• The pump must be earthed.

• All the maintenance should be carried out with the power supply disconnected.

• Do not put any strain on the electrical cable.

• The pump is only designed for clean water use.

• Do not adjust any settings without having carefully read and understood the instructions.

• Extending the cable may aect your factory warranty. Make use of an approved extending plug

adapter.

• The pump should be installed in a ventilated, undercover area to protect the unit against

direct sunlight, rain and spray from an irrigation system.

• Pumping muddy water or water containing suspended solids will severely reduce the life

expectancy of the unit. Note, this type of application falls outside of the factory warranty.

• The booster pump is equipped with a draining screw at the bottom of the suction/discharge

casing. It is advised to drain the unit when temperatures fall below 0°C.

1. Ensure that the power supply cable is connected correctly.

2. The suction and discharge piping should be of rigid characteristics, be able to withstand pressure

of up to 6 bar, be air tight on the suction side and water tight on the discharge side.

3. Follow the priming instructions as per diagrams.

4. Insert a small screwdriver into the fan cover and ensure that the fan is turning freely. If not, consult

your supplier.

5. The booster pump is designed to operate with a 230V single-phase power supply. Voltage

variance is maximum 10% up or down. Further variation will damage the electrical motor.

Operating Instructions

Pump Specifications

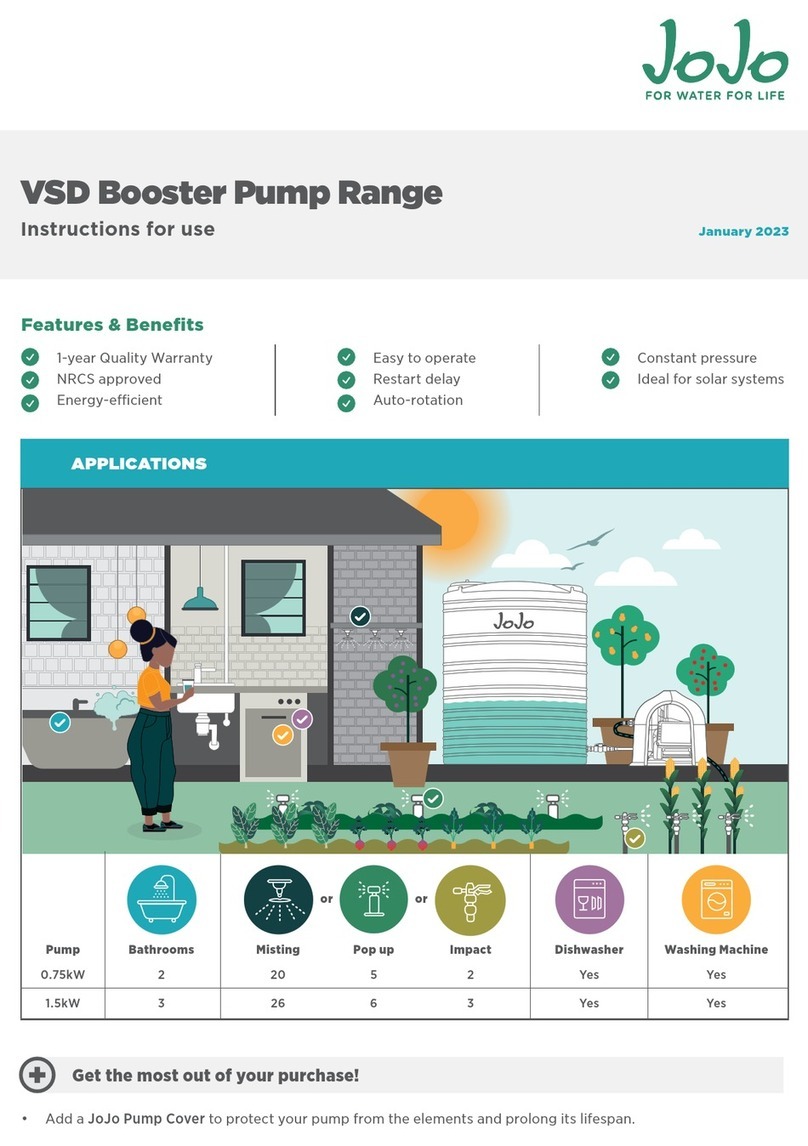

Easy to operate

Low noise level

Automatic start/stop function

Pre-wired with a 3-point plug

Energy-ecient

Up to 80% more energy savings compared to

traditional pump systems

Restart delay

An integral time delay for restart after

3 seconds protects the motor from heat

build-up due to continuous on/o switching

Auto-rotation

A built-in timer will automatically start the

pump within a 12-hour cycle to rotate the

bearings

Constant pressure

A pressure transducer ensures that

constant pressure is maintained even

when multiple water outlets are used

simultaneously

Class leading eciency

The unit has the following integrated

functions for protection from:

• Dry run

• Over-current

• Over/under voltage

• Overload

• Phase-loss

• Abnormal Pressure

Features & Benefits

Pump Performance Curve

CAPACITY Q

YBP750

TOTAL MANOMETRIC HEAD H(m)

0

02 5 50 75 1001 25 1501 75 L/min

M3/h10.5

9.07.56.04.53.01.5

2

4

6

8

10

30

60

80

100

M

Pump Model

Motor Power

Max. Flow

Variable Speed Drive (VSD) defined: The speed at which the pump runs varies as per the pressure

requirements to ensure minimal energy is being used.

• Unit intended for clean water usage such as drinking water or non-potable water piping systems,

as well as for irrigation purposes.

• Unit suitable for use with water temperatures ranging from 2 to 80 degrees celsius.

Max. Pressure

Max. Fluid Temperature

Max. Ambient Temperature

YBP750

0.75kW

66 lt/min

4.5 Bar

80 ˚C

40 ˚C

Important Information