Enthermics EC230L User manual

OPERATION AND CARE MANUAL

Corporate Headquarters:

W164 N9221 Water Street ●P.O. Box 443

Menomonee Falls, Wisconsin 53052-0443 ●U.S.A.

PHONE:

262.251.8356 800.TO.B.WARM

U.S.A./CANADA FAX:

262.251.7067

www.enthermics.com 800.862.9276

U.S.A./CANADA

800.329.8744

AN ISO 13485:2003 CERTIFIED COMPANY MN-28671 Rev 1 • 07/12

printed i n u.s.a.

Fluid

Warming

Cabinet

EC230L

EC340L

EC390L

EC770L

230V

EC230L

EC340L

EC770L

EC390L

INDEX

Transport and Storage ..............................1

Delivery.........................................1

Unpacking.......................................1

Safety Procedures and Precautions ....................2

Installation

Preparation ...................................3

Electrical Information & Capacities .................3

General Information ............................4

Dimension Drawings ...........................5-6

Operating Instructions

Control Features ...............................7

Operational Procedures ..........................8

Care and Cleaning

Cleaning and Preventative Maintenance............9-10

Troubleshooting Guide ...........................11

Service Parts Lists and Drawings .................12-16

Wire Diagrams (Always refer to wire diagram under top

cover of unit for most current version)

Warranty

Transportation Damage and Claims ......... Back Cover

Limited Warranty ...................... Back Cover

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 1

UNPACKING AND SET-UP

Transport and Storage Environmental Conditions (not to exceed 15 days)

• Ambient temperature range of -40° to +70°C (-40° to +159°F)

• Relative humidity range of 10% to 100%, including condensation

• Atmospheric pressure range of 50KPa to 106KPa

DELIVERY

This warming cabinet has been thoroughly

tested and inspected to insure only the highest

quality unit is provided. Upon receipt, check for

any possible shipping damage and report it at once

to the delivering carrier. See Transportation Damage

and Claims section located in this manual.

This appliance, complete with unattached items

and accessories, may have been delivered in one or

more packages. Check to ensure that all standard

items and options have been received with each

model as ordered.

Save all the information and instructions packed

with the appliance. Complete and return the warranty

card to the factory as soon as possible to assure

prompt service in the event of a warranty parts and

labor claim.

This manual must be read and understood by

all people using or installing the equipment model.

Contact the service department if you have any

questions concerning installation, operation,

or maintenance.

NOTE: All claims for warranty must include the

full model number and serial number of

the unit.

UNPACKING

1. Carefully remove the

appliance from the

carton or crate.

NOTE: Do not discard the

carton and other

packaging material

until you have

inspected the unit

for hidden damage

and tested it for

proper operation.

2. Read all instructions in this manual carefully before

initiating the installation of this appliance.

DO NOT DISCARD THIS MANUAL.

This manual is considered to be part of the

appliance and is to be provided to the owner

or manager of the business or to the person

responsible for training operators. Additional

manuals are available from the service department.

3. Remove all protective plastic film, packaging

materials, and accessories from the appliance

before connecting electrical power.

TRANSPORT AND STORAGE

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 2

Knowledge of proper procedures is essential to the safe

operation of electrically and/or gas energized equipment. In

accordance with generally accepted product safety labeling

guidelines for potential hazards, the following signal words

and symbols may be used throughout this manual.

Used to indicate the presence

of a hazard that will cause

severe personal injury, death,

or substantial property

damage if the warning

included with this symbol

is ignored.

Used to indicate the presence

of a hazard that can cause

personal injury, possible

death, or major property

damage if the warning

included with this symbol

is ignored.

Used to indicate the presence

of a hazard that can or will

cause minor or moderate

personal injury or property

damage if the warning

included with this symbol

is ignored.

Used to indicate the presence

of a hazard that can or will

cause minor personal injury,

property damage, or a

potential unsafe practice if the

warning included with this

symbol is ignored.

Used to notify personnel of

installation, operation, or

maintenance information that is

important but not hazard related.

1. This fluid warming cabinet is intended for warming

injection and/or irrigation fluids ONLY. No other use

for this device is authorized or recommended.

2. This device is intended for use in commercial

establishments where all operators are familiar with

the purpose, limitations, and associated hazards of this

device. Operating instructions and warnings must be

read and understood by all operators and users.

3. Any troubleshooting guides, component views, and

parts lists included in this manual are for general

reference only and are intended for use by qualified

technical personnel.

4. This manual should be considered a permanent part of

this device. This manual and all supplied instructions,

diagrams, schematics, parts lists, notices, and labels

must remain with the device if the item is sold or moved

to another location.

NOTE:

SAFETY PROCEDURES AND PRECAUTIONS

NOTE

For equipment delivered for use

in any location regulated by the

following directive:

DO NOT DISPOSE OF ELECTRICAL

OR ELECTRONIC EQUIPMENT WITH

OTHER MUNICIPAL WASTE.

NOTE

This unit should not be left unattended for

periods of more than 24 hours. In case of

absences longer than 24 hours, disconnect

the warmer from its power source.

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 3

Hazardous

Voltage Present

Medical Equipment classified by Underwriters

Laboratories with Respect to Electrical

Shock, Fire and Mechanical Hazards only, in

Accordance with UL 2601-1 and CAN/CSA

C22.2 No. 601.1.

UL File No.

E201645

Grounding reliability can only be achieved when equipment is

connected to an equivalent receptacle marked “Hospital Grade.”

Protective Earth

Ground Symbol

Safety Class I

Equipment

ELECTRICAL INFORMATION

The power specifications are located on the unit identification rating tag. This tag is

permanently attached to the unit and must be located to verify power requirements.

PREPARATION

Before operating the cabinet, clean both the interior and exterior of the unit with a damp cloth and

mild soap solution. Wipe with an appropriate disinfectant.

Wipe dry with a clean cloth or air dry.

CAUTION

THIS UNIT HAS NOT BEEN

APPROVED FOR WARMING OF

BLOOD OR BLOOD PRODUCTS.

CAUTION

INJECTION FLUID MANUFACTURER

SUGGESTS NOT TO WARM INJECTION

FLUIDS OVER 40°C (104°F).

DANGER

DO NOT use this warming appliance

in the presence of flammable

anesthetic mixture (with air or

with oxygen or nitrous oxide).

THIS COULD RISK AN EXPLOSION!

(Not category AP or APG equipment )

DANGER

ENSURE POWER SOURCE

MATCHES VOLTAGE IDENTIFIED

ON APPLIANCE RATING TAG.

Wire diagram located under top cover of unit

To prevent an electrical shock hazard between the appliance and

other appliances or metal parts in close vicinity, an equalization-

bonding stud is provided. An equalization bonding lead must be

connected to this stud and the other appliances / metal parts

to provide sufcient protection against potential difference.

The terminal is marked with the following symbol.

Other international plugs are available, contact factory for more information.

