHES (mm)

COMBUSTIBLE CLEARANCE SERVICE CLEARANCE

MODEL TOP FRONT BACK SIDE BOTTOM FLUE OPPOSITE

BURNER

SIDE

SERVICE/

BURNER

SIDE

CONTROL

PANEL †

DJ(E,S) INDIRECT

FIRED GAS HEAT 6"

(152) 6"

(152) 6"

(152) 1"

(25) 0 9"

(229) NA 24" (610)

42" (1067)

DG INDIRECT

FIRED GAS HEAT 6"

(152) 6"

(152) 6"

(152) 1"

(25) 0 9"

(229) NA 24" (610)

42" (1067)

INDIRECT FIRED

OIL HEAT 6"

(152) 6"

(152) 6"

(152) 1"

(25) 0 9"

(229) 18"

(457) 24" (610)

42" (1067)

FLUID COILS &

RECOVERY

DEVICES

1"

(25) 1"

(25) 1"

(25) 1"

(25) 0 NA NA UNIT

WIDTH 42" (1067)

ELECTRIC HEAT 1"

(25) 1"

(25) 6"

(152) 1"

(25) 0 NA NA UNIT

WIDTH

+10" (254) 42" (1067)

OTHER (NON

GAS) UNITS 1"

(25) 1"

(25) 1"

(25) 1"

(25) 0 NA NA 24" (610) 42" (1067)

† - As required by the Canadian Electrical Code or the National Electrical Code.

For Safety and Service, the minimum clearances must be observed. Minimum clearances also provide

adequate combustion air supply.

ADJ & DG MANUAL

8 of 34 May 12 R2

LIFTING

Engineered Air units are constructed on a structural steel base frame. The unit base frame is equipped with

lifting lugs specifically located to facilitate proper lifting of the unit. Spreader bars must be used to keep

rigging away from the unit cabinetry. All lifting lugs must be used. If using a lift truck, ONLY lift using the

perimeter structural frame. DO NOT allow forks to lift on cabinet or unit floor.

Note: There may be bottom mounted components, such as drain piping, that can be easily damaged.

Warning:

m Injury or death can result from improper rigging and lifting. Rigging and

lifting of equipment must be performed by qualified personnel with proper

equipment using appropriate and approved safety precautions.

MOUNTING

Units must be mounted level. Failure to do so can cause water to be trapped in drain pans or operational

problems that can void warranty. Failure to do so can result in injury or death, damage the equipment

and/or building and can be a cause of poor indoor air quality.

Equipment must be installed so that sufficient working clearance and component access is provided.

Some units are designed for cantilevered installation. Consult the Submittal Record for specific unit

mounting.

Consult the Submittal Record for specific unit mounting. Engineered Air units are constructed for three

types of mounting:

1. Base mounting –Consult the Submittal Record for type of mounting. Unless the unit is specifically

designed for point or other mounting, the base of the unit must be supported continuously by a

mounting support system that is directly below the unit structural base frame and runs the entire

length and width of the unit. Refer to the Submittal Record for mounting information. Units 100”

(2500mm) wide and under can be supported on each side continuously along the length of the unit.

As a minimum, sleepers that are installed perpendicular to the length of the unit must be continuous

across the width of the unit and shall be installed at the end lifting point base rails and the lesser of

80” (2000mm) on center or at all lifting points.

2. Suspended mounting –Where units have been designed for suspended mounting, factory provided

connections for hanger rods will be provided. All hanger rod supports must be used. Suspended

units must be protected from damage. When installed in aircraft hangers, parking garages or

repair garages the installation must comply where applicable with:

a) The Canadian Natural Gas and Propane Installation Code, C.S.A. Standard B149.1

b) The Standard on Aircraft Hangers, ANSI/NFPA 409

c) The Standard on Parking Garages, ANSI/NFPA 88A

d) The Standard on Repair Garages, ANSI/NFPA 88B

3. Roof curb mounting –The curbs are constructed of heavy gauge load bearing, galvanized steel,

and must be fully insulated after installation. Wood nailer strips are provided for easy attachment of

roof flashing. Gasket material is supplied with the unit and must be field mounted on the curb to

seal the joint between the curb and the unit frame. The curb must be supported along its entire

perimeter and any full height cross members as shown on the shop drawings. Point loading of

curbs is not permissible.

