Engineering and Research Corporation Ercoupe 415-C Owner's manual

Ercoupe 415-C

Pilot Operating Handbook

2

Contents

1. General Information

2. Operating Limitations

3. Operating Instructions

(1) Starting and Shutting Off Engine

(2) Taxiing

(3) Takeoff

(4) Maneuvering in Flight

(5) Cruising

(6) Landing

(7) Tying Down

(8) Cross Wind Takeoff

(9) Cross Wind Landing

(10) Cockpit Checklist

4. Service Inspection Instructions

(1) Cleaning

(2) Tires

(3) Brakes

(4) Control System

(5) Propeller

(6) Electrical System

(7) Fuel System

(8) Exhaust System

5. Appendix

January, 2013

This version of the Ercoupe POH was derived from the original 1946 Ercoupe 415-C

"Instructional Manual" that was scanned to a PDF file and is posted on the

www.ercoupe.info website. This version was produced by OCR scanning to produce

editable text and graphics. It has been slightly edited to improve readability and

add useful information. Performance and Operating Limitation data is based on the

original Continental C-75 engine and propeller. Ercoupes with C-85, C90 and O-200

engines will perform differently.

3

GENERAL INFORMATION

The ERCOUPE is a two-place, low wing monoplane of metal

construction. Power is supplied by a 75 horsepower Continental C-

75 engine. Ease of ground handling is assured by the steerable nose

wheel, excellent vision, and brakes.

Simplicity of flight has been achieved by eliminating the rudder

pedals. Only the control wheel is used. Ailerons, rudders, and nose

wheel are mechanically coordinated so that turns, both in the air

and on the ground, are made by turning the control wheel right or

left; the same wheel moved fore and aft controls the elevator. The

ERCOUPE is certified by the Civil Aeronautics Administration as

"characteristically incapable of spinning."

OPERATING LIMITATIONS

Required Information For 75-H.P. Model 415-C

Engine Limits 2275 RPM

Airspeed Limits 108 m.p.h. maneuvering speed

114 m.p.h. maximum structural cruising

144 m.p.h. never exceed

Maximum Weight 1260 lbs, 1320 lbs. with STC

Empty Weight _________________________________

Useful Weight _________________________________

Datum Forward face of firewall

Center of Gravity Range 26.4" to 30.3" rear of datum

Empty Center of Gravity _________________________________

Maneuvering No aerobatic maneuvers of any kind

Special Limitations This airplane is characteristically

incapable of spinning

4

OPERATING INSTRUCTIONS

Experienced operators will be acquainted with much of the

material in this section, but because of the unusual features of the

ERCOUPE, they, as well as new operators, are urged to become

familiar with the following suggested operating practices.

A check on the quantity of gasoline and oil in the tanks should

be made before flying. All fuel tanks should be checked.

A check that the brake is "on" should be made before starting

the engine.

STARTING AND SHUTTING OFF ENGINE

The throttle should be closed, and with the header tank fuel valve

turned on, the engine should be primed two to six "shots"

depending weather. The ignition switch can then be turned to

BOTH, the throttle opened slightly, about 1/8", and the starter

engaged.

If the engine fails to start, the operation should be repeated. If the

engine loads up or becomes flooded, the ignition switch should be

turned off and with the throttle opened full, the starter should be

held on to turn the engine several revolutions. Then the throttle

should be returned to the position for normal starting, and with the

switch turned to the BOTH position to start the engine, the starter

should again be engaged. (This model engine is likely to load up or

flood. Flooding can usually be detected by the odor of gasoline vapor near

the air intake.)

After starting, the engine speed should be kept below 900RPM, and

the oil pressure watched. The gauge should show pressure within

15 seconds after starting.

5

TAXIING

Maneuvering on the ground is accomplished by merely opening the

throttle sufficiently to cause the desired forward motion, and

steering the nose wheel with the control wheel. To stop, the wheel

brakes are applied by means of a foot pedal, or by means of a hand

grip just below the throttle handle. The brake can be locked "on"

for parking by turning the grip to a horizontal position.

If, while taxiing in an extremely high wind, if the airplane should

have a tendency to weathercock into the wind, skidding the nose

wheel somewhat against the pilot's control, improved traction and

steering control can be obtained by keeping the control wheel

forward, applying the brakes a small amount, and turning the

handle to lock them if desired, and using greater engine power for

taxiing.

