entegris INTELLIGEN MV Guide

Installation and use manual

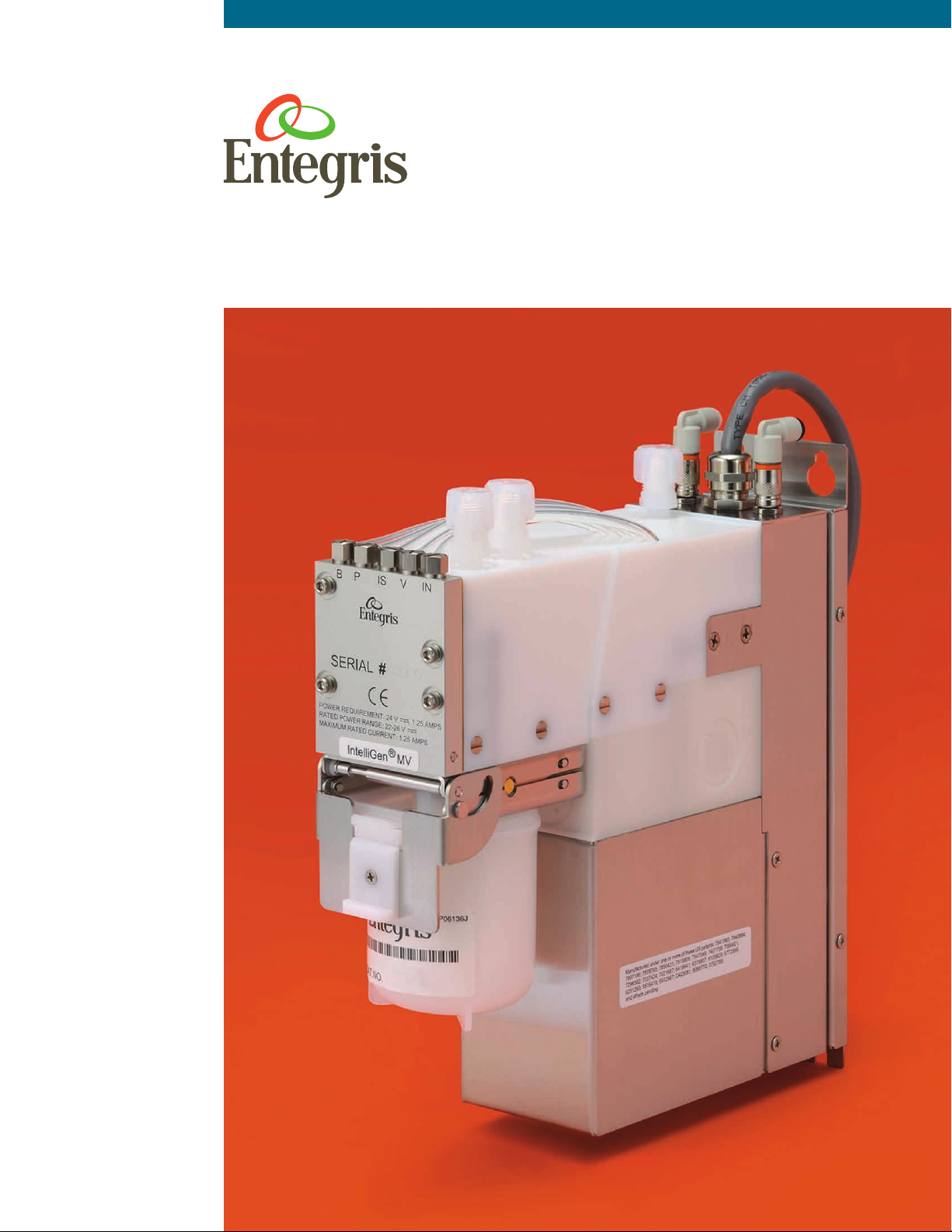

INTELLIGEN® MV DISPENSE SYSTEM

CRITICAL MATERIALS HANDLING

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 1

Table of Contents

Overview .............................................................. 2

Liability Ownership ................................................ 2

General Manual Notes ....................................... 2

Changes to the Manual .......................................... 2

Intended Audience .................................................. 2

Intended Use/Scope ............................................... 2

Safety .................................................................. 3

Handling .................................................................. 4

Chemical Leaks ....................................................... 4

Specifications ..................................................... 6

Compatibility ...................................................... 7

System Overview ................................................. 8

Appearance .............................................................. 9

Two-state Technology

Operating Principle ................................................ 9

Quick Filter Changeout ......................................... 9

Installation ....................................................... 11

Handling ................................................................ 11

Facility Requirements .......................................... 11

Tools and Materials .............................................. 11

Install the Pump ................................................... 12

Install the Filter ................................................... 12

Storage ................................................................... 13

MMI Software ................................................... 14

Installing Software ............................................... 14

Connect Tab ........................................................... 15

System Tab ............................................................ 16

Priming Tab ........................................................... 17

Status Tab .............................................................. 20

Alarms Tab ............................................................ 22

Recipe Tab ............................................................. 23

Recharge Tab ......................................................... 24

Utility Tab .............................................................. 24

Info Tab .................................................................. 24

Self Test Tab .......................................................... 24

Profiling Tab .......................................................... 24

Confirmation Tab .................................................. 26

Maintenance ..................................................... 31

Changing the Filter .............................................. 31

Flushing the System ............................................. 32

Updating the Firmware ....................................... 33

Troubleshooting .............................................. 34

Appendix: Priming Recipe Information ......... 36

Guidelines for Priming a New Filter .................. 36

Priming Settings ................................................... 36

Priming Sequence Examples .............................. 37

Manufacturing Information ............................ 39

System Relocation Notice .................................... 39

Spare Parts ............................................................ 39

Technical Support ................................................ 39

Terms and Conditions of Sale ......................... 39

Product Warranties ......................................... 39

Repair Service ....................................................... 39

INTELLIGEN MV DISPENSE SYSTEM

2 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

Overview

Entegris, Inc. provides the enclosed product

manual for your information.

Prior to using this manual, the user should verify

with the product manufacturer that the user has

the most recent copy of the product manual.

This manual is owned by Entegris, Inc., an affiliated

company or its suppliers and title shall not pass to

you as a result of your use of the manual.