ADJ & DG MANUAL

9 of 34 May 12 R2

The gasket material provided for the curb is closed cell foam. Closed cell foam is dense and does

not compress easily. If the unit is split and shipped in sections there will also be gasket material for

sealing between sections. The gasket material for splits is open cell foam. It is less dense than the

closed cell foam and compresses easily.

ONLY USE THE CLOSED CELL FOAM GASKET PROVIDED FOR SEALING THE CURB.

Curbs may be broken down for shipping. Field assembly is required by the installing contractor. Bolt

all sections together at split joints using hardware provided. The installing contractor must caulk and

seal all joint and corner flashings. All flashings and braces that are provided must be installed. DO

NOT screw/penetrate joint, corner or adaptor flashings. Refer to assembly instructions sent with

roof curb.

SHIPPING MATERIALS

Remove shipping materials. Shipping materials may include, but are not limited to:

• Protective covers over openings, inlets, condenser coils etc.

• Protective covers over split sections if provided.

• Tie-down bolts, straps and blocks on fan and compressor vibration isolators.

• Tie-down bolts, straps and blocks on tilt equipped heat pipes and enthalpy/desiccant wheels if

supplied.

• Indirect fired heat exchangers may be supported with wood for shipping. Remove.

ASSEMBLY

Warning:

m

Assembly of split units requires bolting together the base frame of adjacent

sections. This may require personnel to work under the unit during

assembly. Injury or death can result from improper support or improper

loading of the curb. Additional temporary support shall be provided by the

installer for the safety of personnel.

If the unit is split and shipped in sections, the sections must be field assembled. All sections are pre-drilled

for assembly. The hardware and gaskets are packed in one of the sections. Apply the gasket, align the

sections. The base frame must be bolted together first. Access below the unit for bolting of the base frame

must be provided. Once the base frame has been tightly fastened, loosely assemble all the bolts and nuts,

and then tighten. Caulk all split lines. Install split joint caps. The inlet hood is designed for field installation.

On outdoor units connect the hood to the support flange and attach with appropriate fasteners. Connect all

wiring on units that had been split for shipment.

The gasket material provided for the split is open cell foam. Open cell foam is light and compresses easily.

If the unit is mounted on a curb provided by Engineered Air there will also be gasket material for sealing

the curb. The gasket material for curbs is closed cell foam. It is more dense than open cell foam and does

not compress as easily.

ONLY USE THE OPEN CELL FOAM GASKET PROVIDED FOR SEALING THE SPLIT(S).

SPLIT UNIT WIRING

All split wiring must be completed by an electrician prior to starting the equipment. A number of different

methods are used to reconnect the wiring.

Power wire: this wiring is generally not broken or spliced, and will extend from the device back to the

contactor or terminal block inside the electrical panel(s). The wire will be tagged to identify which panel it

extends to and will be numbered to the corresponding connection.

ADJ & DG MANUAL

10 of 34 May 12 R2

The location of the equipment split line may result in the wire being disconnected at the device it is feeding.

The wire bundle will be tagged and identified. Confirm correct rotation of 3 phase devices after the wiring

connections has been completed.

Control wire: this wire is typically broken near the split line, to be reconnected at either a enclosed terminal

block, junction box or extended to a nearby control panel. Each wire or wire bundle will be tagged and

numbered to indicate the location it is sent to.

Sensor wire shield: The drain wire from the shield must be grounded (at one end only). A ground

connection point is available for connection at the point of termination.

All loose wiring must be securely fastened to the equipment casing upon completion.

PIPING, ELECTRICAL OR CONTROL SERVICE CONNECTIONS

DO NOT install anything that will interfere with equipment access or the rating plate.

Engineered Air equipment is constructed with cabinet and floors designed to prevent water from entering

the building through the installed unit. When ordered, factory installed pipe chases and/or electrical chases

are built into the unit floor. Factory chases are provided with covers that need to be replaced and sealed

after piping and electrical connections are made.

THE FLOOR OF THE UNIT HAS BEEN MADE WATER-RESISTANT. DO NOT CUT OR DRILL HOLES

IN THE FLOOR OR USE PENETRATING FASTENERS.

All penetrations through the unit walls must be caulked and sealed to prevent air and/or water from

entering the unit.

NATURAL GAS AND PROPANE INSTALLATION:

1. Installation must be made in accordance with the requirements of the authorities having jurisdiction.

2. Check the unit rating plate and confirm fuel type, supply pressure, input rating and temperature rise.

3. Refer to the heater rating plate for determining the minimum gas supply pressure for obtaining the

maximum gas capacity for which this heater is specified.