Finally warmed up, the engine will turn approximately 2000 RPM

standing still

TAKING OFF

For the take-off, there's a trim tab adjustment handle on the left

side of the fuselage and above the pocket in the upholstery. The

position indicator shows where to place the handle to trim for take-

off. However, it can be left in the cruising position at take-off as the

control forces are very light.

With its tricycle gear and nearly level wing, the ERCOUPE can be

run along the ground at high speeds. To take off the ground, it is

necessary to increase the angle of attack of the wing by lowering

the tail, and this is usually done by moving the control wheel back

gently after the minimum take-off speed has been exceeded by a

comfortable margin.

The shortest take-off is ordinarily obtained by holding the control

wheel full back throughout the entire take-off run. The tail will not

6

come down until flying speed has been attained. The wheel should

be eased forward after the plane leaves the ground,however, or

the nose will point up too steeply for good climbing and it may

drop again momentarily with some loss of altitude. It is advisable

not to climb steeply after taking off, until an airspeed reading of at

least 60 MPH has been reached, because the airplane will fly at a

lower speed with full power than without power, and the engine

might possibly fail with the airplane at less than its minimum flying

speed without power.

In making a cross wind take-off, it is necessary to turn the control

wheel some to overcome weathervaning (see page 12). As speed is

gained and the ailerons actually begin to work, the upwind wing

will rise. However, the pilot should continue to steer down the

runway. The control wheel should not be pulled back too soon; be

sure to have flying speed so that the plane leaves the ground

completely. Neutralize the control wheel after the airplane breaks

contact. The nose will normally swing and point upwind just about

right to offset drift. The main thing is not to have the nose wheel

lose traction before the airplane can fly, as it will then roll along on

the rear wheels and turn into the wind.

MANEUVERING IN FLIGHT

After taking off, the steepest angle of climb to clear an obstacle is

usually obtained at an airspeed reading of about 60 MPH. The best

rate of climb for getting to altitude is obtained at an airspeed

reading of about 70 MPH near sea level and the reading becomes

lower as the altitude is increased, being about 60 MPH at 10,000

feet.

In flight without rudder pedals, turns are made simply by turning

the control wheel until the proper bank is reached and at the same

time keeping the nose in the position desired by adjusting the fore

and aft position of the control wheel. The airspeed required in a

steady turn is higher than in straight flight because the lift is not

vertical and only the vertical component of the lift will support the

airplane against gravity.

7

For example, the ERCOUPE, in a gliding turn with a 60⁰ bank and

the control wheel full back, will show an airspeed reading of about

63 MPH as compared with about 45 MPH in a straight glide with

the control wheel full back. Sharp turns naturally require steep

banks with the control wheel well back.

If the airplane is in a power-off glide and the speed is gradually

reduced by easing the wheel back, a mild jouncing or buffeting will

be noticed at about 3 MPH above the minimum stall speed. This is

caused by the burbling of the air flow at the juncture of the wing

and fuselage, and has been designed into the airplane as an active

warning that the minimum stall speed is being approached. The

airplane will fly satisfactorily at minimum speed with the wheel all

the way back in a glide, but the practice is not recommended at low

altitude because no reserve energy is available to overcome the

effects of gusty air or misjudgment.

If the control wheel is eased back gradually with power full on, the

airplane will reach an uncomfortable nose-high altitude. In this

condition, the flying will not be smooth or steady, but control can

be maintained.

CRUISING

The airplane may be trimmed to cruise at any desired speed with a

given throttle setting by adjusting the trim tab. In cruising flight,

the nose of the ERCOUPE appears to be down unusually far, which

gives good vision ahead. The cruising speed will be approximately

5 MPH higher with the windows closed. Therefore, to obtain the

best possible cruising performance, the windows should be closed

and the airplane should be flown at the highest altitude at which

cruising RPM can be maintained, due consideration being given, of

course to the wind and the weather

It is acceptable to cruise up to the red line placed on the

tachometer dial at 2275.

The air speed meter indicates the true air speed within

manufacturing tolerances for a definite cir density. This is the

8

density found at sea level when the barometer reads 29.92 inches

of mercury and the temperature is 59⁰F.