Liability Ownership

Read the following carefully before continuing:

In no event shall Entegris or its suppliers be liable

for any damages whatsoever (including, without

limitation, damages for loss of business profits,

business interruption, loss of business information

or any pecuniary loss) arising out of the use of or

inability to use this manual, even if Entegris has

been advised of the possibility of such damages.

General Manual Notes

Changes to the Manual

The manufacturer reserves the right to make

changes to the product covered in this manual

to improve performance, reliability or manufac-

turability.

Although every effort has been made to ensure

accuracy of the information contained in this man-

ual, the manufacturer assumes no responsibility

for inadvertent errors. Contents of the manual are

subject to change without notice.

Intended Audience

This manual is intended for technicians involved in

semiconductor manufacturing, and assumes that

each individual is familiar with the proper handling

of photochemicals and other potentially hazardous

materials. Users must also be familiar with install-

ing and using software on a computer running the

Windows®operating system.

Intended Use/Scope

This manual is intended to be used by experienced

technicians for the planning, installation, and oper-

ation of the described pump system. This manual

contains basic safety information and contains basic

safety information for the installation and use of

the pump system. This manual covers the pump

system only.

WARNING! Mishandling products exposed

to a hazardous substance may result in death

or serious injury. Always follow the recom-

mendations and guidelines provided by the

chemical suppliers and manufacturers. Always

wear appropriate personal protection equip-

ment as required for the chemicals in use.

Refer to the Material Safety Data Sheets

(MSDS) for each chemical.

!

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 3

Safety

DANGER! Failure to follow these safety

instructions may lead to fire, electric shock,

chemical exposure, or other injuries, or

damage to property. Read all safety

information before usage.

Supplier Registration for Safety Updates

The manufacturer requests that you notify us

of your equipment installation, usage and status

and provide appropriate contact information so

that we may advise you with any safety alerts and

information regarding your system. Please register

your usage with your local service center.

Contacting the Supplier with Emergency

Health Issues

Please contact the manufacturer with any

emergency safety and health concerns.

WARNING! Safety is designed into every

product. When followed, these minimum

guidelines provide an acceptable level of

safety for operating and maintaining the

system, but are not a substitute for deter-

mining internal safety procedures.

Failure to comply with the safety precautions

or warnings indicated in this manual violates

the safety standards that form a part of the

intended use of this equipment. The manufac-

turer assumes no liability for the user’s failure

to comply with these requirements.

WARNING! Use of controls, adjustments

or procedures other than those specified in

this manual without consulting a competent

safety professional may result in exposure to

potential hazards. Always follow established

industrial safety practices when operating

the equipment.

CAUTION! End of life statement.

De-commissioning of the system, or

any part of the system shall be in a

manner that is consistent with appro-

priate regulations and guidelines.

WARNING! Chemicals are not supplied

with this equipment. Refer to the chemical

suppliers’ MSDS for specific health and

safety information.

WARNING! POTENTIAL CHEMICAL LEAK!

Use one set of o-rings only. Check that the

filter has o-rings or the manifold has o-rings.

NEVER use o-rings on both the filter and the

manifold or the system may leak chemical.

WARNING! PINCH HAZARD! Keep

fingers clear of jaw mechanism

to prevent personal injury.

WARNING! PINCH HAZARD! Pump weight in

excess of 5 kg (17 lb). Use care in lifting and

carrying the pump to prevent personal injury.

WARNING! Wear chemical-resistant garments

and eye protection while changing the filter

and during start-up. Use additional personal

protective equipment (PPE) as directed by

facility safety personnel, the MSDS or chemical

safety guidelines.

CAUTION! Only technically qualified

personnel should install the equipment.

CAUTION! DO NOT use this equipment in any

manner not specified by the manufacturer.

If the equipment is used in a manner other

than as specified in this document, the safety

protections may be impaired.

CAUTION! Fittings and components damage

easily: handle all components with extreme

care. DO NOT scratch or over-tighten any

component.

CAUTION! EQUIPMENT DAMAGE HAZARD!

Turn off power before connecting or

disconnecting any cable to the device,

or damage may occur.

!

!

!

!

!

!

!

!

!

!

!

!

!

INTELLIGEN MV DISPENSE SYSTEM

4 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

Handling

Each dispense system is manufactured with strict

assembly, test, and inspection processes to ensure

high-quality assembly and protection from unin-

tended chemical release. As with all chemical

handling systems, the dispense system has chemical

connection points which must be handled with

care, including:

• Fluid ports on the top surface

• Filter fittings

The pump mechanism has additional connecting

points:

• Pressure sensor ports on the back (under the

top cover)

• Between valve plate (front) and pump block

• Pump diaphragm mechanism in the pump block

A potential for chemical leak can occur at the above

cited points. Use care to ensure that o-rings are

either on the filter or on the manifold, never on

both, or the system will leak. Refer to filter installa-

tion instructions in this manual.

Do not loosen any screws on the mechanism unless

specifically directed to do so by an Entegris service

engineer. Handle the dispense system with care to

prevent damage to any fluid handling point.

Additional points of critical assembly and perfor-

mance include pneumatic tubings, pressure and

vacuum connecting points, and solenoid manifold

tubes (inside bottom cover or backplane). Use

care to prevent any damage to the unit which

could result in chemical leakage.

Chemical Leaks

In the event of a suspected or confirmed chemical

leak from the pump or in the vicinity of the pump,

please follow the instructions below:

1.Determine chemical currently in use with pump.

2.Obtain Material Safety Data Sheet.

a. Determine if any incompatible materials may

come in contact with the leaking material.

b. Isolate incompatibles with barriers including

spill containment, closing valves, and remov-

ing the chemical supply if it is safe to do so.

c. Identify appropriate chemical protection

equipment requirements including gloves,

face and eye protection and chemical protec-

tive clothing to prevent exposure to or

contact with chemicals.

d. Determine if the chemical has permissible

exposure limits or short term exposure limits:

– Identify limits requiring respiratory

protection.

– Ensure that appropriate monitoring

devices are available to measure air levels.

3.Only employees properly trained to clean up

spills of hazardous materials should conduct

clean up activities. Consult local authorities

or identified hazardous materials emergency

response agencies or contractors for assistance

if the facility does not have trained employees

for spill cleanup or containment.