4. Gas supply pressure higher than the unit rating plate requires an additional field supplied gas regulator.

5. Install an approved appliance shutoff valve on the gas supply in accordance with the requirements of

the authorities having jurisdiction.

6. Gas lines shall not interfere with unit access. The gas line connection at the heater shall have an

approved drip leg with screwed cap.

7. A minimum 1/8 inch NPT plugged tapping, accessible for test gauge connection, must be installed

immediately upstream of the gas supply connection to the unit.

8. On indoor units any control device (regulator, diaphragm valve, high and low pressure switch, etc.) that

requires a bleed or vent line, must be vented in accordance with applicable codes.

ADJ & DG MANUAL

11 of 34 May 12 R2

GAS LINE TESTING (EXTERNAL TO THE UNIT)

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any testing of that system at test pressures in excess of 0.5 psi (3.5 kPa).

The appliance must be isolated from the gas supply system by closing its individual shutoff valve during

any testing of that system at test pressure equal to or less than 0.5 psi (3.5 kPa).

OIL INSTALLATION

Installation must be made in accordance with NFPA 31 or CSA B139 and with the requirements of

authorities having jurisdiction.

1. Check the unit name plate and confirm fuel type and input rating.

2. The heaviest fuel oil type is marked on the unit name plate.

3. The unit is to be supplied with an adequate flow of clean, air free fuel oil at a minimum temperature

of 32°F (0°C) at a neutral pressure. This requirement can be met if the oil is supplied to the unit

from an indoor day tank with a gravity supply.

4. All oil piping to the heater must be installed in accordance with good piping practices. (See

supplemental piping information bulletin from the burner manufacturer).

5. All oil burners should have an oil return line.

6. Oil fired heaters MUST use “A” vent.

7. OIL-FIRED APPLIANCES SHALL BE CONNECTED TO VENTS HAVING SUFFICIENT DRAFT AT

ALL TIMES TO ENSURE SAFE AND PROPER OPERATION OF THE APPLIANCE.

HEAT EXCHANGER CONDENSATE DRAIN ON INDOOR UNITS

The drain must be installed in accordance with all plumbing codes.

The condensate is to be drained with minimum 1/2” (13 mm) nominal drain line, of material suitable for

corrosive condensate, to an indirect drain connection.

ADJ & DG MANUAL

12 of 34 May 12 R2

AS REQUIRED BY

CHIMNEY TYPE "B" OR EQUIVALENT

COMBUSTABLE

VENT CONNECTOR

INDOOR UNIT

DRAFT HOOD

BURNER

INSTALLATION

CODE / AUTHORITY

VENTING PRODUCTS OF COMBUSTION

Installation shall be in accordance with the

requirements of authorities having jurisdiction and

ANSI Z2231/NFPA 54 or CSA B149.1. Heaters

must be provided with sufficient combustion air and

shall not be located in an area where a negative

pressure will be created that will starve the burner

of combustion air. Flue outlet pressure must not

exceed maximum over fire pressure shown on the

nameplate.

Do not connect the vent to any portion of

mechanical draft systems that are under positive

pressure. Do not install dampers or other

restrictive devices in the flue vent pipe.

Vent terminations shall be in accordance with the

requirements of the authorities having jurisdiction.

The vent shall be installed in such a manner that access to the appliance or unit rating plate is not

obstructed.

Indoor

1. A vertical chimney must be certified “A” or “L” or equivalent type on units without draft hoods. Type

“B” vent is acceptable on units with Engineered Air draft hoods. The vent size shall be selected

from appropriate approved Vent Table.

Note: Oil fired heaters MUST use “A” vent.

2. A vent connector shall be of approved material and installation. It shall have a minimum clearance

of 9" (229 mm) to combustible material. All horizontal portions of the venting system shall be

supported to prevent sagging. All horizontal runs shall have a minimum rise of 2% in the direction

of discharge. Horizontal vents shall be properly supported.

3. Units without draft hoods shall have individual chimneys.

4. This appliance shall not be connected to any portion of a mechanical draft system operating under

positive pressure.

5. See separate Supplemental Installation Instructions for units that have side wall venting.

Outdoor

Where appropriate, Engineered Air outdoor vent terminations may be provided. Two styles are shown

below. The standard vent termination on the left and the old style vertical termination on the right. Attach

the vent termination securely to the unit casing using #8 X 5/8” (minimum) sheet metal screws with

washers at all holes provided. Horizontal clearance to obstructions is 24” (600mm) for the standard vent

termination. Flue gases may discolour or damage adjacent surfaces. Vent terminations must not be under

structures or building overhangs.

