Entron WA2 User manual

BF ENTRON LTD.

Monitoring equipment

Weld Analyser

WA2

M O N I T O R I N G E Q U I P M E N T

Weld Analyser WA2

BF ENTRON Ltd.

Building 0 • The Pensnett Estate

Kingswinford • West Midlands • DY6 7FQ

Phone +44 (0)13 4 455401 • Fax +44 (0)13 4 455551

www.bfentron.co.uk

Issue Date Comment

1 02-11-06 Initial release

2 09-01-07 Charger description

3 14-01-13 WA Terminal features

4

11

-

11

-

13

USB

features

. Integrator output.

5

23

-

04

-

14

DC duration amendments

6

13

-

05

-

14

WA Terminal time/date feature

7

17

-

0

-

15

Current sensors

09-10-17 Current sensor

9 29-11-17 Logo changed

Table of Contents

Introduction .............................................................................. 1

Key features............................................................................. 2

Specifications........................................................................... 3

Installation................................................................................ 4

Charging the batteries..................................................................... 4

Current sensors .............................................................................. 5

Connectors............................................................................... 7

Current sensor ................................................................................ 7

USB port ......................................................................................... 7

Integrator output.............................................................................. 7

Controls.................................................................................... 8

Keypad............................................................................................ 8

Display ............................................................................................ 9

Data display...........................................................................................9

Detail display .........................................................................................9

Setup display .......................................................................................10

File display...........................................................................................12

Measuring welds .................................................................... 13

Capturing data with WA terminal ............................................ 14

Installing WA terminal ................................................................... 16

Connecting your WA2 ................................................................... 17

USB port ....................................................................................... 17

Using WA Terminal ....................................................................... 20

Communications Port.................................................................... 21

Record Start/Stop ......................................................................... 21

Save.............................................................................................. 21

Auto-save...................................................................................... 22

Data display .................................................................................. 22

Closing WA Terminal .................................................................... 22

Removing WA Terminal ................................................................ 22

Data persistence ........................................................................... 23

I N T R O D U C T I O N

1

Introduction

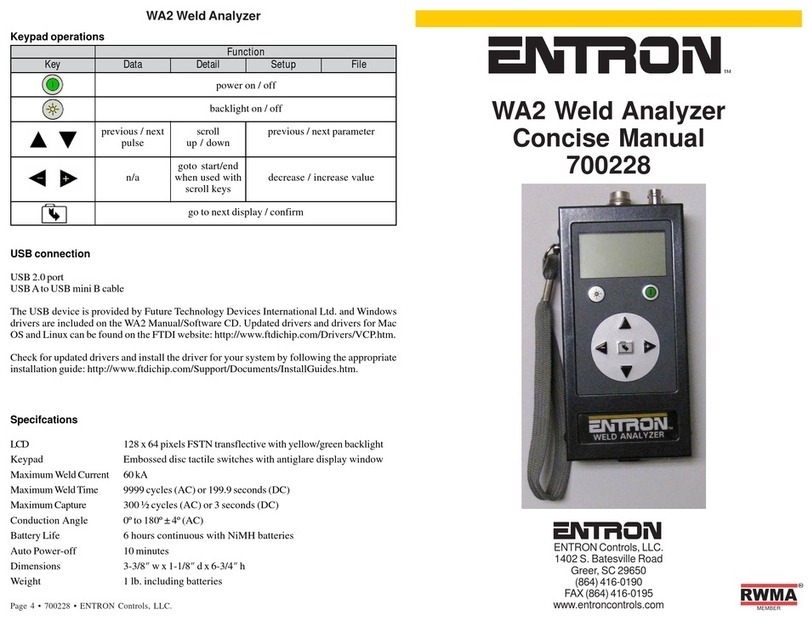

An overview of the WA2

he Weld Analyser WA2 is an RISC based instrument designed for the

comprehensive real-time analysis of resistance welds. It is a compact hand-

held battery operated unit that is an ideal tool for welding, maintenance and

quality control personnel.

The WA2 is capable of measuring AC and MF DC welding current, the number of

pulses in the weld and the duration of each weld. The information is displayed on a

backlit FSTN LC display and may be stored in non-volatile EEPROM. The WA2 may

also be connected to a computer to extend its storage capabilities.

