Envirotainer RKN e1 User manual

This manual is valid for:

RKN container,

P/N 120007R-()

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 www.envirotainer.com

Envirotainer RKN e1 Container

Operations Manual

RECORD OF REVISION

VER. NO. REVISION

Operations Manual RECORD OF REVISION

Envirotainer RKN e1 Container

2.2

Main changes:

• Updated image in chapter 3. Charging.

• Updated images in chapter 6.11 Long-Time Storage (not in shipment).

• Removed informations about “operations centers” and added reference to Envirotainer website.

• Adjusted image of Type 2 ontrol unit in chapter 7.2 Control Unit Operation — Type 2.

• Adjusted text in step 4, chapter 7.2.5 unctional Test.

• Added chapter “Info” in chapter 8 and renamed chapter 8 to 8. Operation Modes, Infos,

Alerts And Alarms.

•Removed “Trip Menu-Rapid Setting” from menu structure in Fig. 17 .

•Removed chapter “Comp X not starting” / “ Comp X out of order” and “Maintenance needed in XX

hours” from chapter 8. Operation Modes, Infos, Alerts And Alarms.

•Removed chapter 10.3.3 “Comp X not starting” / “ Comp X out of order” from chapter 10.

Troubleshooting.

•Removed chapter 10.3. “Maintenance needed in XX hours” from chapter 10. Troubleshooting.

Added information

• Added information about “Info, Pre-conditioning” and “Info, Pre-charging, Please wait” in

new chapter 8.2 Infos.

• Added information about new alerts “Alert, System too warm, harging prolonged” and “Alert,

ontainer stopped, harging required” in chapter 8.3 Alerts.

• Added information in chapter 3. Charging about “Info, Pre-charging, Please wait”.

• Added the following information in chapter 9. Technical Specification: “For other aircrafts, al-

ternative operating procedures may apply.”

Operations Manual TABLE OF CONTENTS

Envirotainer RKN e1 Container

TABLE OF CONTENTS

1. INTRODUCTION.......................................................................................................................... 1

1.1 Scope Of The Manual ...............................................................................................................1

1.2 Safety Instructions....................................................................................................................1

1.3 The Container ..........................................................................................................................1

1.4 Control Unit..............................................................................................................................2

1.5 Charging Unit...........................................................................................................................3

2. LIMITS, AMBIENT CONDITIONS............................................................................................. 4

2.1 Pre-Conditioning Of Cargo ........................................................................................................4

2.2 Minimum Operating Time - Fully Charged Container ...................................................................4

2.3 Exposure To Extreme Heat; Above +30°C (+86°F) ......................................................................4

2.4 Exposure To Extreme Cold; Below -10°C (+14°F) .......................................................................4

3. CHARGING................................................................................................................................... 5

3.1 Charging Procedure .................................................................................................................6

3.2 Additional Charging Adapters....................................................................................................8

3.3 Charging Cable ........................................................................................................................8

4. PRE-CONDITIONING ................................................................................................................. 9

4.1 Cargo Pre-Conditioning ............................................................................................................9

4.2 Container Pre-Conditioning .....................................................................................................10

4.2.1 Pre-Conditioning With Container Operating In Non-Temperature Controlled

Area.........................................................................................................................10

4.2.2 Pre-Condition With A Temperature-Controlled Room....................................................10

5. GENERAL CARGO LOADING GUIDELINES ...................................................................... 11

5.1 Cargo Loading .......................................................................................................................12

5.2 After Cargo Loading................................................................................................................12

(Pro eed on next page!)

Operations Manual TABLE OF CONTENTS

Envirotainer RKN e1 Container

6. GENERAL CONTAINER HANDLING GUIDELINES........................................................... 13

6.1 Forklift Requirements..............................................................................................................13

6.2 Roller beds ............................................................................................................................13

6.3 Ambient Conditions ................................................................................................................13

6.4 Shipment Duration..................................................................................................................13

6.5 Wrapping ...............................................................................................................................13

6.6 Ground Transport Precautions.................................................................................................14

6.7 Aircraft Transport Precautions .................................................................................................14

6.8 Unloading ..............................................................................................................................14

6.8.1 After Unloading: ........................................................................................................14