The true air speed may be found with satisfactory accuracy by

adding to the indicated air speed, 1 percent ofitself for every 10⁰

above 59⁰(or subtracting likewise for below)

For example, if the temperature is 89⁰and the indicated air speed

is 95 MPH, 1 per cent of it is .95 MPH and for 3 percent add 2.85

MPH, making the true air speed 97.85 MPH

For altitudes up to 10,000 feet, at 59⁰, add 1 per cent for every 500

ft. At 6000 feet add to this indicated air speed of 95 MPH, 12 x .95

or 11.40 MPH, making 106.40 MPH. Since the temperature at 6000

feet is 89⁰the 2.85 MPH correction should also be added, making

109.25 MPH

There is also a correction for a change in barometric pressure. If

the barometer at sea level is down 0.6” below the normal 29.92,

another 1 percent is added. Therefore, if the barometer reads 29.62

at sea level, add .5 x .95 or .47 MPH to the 109.25 MPH, making

109.72 MPH the true airspeed.

The carburetor mixture control is operated by means of a push-pull

knob on the instrument panel near the throttle. At altitudes above

5000 ft, the decreased density of the air may cause the mixture to

become too rich for best power. This may be investigated by

moving the mixture control from the full-rich position while

checking the constant load RPM. If the RPM does not increase as

the mixture is made leaner, the control should be returned to the

full-rich position. For average operation below 5000 feet altitude,

the carburetor should be left in the full-rich position. When at part

throttle, the fuel consumption may be improved by leaning the

mixture, but in no case should the control be moved far enough to

decrease the engine RPM. The control should always be moved

back to full-rich before any change in throttle setting

While cruising, the carburetor air heater is controlled by a

push-pull knob on the instrument panel near the throttle. The

engine should be operated with cold air at all times, except when

9

under conditions where icing is likely, in which case the control

should be placed in the full Carb Heat ON position

In cruising flight, the oil temperature will vary from 100⁰F to

220⁰F, depending upon the outside air temperature

LANDING

The mixture control should be placed in the full-rich position prior

to the landing approach.

When the throttle is fully closed, carburetor air heat is applied

automatically through a linkage connected with the throttle arm.

From half throttle to full throttle, cold air is fed automatically to the

engine However, a manual control is also provided and can be used

to keep hot air feeding to the carburetor at more than half throttle

setting when icing conditions prevail.

In glides, the cylinders should be cleared periodically by opening

the throttle to cruising RPM to prevent spark plug fouling.

A good airspeed reading during the approach to a landing is one

between 60 and 70 MPH. As the ground is approached the flight

path is leveled off so as to reduce the vertical velocity. At the same

time the airplane is flared in the conventional manner until it loses

its flying speed. This practice is always advisable in case of rough

terrain. However, the airplane may be set on the ground at up to

twice the minimum speed, and as long as the control wheel is not

pulled back, it will stay on the ground. After contact the wheel

should therefore, either be held still or eased forward gently,

preferably the latter.

If the airplane it glided in at an indicated speed that is too slow, it

will be found that as it reaches the flareout point, the control wheel

is already nearly all the way back and what is left doesn't check the

descent soon enough to keep from landing flat and too hard. Even

if the airplane is brought in with just sufficient speed to flare of the

flight path under still air conditions, if a wind is blowing it may

come down into a much more slowly moving layer of air close to

the ground and have this induce a moderate dropping of the nose

10

enough to nose it into the ground and thereby put excessive loads

on the nose gear.

Either of these conditions can be checked (by immediately opening

the throttle) and at the same time exercising care not to lower the

nose by pushing forward on the control wheel. On the other hand,

there is no point in steaming in at excessively high speed, even

though the speed doesn't complicate things as it might were the air

plane not landing level as it does on tricycle gear. It is therefore

recommended that the normal approach speed be held to the

suggested range of 60 to 70 MPH.

If, in the approach to landing, the pilot finds that he is overshooting

slightly, he can nose the airplane down, remembering to level off

and check the vertical velocity and put it on the ground

immediately at a relatively high speed. With immediate application

of the brakes, the landing will require decidedly less overall

distance than it would if the airplane were held off the ground until

minimum speed had been reached. Also, if the approach has been

made at too high an altitude the flight path can be steepened by

rolling the airplane from side to side, dipping each wing 20 or 30

degrees. If the altitude is sufficiently high this can be done

satisfactorily with the wheel full back, and height is lost quite

rapidly, but, because of the high vertical velocity attained, the

airspeed reading should be increased to 60 MPH or above at an

altitude of about 200 feet, and the flight direction should be held

straight from about 50 feet altitude to the ground

In making cross wind landings, the airplane is headed or crabbed

into the wind (See page 13). As the ground is approached the flight

path is leveled off, and the airplane is held off the runway in the

conventional manner until it loses flying speed.