4.Ensure adequate monitoring and protective

equipment is available for cleanup of hazardous

materials.

5.Obtain supplies for cleanup and containment

compatible with the chemical.

6.Obtain compatible containers to collect spilled

material and cleanup materials.

7.Ensure adequate ventilation is provided before

opening cabinet or equipment where a buildup

of vapors could occur. If flammable material is

in use:

a. Monitor area for flammable levels with

appropriate monitoring devices.

b. Isolate all power sources or potential

sources of sparks.

c. Use intrinsically safe tools and monitoring

equipment.

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 5

8.Isolate pump from power sources to prevent

fluids from flowing through unit during cleanup

of leak or spill.

a. Use appropriate lockout/tagout out

procedures to de-energize unit.

b. De-energize all areas of unit that may be

in contact with spilled or leaking material.

c. When disconnecting nitrogen and/or any

pressurized gas, wear appropriate Personal

Protective Equipment (PPE) including gloves,

then close the facility gas supply to prevent

gas release when disconnecting lines.

9.If spilled material is within equipment, wipe

all surfaces carefully with wipes appropriate

for the chemical.

10. If material is contained in the tubing or the

pump, provide collection container under

the lines or pump during removal to collect

chemical and prevent additional spills.

11. Decontaminate surfaces with appropriate

decontamination materials per recommendation

of chemical manufacturer.

12. Contain cleanup materials and contaminated

debris and equipment.

13. Dispose of materials in accordance with local,

state and national regulatory requirements.

14. Provide any required service to the equipment

and verify all spilled material is collected or

cleaned from surfaces.

15. Replace any equipment and secure lines in

accordance with normal maintenance and

service requirements.

16. Confirm air levels are safe.

17. Return equipment to service per standard

procedures.

INTELLIGEN MV DISPENSE SYSTEM

6 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

Specifications

Dispense

performance:

Volume 0.1 –10.0 mL in 0.001 mL increments

Rate 0.1 – 3.0 mL/sec in 0.001 mL/sec increments

Repeatability <0.02 mL 3 sigma

Viscosity range* 100 – 300 cP

Maximum dispense pressure** 0.40 MPa (60 psi)

Recharge

performance:

Fill rate, filtration rate,

vent rate, purge rate

0.1 – 3.0 mL/sec in 0.01 mL/sec increments

Vent frequency Auto-venting or 1 –10,000 dispense cycles

Mechanical: Wetted surfaces Modified PTFE, PTFE, Kalrez®

Connection type Insert style, Super Pillar®, Super 300 Type Pillar or Flowell™ 60 series

Filter Impact® 2 V2 (OF style)

Inlet, outlet and vent tubing OD 6.35 mm (0.25”) or 6.0 mm (0.24”)

ID 3.97 mm (0.15628”) or 4.0 mm (0.16”)

Gas Inlet gas type Regulated N2or CDA

Inlet gas pressure 448 kPa – 469 kPa (65 psi – 68 psi)

Vacuum -68 kPa (20 in -Hg min.)

Dimensions: Height 242.6 mm (9.55")

Width 60.7 mm (2.39")

Depth 235.0 mm (9.25")

Weight: Approx. 5 kg (11 lb)

Electrical: Current rating 1.25A

Input voltage (system) 24 VDC ±10%

Serial communication Specifications are dependent on interface module use

Parallel communication Triggers and acknowledgments

Certifications: See provided documentation.

Environment: Indoor use only

Altitude below 2000 m (2187.22 yd)

Ambient temperature 5°C – 40°C (41°F –104°F)

Maximum relative humidity 80% for temperatures up to 31°C (88°F) decreasing linearly to

50% relative humidity at 40°C (104°F)

Mains supply fluctuations from 22 – 26 VDC

Transient overvoltages of overvoltage category II

Pollution degree 2

*Depends on tool configuration. Contact applications support for detailed window of operation.

**Maximum pressure is a limit on the Window of Operation. Actual volumes and rates may be restricted to comply with the pressure

limits for a given viscosity, tubing diameter, tubing length and tubing height.

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 7

Acetone

Adamantane (tricyclodecane)

n-Amyl acetate

Anisole (Methyl phenyl ether,

Methoxybenzene)

2-Butoxyethanol (ethylene glycol

monobutyl ether, butyl cellosolve)

n-Butyl acetate

Butyl alcohol

Butyl cyclohexane

Butyl ether (Dibutyl ether)

Cyclopentanone

Cyclohexanone

Developer (Positive, 0.26N TMAH)

Diacetone alcohol

DI water

Dichloromethane

(methylene chloride)

Diethyl maleate

DIGLYME

(Diethylene glycol dimethyl ether)

Dimethyl acetamide

Dimethyl cyclohexane

Dimethyl maleate

Dimethyl sulfoxide

1,3-Dioxolane

(glycol methylene ether)

EEP (Ethyl 3-ethoxypropionate)

ECA, EEA, EGMEA (Cellosolve acetate)

Ethanone (2,2-dimethoxy-1,2-diphe-

nyl, dimethoxy phenylacetophenone)

Ethyl acetate

Ethyl acetyl acetate

(ethyl acetoacetate)

Ethyl alcohol

Ethyl benzene

Ethyl cyclohexane

Ethyl lactate

Ethyl malonate (diethyl malonate,

malonic ester)

Ethyl pyruvate

Gamma butyrolactone

2- Heptone (methyl amyl ketone)

Hexane

2-Hexanone (methyl butyl ketone,

propylacetone)

HMDS (Hexamethyldisilazane)

Hexamethyldisiloxane

1,6-hexanediol diacrylate

2-hydroxy-2-methylpropiophenone

IPA (Isopropyl alcohol, 2-Propanol)

Isoamyl acetate

Isobutyl ketone (2,6-Dimethyl-4-

heptanone,

diisopropylacetone)

MCA (methyl cellosolve acetate,

2-Methoxyethyl acetate)

Mesitylene (1,3,5 trimethylbenzene)

Methyl acetate (methyl acetic ester)

Methyl alcohol

Methyl ethyl ketone (2-Butanone)