6.9 Storage .................................................................................................................................14

6.10 Battery Switch........................................................................................................................14

6.11 Long-Time Storage (not in shipment) .......................................................................................15

7. CONTROL UNIT OPERATION — TYPE 1 AND TYPE 2.................................................... 17

7.1 Control Unit Operation — Type 1 .............................................................................................17

7.1.1 Start The Control Unit................................................................................................17

7.1.2 Setting Temperature ..................................................................................................19

7.1.3 Checking Operation Mode .........................................................................................19

7.1.4 Battery Level Check ..................................................................................................19

7.1.5 Functional Test..........................................................................................................20

7.1.6 Calibration Sticker.....................................................................................................21

7.1.7 Seal Control Unit.......................................................................................................21

7.2 Control Unit Operation — Type 2 .............................................................................................23

7.2.1 Start The Control Unit................................................................................................23

(Pro eed on next page!)

Operations Manual TABLE OF CONTENTS

Envirotainer RKN e1 Container

7.2.2 Setting Temperature ..................................................................................................24

7.2.3 Checking Operation Mode .........................................................................................24

7.2.4 Battery Level Check ..................................................................................................25

7.2.5 Functional Test..........................................................................................................25

7.2.6 Calibration Sticker.....................................................................................................26

7.2.7 Seal Control Unit And Info Button ...............................................................................26

8. OPERATION MODES, INFOS, ALERTS AND ALARMS ................................................... 28

8.1 Operation Modes....................................................................................................................28

8.1.1 Cooling Powerstep X .................................................................................................28

8.1.2 Heating Powerstep X.................................................................................................28

8.1.3 Defrosting Powerstep 2 .............................................................................................28

8.2 Infos......................................................................................................................................29

8.2.1 "Info, Preconditioning" ...............................................................................................29

8.2.2 "Info, pre-charging, please wait" .................................................................................29

8.3 Alerts.....................................................................................................................................30

8.3.1 "Batteries At 30% Charge Level" ................................................................................30

8.3.2 "Alert, Container stopped, Charging required" .............................................................30

8.3.3 "Alert, System too warm, Charging prolonged" ............................................................30

8.3.4 "Inside Temp Out Of Spec".........................................................................................31

8.3.5 "Ambient Temp Out Of Spec" .....................................................................................31

8.4 Alarms...................................................................................................................................32

9. TECHNICAL SPECIFICATION................................................................................................ 33

9.1 External Dimensions...............................................................................................................34

9.2 Loading Space .......................................................................................................................34

(Pro eed on next page!)

Operations Manual TABLE OF CONTENTS

Envirotainer RKN e1 Container

10. TROUBLESHOOTING.............................................................................................................. 35

10.1 No Display .............................................................................................................................35

10.2 Batteries Do Not Charge .........................................................................................................36

10.3 Alert ......................................................................................................................................37

10.3.1 “Temperature Too Warm” ...........................................................................................37

10.3.2 “Temperature Too Cold” .............................................................................................38

10.3.3 “Ambient Temperature Out Of Specification”................................................................39

10.3.4 If An Adapter Is Lost ..................................................................................................39

11. RKN E1 CONTAINER CHECK LIST ...................................................................................... 40

Operations Manual 1. INTRODUCTION

Envirotainer RKN e1 Container

1. INTRODUCTION

1.1 SCOPE OF THE MANUAL

This manual provides information for personnel involved in the handling and transport of

Envirotainer container series RKN e1 and is published by Envirotainer AB without warranty.

If there are questions regarding this manual or the container, send an e-mail to

To get in contact with one of our operations centers, please refer to our website

www.envirotainer.com.

1.2 SAFETY INSTRUCTIONS

• The design minimizes hazards to personnel and equipment during use. No material used in

the construction constitutes a risk to the health of the personnel involved. All structural and

mechanical components are free of sharp edges. Every attempt has been made to anticipate

potential dangers and build in protections to prevent injury to personnel.

• Normal precautions should be observed when handling locks, doors and lids. Wherever

necessary, warning stickers or texts will be attached to the container as a warning to users and

ground handler personnel.

• Always follow the "IATA Dangerous Goods Regulations" when loading the container. The

container must not be connected to the electrical outlet inside an airplane.