EC770L POWER REQUIREMENTS

230 V.A.C. — 50 Hz, 1 ph

0.8 kW, 3.5 Amps

Type B Equipment

BS 1363 Plug

(UK only)

CEE 7/7

220-230V Plug

EC340L POWER REQUIREMENTS

EC390L POWER REQUIREMENTSEC230L POWER REQUIREMENTS

230 V.A.C. — 50 Hz, 1 ph

0.7 kW, 3.0 Amps

Type B Equipment

BS 1363 Plug

(UK only)

CEE 7/7

220-230V Plug

230 V.A.C. — 50 Hz, 1 ph

0.82 kW, 3.6 Amps

Type B Equipment

BS 1363 Plug

(UK only)

CEE 7/7

220-230V Plug

230 V.A.C. — 50 Hz, 1 ph

0.9 kW, 3.9 Amps

Type B Equipment

BS 1363 Plug

(UK only)

CEE 7/7

220-230V Plug

IMPORTANT

Do not load each basket beyond the recommended

maximum capacity:

EC230L = 16 liters/basket

EC340L = 14 liters/basket (28 total liters/unit)

EC390L = 18 1-liter bottles or 29 1-liter bags

EC770L = 24 liters/basket (72 total liters/unit)

Overloading may cause lower or uneven

temperatures of product and damage to basket

and basket rail supports. Baskets that are

overloaded may slip off rail supports, resulting

in possible damage to product and equipment, as

well as causing possible injury.

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 4

GENERAL INFORMATION

CAUTION

THIS UNIT HAS NOT BEEN

APPROVED FOR WARMING OF

BLOOD OR BLOOD PRODUCTS.

DANGER

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

ANY KIND. DO NOT USE WATER JET

TO CLEAN.

SEVERE DAMAGE OR

ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

This warming cabinet is designed to safely warm and store either

irrigation uids or injection uids.

The single-chambered warming cabinet is constructed with 20

gauge stainless steel exterior casing and door with handle and

hinges designed to withstand heavy usage. A door with window

allows observation of inventory with the door closed. The cabinet

is warmed using low-heat-density electrothermal cable array. The

electrothermal cable is positioned in the oor and two sides of the

warming cabinet, providing even heating of the interior chamber.

The interior chamber temperature is regulated by an electronic

control consisting of a 4 digit L.E.D. display, ON/OFF key,

INCREASE and DECREASE keys, integrated LOCK feature and a

series of prompt sequence indicators.

The electronic control can easily be set to operate in Fahrenheit

or Celsius. After a power failure, the cabinet will remember its

programming and begin to operate as before. The ON/OFF

indicator will blink to indicate a failure occurred; pressing the

ON/OFF key once will eliminate this blinking. A thermal shut-

off system, separate from the electronic control, is included as an

additional safety feature.

The control will display temperature in whole degrees.

Fluid warming chamber

The warming cabinet can be programmed to warm either irrigation

uids (IRR) or injection uids (INJ), with separate temperature

ranges provided depending on the choice selected.

• IRR temperature range: 37° to 66°C (98° to 150°F),

• INJ temperature range: 37° to 40°C (98° to 104°F).

A fan located inside the chamber mixes the air to prevent

temperature strati cation and to ensure an accurate chamber

temperature for each mode.

• Within +0/-1.67°C (+0/-3ºF) for set points of

43° to 66°C (110° to 150°F)

• Within +0/-1.12°C (+0/-2ºF) for set points of

37° to 43°C (98° to 109°F).

If selected, an alarm will sound if temperatures exceed 6°C (10°F)

over the set-point temperature, and an OVERTEMP indicator will

blink indicating an over-temperature condition.

EC230L INFORMATION:

The warming cabinet is equipped with one (1) white, epoxy-

coated wire basket to accommodate uids packaged in bags

or bottles, mounted on basket rail supports. The basket

has a 16 liter maximum capacity. The cabinet is furnished

with four (4) 1-1/4" (31mm) non-skid rubber feet.

EC340L INFORMATION:

The warming cabinet is equipped with two (2) white, epoxy-

coated wire baskets to accommodate uids packaged in bags

or bottles, mounted on basket rail supports. Each basket

has a 14 liter maximum capacity. The cabinet is furnished

with a full perimeter rubber bumper assembly and one set of

5" (127mm) heavy duty casters, two with locking brakes.

EC390L INFORMATION:

The warming cabinet is equipped with one (1) stationary

white, epoxy-coated shelf to accommodate uids packaged in

bags or bottles. The basket has a capacity of 18 1-liter bottles

or 29 1-liter bags.The cabinet is furnished with one set of

0.5" (13mm) levelling feet.

EC770L INFORMATION:

The warming cabinet is equipped with three (3) white, epoxy-

coated wire baskets to accommodate uids packaged in bags

or bottles, mounted on basket rail supports. Each basket has

a 24 liter maximum capacity. The cabinet is furnished with

a full perimeter rubber bumper assembly and one set of

5" (127mm) heavy duty casters, two with locking brakes.

(IPX-0 - Listed as Ordinary)