Contact is made with the ground while the airplane is still crabbed

and the nose automatically swings so as to line the plane up and

permit it to continue moving in the direction in which it was

moving in the approach. Therefore, at the time of contact the

control wheel should be held lightly or momentarily released to

permit this automatic adjustment. During the ground run, hold a

11

little steering pressure on the control wheel to keep it from turning

into the wind.

This brings up a change in point of view that it seems an

experienced pilot of conventional airplanes must pass through

before he can be satisfied with two control operation (without

rudder pedals). He has been accustomed to controlling the attitude

of his airplane about all three axes; as well as controlling the flight

path and the speed. With two-control operation he must be willing

to rely upon the stability of the landing gear to handle the drift in a

cross wind landing. Not until he feels fully confident that the

airplane itself will take care of this item satisfactorily and without

strain, can he be expected to fly a two-control airplane with a

feeling of comfort and pleasure.

In gusty air or in high winds in general, it is usually advisable to

approach and land at a somewhat higher speed than in still air, and

to have the airplane at all times either definitely in the air or

definitely on the ground

After landing, the brakes may be used as desired. In an emergency

they may be applied before the landing is made, but this procedure

is not recommended as standard practice on account of the tire

wear involved

Slippery terrain or loose gravel can bring on skidding during the

landing run. If a tendency to skid and turn sort of sideways is

noticeable, momentarily release the brake and it will straighten out

and roll in the direction it was originally going. It's the same in a

car. If the rear end starts skidding around to the right, turn right

and immediately attempt to stop the skid.

TYING DOWN

Eyebolts are provided on the underside of each wing and on the tail

cone for tying the airplane down when parked outdoors under

questionable weather conditions. In tying down, the tail should be

as well secured as the wings The eyebolts may be removed by

unscrewing and can be carried in the glove compartment.