• Normal precautions should be observed when charging the container. Do not charge the

container outdoors or in a damp, moist environments because of the risk for electric shocks.

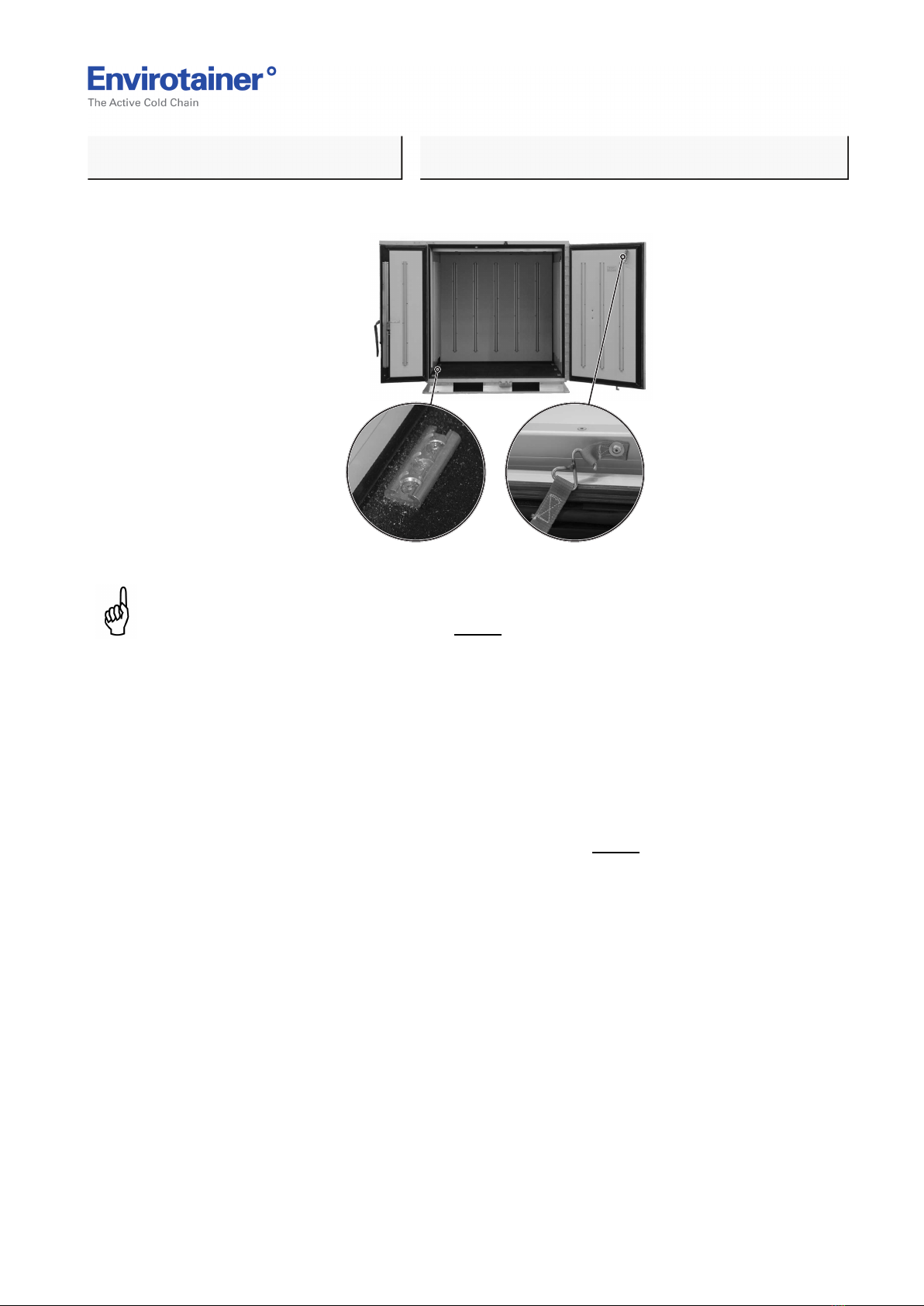

1.3 THE CONTAINER

• The RKN e1 container is a temperature controlled air cargo container used to transport

temperature sensitive cargo in the refrigerated and controlled room temperature ranges.

