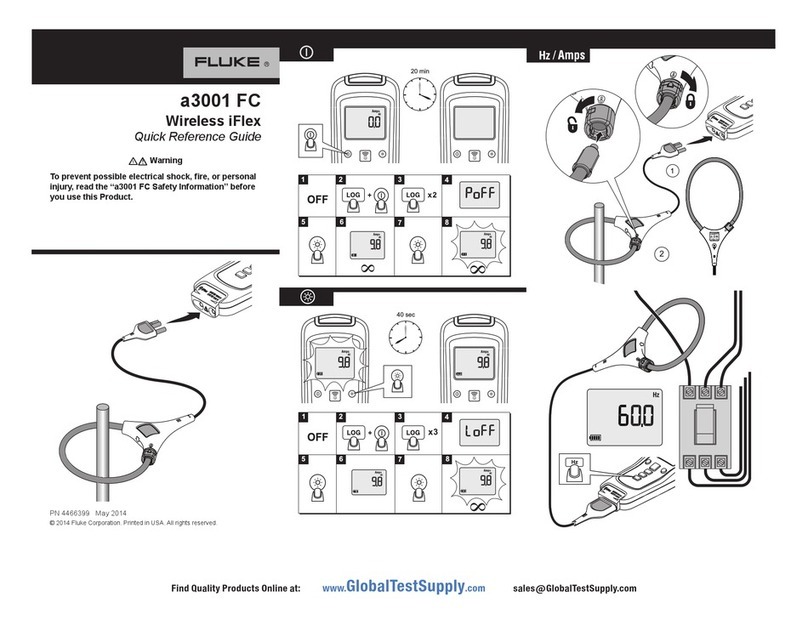

AC Operation on WA2 Weld Analyzer

Data Display

Detail Display

Setup Display

WeldcurrentinkA

Weldtimeincycles

Pulsecountand

pulsenumber

ifappropriate

Conductionangle

oflastweld

Current for every ½ cycle

+indicateshighest½cycle

-indicateslowest½cycle

Pulsenumber

(in weld)