Every WA2 is supplied with a traceable calibration certificate.

Section

1

T

I N T R O D U C T I O N

2

Key features

•Portable, hand-held compact unit

•12 x 64 LC display with yellow/green backlight and antiglare coating

•Tactile keypad

•Powered by three rechargeable AA batteries

•Automatic power-down after 10 minutes of inactivity

•Menu driven commands

•USB port (data exchange only)

•Measures RMS AC and DC welding current

•Selectable ranges of 60, 120, 1 0, 240 and 300 kA

•High and low current indicators

•Measures welding time in ½ cycles up to 9999 cycles (AC) or 10 ms intervals

up to 199.9 seconds (DC)

•Captures up to 300 ½ cycles (AC) or 3 seconds (DC)

•Measures conduction angle for each ½ cycle (AC)

•Over- and under-range indicators

•Weld indicator

•Multi-pulse weld indicator

I N T R O D U C T I O N

3

S ecifications

dimensions

5w x 30d x 170h mm

weight

500 g including batteries

operating temperature

0º to 45º C ambient

power source

three

rechargeable

NiMH AA batteries

battery life

6

hours minimum, 2000mAh

@ 25º C

display

12 x 64 pixels FSTN transflective

keypad

e

mbossed disc tactile switches

weld current

2 to 300 kA, accuracy ± 2 % of full scale

weld time

0.5 to 9999 cycles (AC) or 0.01 to 199.9

seconds (DC)

capture time

300 ½ cycles (AC) or 3 seconds (DC)

with programmable end-of-capture

conduction angle

0º to 1 0º ± 4º (AC)

pulse count

1 to 99

I N S T A L L A T I O N

4

Installation

Connecting the WA2

he rechargeable batteries supplied with the WA2 may be in a discharged state.

It is recommended that the batteries are fully recharged before using the WA2.

Charging the batteries

Use only the supplied charger. Other chargers must not be used.

•Ensure that the correct mains adaptor is fitted for your territory. Consult the

documentation supplied with the charger.

•Ensure that the 2.5 mm jack plug adaptor is fitted and connected correctly –

positive + terminal to positive + terminal.

•Switch off the WA2.

•Ensure the charger is switched off. Connect it to the WA2 and switch the

charger on. The red Power LED indicates that the charger is ready for use.

Section

2

T

Caution: use only

NiMH batteries rated at 1.2 V. Alkaline batteries rated at 1.5

V must not be used.

Warning: do not connect or disconnect the charger while it is switched on.

Note: the USB connection cannot be used to recharge the batteries.

I N S T A L L A T I O N

5

•If the WA2 batteries are new or have only been used a few times, use the

charger’s discharge mode before charging. Consult the charger’s

documentation.

•If the batteries are older or have been conditioned by the charger’s discharge

cycle, the charger will fast charge the batteries and then revert to a trickle

charge; this may take several hours depending on the condition of the batteries.

•The green Ready indicates that the batteries are fully charged. The indicator

will flash after two minutes and the charger will revert to trickle charge. At this

stage, charging is complete.

•Switch off the charger and disconnect it from the WA2. The WA2 is now

ready to use.

Current sensors

The WA2 is supplied with a 6” (150 mm) diameter tube-

profile current sensor:

Flat-profile current sensors are also available:

3” (75 mm) diameter W296557

6” (150 mm) diameter W29655

12” (300 mm) diameter W296559

I N S T A L L A T I O N

6

Connect the WA2 as shown below:

Note that the joint

in the current

sensor can result

in reduced

accuracy and the

sensor should be

orientated as

shown.

sensor

computer (optional)

oscilloscope (optiona

l)

I N S T A L L A T I O N

7

Connectors

Current sensor

Connect the calibrated current sensor to the WA2.

USB ort

Connect to a computer USB 2.0 port using a USB A to

USB mini B cable if required.

The USB device is provided by Future Technology Devices International Ltd. and

Windows drivers are included on the WA2 companion CD. Updated drivers and

drivers for Mac OS and Linux can be found on the FTDI website:

http://www.ftdichip.com/Drivers/VCP.htm. Check for updated drivers and install

the driver for your system by following the appropriate installation guide:

http://www.ftdichip.com/Support/Documents/InstallGuides.htm

Integrator out ut

Connect an oscilloscope or other recording instrument

if required.