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 5

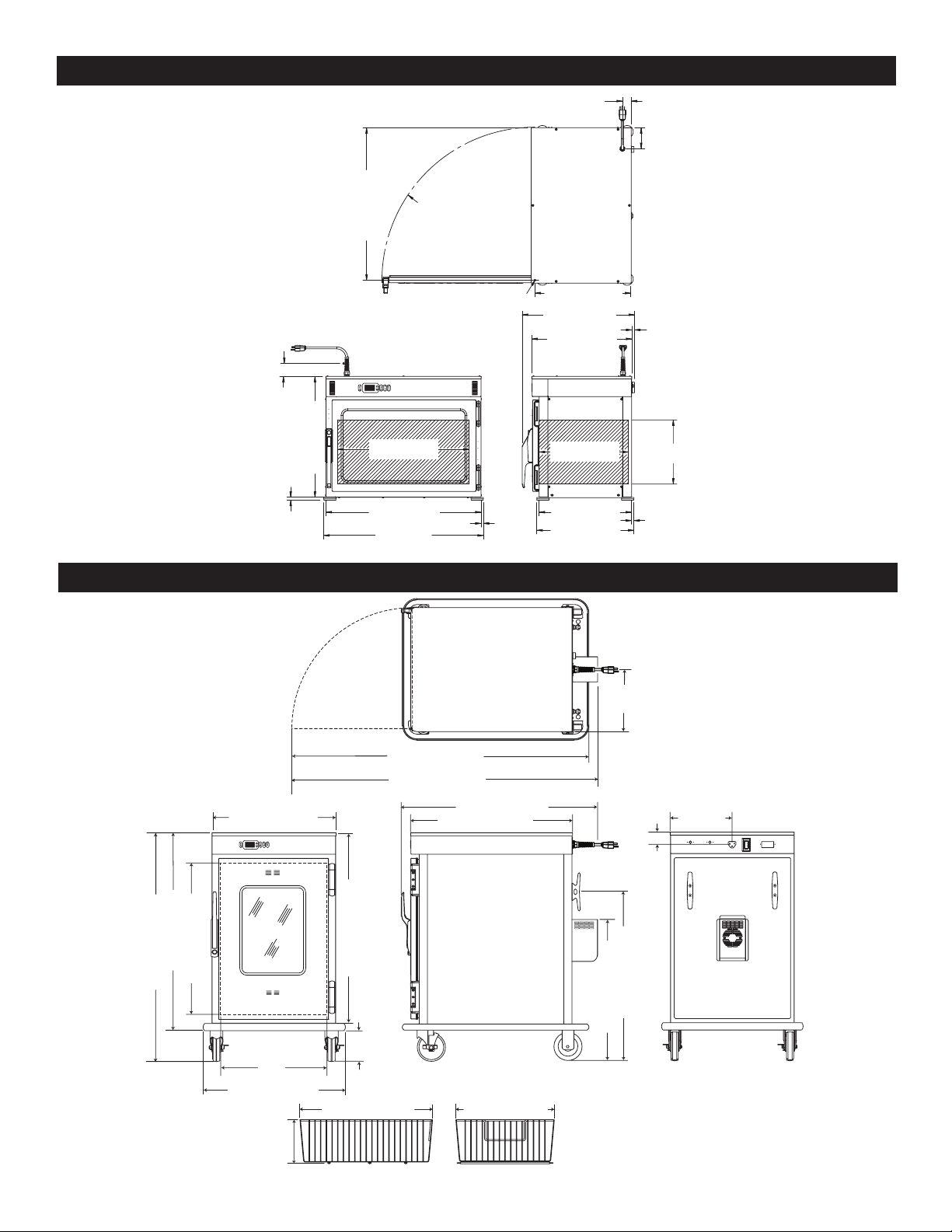

EC230L DIMENSIONS

EC340L DIMENSIONS

38.88" (986.8mm)

22.813" (580.2mm)

C

L

19.41" (492.8mm)

13.84" (351.4mm)

CAVITY

1.24"

(31.4mm)

13.12" (333.2mm)

CAVITY

16.2" (410.4mm)

18.96" (475.1mm)

ELECTRICAL CONNECTION

21.50" (546.7mm)

CAVITY

28.0" (710.7mm)

17.50" (445.3mm)

11.89" (301.9mm)

40.91" (1039.0mm)

17.85" (453.4mm)

9.189" 233.4mm)

11.50" (292.1mm)

8.07"

(204.5mm)

ELECTRICAL

CORD LENGTH (est.)

8' (2,438mm)

33.4" (849.2mm)

26.96" (684.6mm)

20.0" (508.0mm)

CAVITY HEIGHT

14.13" (358.7mm)

CAVITY WIDTH

21.63" (549.3mm)

CAVITY DEPTH

1.462" (36.9mm)

CORD

43.38" (1101.8mm)

OVERALL

HANDLE TIP

28.53" (724.5mm)

24.13" (612.7mm)

8.70"

(220.8mm)

17.37" (441.1mm)

20.67" (525.0mm)

CORD POS.

7.69

"

(195.28mm)

12.27

"

(311.56mm)

16.27

" (413.05mm)

CORD LENGTH (est.)

8' (2,438mm)

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 6

EC390L DIMENSIONS

PIVOT

4.09" (104.0mm)

1.71" (43.4mm)

18.61" (472.6mm)

PIVOT

29.70" (754.5mm)

RADIUS

29.62" (752.3mm)

PIVOT

2.50" (63.5mm)

MINIMUM

0.56" (14.2mm) FEET

23.46" (596.0mm)

30.08" (763.9mm)

30.98" (767.0mm)

WITH FEET

0.45"

(11.5mm)

21.80" (553.8mm)

WITH HANDLE 0.53" (13.6mm)

19.42" (493.2mm)

25.46" (646.7mm)

CAVITY 17.34" (440.3mm)

CAVITY

18.84" (478.6mm)

WITH FEET

17.93" (455.5mm)

0.45" (11.5mm)

12.45" (316.3mm)

CAVITY

CORD LENGTH (est.)

8' (2,438mm)

EC770L DIMENSIONS

11.00"

(280.3mm)

52.80" (1341.0mm)

35.00" (889.5mm)

28.00" (730.8mm) 11.00"

(280.3mm)

2.20" (55.6mm)

OFF

ON

30.10" (764.2mm)

25.10" (637.7mm)

5.500" (140.4mm)

18.90" (480.3mm)

Cavity

25.20" (639.2mm)

26.90" (683.5mm)

Cavity

35.10" (892mm)

40.80" (1036.2mm)

54.19" (1382.0mm)

33.876" (860.5mm)

22.3" (566.5mm)

22.10

"

(561.3mm)

7.69"

(195.3mm)

17.10

"

(434mm)

CORD LENGTH (est.)

8' (2,438mm)

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 7

The following refers to features that are available when the control is

powered on.

CONTROL PANEL KEYS

ON/OFF KEY

Press the ON/OFF key to power on the control. Press and hold

the ON/OFF key for 2 seconds to turn the control off. The status

indicator L.E.D. will illuminate in the power ON state. Note: The

IRR or INJ must be selected to turn on the heating circuit.

UP ARROW / DOWN ARROW KEYS

These keys are used to increase or decrease the temperature set-

point as desired. Continual pressure to a key will increase the

increments in which the values will change.

OVERTEMP ALARM KEY

Depressing this key displays the current over-temperature

trip-point. The alarm trip-point is always 6°C (10°F) above the

temperature setting. When the green OVERTEMP indicator is

blinking, the warmer has entered an over-temperature condition.

IRR KEY

The IRR key is used to select the IRRIGATION FLUIDS mode and

to display the IRR set-point temperature. The temperature range is

37° to 66°C (98° to 150°F). The green IRR indicator and the yellow

indicator below the IRR key illuminates when the IRR set-point

temperature is being displayed.

INJ KEY

The INJ key is used to select the INJECTION FLUIDS mode and

to display the INJ set-point temperature. The temperature range is

37° to 40°C (98° to 104°F). The green INJ indicator and the yellow

indicator below the INJ key illuminates when the INJ set-point

temperature is being displayed.

NOTE: When the control is powered on, IRR or INJ must be selected

to turn on the heating circuit. To switch between the irrigation

and the injection mode, you must rst turn the control off and

back on. Be careful to cool the cavity down prior to switching

from a high temperature to a lower temperature or the control

will display an unwanted overtemp alarm.

L.E.D. DISPLAY STATUS INDICATORS

OVERTEMP

When the control senses a temperature 10°F (6°C) greater than

the set point, this indicator will illuminate. The audible alarm will

sound. The ON/OFF key indicator will ash. The green indicator of

the overtemp key will stop blinking once the warmer temperature

drops back to the set point temperature range. To silence the alarm

and extinguish the ERROR indicator after the temperature has

dropped into the selected temperature range, use the ON/OFF key

to reset the control. Inspection of the product in the cavity may

be necessary.

ERROR

This illuminates when an over-temperature condition is detected.

The ERROR indicator will remain illuminated, even after the

over-temperature condition is cleared, until the warmer is turned

off. This will alert the operator that the control has indicated an

OVERTEMP and the product in the cavity should be inspected.

LOCK

Illuminates when the lock feature is engaged.

POWER FAIL DETECT

If the power were to fail for any reason while control is powered

on, the warmer will retain in memory its current operating state.