ADJ & DG MANUAL

13 of 34 May 12 R2

When the chimney and flue cap are provided by others, install in accordance with the instructions for the

chimney and flue cap and to the requirements of the authorities having jurisdiction. The chimney shall

have a temperature rating equivalent to “A” vent and be suitable for outdoor installation. Support the

chimney independent of the unit.

DUCT FURNACE INSTALLATION

A Duct Furnace is an indirect fired furnace without the fan. If a duct furnace is connected to areturn air

duct or any other inlet air restriction, the duct furnace shall be installed on the positive pressure side of the

air-circulating fan. The airflow at the heater shall be suitably measured and shall be adjusted to within

± 10% of the stated airflow on the nameplate.

Duct Furnaces shall be installed with inlet duct that provides air distribution equivalent to a straight run of

duct having the same cross-sectional area as the inlet connection and not less than 2 equivalent diameters

in length.

Removable air tight access panels shall be provided on both the upstream and downstream sides of the

duct furnace. The access panels shall be accessible when the appliance is installed for service and shall

be sized to allow observation of smoke or light inside the casing to indicate the presence of leaks in the

heat exchanger.

PIPING, ELECTRICAL OR CONTROL SERVICE CONNECTIONS

DO NOT install anything that will interfere with equipment access or the rating plate.

Engineered Air equipment is constructed with cabinet and floors designed to prevent water from entering

the building through the installed unit. When ordered, factory installed pipe chases and/or electrical chases

are built into the unit floor. Factory chases are provided with covers that need to be replaced and sealed

after piping and electrical connections are made.

THE FLOOR OF THE UNIT HAS BEEN MADE WATER-RESISTANT. DO NOT CUT OR DRILL HOLES

IN THE FLOOR OR USE PENETRATING FASTENERS.

All penetrations through the unit walls must be caulked and sealed to prevent air and/or water from

entering the unit.

ELECTRICAL INSTALLATION

DO NOT install anything that will interfere with equipment access or the rating plate.

ADJ & DG MANUAL

14 of 34 May 12 R2

The unit must be electrically grounded and all wiring must be installed in accordance with the National

Electrical Code, ANSI/NFPA 70, and/or the Canadian Electric Code CSA 22-1 and to the approval of the

authorities having jurisdiction. THE FLOOR OF THE UNIT HAS BEEN MADE WATER-RESISTANT. DO

NOT CUT OR DRILL HOLES IN THE FLOOR OR USE PENETRATING FASTENERS.Field wiring

diagrams, internal wiring diagrams and operating functions are included in the control cabinet. The power

requirements are indicated on the rating plate. Where field wiring of control circuits is required, take care to

size the field wiring for a maximum 10% voltage drop. The control circuit ampacity is noted on the field

wiring diagram. See the field wiring diagram for requirements for shielded or twisted pair wire for solid state

devices.

Caution:

m

Temporary Power Generation

The warranty will be void if the voltage being fed from any temporary

generator is not within 10% of the nominal rated nameplate voltage and

voltage imbalance shall be limited to 2%. A power monitor shall be installed

by others to properly monitor power quality and conditions.

All generator sets shall be provided with overcurrent and earth-fault

protection. The protective apparatus should be capable of interrupting,

without damage, any short-circuit current that may occur.

Warning:

m No unspecified external load shall be added to the control transformer

circuit(s) or to the main power circuit(s).

Recommended 24V Field Wiring Size:

Copper conductors only Maximum Total Length of Run

< 50 Ft

< 100 Ft

< 150 Ft

< 200 Ft

< 250 Ft

< 300 Ft

< 350 Ft

< 400 Ft

< 450 Ft

< 500 Ft

Circuit

Load

(Amps)

(1) (~ 15 m)

(~ 30 m)

(~ 45 m)

(~ 60 m)

(~ 75 m)

(~ 90 m)

(~ 105 m)

(~ 120 m)

(~ 135 m)

(~ 150 m)