The signal corresponds to the integrated output from

the current sensor, maximum amplitude +/- 15 V.

Caution: the integrator out ut should only be connected to high im edance

recording instruments.

C O N T R O L S

8

Controls

Operating the WA2

he WA2 is controlled via a tactile keypad in conjunction with a graphical LC

display.

Key ad

The function of the keys is described below:

Key

Function

Data display Detail display Setup display

File display

power on/off

backlight on/off

previous/next

pulse

scroll

up/down previous/next parameter

n/a

goto

start/end

when used

with scroll

keys

decrease/increase value

go to next display/confirm

Section

3

T

C O N T R O L S

9

Dis lay

The keypad allows navigation through the features of the WA2 via a number of

different displays as described below:

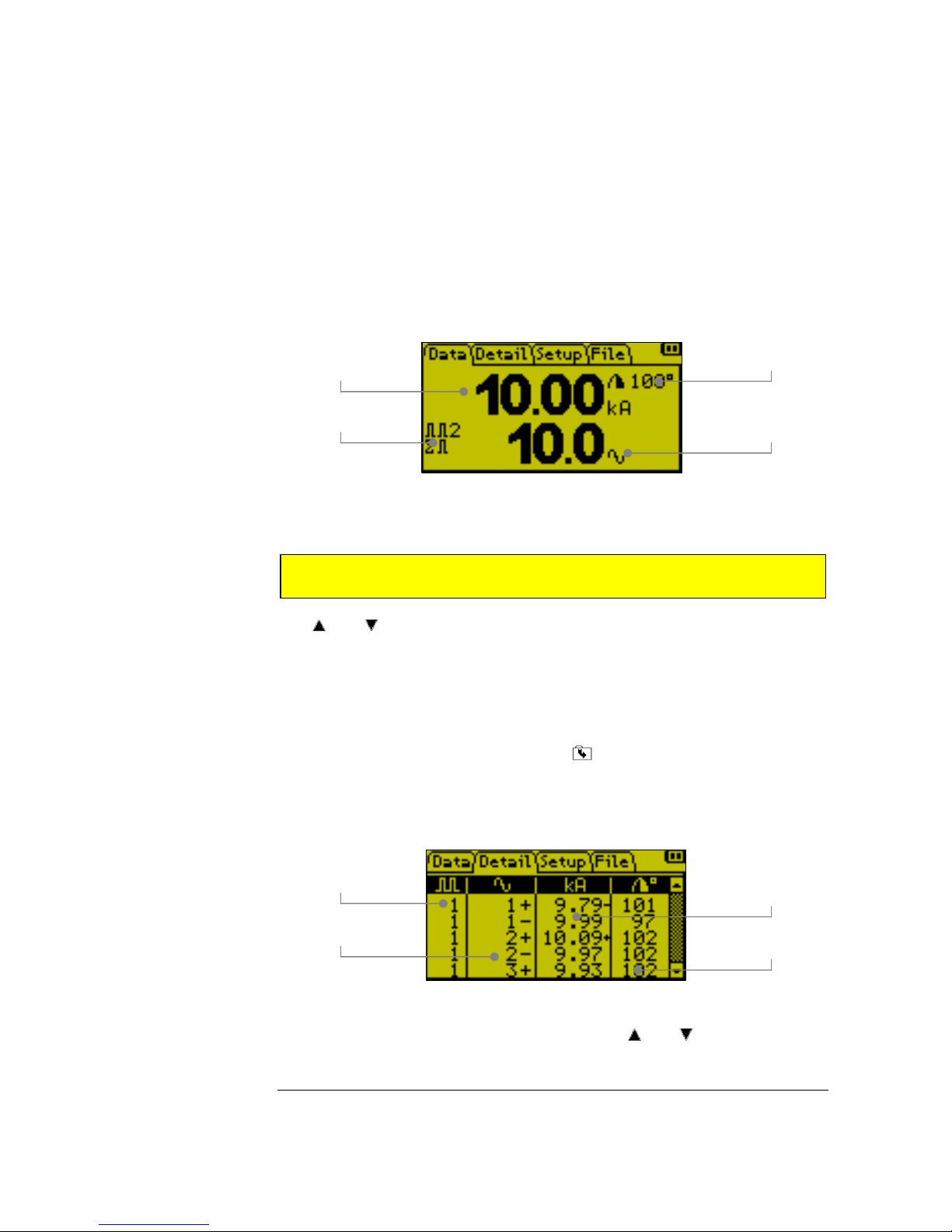

Data dis lay

This is the default display and shows a summary of the most recent weld. The diagram

shows an example for an AC weld:

For DC welds, the weld time is shown in ms and cycles. The conduction angle is not

applicable to DC welds.