• The container consists of two primary parts: the cargo space and the refrigerating system unit

(refer to ig. 1 ). The refrigerating system is controlled by a control unit and powered by

internal, rechargeable batteries.

• The RKN e1 is a forkliftable LD-3 air cargo container designed to hold one (1) US-pallet

1220 x 1016 mm (48 x 40") or one (1) EURO-pallet 1200 x 800 mm (47.3 x 31.5") of

cargo.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 1 (42)

Operations Manual 1. INTRODUCTION

Envirotainer RKN e1 Container

1.4 CONTROL UNIT

• The control unit is the user interface for starting the container, setting the temperature,

reading the actual air temperature inside the cargo space and other information.

• The control unit also has charging, alert and alarm indicators.

• The control unit is located outside the container on the left side of the doors ( ig. 1 ).

Refer to chapter 7. Control Unit Operation — Type 1 and Type 2.

The system indicator (green light) is lit when the container system is operating.

The charging indicator (blue light) flashes to indicate that charging is in progress and

remains lit when the charging has been completed.

The alert indicator (yellow light) flashes to indicate that the container needs

attention. If the alert indicator is flashing, measures can be taken to continue with

the shipment.

The alarm indicator (red light) flashes to indicate that a technical part of the

refrigerating system is out of order.

If the alarm indicator is flashing, the container is not functioning properly and the

shipment must be stopped.

Fig. 1

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 2 (42)

Operations Manual 1. INTRODUCTION

Envirotainer RKN e1 Container

1.5 CHARGING UNIT

• The charging unit is the user interface for charging the internal batteries of the container.

• The charging unit contains a charging cable and adapters for different countries.

• The charging unit is located on the left side of the doors ( ig. 1 ).

Refer to chapter 3. Charging.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 3 (42)

Operations Manual 2. LIMITS, AMBIENT CONDITIONS

Envirotainer RKN e1 Container

2. LIMITS, AMBIENT CONDITIONS

• The container is designed to maintain the temperature of the cargo shipped by cooling or

heating the air inside the container.

The following conditions must apply for the container to work properly:

2.1 PRE-CONDITIONING OF CARGO

• The container does not have battery capacity to cool down or heat up a large quantity of

cargo.

• The container is designed to maintain the temperature of the cargo. It is therefore very

important that the cargo is pre-conditioned correctly.

2.2 MINIMUM OPERATING TIME - FULLY CHARGED CONTAINER

• For a +5° (+41°F) container set temperature the minimum operating time without

recharging the batteries is 30 hours provided that the ambient temperature is between -10°

and +30° (+14°F and +86°F). However, the operating time will increase if the ambient

temperature is closer to the container set temperature of the cargo space.

• For other container set temperatures contact Envirotainers ustomer are team for advice:

2.3 EXPOSURE TO EXTREME HEAT; ABOVE +30°C (+86°F)

The container can maintain the temperature in the loading area even though the ambient

temperature is between +30° and +40° (+77°F and +104°F), but the battery consumption

will increase, and the container operating time will therefore decrease.

For example, if the ambient temperature is +35° (+95°F) and the container set temperature is

+5° (+41°F), the container can maintain the temperature but the container operating time will

be reduced.

2.4 EXPOSURE TO EXTREME COLD; BELOW -10°C (+14°F)

The container can maintain the temperature in the loading area even though the ambient

temperature is between -10° and -20° (+14°F and -4°F), but the battery consumption will

increase, and the container operating time will therefore decrease.

For example, if the ambient temperature is -20° (-4°F) and the container set temperature is

+5° (+41°F), the container can maintain the temperature but the container operating time will

be reduced.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 4 (42)

Operations Manual 3. CHARGING

Envirotainer RKN e1 Container

3. CHARGING

WARNING

• Charging must not take place inside an airplane!

• Do not charge the container outdoors or in a damp, moist environments because of the risk for

electric shocks.

• Caution should be exercised when the container is moved and the electrical cable is fully extended.

In addition please visually inspect the electrical cable for any abnormalities before connecting it to

a power source.

IMPORTANT

• The battery switch only disconnects the batteries from the refrigeration system.