When the power is restored, the control will alarm once and resume

operating in its previously set mode, but will alert the operator that

such an event has occurred: The ON/OFF status indicator will ash.

Press the ON/OFF key once to acknowledge that the power has been

restored. The ON/OFF status indicator will stop ashing. When

pushing the ON/OFF key, the display will indicate the time period

of the outage in hours and minutes (HH:MM), then return to the

normal display and previously set mode. Inspection of the product

in the cavity may be necessary.

FAHRENHEIT OR CELSIUS SELECTION

While the controller is in the OFF mode, press and hold the UP

ARROW key for 5 seconds to view the current setting. Press again

to switch between °F (Fahrenheit) or °C (Celsius).

CAVITY TEMPERATURE DISPLAY

To reference the cavity air temperature, push and hold the

OVERTEMP and UP ARROW keys. While holding both keys, the

value in the display refers to the temperature at the cavity sensor.

AUDIBLE ALARM SELECTION

While the controller is in the off mode, press and hold the DOWN

arrow key for 5 seconds. Press again to switch between audible

alarm ON (Ι) and OFF (O) mode.

CONTROL LOCK PROGRAMMING

The warmer control can be locked so that no changes can be made

to the temperature set-point or the mode selection. Press and hold

the ON/OFF key and the UP arrow key at the same time. The LOCK

indicator will illuminate. Attempts to operate the ON/OFF key, or

to change the temperature set-point will be unsuccessful. To unlock

the control, press and hold the ON/OFF key and the DOWN arrow

button at the same time. The control will unlock, and the LOCK

indicator will go out.

THERMOSTAT CONTROL AND L.E.D. DISPLAY

ON/OFF KEY

STATUS

INDICATOR L.E.D.

STATUS

INDICATOR

L.E.D.

IRRIGATION

MODE KEY

UP

ARROW

DOWN

ARROW

OVERTEMP

ALARM KEY

INJECTABLES

MODE KEY

MAIN DISPLAY

SET-POINT

TEMPERATURE

LOCKOVERTEMP

ERROR

FLUID CONTROL FEATURES

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 8

1. The appliance should be plugged into an appropriate

hospital grade receptacle for a 230V appliance.

2. Turn on the power circuit breaker

switch, which is located at the back

of the appliance. It is a rocker-type

switch with international ON (I) and

OFF (O) markings.

3. ACTIVATE CONTROL BY PRESSING THE

ON/OFF KEY ON CONTROL PANEL ONCE.

The ON/OFF indicator will illuminate and remain lit

until the unit is turned off. The digital display will

indicate last temperature set-point of compartment.

4. SELECT DESIRED MODE OF OPERATION.

Press the IRR key to select the IRRIGATION FLUIDS

mode or the INJ key to choose the INJECTION FLUIDS

mode. The last set-point temperature for that mode of

operation will appear in the display.

NOTE: In order to switch between the irrigation and

injection modes, you must rst turn the unit

off and then turn the unit back on.

5. SET DESIRED TEMPERATURE.

To set the uid warming temperature, press and hold the

UP or DOWN ARROW keys to change the value shown

in the display.

The IRRIGATION FLUIDS set-point

temperature range is 37° to 66°C (98° to 150°F) and

the INJECTION FLUIDS set-point temperature range

is 37° to 40°C (98° to 104°F).

NOTE: The warmer is designed to warm uids to the

appropriate temperature recommended by your

supplier. The warm-up stabilization time will vary

depending on the warmer load. Exercise judgment

to determine inventory rotation protocols and

warm-up time for the uids you use.

Caution:

• Check fluid temperature prior to use.

• Verify that the fan at the back or top of the chamber is

rotating freely. If it is not working, discard your inventory,

contact your service representative, and discontinue use of

unit until it is repaired.

• If the warmer control has failed, or if error messages

are displayed, discard your inventory and contact your

service representative.

• The unit may tip over if more than one drawer is

extended simultaneously. Open only one drawer at a time

when loading or unloading uids.

POWER

CIRCUIT BREAKER

SWITCH

OPERATIONAL PROCEDURES

POWER

CIRCUIT BREAKER

SWITCH

or

WARNING

REFER TO FLUID MANUFACTURER’S

LABELING FOR RECOMMENDED

WARMING PROCEDURES

CAUTION

INJECTION FLUID MANUFACTURER

SUGGESTS NOT TO WARM INJECTION

FLUIDS OVER 40°C (104°F).

WARNING

TRANSPORT SHALL ONLY BE DONE

WITH THE DOORS CLOSED

DANGER

DISCONNECT UNIT FROM

POWER SOURCE BEFORE

CLEANING OR SERVICING.

DANGER

DO NOT use this warming appliance

in the presence of flammable

anesthetic mixture (with air or

with oxygen or nitrous oxide).

THIS COULD RISK AN EXPLOSION!

(Not category AP or APG equipment )

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 9

CLEANING AND PREVENTIVE MAINTENANCE

PROTECTING STAINLESS STEEL, EPOXY COATED AND

PLASTIC SURFACES

It is important to guard against

corrosion in the care of stainless

steel surfaces. Harsh, corrosive,

or inappropriate chemicals can

completely destroy the protective

surface layer of stainless steel, epoxy

or plastic. Abrasive pads, steel wool,

or metal implements will abrade

surfaces causing damage to this protective coating and

will eventually result in areas of corrosion. Even water,

particularly hard water that contains high to moderate

concentrations of chloride, will cause oxidation and pitting

that result in rust and corrosion. In addition, many acidic

spills left to remain on metal surfaces are contributing

factors that will corrode surfaces.

Proper cleaning agents, materials, and methods are vital

to maintaining the appearance and life of this appliance.

Spilled items should be removed and the area wiped as

soon as possible but at the very least, a minimum of once

a day. Always thoroughly rinse surfaces after using a

cleaning agent and wipe standing water as quickly as

possible after rinsing.

CLEANING AGENTS

Use non-abrasive cleaning products designed for use on

stainless steel surfaces. Cleaning agents must be chloride-

free compounds and must not contain quaternary salts.

Never use hydrochloric acid (muriatic acid) on stainless

steel surfaces. Always use the proper cleaning agent at the

manufacturer’s recommended strength. Contact your local

cleaning supplier for product recommendations.

CLEANING MATERIALS

The cleaning function can

usually be accomplished

with the proper cleaning

agent and a soft, clean

cloth. When more aggressive

methods must be employed,

use a non-abrasive scouring

pad on difficult areas and

make certain to scrub with

the visible grain of surface

metal to avoid surface

scratches. Never use wire

brushes, metal scouring pads,

or scrapers to remove residue.

ANNUAL PREVENTATIVE MAINTENANCE

1. Ensure that the correct Operation and Care Manual is

available to all users.

2. Ensure that all users have been properly trained in

unit’s operation.

3. Do not exceed the unit’s capacity.

4. Inspect condition of plug and cord. Replace if damaged.

5. Clean dust from outer vents surrounding the unit and

around top of bonnet (if applicable).

6. Check door gasket integrity. Are there any tears? Is the

gasket worn or loose? Make sure seal is tight to unit

body. Replace gasket if integrity is compromised.