The and keys may be used to select the previous or next pulse in the weld (if

applicable). The pulse count is incremented if there is an interruption in the current of

1 cycle (AC) or 10 ms (DC); an interruption in the current of more than 200 ms is

interpreted as the end-of-weld.

Detail dis lay

The Detail Display is accessible by pressing from the Data Display. The Detail

Display shows the detailed results of the most recent weld. The diagram below shows

an example for an AC weld:

For DC welds, the ½ cycles are replaced with the cumulative weld time in ms. The

conduction angle is not applicable to DC welds. The and keys may be used to

Note: DC weld currents less than 4.0kA may lead to inaccuracies in the

measured weld time.

conduction angle of last weld

weld time in cycles

weld current in kA

pulse count and pulse

number if appropriate

pulse number (in weld)

cycle number (in pulse)

current for every ½ cycle

+ indicates highest ½ cycle

- indicates lowest ½ cycle

conduction angle for each

½ cycle

C O N T R O L S

10

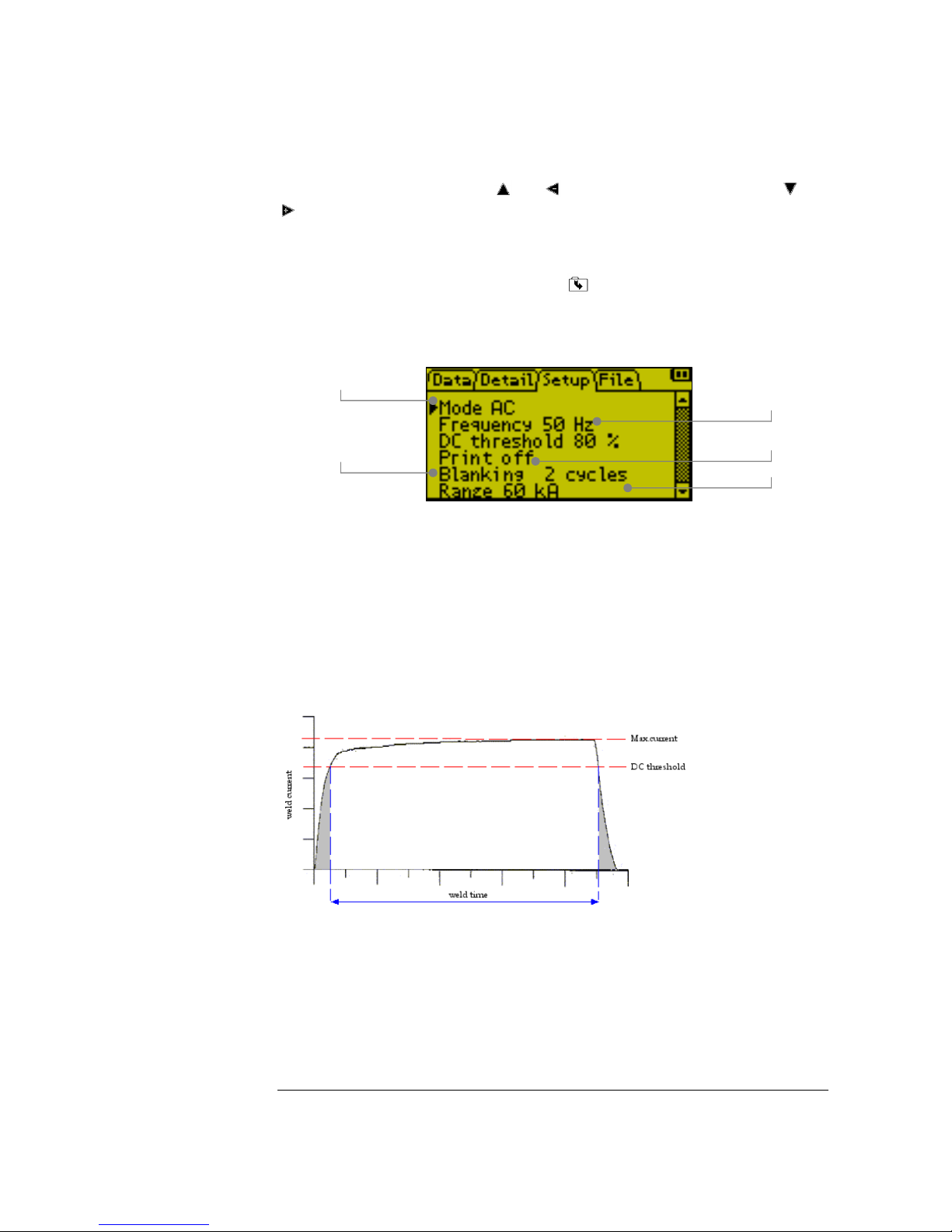

The shaded sections

of the weld are not

included in the dc

current and duration

calculations

scroll through the readings. Press and to go to the start of the list; press and

to go to the end of the list.

Setu dis lay

The Setup Display is accessible by pressing from the Detail Display. The Setup

Display allows the WA2 to be configured for specific applications. The diagram below

shows the typical settings for a 50 Hz AC application.

The Mode parameter determines the type of welding current to be measured, AC or

DC.

The Frequenc parameter relates to the mains supply frequency. If DC mode is

selected, the Frequenc parameter is used to calculate the equivalent weld time in

cycles for the Data Display.

The DC threshold determines the % of the maximum weld current that is included in

the current and duration calculations; it is not applicable in AC mode.

The Print parameter determines the output from the USB port at the end of each

weld. If printing is off, there is no output; if printing is set to all, the WA2 outputs the

results of every ½ cycle (AC) or 10 ms (DC) reading; if printing is set to summar , the

WA2 outputs the average current and duration for the weld.

The Blanking parameter is used to mask transient conditions at the start of the weld.

AC welding

cycles e cluded from

the RMS calculation

line freq

uency

printing off/all/summary

current range

C O N T R O L S

11

The Range parameter is used to determine the maximum current that can be