2-Methoxy-1-propanol

(monopropylene glycol methyl ether)

MIBK (Methyl isobutyl ketone,

4-Methyl-2-pentanone)

Mineral oil

Mineral spirits

MMP (Methyl 3-methoxypropionate)

Morpholine

NMP (N-methyl pyrrolidinone)

Octamethyltrisiloxane

Orthodichlorobenzene

(1,2-Dichlorobenzene)

2- Pentanone (methyl propyl ketone)

Petroleum spirits (Petroleum Ether)

PGE (Propylene glycol monoethyl

ether, 1-ethoxy-2propanol)

PGME (Propylene glycol monomethyl

ether, 1 methoxy-2-propanol)

PGMEA (Propylene glycol

monomethyl ether acetate,

1-Methoxy-2-propyl acetate)

PGPE (Propylene glycol propyl ether,

1-propoxy-2-propanol)

2-Propenamide

(N,N-dimethylacrylamide)

2-Propenoic acid

Propyl alcohol

Tetrahydrofuran

Trichloroethylene

2.5% TMAH (Tetramethyl ammonium

hydroxide) in DI water

Toluene

Xylene

Compatibility

The IntelliGen®dispense system has been optimized for the dispense of photoresists and other

photochemicals. The system is uniquely designed to deliver highly accurate dispenses even at very

low volumes with high repeatability.

The internal wettable surfaces of the dispense system are PTFE, modified PTFE and Kalrez.

The following is a partial list of compatible solvents. Please contact technical support for compatibility

of a specific solvent that is not included in the list.

INTELLIGEN MV DISPENSE SYSTEM

8 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

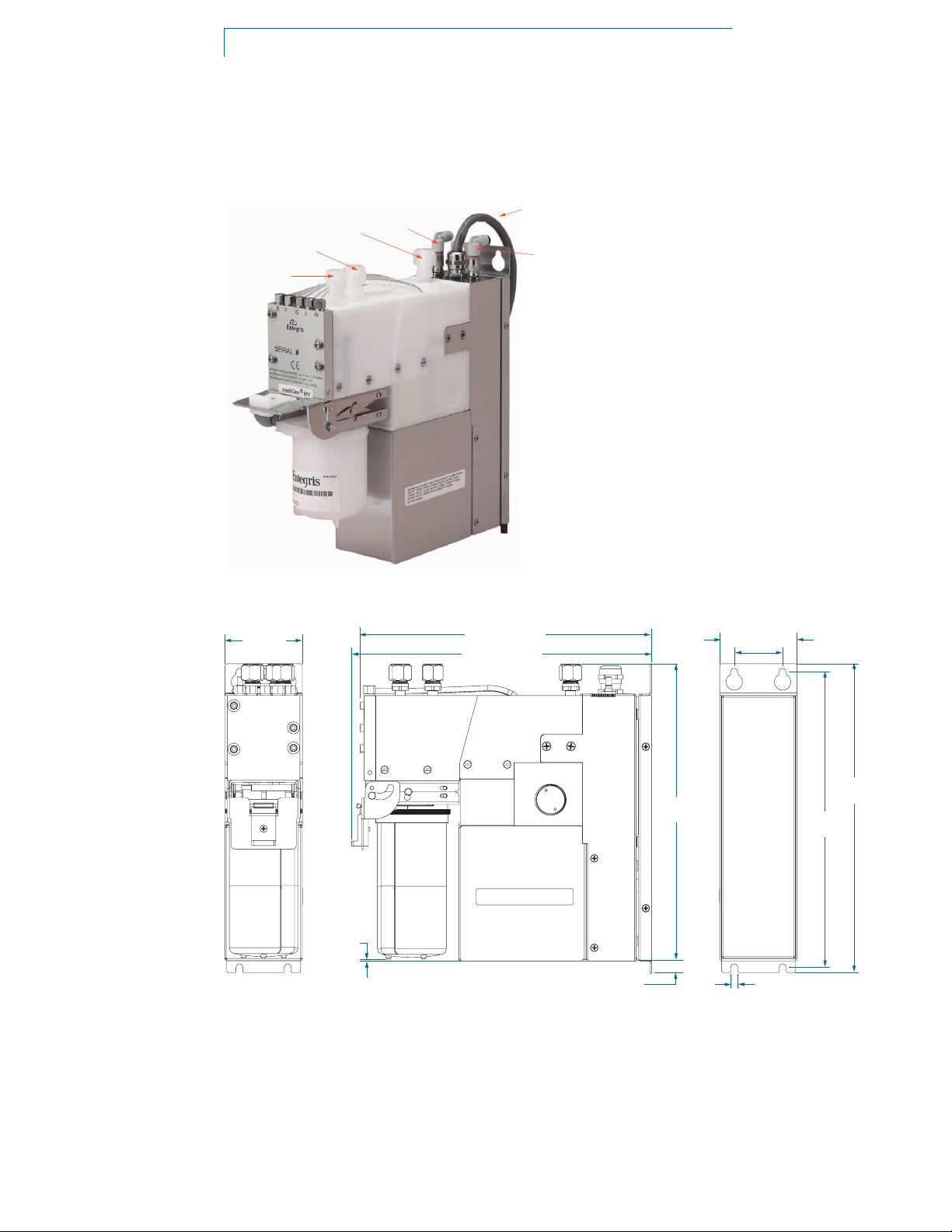

Communications/

power cable

Vacuum

inlet

Pressure

inlet

Fluid

inlet

Vent

Fluid

outlet

228.2 mm (8.98”)

2×5.5 mm (0.22”)

1.3 mm

(0.05”)

9.8 mm

(0.39”)

60.7 mm

(2.39”)

235.0 mm (9.25”)

242.5 mm

(9.55”)

38.0 mm

(1.50”)

60.7 mm

(2.39”)

232.0 mm

(9.14”)

242.6 mm

(9.55”)

Front View Side View Rear View

System Overview

Appearance

Note: Refer to installation drawings provided with system.