7. Check air temperature sensor mount on the interior of

chamber. Is the guard in place? Are the wires in

good condition?

8. Check insert assembly (depends on unit):

• Blanket Warmer: Check the blanket support

assembly and shelf. Is the assembly in place?

Are any pieces missing?

• Fluid Warmer: Check basket and side rail condition.

Do baskets move smoothly and freely?

9. Check condition of casters or feet condition. Ensure

components are secure and tightly threaded.

10. Check control panel overlay condition. Are there any tears

or excessive wear on the graphic? Does the control work

properly when buttons are pushed?

11. Check that all control and interior LEDs light up.

12. Is the set temperature comparable to the actual

temperature displayed?

Contact service for immediate repair

if any of the above problems exist.

CAUTION

TO PROTECT STAINLESS STEEL

SURFACES, COMPLETELY AVOID

THE USE OF ABRASIVE CLEANING

COMPOUNDS, CHLORIDE BASED

CLEANERS, OR CLEANERS

CONTAINING QUATERNARY SALTS.

NEVER USE HYDROCHLORIC ACID

(MURIATIC ACID) ON STAINLESS

STEEL. NEVER USE WIRE

BRUSHES, METAL SCOURING

PADS OR SCRAPERS.

N

O

W

I

R

E

B

R

U

S

H

E

S

N

O

S

T

E

E

L

P

A

D

S

N

O

S

C

R

A

P

E

R

S

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 10

The cleanliness and appearance of this equipment will contribute considerably to its operating

efficiency. Make certain the cabinet and door gasket are kept free of any debris that may accumulate.

Good equipment that is kept clean works better and lasts longer.

CLEAN THE UNIT REGULARLY:

1. Disconnect the cabinet from the power source.

2. Remove all detachable items such as metal basket and basket rail supports. Clean

these items separately.

NOTE: Avoid the use of abrasive cleaning compounds, chloride based cleaners, or cleaners

containing quaternary salts. Never use hydrochloric acid (muriatic acid) on stainless steel.

3. Clean the interior metal surfaces of the cabinet with a damp cloth and any mild

commercial detergent. Avoid the use of abrasive cleaning compounds. Rinse surfaces

by wiping with sponge & clean warm water. Remove excess water with sponge and

wipe dry with a clean cloth or air dry. Leave doors open until interior is completely dry.

4. Interior can be wiped with a sanitizing solution after cleaning and rinsing. This solution must be approved for use

on stainless steel surfaces. Replace support assembly.

5. Clean the exterior of the cabinet with a cleaner recommended for stainless steel surfaces. Spray the cleaner on a clean

cloth and wipe with the grain of the stainless steel.

6. Clean the window glass with a standard commercial glass cleaner.

7. Wipe control panel, door vents, door handles, and door gaskets thoroughly since these areas can harbor debris.

8. Wipe door gaskets and control panel dry with a clean, soft cloth.

9. To help maintain the protective film coating on polished stainless steel, clean the exterior of the cabinet with a

cleaner recommended for stainless steel surfaces. Spray the cleaning agent on a clean cloth and wipe with the grain

of the stainless steel.

Always follow appropriate state or local health (hygiene) regulations regarding all applicable cleaning and sanitation requirements.

CARE AND CLEANING

(Listed as Ordinary Equipment.)

DANGER

DISCONNECT UNIT FROM

POWER SOURCE BEFORE

CLEANING OR SERVICING.

DANGER

AT NO TIME SHOULD THE INTERIOR

OR EXTERIOR BE STEAM CLEANED,

HOSED DOWN, OR FLOODED WITH

WATER OR LIQUID SOLUTION OF

ANY KIND. DO NOT USE WATER JET

TO CLEAN.

SEVERE DAMAGE OR

ELECTRICAL HAZARD

COULD RESULT.

WARRANTY BECOMES VOID IF

APPLIANCE IS FLOODED

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 11

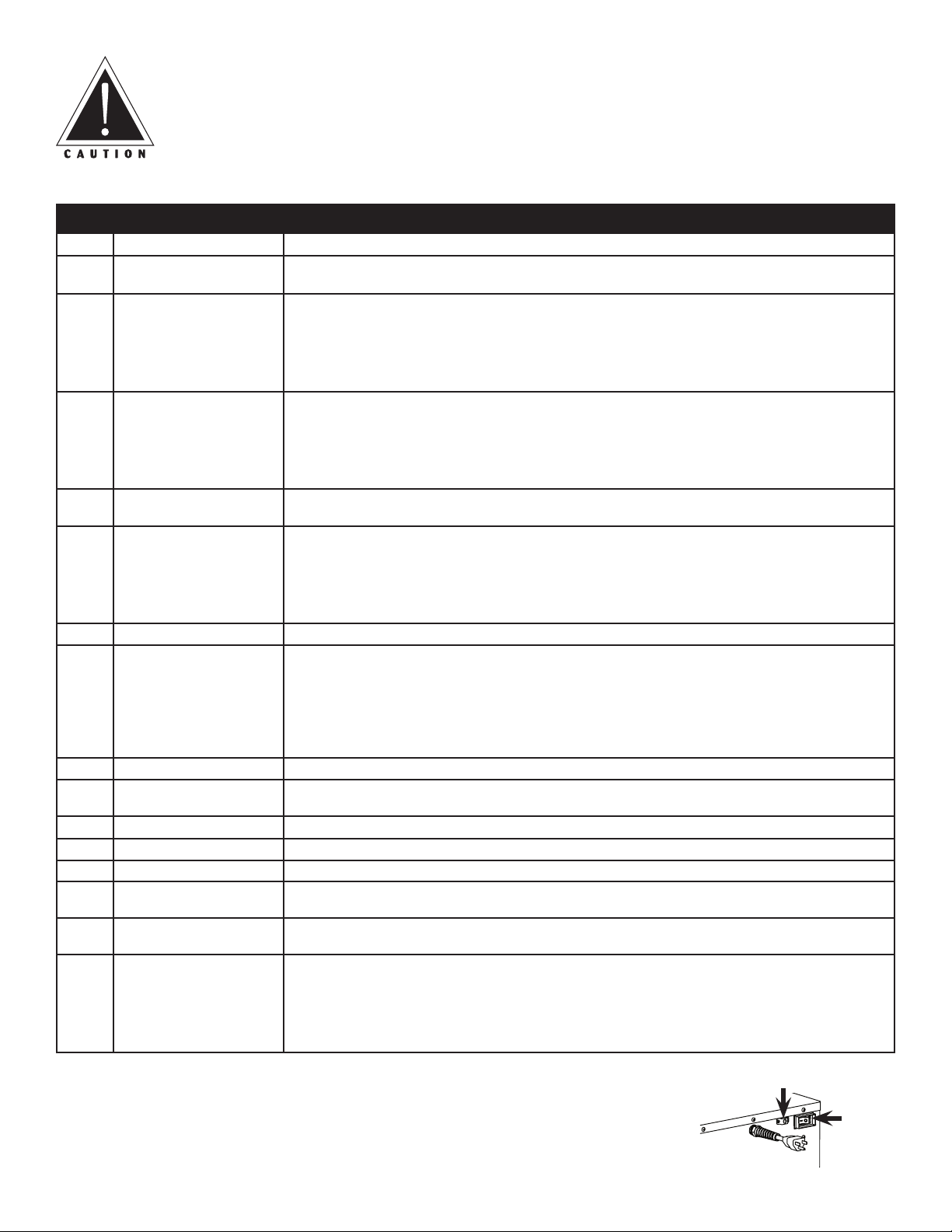

TROUBLE SHOOTING GUIDE

CODE DESCRIPTION ACTION REQUIRED

door Door left open for more

than 3 minutes

• Close door

• Verify door switch operation. Replace if necessary.