Refer to hapter 6.10 Battery Swit h.

• The container can be charged while it is operating or while it is switched off. The charging

procedure / charging time is not affected if the container is operating while charging.

• The time required to charge the container will depend on the battery level at the start of charging.

The maximum time needed for charging is 8 hours. This is true regardless of whether the

container is operating during charging or not.

• During the first hour of charging the SOC (battery percentage) is not updated on the display. As

long as the blue charge indicator is flashing, charging is in progress. The display will switch

between showing ”Container info” and “Info, Pre- harging, Please wait”.

• Always pull out all of the cable when charging, approximately 10 meters (32 ft.). Charging with

part of the cable inside the cable winder can cause damages to the cable winder.

• Avoid use of additional extension cable as far as possible.

• The container charges quickest in ambient temperatures between 0°C to +20°C

(+32°F to +68°F). If charging is carried out in temperatures outside this temperature range the

charging capacity, and consequently the resulting battery energy, may be reduced.

• Charging shall not be performed if the ambient temperature is below -20°C (-4°F) or above

+40°C (+104°F).

• To avoid overload of power supply fuse, only connect one container per single-phase. The charging

requires 1200 W when the container is switched off and 18 0 W when the container is operating

during charging.

• 120V supply will as minimum require a 20A circuit capability.

• 240V supply will as minimum require a 10A circuit capability.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 5 (42)