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 9

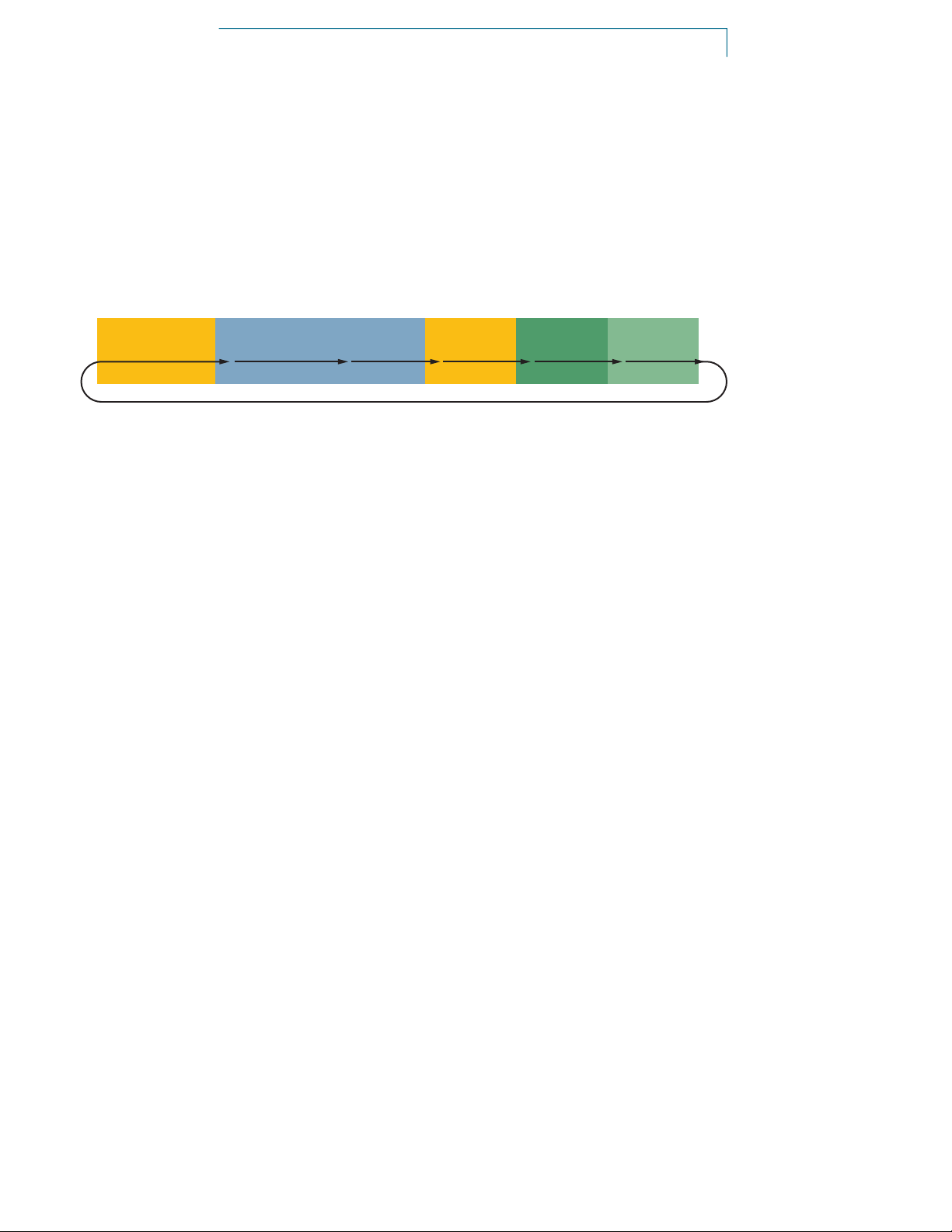

Two-stage Technology Operating Principle

The IntelliGen dispense system uses a proven, unique two-stage design to operate dispense and

filtration functions independently. Filtration occurs at a reduced rate, which prevents microbubble

formation and maximizes filter performance.

The system uses two motors (one for fill, one for dispense), and advanced fluid paths to deliver extreme

repeatability at dispense rates down to 0.1 mL/sec. During normal operation, the dispense system cycles

through the dispense/fill, filtration, vent, purge, fill/ready and ready states.

1. READY State

• The inlet, external outlet, vent and purge

valves are closed.

• The isolate and barrier valves remain open

for a time to allow the system to reach ambient

pressure, then the valves close.

• The dispense chamber is full of fluid and is

ready to dispense.

2. DISPENSE and FILL State

• The external valve opens as the dispense

motor pushes fluid through the outlet and

onto the wafer.

• The dispense rate and volume are motor-

controlled and independent of the fill and

filtration rate.

• Simultaneously during dispense, the inlet valve

can open and begin filling the inlet chamber.

3. FILTRATION State

• The isolation and barrier valves open and the

fill motor pushes fluid through the filter and

into the dispense chamber, as the dispense

motor retracts.

• At the programmed filtration rate, the dispense

chamber fills with filtered fluid.

4. VENT State

• The barrier valve closes and the vent valve opens.

• The fill motor pushes fluid and bubbles upstream

of the filter membrane through the vent port.

5. PURGE State

• The barrier valve closes as the purge valve

opens and the dispense motor pushes fluid out

of the dispense chamber to the inlet source.

This step ensures that the dispense fluid

contains no bubbles.

6. READY/FILL State

• The dispense chamber is full of fluid and

ready to dispense.

Quick Filter Changeout

Patented Connectology®allows start-to-finish filter

change in under a minute. No tools are required, no

photochemicals to clean up and there is minimal

personnel exposure to potentially hazardous volatile

organic compounds (VOCs). Additionally, the dis-

pense systems use a patented two-stage technology

which provides rapid priming of the filter, resulting

in significant chemical savings.

Dispense/FillFiltrationPurge Fill/Ready Ready

Vent

(optional)

INTELLIGEN MV DISPENSE SYSTEM

10 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

The following diagram shows the absolute mini-

mum required clearances for filter replacement.

The filter can be placed into the service area, then

slid into the manifold. This feature allows easy

installation into tight areas with drip trays, etc.

below the equipment.

CAUTION! DRIP HAZARD! If the pump has

been installed with minimum changeout

space, use appropriate wipes, caps, and/or

other materials to prevent spilling of fluid

from the filter during changeout.

!