E-10 Cavity Air Sensor Shorted

• Detach the sensor from the terminal block. Use an Ohm meter to measure the resistance of the sensor.

Check sensor at 32°F (0°C) using a container of ice water. If Ohm reading is 100, replace display. If

Ohm reading is ±10, replace sensor.

• Check wires for integrity. Check for proper and secure connections at the control and terminal block.

If necessary, re-secure the faulty connections.

• If error continues call Service.

E-11 Cavity Air Sensor Open

• Detach the sensor from the terminal block. Use an Ohm meter to measure the resistance of the sensor.

Check sensor at 32°F (0°C) using a container of ice water. If Ohm reading is 100, replace display. If

Ohm reading is ±10, replace sensor.

• Check wires for integrity. Check for proper and secure connections at the control and terminal block.

If necessary, re-secure the faulty connections.

• If error continues call Service.

E-30 Under Temperature

(Blanket warmers only)

• Blanket chamber temperature has been lower than the set temperature for 90 minutes or longer.

• Check that door is closed.

E-31 Over Temperature • Unit may be overloaded. Redistribute inventory. Do not exceed height of insert.

• Check sensor at 32°F (0°C) using a container of ice water. The sensor reading should be 100 ohms.

•

Check wires for integrity. Check for proper and secure connections at the control and terminal block.

If necessary, re-secure the faulty connections.

• Relay may be defective.

• If error continues call Service.

E-50 Temp. Measurement Error • Call Service.

E-60 Real-Time Clock Error • Unit may have been unplugged for an extended period of time.

• To resolve, turn circuit breaker switch to ON position for 1 minute, then turn circuit breaker switch to

the OFF position for 5 seconds, and then back to ON. The error message should no longer appear in

the display.

• In order for the unit to fully recharge, it should remain plugged in and power circuit breaker switch

turned ON for at least 24 hours after resetting.

• Upon resolving an E-60 error, check that the date and time are correct.

E-61 Real-Time Clock Error • Call Service.

E-80 EEPROM Error • Ensure that all temperature and times are properly set.

• If error continues call Service.

E-81 EEPROM Error • Call Service.

E-82 EEPROM Error • Call Service.

E-83 EEPROM Error • Call Service.

E-87 EEPROM Error • Stored offsets corrupted. Offsets reset to 0. Control may need a recalibration. Possible bad EEPROM.

• If error continues call Service.

E-90 Button Stuck • A button has been held down for >60 seconds. Adjust control. Error will reset when the problem has

been resolved.

E-99 Hardware Over Temp • Inspect connections and condition of high limit bimetal thermostat and the fan switch ( uid warmers

only). Adjust if necessary.

• Check operation of cavity fan motor ( uid warmers only). Air movement from the cavity fan blade

should move the safety sail switch to the closed position. Adjustment to the fan blade may be needed

or replacement of the fan motor.

• If error continues call Service.

NOTE: All error codes must be cleared using the circuit breaker switch or power switch on the rear of the unit.

Manual Reset Instructions: Locate the manual reset button on back of unit. (Location may vary slightly from

diagram.) Using a pen, screwdriver or other long, thin implement, rmly push reset button. You will hear

an audible click when the button is reset. If reset button trips again while unit is running, contact a quali ed

service technician.

Circuit

breaker

Manual reset button

If your unit is not operating properly, check the following before calling your authorized service agent. Check the power

applied to the unit. Is the plug in outlet? Is the power circuit breaker switch in rear of unit OK? Has the high limit

manual reset tripped? If so, reset. (See “Manual Reset Instructions” below.)

If temperature calibration adjustment is required, call service for proper instruction.

Do not attempt to repair or service beyond this point. Contact manufacturer for nearest authorized service agent. Repairs

made by any other service agent without prior authorization by manufacturer will void the warranty on the unit.

This chart is provided for the assistance of qualified technicians only and is not intended for use by untrained or

unauthorized service personnel.