1 16 AWG

16 AWG

16 AWG

16 AWG

16 AWG

16 AWG

14 AWG

14 AWG

14 AWG

12 AWG

2 16 AWG

16 AWG

16 AWG

14 AWG

12 AWG

12 AWG

12 AWG

10 AWG

10 AWG

10 AWG

3 16 AWG

16 AWG

14 AWG

12 AWG

12 AWG

10 AWG

10 AWG

10 AWG

4 16 AWG

14 AWG

12 AWG

10 AWG

10 AWG

10 AWG

5 16 AWG

12 AWG

12 AWG

10 AWG

6 16 AWG

12 AWG

10 AWG

10 AWG

7 14 AWG

12 AWG

10 AWG

8 14 AWG

10 AWG

10 AWG

9 14 AWG

10 AWG

10 12 AWG

10 AWG

11 12 AWG

10 AWG

12 12 AWG

10 AWG

13 12 AWG

14 12 AWG

15 12 AWG

Notes:

ADJ & DG MANUAL

15 of 34 May 12 R2

1) The field wiring load depends on the actual load on a particular control circuit the field wiring is

connected to. Refer to the internal wiring diagram of the unit.

2) The table above is based on a maximum 10% voltage drop on a 24V control circuit. Wire size was

calculated using the following formula:

CM = (25 x I x L ) / V

Where CM is circular mils of conductor for a constant load of Iamps, wire length L in feet from the

unit to the field device and back, and voltage drop V.

When connecting to a three phase power supply, check for the correct rotation of all motors and fans. If the

rotation is incorrect, reverse the rotation at the incoming power only. All electrical conduit outlets in the

control panel must be sealed to prevent moist building air from migrating to the control panel.

All penetrations through the unit walls must be caulked and sealed to prevent air and/or water from

entering the unit.