267.3 mm (10.52”)

1.3 mm

(0.05”)

7.4 mm

(0.29”)

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 11

Installation

This section covers the site requirements, tools and

equipment to install the system. Technical support

is available for all installation types.

NOTE: All components are shipped in pro-

tective packaging to prevent damage during

transport. If damage is found, please file a

damage claim with the transportation carrier

and contact customer support immediately.

CAUTION! Avoid particulate contamination.

Do not unwrap any cleanroom-packaged item

until immediately before installation.

WARNING! Only technically qualified

personnel should install the system.

Wear chemical-resistant garments and

eye protection. Chemicals are not supplied

with this equipment. Obtain a chemical

MSDS for each chemical used with the

system and follow all safety requirements.

CAUTION! Fittings and components damage

easily; handle them with extreme care.

Do not scratch or over-tighten any part.

Handling

Use care when lifting and carrying the pump. The

pump weighs in excess of 5 kg (11 lb), has blunt

edges, and can cause pinch or other personal injury.

WARNING! PINCH HAZARD! Pump weight in

excess of 5 kg (11 lb). Use care in lifting and

carrying the pump to prevent personal injury.

Facility Requirements

• Filtered N2or CDA, 551 kPa (80 psig)

• Vacuum >20 in Hg

• 24 VAC input power

WARNING! Installation location must provide

adequate exhaust ventilation and monitoring.

The installation location should incorporate

secondary containment and spill detection.

Facility must have appropriate alarm and

shutdown procedures for the chemicals in use.

Tools and Materials

Verify all system facility hookups including liquid

and power supplies. The following tools and materi-

als are required:

• Inlet/outlet tubing appropriately sized for the sys-

tem and compatible with the fluid in use

• Tube cutter

• Adjustable wrench

• Electrical power cable

• Tie wraps

• Cleanroom wipes

• Pillar insertion tool/fixture

• Flaring tools

• Mounting hardware

• Impact 2 V2 (OF style)

(sold separately)

• External stop/suckback valve

!

!

!

!

!

INTELLIGEN MV DISPENSE SYSTEM

12 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

Install the Pump

Step 1: Preparation

1. Use the dimensional drawings as a reference

for dimensions and locations.

2. Leave appropriate space around the system

to perform any connections, maintenance

or troubleshooting. Clearance space can be

shared space with other equipment.

3. Verify all system facility hookups including

liquid and power supplies. Refer to system

specifications.

Step 2: Unpack and Position the System

Allow space to make fluid fitting connections and

power and other cable connections. Please consult

customer support with any installation questions.

1. Remove the outer protective bags in your change

room. Wipe the inner bags according

to your cleanroom procedures.

2. Bring the system components to the installation

location. Remove the inner bags.

3. Leave enough clearance around the system to

allow service access. Refer to system dimensional

drawings on previous pages.

Step 3: Connect Electrical Supply Cable

1. Connect power/communications cable. Contact

Entegris for any pinout or connection details.

Step 4: Connect N2and Vacuum Supplies

1. Connect filtered and regulated N2or CDA

supply to the inlet connection. Do not turn

on the supply at this time.

2. Connect vacuum supply to the vacuum

connector. Rating is >20 in Hg.

Step 5: Install the Filter

The dispense system cannot operate without a

filter or a flushing shell installed.

WARNING! POTENTIAL CHEMICAL HAZARD!

Obtain the chemical supplier’s MSDS sheets

for specific health and safety information.

WARNING! Wear chemical-resistant garments

and eye protection at all times when working

on or near the fluid system. Obtain the chemi-

cal supplier’s MSDS for each chemical in use

for specific health and safety information.

NOTE: UPE filter membrane does not require

pre-wetting for use with most photochemicals.

Consult a technical support representative for

additional information on filter selection and

compatibility.