measured. This parameter should match the setting on the optional attenuator module

or set to 60 kA if no attenuator module is used.

The Auto shutdown parameter (not shown) is used to enable or disable the automatic

shutdown feature. If this parameter is set to on, the WA2 will shutdown after 10

minutes of inactivity to conserve battery power. If this parameter is set to off, the WA2

will not automatically shutdown.

The Stop parameter (not shown) can be used to capture a specific section of a long

weld. The WA2 will capture 300 cycles (AC) or 3 seconds (DC) of welding prior to the

Stop parameter.

If DC mode is selected, the Blanking and Stop parameters are programmed in ms.

C O N T R O L S

12

File dis lay

The File Display is accessible by pressing from the Setup Display. The File Display

allows welds to be stored and retrieved for analysis at a later date.

The display shows the memory that is available for storing welds; the value will change

according to the quantity and duration of welds that are stored.

The Action parameter determines if the weld will be saved, loaded from memory,

erased from memory or printed.

The ID is a numeric identifier that is used to access the stored weld.

Select an action and an ID (if applicable), then press to confirm the action. The

WA2 will perform the action and then revert to the Data Display.

available memory

E Empty

F Full

file ID

0 to 99 or all

action cancel / save /

load / erase / print

M E A S U R I N G W E L D S

13

Measuring welds

Using the WA2

hen the WA2 is charged and installed as described in Section 2, it is ready

to measure the parameters of the every weld.

•Connect the WA2 sensor to the welding machine and ensure the sensor is

connected securely to the WA2.

•Switch on the WA2 by pressing the button; wait for the Data Display to

appear .

•Use the button to access the Setup Display and check that the values

correspond to the application. Select the Print format if required.

•Use the button to return to the Data Display.

•Use the welding machine to produce a weld and check that the WA2 has read

the welding current, duration and (if appropriate) the conduction angle and

pulses. The Data Display shows a summary of the weld.

•Use the button to view the results in greater detail using the Detail Display.

Use the and to scroll through the list.

•Use the button to access the File Display and save the results if required.

The results can be retrieved, printed or erased at a later date if required.