Cyclenumber

(inpulse) Conductionanglefor

each½cycle

Linefrequency

ACwelding

Cyclesexcluded

fromtheRMS

calculation Endofcapture

forlongwelds

Print:off/all/summary

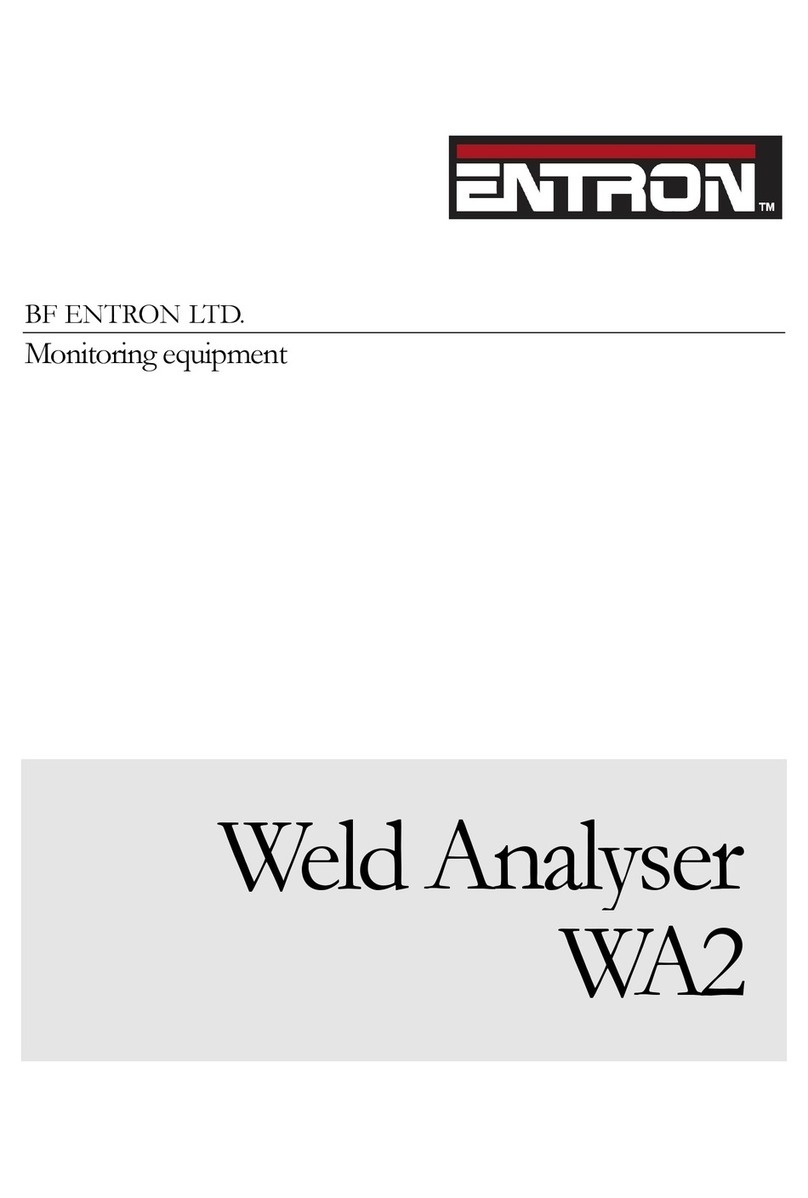

DC Operation on WA2 Weld Analyzer

Data Display

Detail Display

Setup Display

WeldcurrentinkA

Weldtimeinms

Pulsecountand

pulsenumber

ifappropriate

Weldtimeincycles

Pulsenumber

(in weld)

Cyclenumber

(inpulse)

Current for every ½ cycle

+indicateshighest½cycle

-indicateslowest½cycle

DCwelding

Timeexcluded

fromtheRMS

calculation Endofcapture

forlongwelds

Print:off/all/summary

%ofweldincludedin

RMSandduration

calculations

File operation

Availablememory

E=Empty

F=Full Action:cancel/save

/load/erase/print

FileID

0to 99 or all

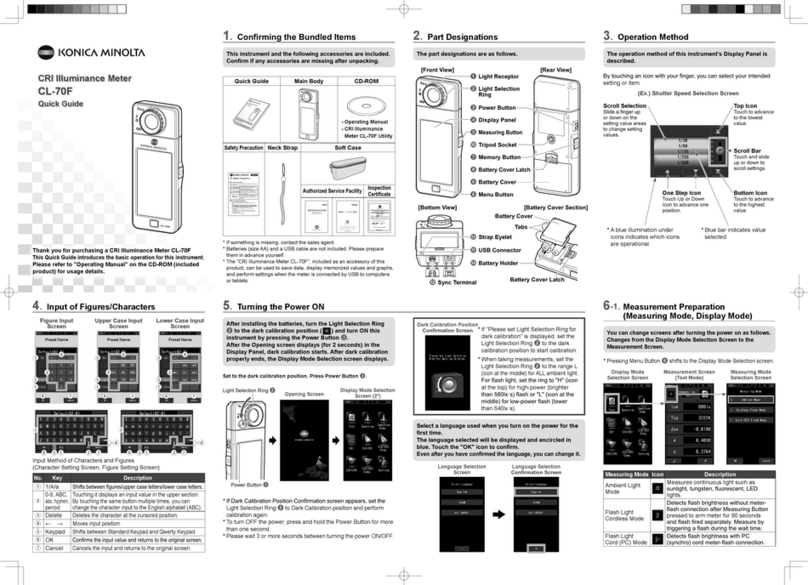

Setup notes

•Mode should be set to the type of welding current –AC or DC.

•Frequency should be set to the supply frequency – 50 or 60 Hz (AC welding only).

•DCthreshold readings below this percentage of the maximum current will be excluded from

the RMS and duration calculations (DC welding only).

•PrintviaPC

off – no printing; all – prints every ½ cycle (AC) or 10 ms (DC) reading; summary – prints

average current and duration for each weld pulse.

USBdriver – www.ftdichip.com/Drivers/VCP.htm

•Blankingis the number of cycles/ms after the start of the weld that will be excluded from the

RMS calculation.

•Range determines the maximum current that can be measured.

•Auto shutdown enables or disables power saving mode.

•Stop after nn cycles/ms can be used to capture a specific section of a long weld. If the weld

is longer than this parameter, a symbol will be shown alongside the weld time.

Page 2 • 700228 • ENTRON Controls, LLC. ENTRON Controls, LLC. • 700228 • Page 3