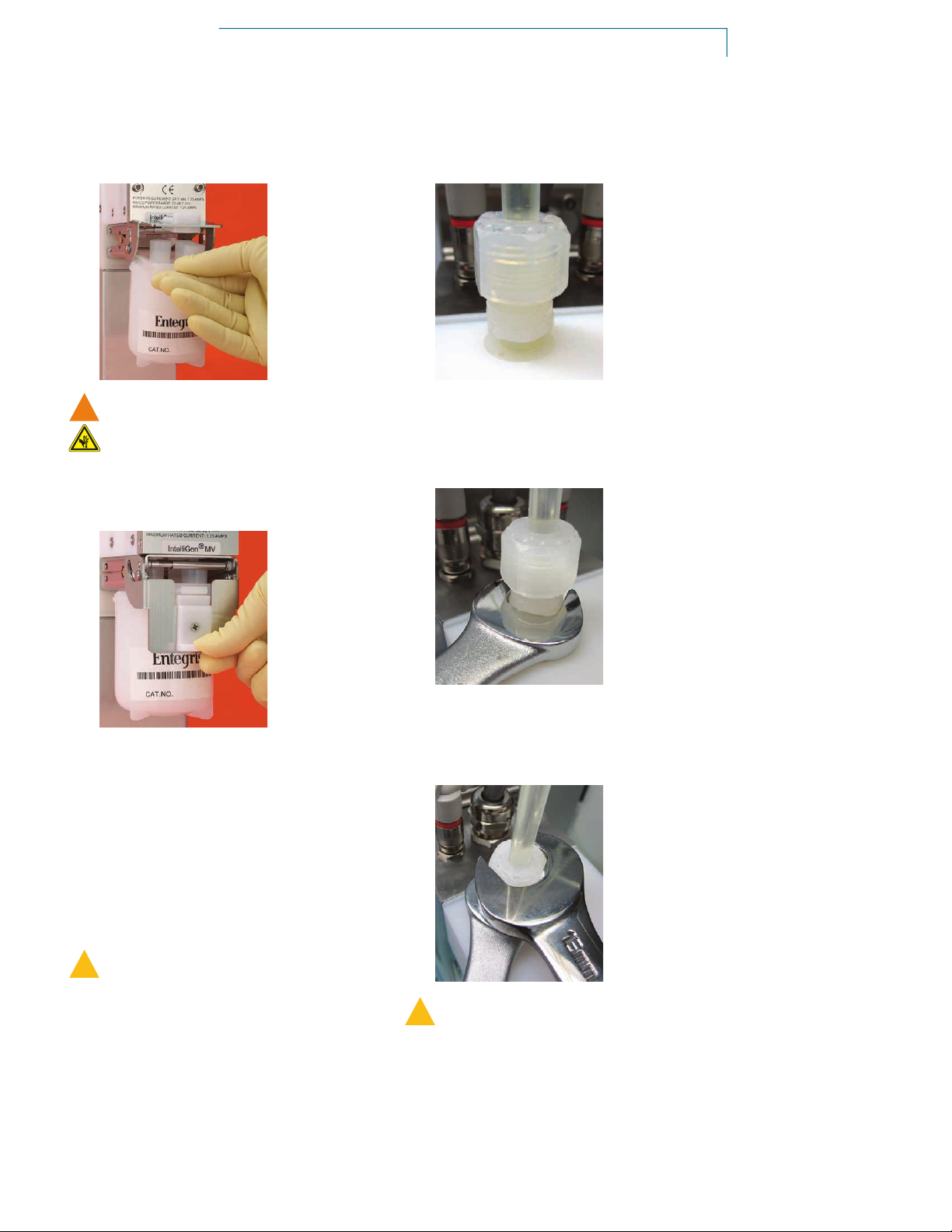

1. Wear protective personal protection equipment.

2. Pull down the tab on the lever until it clears

the catch (shown with filter installed for

reference).

3. Raise the lever to open the filter manifold.

4. Verify that only ONE set of o-rings is used.

WARNING! POTENTIAL CHEMICAL LEAK!

Use one set of o-rings only. Check that the

filter has o-rings. NEVER use o-rings on both

the filter and the manifold or the system may

leak.

!

!

!

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 13

5. Slide in a new filter.

WARNING! PINCH HAZARD! Keep

fingers clear of jaw mechanism

to prevent personal injury.

6. Keep your fingers CLEAR of the jaws, then

lower the lever until the tab clicks into place

on the filter.

Step 6: Connect Fluid Lines

Minimize tubing lengths whenever possible and

maximize fluid tubing size wherever practical to

further reduce pressure drop through the tubing.

Use the shortest tube length practical, while

providing adequate service loops.

As a general rule, minimize the distance between

the source liquid and the system and between the

system and the point-of-dispense.

CAUTION! DRIP HAZARD! Do not over-tighten

fittings. Excessive force will damage the

internal seals. Tighten the fittings by hand;

then use a small adjustable wrench to tighten

for the final 1⁄4turn.

1. Insert Pillar sleeve and tube assembly into the

fluid fitting adapter.

2. Hand tighten Pillar nut.

3. Use a 13 mm wrench to hold the fluid fitting

adapter from turning when tightening the

Pillar nut, sleeve and tube assembly.

This is only to hold, Not to turn it.

4. While holding the fluid fitting adapter with

the 13 mm wrench tighten the Pillar nut

using a 16 mm wrench to the specified Pillar

recommended specifications.

CAUTION! Tightening the union nut:

Refer to Super Type Pillar Fitting

Instruction Manual No. 048L-1.

Refer to the standard Super 300 Type Pillar or

Flowell manufacturer’s installation instructions

for the making of other fitting connections.

!

!

!

INTELLIGEN MV DISPENSE SYSTEM

14 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

Storage

Short-term “Wet” Storage

A wet pump should be left in auto-recirculation

mode to recirculate fluid and avoid problems

related to stagnant chemical.

Long-term “Dry” Storage

For long-term storage, the pump should be flushed

and cleaned prior to performing a shut-down. See

the Flushing the System section of this manual.

MMI Software

The new and improved user-friendly MMI

(Man-Machine Interface) Software provides

more information at the point of dispense for

better control of the dispense.

New features include:

• A pressure sensor on the fill side of the dispense

pump to better understand what is occurring

during the fill stage. This allows better recharge

control and also provides an indication of when

filter replacement is necessary. • An improved

dispense confirmation page with additional tests

to determine the changes that occur between dis-

penses with the ability to

compare dispenses and the referenced dispense

assigned to the recipe number.

• An improved profiling page that allows side-by-

side comparisons between last dispense profile,

any saved dispense profile, or any referenced

dispense profile (accessed from the Confirma-

tion page) for four traces: dispense pressure,

dispense motor position, fill pressure, and fill

motor position.

• A self-test page with tests designed to evaluate

the status of the dispense pump.

• An improved alarms page that allows the user

to search and sort alarms history to determine

changes to the system. Every header column

can be sorted.

• An information page that allows the user to

assign names for fab, tool, coater, resist, or fluid.

This page also is a quick reference pump infor-

mation page.

• A mouse-over feature that provides a brief

description, the minimum and maximum limits,

and the default value.

• The ability to record pump information in

real time and save to csv file.

Installing Software

To program the pump, you must establish commu-

nications with a host computer, laptop or similar

system, using the supplied software.

To install the software and establish communica-

tions with the dispense system:

1. Verify that a filter has been installed in the

pump.

2. Connect the cables as appropriate for your

configuration, as covered in the Installation

section of this manual.

3. Verify that power is being supplied to the

dispense system.

4. Install the MMI software into a separate

directory on your computer, then double-click on

the *.exe file to start the program.