Operations Manual 3. CHARGING

Envirotainer RKN e1 Container

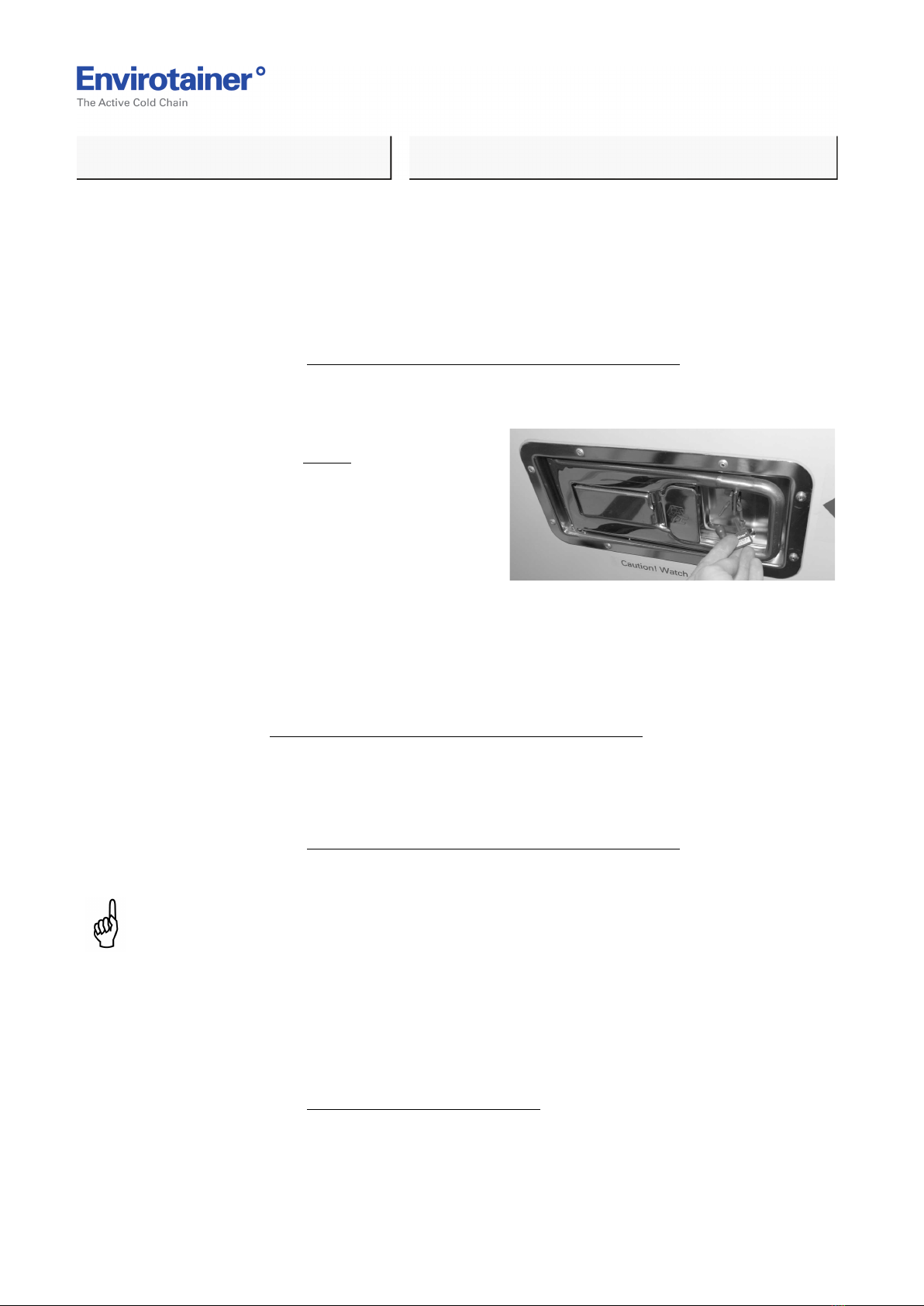

3.1 CHARGING PROCEDURE

The recommended procedure is:

1. Open the cover of the charging unit ( ig. 1 ).

2. Pull out the cable from the charging unit ( ig. 3 ).

IMPORTANT

Pull out all of the cable.

3. The container can be charged either by connecting the blue EE industry plug to a

suitable socket or by using one of the adapters.

Follow step 4-5 if an adapter is to be used. Otherwise continue from step 6.

Fig. 2

4. Pick the appropriate type of adapter ( ig. 2 ) from the adapter case. There are also

additional adapters that can be ordered separately from Envirotainer.

Refer to chapter 3.2 Additional Charging Adapters.

(PROCEED ON NEXT PAGE!)

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 6 (42)

Operations Manual 3. CHARGING

Envirotainer RKN e1 Container

Fig. 3

5. onnect the adapter to the charging cable

(ig. 3 ).

6. onnect the adapter / blue EE industry plug to the power supply. The charge indicator

(blue light) on the control unit starts flashing to highlight that charging is in progress.

During the first hour the display will switch between showing ”Container info” and

“Info, Pre-charging, Please wait”.

NOTE:

• It may take up to 30 seconds before the charge indicator starts flashing.

• During the first hour of charging the SOC (battery percentage) is not updated on the display. As

long as the blue charge indicator is flashing, charging is in progress.

• During the first hour the display will switch between showing ”Container info” and “Info,

Pre- harging, Please wait”.

7. When the charging is complete the blue charging indicator will illuminate (fixed light) to

indicate that the charging has been completed.

NOTE:

The charging indicator may illuminate (fixed light) at 9 % battery status.

If fixed light occurs at 9 % the batteries are considered fully charged.

8. Disconnect the adapter from the power supply and disconnect the adapter from the

charging cable.

9. Ensure all five adapters and the cable for recharging have been properly stored in the

charging unit.

10. Make sure the battery switch is on.

Refer to chapter 6.10 Battery Switch.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 7 (42)

Operations Manual 3. CHARGING

Envirotainer RKN e1 Container

3.2 ADDITIONAL CHARGING ADAPTERS

Beside the adapters for different countries included within the charging unit; the following

additional adapters can be ordered separately from Envirotainer.

British Standard 546 15A, 3 pins P/N 807W

NEMA 6-15R 15A, 250V P/N 807X

NEMA L15-30P 30A, 250V P/N 807Y

Danish SRAF 1962/DB 16/87 10A, 250V, K-plug P/N 807Z

3.3 CHARGING CABLE

Avoid use of additional extension cable as far as possible. If necessary, use as short extension

cable as possible and make sure the cross-section of the wires are at least 2.5 mm² (0.0039 inch²).

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 8 (42)

Operations Manual 4. PRE-CONDITIONING

Envirotainer RKN e1 Container

4. PRE-CONDITIONING

The cargo and container must be pre-conditioned to the container set temperature prior to

loading. Improper pre-condition will affect the container's ability to maintain cargo temperature.