12

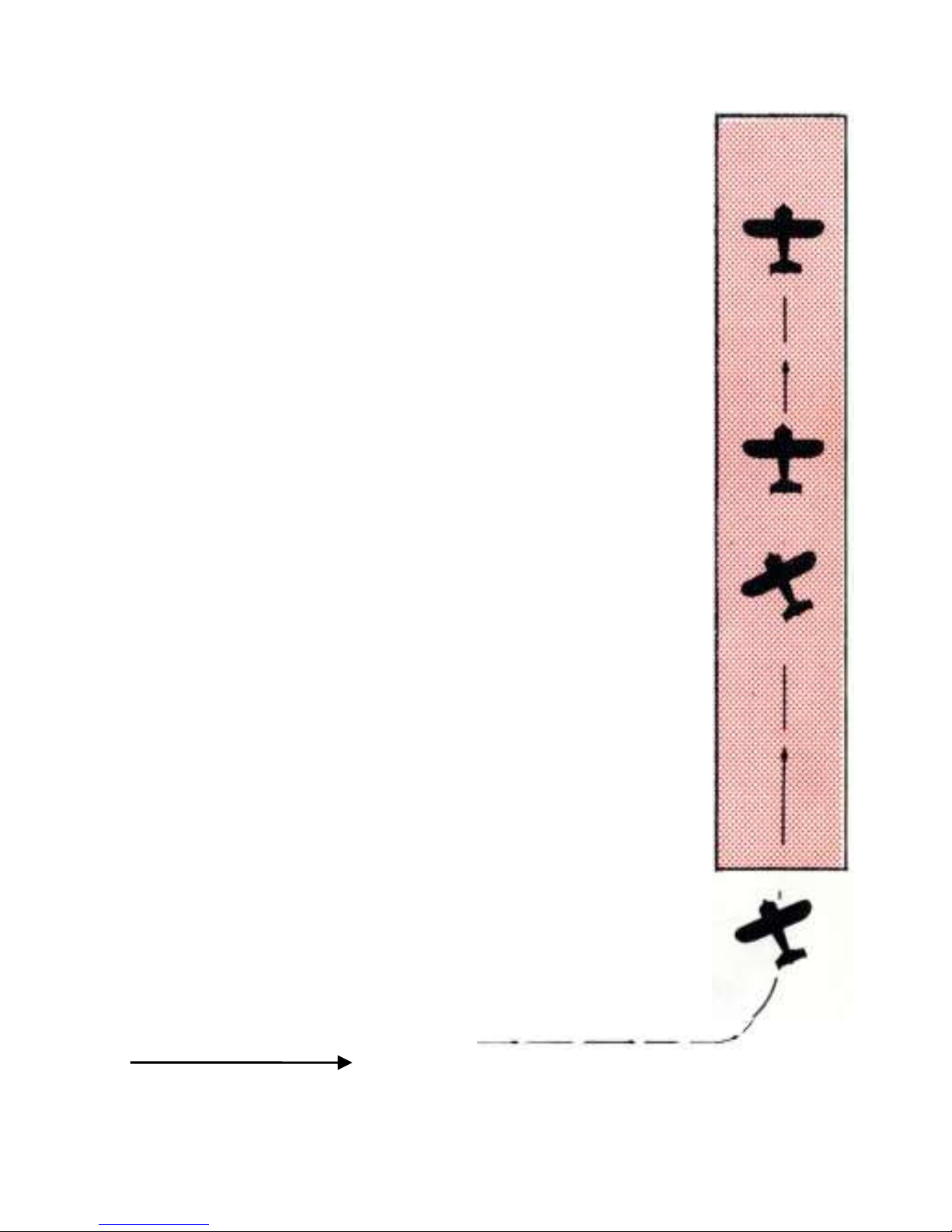

CROSS WIND TAKEOFF IN

AN ERCOUPE

START AT THE

BOTTOM AN READ UP

In taking off cross wind, it

is advisable to keep the

control wheel well forward,

which holds the nose wheel

firmly on the ground and

gives good steering control.

Some excess in forward

speed should be gained to

allow the airplane to take

off very definitely, and at

the moment of breaking

contact with the ground,

the control wheel should

be straightened laterally to

a neutral position. The air-

plane may weathercock

into the wind just after it

leaves the ground but this

need cause no concern as it

is merely adjusting itself to

true flight with respect to

the air, and a straight

course of travel is

maintained without

difficulty. The pilot should

not hesitate to make slight

turns near the ground in

order to maintain the

desired path and avoid

being drilled off course by

the wind.

4. A straight course of flight

is maintained on the center

line of runway during the

climb. If the plane drifts

sideways, make slight turns

to get back to center of

runway

3. The airplane weather-

cocks into the w ind just

after leaving the ground.

Wings are held level.

2. Gain some excess

forward speed and take off

very definitely. At the

moment of breaking contact,

straighten the control wheel

laterally to a neutral

position.

1. On ground run, keep

forward pressure on the

control wheel and some

right control necessary to

overcome weathervaning

(tendency to head into the

wind )

WIND FROM THE LEFT

13

CROSS WIND LANDING IN

AN ERCOUPE

START AT THE

BOTTOM AN READ UP

In the approach to a cross

wind landing, the airplane

will be pointing up wind

sufficiently to keep the flight

path in line with the runway

rather than attempt to drop

the windward wing as is

done in the three control

plane. The glide should be

continued in this crabbing

attitude down until contact

is made with the ground. At

the moment of contact the

airplane should be given its

head, and the grip on the

control wheel relaxed. This

allows the nose wheel to

caster and line up with the

direction of motion of the

airplane along the ground.

Immediately thereafter, ease

the control wheel forward

slowly and roll down the

runway. Prompt application

of the brakes or setting the

brake on about half way

during the glide approach

brings the nose down and

completes the change in

heading more quickly

5. During ground run steer

like a car.

4. On ground plane will

change heading to line up

with path along runway.

3. Make contact decisively

at low speed with plane

still crabbed, but relax grip

on control wheel to allow

nose to caster and ease

forward on control wheel

slowly

2. If plane drifts sideways,

make slight turns to get

back to center line of

runway

1- Finish turn with

Ercoupe on extended cen-

terline of runway and

headed or crabbed into

wind just enough to keep

its flight path (not head-

ing} on the extended

centerline.