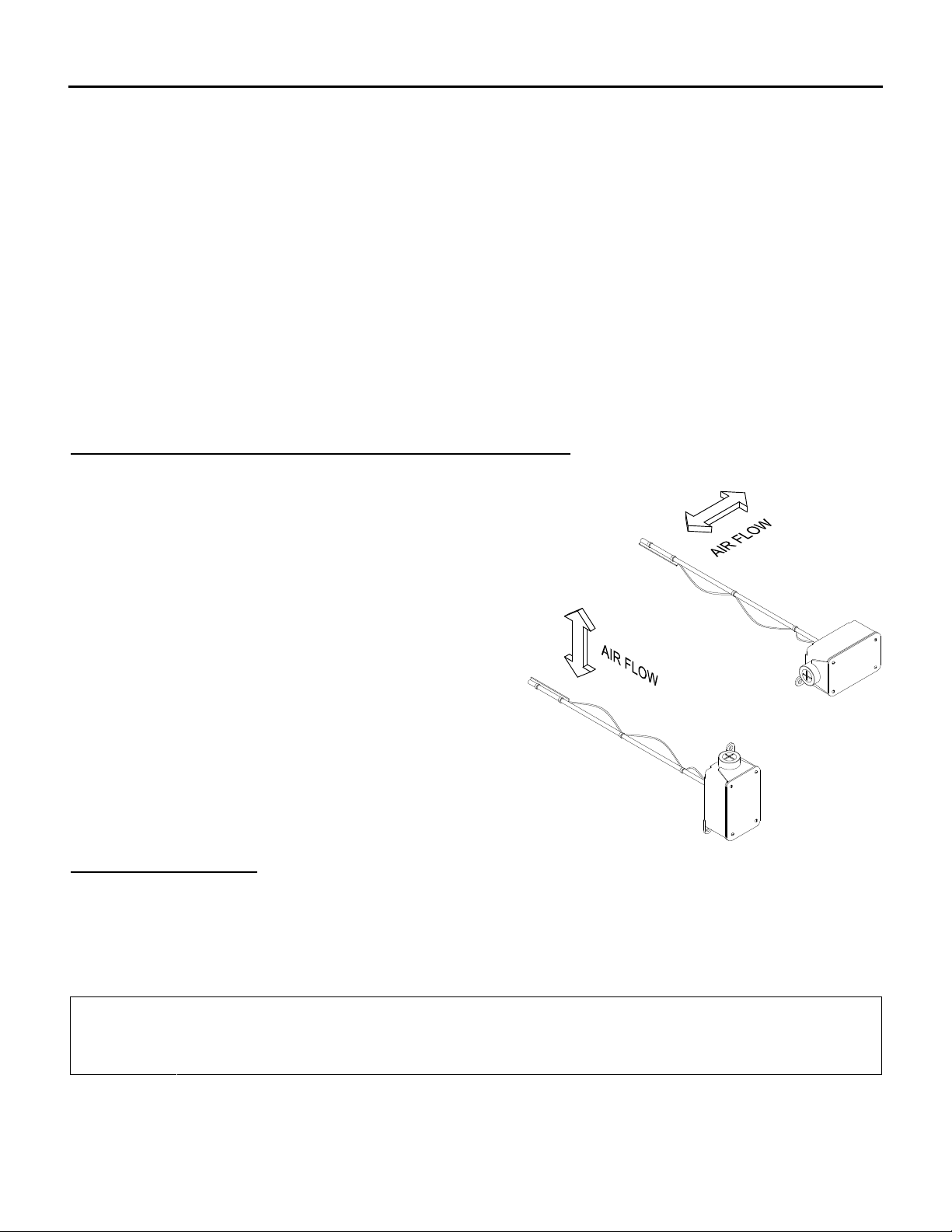

DUCT MOUNTED TE-6000-EA3 TEMPERATURE SENSOR

Some applications require field installed discharge air

sensors.

The sensor strip must be parallel to the air flow. The

sensor should be mounted near the center of a straight

duct 5 to 10 feet (1500 to 3000mm) downstream of the

supply air connection to the Engineered Air unit. Avoid

installing near duct transitions or elbows.

Use twisted pair or shielded wiring. The ground shield

should be grounded only at the unit control panel end.

Protect the opposite end ground and any unused wire with

electrical tape.

When installing an Engineered Air TE-6000-EA3 duct

mounted temperature sensor, the sensor strip must be

parallel to the air flow as shown.

COIL CONNECTIONS

This equipment may require field connection of water, steam or refrigerant coils. For proper operation

airflow must be counterflow to the flow of the fluid. The inlet water connection is normally at the bottom of

one header and the outlet water connection at the top of the other header. The steam connection is at the

middle of the supply header and the condensate is at the bottom of the other header.

Caution:

m Use a backup wrench on threaded coil connections when installing piping.

For refrigerant coils, all piping is to be installed by a qualified refrigeration mechanic. All refrigeration

specialties shall be installed using good refrigeration installation and design practices.

ADJ & DG MANUAL

16 of 34 May 12 R2

Recovery, reuse, recycling, reclamation, and safe disposal of refrigerant is the only acceptable practice

today. Venting of refrigerant into the atmosphere during installation or servicing is unacceptable. To avoid

damage, use an accepted refrigerant recovery system whenever removing refrigerant. When working with

refrigerants you must comply with all local government safety and environmental laws.

DRAIN TRAPS

Each drain connection requires a separate drain trap supplied and installed by the contractor. For a trap to

work properly, it must be primed. During freezing periods, primed traps may need to be heat traced or drain

and plug the trap when not in use. If a drain connection has a smaller pipe inside, connect to the outer pipe

only. Ensure that the trap is of adequate depth to operate against a static that includes the extra pressure

drop for dirty filters.

Warning:

m Failure to properly trap each connection can result in drain pan flooding,

standing water in unit, building damage, injury or death, cause poor air

quality or other problems.

In some applications (e.g. heat recovery units) there may be additional drain connections inside the curb

intended to be connected to the building drainage system. These drains must be connected and properly

trapped.

Cooling coil drain pans may have multiple drain connections extending outside the unit casing. Multiple

drains may be connected to a common drain providing that each drain is individually trapped and vented to

avoid problems from drains in different pressure zones. The drain must be properly sized and sloped.

Size drain trap with the following minimum requirements:

a) Units With Draw Through Drain Pans:

H1 = Negative Static†x 1.5 + 3.5” (89mm)

H2 = Negative Static†x 0.75 + 2.5” (64mm)

b) Units With Blow Through Drain Pans:

H2 = Maximum Positive Static†x 1.5

H1 = H2 + 0.5” (13mm)

† Static Water Column (WC) in inches or mm

including fully loaded filters.

Ensure adequate clearance for properly sized drain traps.

FLUSHING AND DEGREASING OF WATER AND GLYCOL COILS

Coil tubing may contain material or residue from manufacturing, transportation or storage. To prevent

possible damage to other components in the system, the coils must be flushed and degreased. Consult a

qualified water treatment specialist.

H1

H2

H1

H2

VENT& PRIMING

FUNNEL

TO DRAIN

OPTIONAL

CLEANOUT

ATMOSPHERIC

ADJ & DG MANUAL

17 of 34 May 12 R2

HEAT TRANSFER FLUIDS

The coil(s) provided have been selected for use with a specific heat transfer fluid as shown on the

Submittal Record. Use of other fluids will result in different performance and can damage the coil(s).

