The essential performance of the P-2010-S is to not exceed internal temperature of 250 degrees F (+10%) at any setting.

4

GENERAL WARNINGS

The P-2010-S requires special precautions regarding EMC

and needs to be installed and put into service according to

the EMC information provided below.

Portable and mobile RF communications equipment can

affect medical electrical equipment.

The P-2010-S does not have any cables or transducers that

are detachable. The P-2010-S has a permanently attached

power cord that is ~2.5m in length.

WARNING: A risk of increased emissions or decreased

immunity may result if the power cord attached is altered or

a manufacturer supplied power cable is not used.

The P-2010-S should not be used adjacent to or stacked with

other equipment.

WARNING: observe to verify normal operation if it is

necessary to use adjacent to or stacked with other equipment.

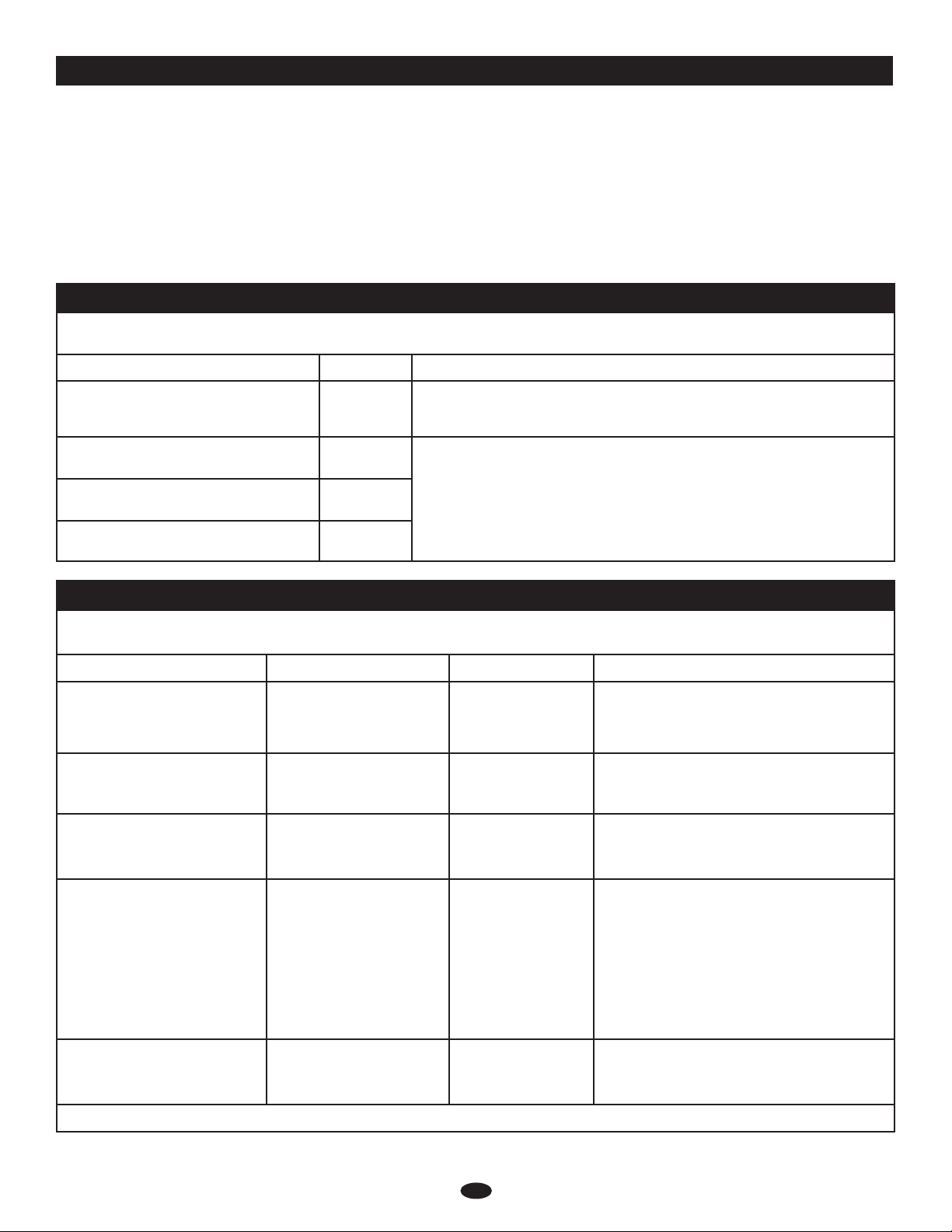

Guidance and manufacturer’s declaration – electromagnetic emissions

The Model P-2010-S is intended for use in the electromagnet environment specified below. The customer or the end user of the Model

P-2010-S should assure that it is used in such an environment.

Emissions test Compliance Electromagnetic environment - guidance

RF emissions

CISPR 11

Group 1 The Model P-2010-S uses RF energy only for it internal function. Therefore, its

RF emissions are very low and are not likely to cause any interference in nearby

electronic equipment.

RF emissions

CISPR 11

Class B The Model P-2010-S is suitable for use in all establishments, including domestic

establishments and those directly connected to the public low-voltage power

supply network that supplies buildings used for domestic purposes.

Harmonic emissions

IEC 61000-3-2

Class A

Voltage fluctuations/Flicker emissions

IEC 61000-3-3

Complies

Guidance and manufacturer’s declaration – electromagnetic immunity

The Model P-2010-S is intended for use in the electromagnet environment specified below. The customer or the end user of the Model

P-2010-S should assure that it is used in such an environment.

Immunity test IEC 60601 test level Compliance level Electromagnetic environment - guidance

Electromagnetic discharge (ESD)

IEC 61000-4-2

±6 kV contact

±8 kV air

±6 kV contact

±8 kV air

Floors should be wood, concrete or ceramic tile.

If floors are covered with synthetic material, the

relative humidity should be at least 30%.

Electrical fast transient/burst

IEC 61000-4-4

±2 kV for power supply lines

±1 kV for input/output lines

+2 kV for power

supply lines

Mains power quality should be that of a typical

commercial or hospital environment. The

P-2010-S does not have any input/output lines.

Surge

IEC 61000-4-5

±1 kV differential mode

±2 kV common mode

±1 kV differential

mode

±2 kV common mode

Mains power quality should be that of a typical

commercial or hospital environment.

Voltage dips, short interruptions

and voltage variations on power

supply input lines

IEC 61000-4-11

<5 % UT (>95 % dip in UT)

for 0.5 cycle

40 % UT (60 % dip in UT)

for 5 cycles

70 % UT (30 % dip in UT)

for 25 cycles

<5 % UT (>95 % dip in UT)

for 5 sec

<5 % UT (>95 % dip in

UT) for 0.5 cycle

40 % UT (60 % dip in

UT) for 5 cycles

70 % UT (30 % dip in

UT) for 25 cycles

<5 % UT (>95 % dip in

UT) for 5 sec

Mains power quality should be that of a typical

commercial or hospital environment. If the

user of the Model P-2010-S requires continued

operation during power mains interruptions,

it is recommended that the Model P-2010-S be

powered from an uninterruptible power supply or

a battery.

Power frequency (50/60 Hz)

magnetic field

IEC 61000-4-8

3 A/m 3 A/m Power frequency magnetic fields should be at

levels characteristic of a typical location in a

typical commercial or hospital environment.

NOTE UT is the a.c. mains voltage prior to application of the test level.