Section

4

W

C A P T U R I N G D A T A W I T H W A T E R M I N A L

14

Ca turing data with WA terminal

An overview of WA Terminal

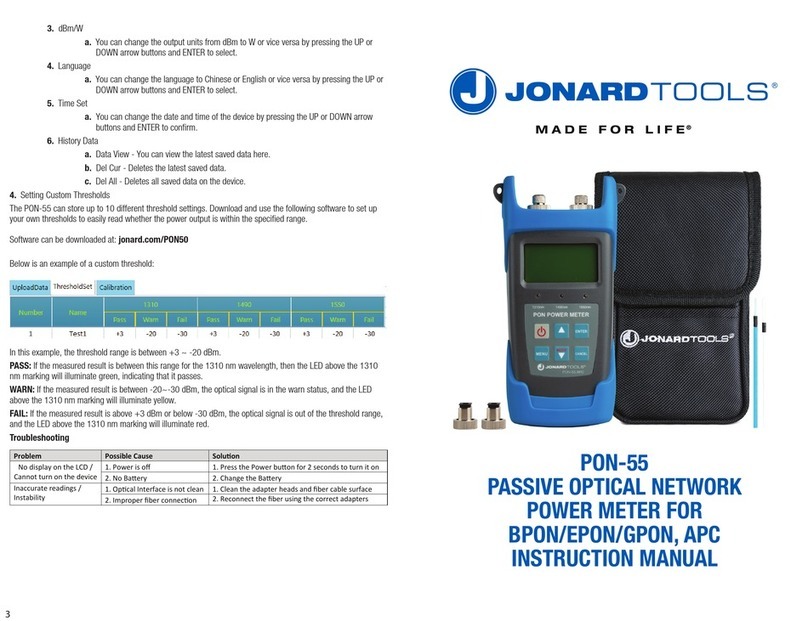

he WA Terminal utility is a Microsoft Windows compatible program that

allows you to capture the data from your WA2 in applications where long-

term data logging is required.

WA Terminal connects to your WA2 via your computer’s USB port. As your WA2

records each weld the information is transmitted to WA Terminal where the

information can be inspected, saved or printed. The program has minimal setup

requirements and virtually unlimited storage capacity.