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 12

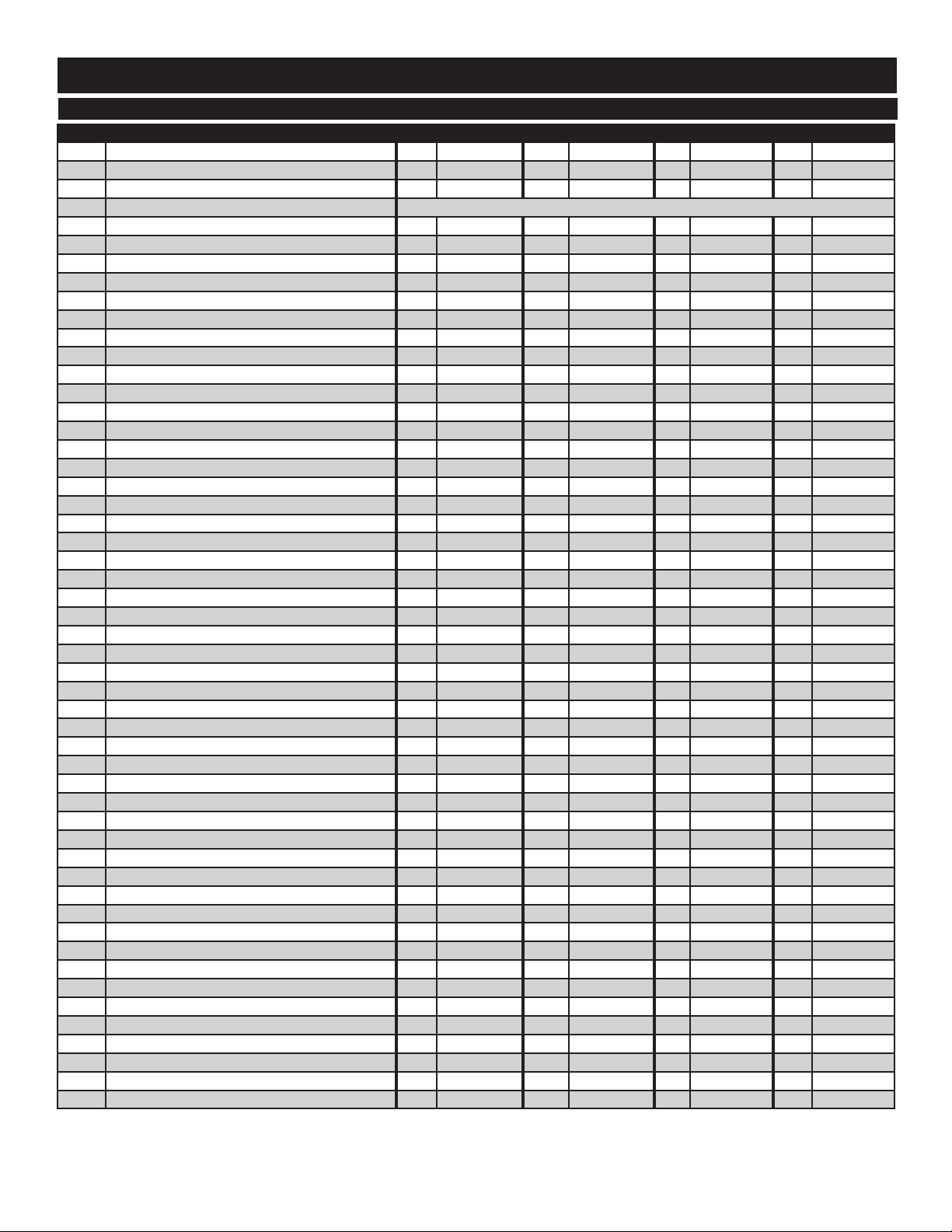

SERVICE

FULL ASSEMBLY VIEW (EC770L & EC390L shown)

* QUANTITY VARIES **NOT SHOWN PART NUMBERS AND DRAWINGS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

† Note: The cavity fan motor has a one year life expectancy. The cavity fan motor parts warranty remains in effect one (1)

year from installation or fifteen (15) months from the shipping date, whichever occurs first.

LOC DESCRIPTION QTY EC230L P/N QTY EC340L P/N QTY EC390L P/N QTY EC770L P/N

1. TOP 1 5000730 1 5010831 1 1010247 1 5003367

2. SCREWS, 8-32 X 1/4" * SC-2459 * SC-2459 * SC-2459 * SC-2459

3. STRAIN RELIEF BUSHING 1 BU-34836 1 BU-34836 1 BU-34836 1 BU-34836

4. CORDSET, HOSPITAL GRADE various international plugs are available, contact factory for more information.

5. PLATE, MOTOR MOUNT — — — — — — 1 1004300

6. MOTER SPACER — — — — — — 1 1004303

7. FAN MOTOR† 1 FA-33947 1 FA-33947 — — 1 FA-34780

8. WASHER, #10 FLAT NYLON — — — — — — 2 WS-2420

9. NUT, 8-32, NC HEX — — — — — — 2 NU-2296

10. NUT, 8-21, NC ACORN — — — — — — 2 NU-2455

11. MOTOR BOX 1 1009331 1 1009331 — — 2 5003358

12. BOX FAN — — — — 1 FA-3974 1 FA-3974

13. SCREW, 10-32 X 1/2", MOTOR MOUNT — — — — — — 4 SC-2661

SCREW, 8-32 X 5/8", MOTOR MOUNT 3 SC-2077 3 SC-2077 — — — —

14. NUT, 8-32 — — — — — — 2 NU-26526

15. SIDES — — 2 1010721 2 1010279 2 1010744

16. FULL PERIMETER RUBBER BUMPER — — 1 5010798 — — 1 5010873

17. CASTERS, 5" (127mm) RIGID — — 2 CS-24874 — — 2 CS-24874

18. CASTERS, 5" (127mm) SWIVEL W/ BRAKE — — 2 CS-24875 — — 2 CS-24875

19. SCREWS, 1/4 - 20 X 3/4" HEX — — 8 SC-25286 — — 8 SC-25286

20. BASKET SUPPORT ASSEMBLY 1 5014017 1 5014018 1 5012206 1 5014019

21. BASKET 1 BS-28518 2 BS-28517 — — 3 BS-28516

22. BASKET SUPPORT RAIL 2 1002305 4 1002302 — — 6 1002304

23. BASKET SLIDE GUIDE (1 SET OF 2) 1 GI-25941 2 GI-25941 — — 3 GI-25942

24. WINDOW DOOR ASSEMBLY,right hinge 1 5009043 1 5010808 1 5010908 1 5001253

25. DOOR HANDLE 1 HD-24171 1 HD-24171 1 HD-24171 1 HD-24171

26. SCREW, 10-32 X 1/2" FLAT 4 SC-2073 4 SC-2073 4 SC-2073 4 SC-2073

27. DOOR GASKET ASSEMBLY 1 E2132GS 1 GS-22950 1 GS-26321 1 GS-23794

28. PLATE, COVER, VENT — — 2 1010827 — — 2 1010827

29. HINGE SET (1 SET OF 2 HINGES) 1 HG-2015 1 HG-22338 1 HG-2015 1 HG-22338

30. SCREW, 10-32 X 3/4" FLAT 12 SC-2072 12 SC-2072 12 SC-2072 12 SC-2072

31. FAN GUARD 1 1012553 1 1012555 1 1010254 1 1012557

32. FAN BLADE 1 FA-34604 1 FA-34602 1 E3045FA 1 FA-34603

33. SCREW, M3 X 0.5 X 16MM PAN 2 SC-22270 2 SC-22270 — — 2 SC-22270

34. FAN SWITCH 1 SW-33907 1 SW-33907 — — 1 SW-33907

35. FAN SWITCH BRACKET 1 1011007 1 1011008 — — 1 1011008

36. LED LAMP ASSEMBLY 1 LP-34578 1 LP-34578 1 LP-34578 1 LP-34578

37. PLATE ACCESS, LED LAMP 1 1009718 1 1009718 — — 1 1009718

38. BUSHINGS, SNAP 2 BU-3419 2 BU-3419 1 BU-3419 2 BU-3419

39. SENSOR BLOCK 1 BK-28344 1 BK-28344 1 BK-28344 1 BK-28344

40. SENSOR 1 SN-33541 1 SN-33541 1 SN-33541 1 SN-33541

41. THERMOSTAT, MANUAL RESET 1 E3030TT 1 E3030TT 1 E3030TT 1 E3030TT

42. SCREW, 8-32 X 1" FLAT 2 SC-22138 2 SC-22138 2 SC-22138 2 SC-22138

43. NUT, M3 - 0.5 HEX 2 NU-22285 2 NU-22285 — — 2 NU-22285

44. WASHER, M3 X 9MM FLAT 2 WS-22293 2 WS-22293 — — 2 WS-22293

45. REAR COVER — — 1 1010720 1 5009685 1 1010741

46. LEVELING FEET — — — — 4 FE-28909 — —

INSERTS, LEVELING FEET — — — — 4 FE-28910 — —

47. BOTTOM ASSEMBLY 1 E4042** — — 1 1010251 — —

48. BASKET HEADER — — — — 1 1003076 — —

49.** BUMPER FEET 4 BM-22606 — — — — — —

50.** CASING 1 1009697 — — — — — —

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 13

SERVICE

PART NUMBERS AND DRAWINGS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

FULL ASSEMBLY VIEW (EC770L & EC390L shown)

2

1

3

4

5

6

7

89

2

10

9

8

11

12

13

8

14

15

16

2

17

18

19

20

21

22

23

24

25

26

27

2

28

29

30

31

32

33

34

2

35

36

38

37

2

39

40

41

42

43

44

2

25

24

27

29

15

15

1

3

4

31

45

45

46

32 39

40

36

31

EC770L

EC390L

20

47

7

13

EC230L & EC340L

48

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 14

SERVICE

ELECTRICAL VIEW (EC770L & EC390L shown)

*NOT SHOWN PART NUMBERS AND DRAWINGS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

† Note: The cavity fan motor has a one year life expectancy. The cavity fan motor parts warranty remains in effect one (1)

year from installation or fifteen (15) months from the shipping date, whichever occurs first.