WIND FROM THE LEFT

14

COCKPIT CHECK LIST

STARTING

1. Check quantity of fuel and oil

2. Both fuel valves ON

3. Mixture—FULL RICH at all times

4. Carburetor Air heat OFF

5. Prime 2 to 6 strokes—Lock Plunger

6. Throttle - Crack 1/8 inch

7. Ignition on - Pull Starter

8. Warm up - 900 to 1200 RPM

BEFORE TAKE-OFF

1. Carburetor Air Heat Off (use full heat in icing conditions)

2. Oil temperature - 90⁰F min

3. Oil pressure - >35 lb/sq inch (above 1900 RPM).

4. Full throttle - 2000 RPM approximately

5. Ignition Check - maximum 75 RPM drop on either magneto

and with Carb Heat

6. Check for good idle

FLIGHT

1. Oil pressure - >35 lbs

2. Oil temperature range 100⁰to 220⁰F

3. Adjust mixture control for best RPM (ABOVE 5000 FT.)

LANDING

1. Mixture control- FULL RICH.

2. Open throttle periodically in glide to clear cylinders

15

SERVICE AND INSPECTION INSTRUCTIONS

PARTS AND ADJUSTMENTS

Genuine ERCOUPE replacements parts are available only through

authorized Distributors and Dealers. These representatives have a

stock of the most needed repair parts and a file of information for

the repair and adjustment of the ERCOUPE The nearest dealer may

be determined from the list in the back of this book. He should be

contacted for needed service.

The ERCOUPE owner should write the distributor or dealer in his

territory and request that he be put on the mailing list to receive

any special notice for ERCOUPE owners. This will assure him

immediate advice should changes or modifications in his airplane

be recommended.

The serial number on the nameplate fastened on the deck behind

the baggage compartments should be included in all

correspondence requesting information or parts for the ERCOUPE.

WINDSHIELDS AND WINDOWS

Flush off the excess dirt and grit with clear water and then use a

soft, grit free sponge or open-mesh cheese cloth and mild soap. All

rubbing should be done as lightly as possible to avoid scratching.

Do not use glass cleaning solutions, as they may contain solvents

that are harmful to plastic.

ALUMINUM

Remove all loose dirt and grit from surface so that it will not be

scratched when cleaner is applied. Wet a pad of Turkish toweling

with aluminum cleaner and rub surface until cleaner has mixed

with and absorbed all foreign matter. Wipe off remaining polish

with a soft dry cloth.

16

OUTER PANEL WING COVER

The original high luster finish can be preserved, and the life of the

covering can be lengthened by observing the following;

1. Rinse off the excessive dirt with clear water and then wash

with a mild soap.

2. To restore the luster, polish with a mild rubbing compound

and coat with wax (Avoid rubbing too hard on covering at

sharp edges).

TIRES - MAIN WHEELS

It is necessary to remove the wheel hub cap to reach the valve stem

for pumping up the tires In removing tire proceed as follows:

1. Remove hub cap.

2. Remove nuts that hold wheel halves together.

3. Remove axle nut.

4. Pry bead of tire loose.

5. Remove outer wheel half and tire Leave inner wheel half

remaining on axle.

TO INSTALL TIRE, REVERSE REMOVAL PROCEDURE

TIRE - NOSE WHEEL

In removing tire proceed as follows:

1. Remove nuts that hold wheel halves together

2. Have someone hold tail down to lift nose wheel

3. Pry bead of tire loose

4. Remove outer wheel half and tire. Leave inner wheel half

remaining on axle

TO INSTALL TIRE, REVERSE REMOVAL PROCEDURE

BRAKE

The brake fluid reservoir is located under the hood on the firewall

and should be kept nearly full of fluid. Excessive lost motion in the

operation of the hand control should be eliminated by adjustment

of the clevis at the end of the control wire. However, be sure that

the master cylinder returns its full travel.

17

The brakes do not require adjustment of the lining surfaces.

To bleed the brake system

1. Fill the reservoir with fluid.

2. Remove the bleeder screw from fitting on one side only of the

wheel brake assembly and place finger lightly over the hole.

3. Have someone operate the brake control to full on" then hold

finger over hole firmly and return control to "off" position.

Allow a few seconds for the fluid to flow into the master

cylinder and repeat the operation several times. Be sure to

keep the reservoir full during this operation.

4. Install the bleeder screw.

5. Remove the bleeder screw from the other side and repeat

operation (3)

6. Install the bleeder screw.

7. Continue bleeding until brake has a solid feel when applied.

Note: Do not allow hydraulic brake fluid to get on linings. Wash

clean with carbon tetrachloride or naphtha.

CONTROL SYSTEM

To Check Control System Alignment:

1. Neutralize the control wheels and check the control mast

under the baggage compartment to be sure the arms are also

neutral.