It is imperative to properly select and apply heat transfer fluids used in heating and cooling systems.

Untreated, improperly treated or improper use of fluids or use of fluids not approved for use in commercial

heating and cooling systems can damage coils and system components. For selection and application of

heat transfer fluids, always follow the manufacturers’ recommendations including treatment, mixing and

filling. Warranty will be void if coil damage results from misapplication or improper treatment of the heat

transfer fluid.

Some systems may use CPVC piping. Do not use propylene glycol with CPVC.

BEFORE START-UP

Remove tie-down bolts, straps and blocks on fan and compressor vibration isolators, tilt equipped heat

pipes and enthalpy/desiccant wheels if supplied.

Perform a Safety Shutoff Valve Leak Test as described in this manual.

START-UP CHECK LIST

Warning:

m

c

This unit is connected to high voltages. Electrical shock or death could occur

if instructions are not followed. This equipment contains moving parts that

can start unexpectedly. Injury or death could occur if instructions are not

followed. All work should be performed by a qualified technician. Always

disconnect and lock out power before servicing. DO NOT bypass any

interlock or safety switches under any circumstances.

The start-up and operation must be in accordance with safe practices. Start-up must be performed by

qualified personnel. Complete attached start-up record.

1. Set all associated electrical switches, controls, thermostats and main disconnect switch to “OFF”

position.

2. Close all manual valves and field piping valves.

3. Confirm that all shipping materials have been removed. See any supplemental instructions shipped

with the unit to help identify possible locations.

4. Check all bearings, drive and fan set screws for tightness. See TABLE I

5. Check drive alignment and belt tension. Refer to Maintenance, page 25.

6. Turn disconnect switch ON (control switch is still off) and check the supply voltage. Voltage must be

within 10% of rating plate. If not, contact the installing electrical contractor and have the voltage

condition corrected before continuing start-up.

7. Check all fan motors for correct rotation. If incorrect, reverse rotation on incoming power only.

8. Set thermostat or controller to the “OFF” position and turn unit control switch “ON”.

ADJ & DG MANUAL

18 of 34 May 12 R2

9. Check the amperage draw of each motor and compressor. Refer to unit or motor rating plate for full

load amps. At the unit, check and record the voltage while it is running. For 3 phase power the

phase to phase voltage imbalance should be less than 2%. A 2% voltage imbalance can cause up

to a 10% current imbalance that will overheat motor windings.

To calculate voltage imbalance (NEMA method) refer to the following example:

Phase to phase voltage readings: 235V 236V 230V

The average Voltage between legs is 233.7V (235+236+230)/3

Highest voltage deviation from average is: 233.7V –230V = 3.7V

Voltage imbalance percentage = Highest deviation divided by average X 100

3.7 / 233.7 x 100 = 1.6% This imbalance is less than 2% and therefore is OK

If voltage imbalance is greater than two percent (2%), turn off main disconnect and contact

the installing electrical contractor to have the voltage condition corrected.

10. Purge all the air from the gas (oil) lines. Refer to the Canadian Natural Gas and Propane

Installation Code, C.S.A. Standard B149.1 or the National Fuel Gas Code ANSI/Z223.1/NFPA 54

for proper method. Check all connections for leaks and correct. Ensure that the inlet pressure

agrees with the approval label.

11. Enable heating and/or cooling; refer to unit function for correct sequence and operation.

12. Confirm field wiring voltage drop is less than 10% when equipment is operating.

13. For the unit to operate properly a system air balance must be performed to ensure correct air flow.

Failure to do so can damage the equipment and/or building and can be a cause of poor indoor air

quality.

14. Damper sections:

a. Flat mixing dampers:

Both the fresh air and return air dampers are fully open when the dampers are at a 45° angle when

fully stroked. This provides optimum mixing of the air streams for this damper arrangement.

b. Angle mixing damper:

Angle mixing section dampers open to an angle of 90° when fully stroked. This provides optimum

mixing of the air streams for this damper arrangement.

15. Some units are equipped with an adjustable coil air bypass. This must be field adjusted during the

system air balance to ensure proper air flow across the coil. Adjust the bypass to achieve coil

pressure drop as stated on the submittal and/or the unit function sheet.