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 15

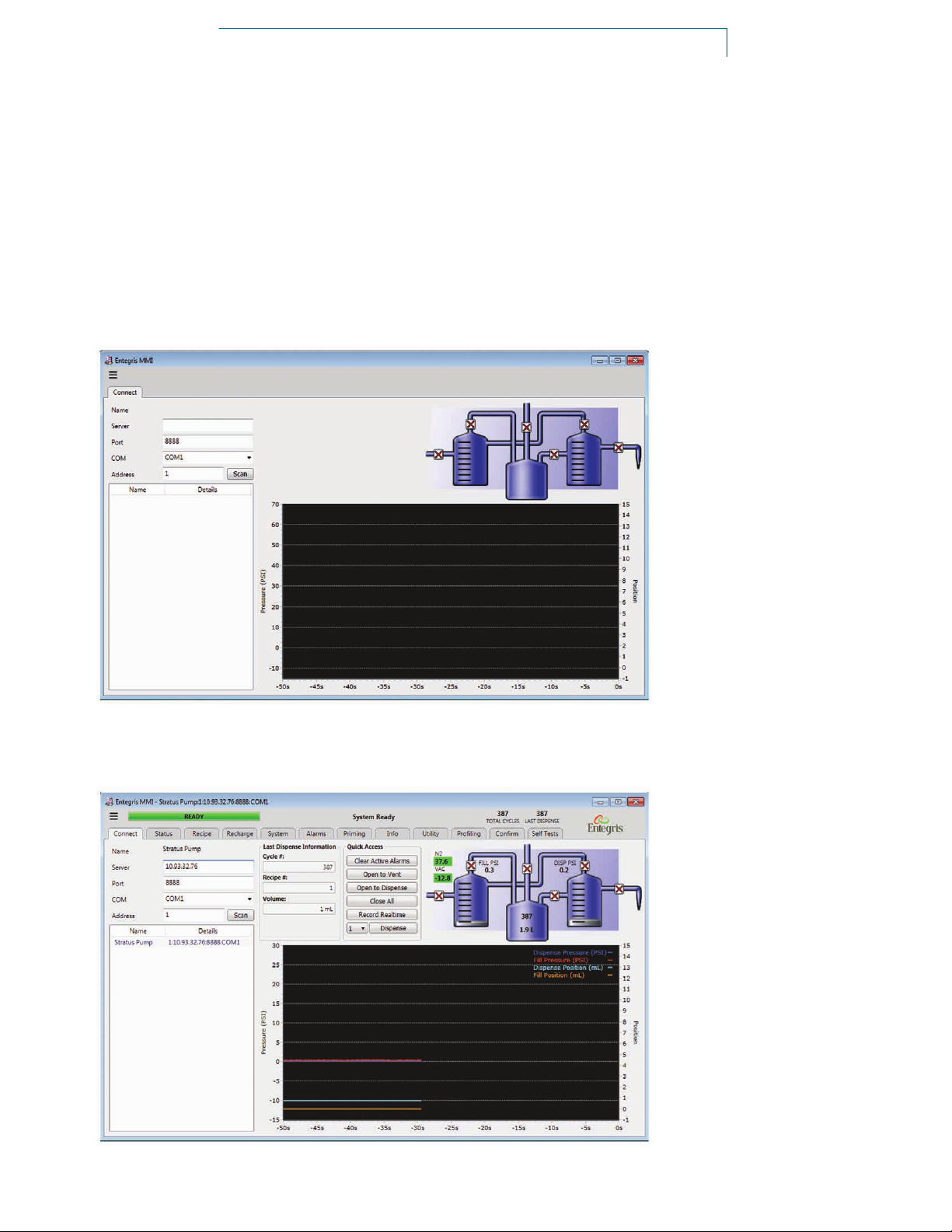

Connect Tab

The Connect tab establishes the connection between the dispense pump and the MMI software.

1. Enter the Server, Port, and Comm information.

• The exact COM port will depend on the specific computer connection and system setup.

2. Enter the Address, or click “Scan” to search for pump connections.

• Each IntelliGen MV system can be assigned a unique address from 1 to 63.

3. Click “Connect” to connect to the pump.

• The Connect tab will record all previous connections with the latest connection at the top.

4. A Time Synchronization screen may appear. Read the instructions displayed to synchronize the time

stamps between the computer and the dispense system.

When communications have been established, the MMI display will come alive with realtime dispense.

INTELLIGEN MV DISPENSE SYSTEM

16 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

System Tab

The System tab provides variables relating to the system management of the pump.

Variables can be changed from the default values to optimize the dispense system.

Use the mouse-over feature to obtain more information on displayed variables.

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 17

Priming Tab

The Priming tab provides the ability to purge the dispense pump and system of air using a “priming

sequence” of steps.

• Use “Loading a Sequence from a Saved File” to load an existing priming sequence.

• Use “Creating a Sequence” to create a new priming sequence.

Samples of priming sequences are provided in Appendix 1.

Loading a Sequence from a Saved File

A priming sequence can be loaded from a previously created sequence:

1. Click on the Menu logo.

2. Select File.

3. Select Import.

4. Select Priming.

5. Select number to be assigned.

6. Select priming file to be downloaded.

7. Press Open.

8. Press Start to being priming.

INTELLIGEN MV DISPENSE SYSTEM

18 INSTALLATION AND USE MANUAL P/N P92500 REV. A ENTEGRIS, INC.

Creating a Sequence

A priming sequence can be created with multiple steps to provide the most efficient sequence

for a specific fluid type and viscosity:

1. Under “Type” select a type of priming.

2. Under “Count” enter how many times the type of priming is to be performed.

3. For each step type, rates can be changed based on application needs.

4. Continue adding types and counts that will purge the system of air.

5. Press Apply.

6. Press Start to begin priming.

7. Priming sequence can be saved by clicking on the menu logo. Select file, select save,

select number, assign name of the priming sequence, press save.

INTELLIGEN MV DISPENSE SYSTEM

ENTEGRIS, INC. INSTALLATION AND USE MANUAL P/N P92500 REV. A 19

Priming

When in use, the Priming tab is divided into three sections:

• In the top section, pump status and priming step is displayed.

• In the middle section, an estimated time of completion and countdown is displayed.

• In the priming field, finished steps are highlighted in light blue, the current step is highlighted in dark

blue and unfinished steps remain in gray.

Table of contents

Popular Water Pump manuals by other brands

flamco

flamco Flamcomat Installation and operating instructions

Reefe

Reefe RCE160 Exploded View & Instruction Manual

Husqvarna

Husqvarna WT 10MP Operator's manual

Blue Angel Pumps

Blue Angel Pumps Professional BSP45 Operating instructions and parts manual

Bijur Delimon

Bijur Delimon FZ-A Operation manual

Strend Pro

Strend Pro SWP-110 instruction manual

Xylem

Xylem Flojet G55 Series Installation and operation manual

Beckett

Beckett CB25 owner's manual

BOC Edwards

BOC Edwards EO2K instruction manual

Jojo

Jojo YBP750 Instructions for use

Lincoln

Lincoln SKF A Series User and maintenance instructions

GORMAN-RUPP

GORMAN-RUPP GHC Series Installation, operation and maintenance manual