Ke features

•Microsoft Windows compatible

•Minimal installation

•Minimal set-up requirements

•Minimal performance overhead

•Virtually unlimited storage capacity

•Data is recorded in real time

•Data can be saved automatically

Section

5

T

C A P T U R I N G D A T A W I T H W A T E R M I N A L

15

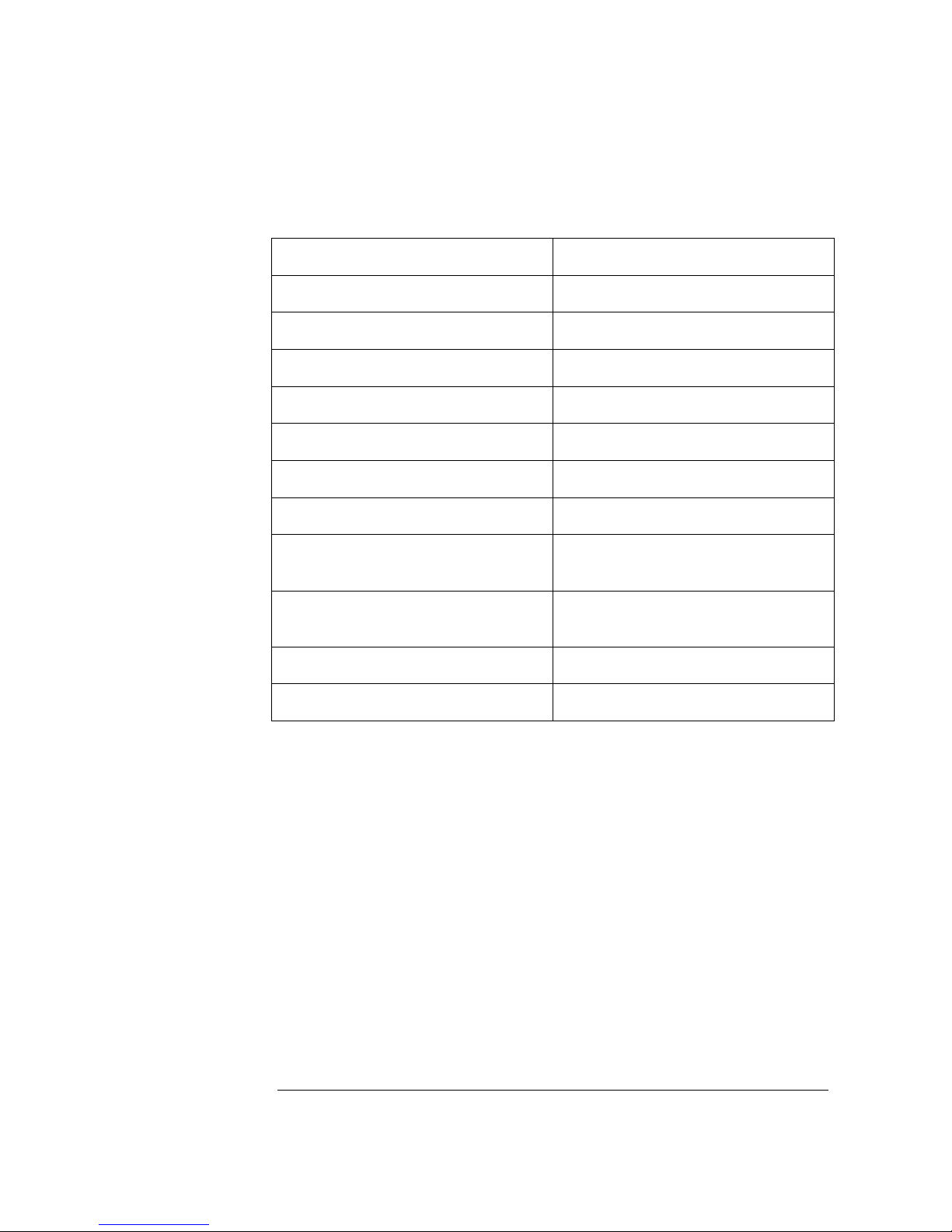

Specifications

compatibility

Microsoft Windows:

/7/Vista/XP

Server 200

minimum

requirements

Pentium 233

-

megahertz (MHz) processor

or faster (300 MHz is recommended)

At least 64 megabytes (MB) of RAM (12

MB is recommended)

At least 1.5 gigabytes (GB) of available

space on the hard disk

Keyboard and a compatible pointing

device

Video adapter and monitor with Super

VGA ( 00 x 600)or higher resolution

USB 2.0 port

USB A to USB mini B cable

user interface

conforms to user’s display and scheme

settings

resizeable main window with persistent

settings

horizontally and vertically scrollable data

display

Start/Stop recording function

Start/Stop recording indicator

Save data function

Auto-save data function

communication ports

COM1 to COM

C A P T U R I N G D A T A W I T H W A T E R M I N A L

16

Installing WA terminal

WA Terminal is a self-contained program and requires no installation. The program is

supplied as a single executable file named WAT.EXE and is included on the WA2

companion CD. Copy the WAT.exe file to a location on your computer and run the

program from there.

C A P T U R I N G D A T A W I T H W A T E R M I N A L

17

Connecting your WA2

Connect your WA2 as shown below:

USB ort

Connect to a computer USB 2.0 port using a USB A to

USB mini B cable.

The USB device is provided by Future Technology Devices International Ltd. and

Windows drivers are included on the WA2 companion CD. Updated drivers and

drivers for Mac OS and Linux can be found on the FTDI website:

http://www.ftdichip.com/Drivers/VCP.htm. Check for updated drivers and install

the driver for your system by following the appropriate installation guide:

http://www.ftdichip.com/Support/Documents/InstallGuides.htm

The USB driver will allocate a COM port number to be used for the connection. The

COM port number can be determined via Windows Device Manager as follows:

Other manuals for WA2

1

Table of contents

Other Entron Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

SIGLENT

SIGLENT SSA3021X user manual

Flow vision

Flow vision FC50-CA Instructions for installation

YOKOGAWA

YOKOGAWA IS8000 user manual

Topcon

Topcon KR-1W user manual

Magnetrol

Magnetrol Echotel 335 Installation and operating manual

SENSIT Technologies

SENSIT Technologies ULTRA-TRAC APL Quick start instructions