16. Check setting of fan limit control(s). Adjust high limit to value indicated below unless wiring diagram

shows a different value.

High Limit 180°F (82°C)

Fan Switch ON 125°F (52°C)

OFF 90°F (32°C)

17. Set all controls to the settings indicated on the wiring diagram.

18. Re-install all access panels.

ADJ & DG MANUAL

19 of 34 May 12 R2

19. Remove any packing material or debris and dispose appropriately.

OPERATION

Warning:

m

c

This unit is connected to high voltages. Electrical shock or death could occur

if instructions are not followed. This equipment contains moving parts that

can start unexpectedly. Injury or death could occur if instructions are not

followed. All work should be performed by a qualified technician. Always

disconnect and lock out power before servicing. DO NOT bypass any

interlock or safety switches under any circumstances.

Warning:

m

Proper commissioning and start-up of the air handling system is the

responsibility of the installing contractor. It is recommended that an air

balance be completed by a certified air balancing contractor to insure the air

volume being delivered matches the unit rating plate. Failure to perform a

proper air balance can cause injury or death, damage to the equipment,

property damage, system operational problems, or be a cause of poor air

quality. Moisture carry over can result from improper air flow.

This unit may incorporate one or more functions and a variety of controls and options to suit individual

requirements. A description of the unit functions and options is shown on the Electrical Data Sheet and

unit wiring diagram. Carefully check your wiring diagram to verify that all remote controls are properly

located and correctly field wired.

Some equipment may contain programmable unitary controllers or programmable logic controllers (PLC).

Additional information can be obtained from the specific programmable control manufacturer. Often this

information is available from the control manufacturer’s website.

ADJ & DG MANUAL

20 of 34 May 12 R2

SAFETY SHUTOFF VALVE LEAK TEST:

Safety shutoff valves require a qualified technician to perform a leak (bubble) test to determine tightness of

closure on a least an annual basis. A very small amount of leakage is normal. Valve leakage rates

exceeding those noted in the table below require repair or valve replacement.

1. De-energize the control system.

2. Close the upstream manual gas valve.

3. Connect a ¼” (6mm) tube to the outlet

pressure tap on the safety shutoff valve.

4. Immerse the opposite end of the ¼” (6mm)

tube (cut to a 45° angle) vertically ½” (13mm)

into a clear container of water.

5. Count the number of bubbles appearing

during a 10 second period.

6. If the bubble rate is greater than that noted in

the table repair or replace the valve.

7. If bubble rate is less than noted in the table,

remove the ¼” (6mm) tube, reconnect the

outlet pressure tap plug.

8. Energize the control system and open

upstream manual gas valve.

9. After testing check all piping connections and

plugs for external leakage.

The table below indicates the maximum number of

bubbles in relation to the size and type of valve.

Manufacturer Pipe size (in.) Model Maximum leakage rate

(bubbles/10sec.)

1, 1¼

V4943, V8943

13

1½, 2

V4943, V8943

16

¾, 1, 1¼, 1½

V5055, V5097

14

Honeywell

2, 2½ ,3

V5055, V5097

24

¾

K3A551/651

6

1

K3A551/651

6

1 ¼

K3A551/651

7

ASCO

1 ½

K3A551/651

9

For valves not listed contact the valve manufacturer for testing procedure and acceptable leakage rate.

GAS MANIFOLD

It is recommended that at least once each year the safety devices should be checked. Follow operational

check at detailed in this manual.

The Safety Shut Off Valves must be tested on at least an annual basis or as per the manufacturer’s

recommendations which ever is less.

Regulators with vent terminals must have yearly cleaning of the screen.

1/2 (13mm) CUT AT

45 DEGREE

ANGLE

JAR OR GLASS WITHWATER

1/4 IN (6MM) ALUMINUM OR

COPPERPILOT TUBING

1/4 (6MM) FLEXIBLE TUBING

GAS SUPPLY

UPSTREAM

MANUAL

GAS COCK

PVR SSOV MANUAL

GAS COCK

DOWNSTREAM

TEST

TAP

LEAK

A B C ED

1CAN ALSO BE A PERMANENT PETCOCK.

PRV = PRESSURE REGULATING VALVE.

2

USE ONLY ONE OF THE DOWNSTREAM TAPS ON THE SSOV.

SSOV = SAFETY SHUTOFF VALVE.

4

3

23

4

DOWNSTREAM

GAS COCK

MANUAL

1

F

This manual suits for next models

3

Table of contents