2. This should place the ailerons in line with the wing airfoil

section.

3. In neutral, the nose wheel should also line up straight with the

centerline of the airplane.

4. Now check rudders (everything inneutral) using two

straightedges paralleling the fin. Both should be straight.

5. Elevator limits are fixed by contact of a stop ring placed on the

control wheel tube with the instrument panel and should

permit 13⁰ ±1⁰ up travel. The up travel of the elevator is

controlled by a turnbuckle which is sealed at the factory with a

18

lead seal. This seal must not be broken except by an

authorized ERCOUPE Service Station who will reseal it after

making any necessary adjustment

STEERING LINKAGE

If shimmy occurs in the nose wheel while the airplane is running

along the ground, it is an indication of looseness in the joints of the

steering linkage, or of tire unbalance To eliminate the shimmy

remove the excess play and balance the tire on the wheel

PROPELLER

The propellers approved for the ERCOUPE are the Sensenich

design 74FCT 48 (for the taper shaft) and the 74FKT 48 (for the

flanged shaft). Both are fitted with extra durable stainless steel

leading edge tipping. Either propeller can be altered to fit the other

type shaft, by a properly equipped shop.

Watch for signs of wear and dents on the leading edges or

scratches which expose the wood and permit the absorption of

moisture. Bare spots should be sanded and sealed with spar

varnish. Moisture entering through exposed wood will cause

roughness by disturbing the weight balance. Any large repair will

require the propeller to be balanced and should be made by an

approved repair station

ENGINE IDLING SPEED

After the engine is warmed, and with the throttle fully closed, the

engine should maintain 650 RPM on the tachometer. With a lower

idling RPM the engine may stop in a slow glide

MAGNETO AND SPARE PLUG CHECK

With the engine warmed, the magnetos should be tested separately

for proper firing. Revolution speed of engine with full throttle

should not drop off more than 75 RPM on either single magneto

from operation with both magnetos. Prolonged full throttle

operation on the ground should be avoided.

19

ENGINE COMPRESSION CHECK

While the engine is warm and with the ignition switch turned "off,"

pull the motor through four complete compression strokes to check

for weak compression of any cylinder. An indication of poor

compression should be checked with a competent engine man for

his final decision.

Note: Do not pull engine through by hand immediately after

running, as the engine may start

IGNITION SWITCH

The switch key is numbered and this number should be recorded in

the log book for future reference in ordering duplicate keys.

FUEL SYSTEM

The engine driven fuel pump moves fuel from the wing tanks to the

six gallon fuselage header tank. Excess fuel drains from the header

tank overflow line back to the wing tanks. Fuel is gravity feed from

the header tank to the engine carburetor. In case of fuel pump

failure, the engine will continue to function until the six gallon

header tank is empty.

The Main Fuel Valve is located approximately halfway between the

brake handle and the pilot's control wheel shaft under the

instrument panel. This main valve should be ON (lined up with

down pipe) at all times except in case of an emergency.

The Wing Tank Shut-Off Valve is located on the right side skin

forward of the seat. The valve handle should be ON (lined up with

fuel line) and secured with a piece of brass safety wire. The only

time this valve should be off is in a case of emergency or a

malfunction. If the valve is turned OFF, the fuel cannot be pumped

from the wing tanks to the header tank and the engine fuel supply

and the remaining flying time, is limited to what fuel remains in the

header tank.

20

Wing tank caps should be checked for good gaskets and functioning

vent.

The wing tank gauge indicates the quantity of fuel in both wing

tanks as a fraction of 18 gallons. The gauge is located close to the

floor on the pilots side of the cockpit.

The header tank gauge, located forward of the windshield, is a

visual check of the remaining fuel in the header tank. When the

gauge is fully up there are six gallons in the tank. When it reaches

the fully down position, at least one gallon should be left in the

tank. Check the condition of the float frequently to ensure proper

reading from this gauge.

FUEL SYSTEM

Table of contents

Popular Tools manuals by other brands

Vela

Vela 011725 Mounting instructions

Trick-tools

Trick-tools Hougen-Ogura PUNCH PRO 75006PR Operator's manual

Utility Solutions

Utility Solutions Jack Jumper USJJ-004 quick start guide

BGS technic

BGS technic 9414 instruction manual

ATD Tools

ATD Tools ATD-81045 Operating instructions & parts manual

Clas Ohlson

Clas Ohlson 40-8674 Mounting