LOC DESCRIPTION QTY EC230L P/N QTY EC340L P/N QTY EC390L P/N QTY EC770L P/N

1. CONTROL PANEL OVERLAY 1 PE-28314 1 PE-28315 1 PE-28920* 1 PE-28316

2. SCREW, 6-3 X 1/2" 2 SC-2472 2 SC-2472 2 SC-2472 2 SC-2472

3. BEEPER, SOLID STATE 1 BP-3567 1 BP-3567 1 BP-3567 1 BP-3567

4. RELAY, 12V DC, COIL 1 RL-34434 1 RL-34434 1 RL-34434 1 RL-34434

5. SCREW, 8-32 X 3/8" PAN 2 SC-29631 2 SC-29631 2 SC-29631 2 SC-29631

6. POWER SUPPLY BOARD 1 BA-34693 1 BA-34693 1 BA-34693 1 BA-34693

7. SCREW, 6-32 X 1-1/4" PAN 2 SC-2365 2 SC-2365 2 SC-2365 2 SC-2365

8. TERMINAL BLOCK, 3 FORM COMPRESS 1 BK-3019 1 BK-3019 1 BK-3019 1 BK-3019

9. CIRCUIT BREAKER SWITCH 1 SW-33826 1 SW-33826 1 SW-33826 1 SW-33826

10. TERMINAL BLOCK, PORCELAIN 1 BK-33546 1 BK-33546 1 BK-33546 1 BK-33546

11. SCREW, M4 X 0.7 X 6MM PAN 2 SC-22271 2 SC-22271 2 SC-22271 2 SC-22271

12. COVER, HI-LIMIT 1 1009751 1 1009751 1 1009751 1 1009751

13. THERMOSTAT, MANUAL RESET 1 E3030TT 1 E3030TT 1 E3030TT 1 E3030TT

14. GROUND SCREW 1 SC-2190 1 SC-2190 1 SC-2190 1 SC-2190

15. WASHER, #10 LOCK 1 WS-2467 1 WS-2467 1 WS-2467 1 WS-2467

16. SCREW, 8-32 X 3/8" 2 SC-29631 2 SC-29631 2 SC-29631 2 SC-29631

17. RELAY, 25A, ZERO CROSSING 1 RL-33829 1 RL-33829 1 RL-33829 1 RL-33829

18. FILTER 1 FI-34825 1 FI-34825 1 FI-34825 1 FI-34825

19. CONTROL ASSEMBLY 1 CC-34765 1 CC-34765 1 CC-34765 1 CC-34765

20. CONNECTORS 1 CR-33718 1 CR-33718 1 CR-33718 1 CR-33718

21. CONNECTORS 1 CR-33717 1 CR-33717 1 CR-33717 1 CR-33717

22. NUT 8-32 4 NU-26526 4 NU-26526 4 NU-26526 4 NU-26526

23. BOX FAN — — — — 1 FA-3974 — —

24. FAN MOTOR† — — — — 1 FA-34780 — —

25. THERMOSTAT, HI-LIMIT 1 E3040TT 1 E3040TT 1 E3040TT 1 E3040TT

26. WASHER, FLAT, 3/8" ID 7/8" — — — — 2 WS-23991 — —

27. WASHER, FLAT, 4.5MM x 13.5 MM — — — — 2 WS-22323 — —

28.* EQUIPOTENTIAL STUD 1 ST-25670 1 ST-25670 1 ST-25670 1 ST-25670

29.* WIRE DIAGRAM 1 7659 1 7749 1 77273 1 7784

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 15

SERVICE

PART NUMBERS AND DRAWINGS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

18

19

20

13

14

15

16

17

12

11

10

9

8

7

6

5

4

3

2

1

EC770L

EC390L

ELECTRICAL VIEW (EC770L & EC390L shown)

19

20 21

3

21

17

9

8

23

14

13

6

4

10

24

24

26

27

22

located under the bonnet

located under the bonnet

24

22

18

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 16

PART NUMBERS AND DRAWINGS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

HEATING CABLE REPLACEMENT KITS*

EC230L EC340L EC390L EC770L

CABLE REPLACEMENT KIT NUMBER 4879 4880 4875 4881

SERVICE KIT INCLUDES:

CB-3045 CABLE HEATING ELEMENT 105ft (11m) 134 ft (41m) — 210 ft (64m)

CB-3044 CABLE HEATING ELEMENT — — 150 ft (46m) —

BU-3106 CUP BUSHING 6 8 6 12

TA-3540 ELECTRICAL TAPE 1 ROLL 1 ROLL 1 ROLL 1 ROLL

NU-2215 HEX NUT 24 32 12 24

IN-3488 INSULATION CORNER 8 ft (2m) 8 ft (2m) 8 ft (2m) 8 ft (2m)

SL-3063 INSULATING SLEEVE 6 8 6 12

CR-3226 RING CONNECTOR 6 8 6 12

BU-3105 SHOULDER BUSHING 68 6 12

ST-2439 STUD, 10-32 68 6 12

*NOT SHOWN

OPTIONS AND ACCESSORIES QTY EC230L P/N QTY EC340L P/N QTY EC390L P/N QTY EC770L P/N

CART WITH CASTERS -

CONTACT

FACTORY

-

CONTACT

FACTORY

- N/A - N/A

CASTERS, 3" (76mm) - Platform (E5089)

must be ordered as a base when ordering

casters or legs for this unit. 1 SET 5012693 - N/A - N/A - N/A

CASTERS, 5" (127mm) - Platform (E5089)

must be ordered as a base when ordering

casters or legs for this unit. 1 SET 4007 - N/A - N/A - N/A

COMBINATION LOCK KIT 1 5008370 1 5008361 5008361 1 5008361

CYLINDER LOCK FOR DOOR HANDLE 1 LK-22567 1LK-22567 1LK-22567 1 LK-22567

LEG KIT, 6" (152mm) 1 5205 1 44093 - N/A 144093

WINDOW DOOR ASSEMBLY,

LEFT HINGE

-5009043 15010833 5010908 1 5009613

OPTIONS & ACCESSORIES PARTS LIST*

*NOT SHOWN

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 17

REFER TO WIRE DIAGRAM UNDER TOP COVER FOR MOST CURRENT VERSION

MN-28671 Rev 2 • 230V Enthermics Fluid Warming Cabinet Operation & Care Manual • 18

REFER TO WIRE DIAGRAM UNDER TOP COVER FOR MOST CURRENT VERSION

This manual suits for next models

3

Table of contents

Other Enthermics Warming Drawer manuals