4.1 CARGO PRE-CONDITIONING

The cargo must be pre-conditioned to the temperature that is to be maintained during transport.

IMPORTANT

To avoid the risk of temperature deviations, the cargo must be properly pre-conditioned to the

container set temperature.

Cargo temperature recording

• If records must be kept of product temperature, Envirotainer strongly recommends that

temperature recorders are placed as close to the product as possible, preferably in the box,

otherwise between the boxes.

• The temperature displayed on the control unit is the temperature of the air at the sensor

inside the container. This temperature can differ slightly from the actual product temperature.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 9 (42)

Operations Manual 4. PRE-CONDITIONING

Envirotainer RKN e1 Container

4.2 CONTAINER PRE-CONDITIONING

Prior to pre-conditioning, a functional test of the container should be performed.

Refer to chapter 7. Control Unit Operation — Type 1 and Type 2.

There are two recommended practices for container pre-conditioning:

4.2.1 PRE-CONDITIONING WITH CONTAINER OPERATING IN NON-

TEMPERATURE CONTROLLED AREA

• It is recommended that this type of pre-conditioning is performed with the container

connected to the power supply.

• When the container is connected to the power supply, the heating and cooling equipment

will run on power from the power supply and no battery power is consumed.

• This type of pre-conditioning can also be done during charging without affecting the

charging time.

The recommended procedure is:

1. Make sure the container is operating and the container set temperature is correct.

Refer to chapter 7. Control Unit Operation — Type 1 and Type 2.

2. Make sure the doors to the cargo space are closed.

3. At change of set temperature:

The display will switch between showing ”Container info” and ”Info, Preconditioning”

until the set temperature has been reached (this can take up to 90 minutes). Wait until the

info on the display disappears before loading cargo.

4. During operation:

The display will show the alert "Inside temp out of spec" until the container’s inside

temperature is within tolerance (this can take up to 90 minutes). Wait until the alert on the

display disappears before loading cargo.

4.2.2 PRE-CONDITION WITH A TEMPERATURE-CONTROLLED ROOM

The recommended procedure is:

1. Place the container in a temperature-controlled room that is set to the desired temperature.

2. Open the doors to the cargo space.

3. Allow at least one hour for container pre-conditioning before loading the cargo.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 10 (42)

Operations Manual 5. GENERAL CARGO LOADING GUIDELINES

Envirotainer RKN e1 Container

5. GENERAL CARGO LOADING GUIDELINES

Fig. 4

NOTE:

• Use the door straps (Right illustration in Fig. 4 ) to hold the doors open when loading.

• Load the cargo on a pallet.

• Do not load cargo between the spacers inside the container walls.

• Ensure that the air inlet at the lower left side of the loading area is not blocked by the cargo.

• If the cargo is shrink-wrapped it is recommended that the pallet base isn’t wrapped in order to

allow air flow onto the floor.

• Ensure proper weight distribution.

• Secure the cargo to the tie-down brackets (Left illustration in Fig. 4 ) using straps.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 11 (42)

Operations Manual 5. GENERAL CARGO LOADING GUIDELINES

Envirotainer RKN e1 Container

5.1 CARGO LOADING

The recommended procedure is:

1. Switch on the container (if pre-conditioned without container operating) and ensure

container set temperature is correct and container is pre-conditioned to the required cargo

temperature.

Refer to chapter 7. Control Unit Operation — Type 1 and Type 2.

2. Load the container (minimize the time the container doors are open during loading).

Fig. 5

3. lose and lock the doors. Secure the right

door with a seal ( ig. 5 ) if applicable.

The left door cannot be opened before the

right door has been opened.

4. Place any shipping documents or check lists in the container placard holder.

5.2 AFTER CARGO LOADING

Refer to chapter 7. Control Unit Operation — Type 1 and Type 2.

The recommended procedure is:

1. heck that the battery level is 95% or above.

2. onfirm container set temperature is correct on the control unit.

Refer to chapter 7. Control Unit Operation — Type 1 and Type 2.

3. heck that the yellow alert indicator on the control unit has not been activated.

NOTE:

The alert for inside temperature may appear due to the door opening during loading. Ensure

temperature recovers and alert disappears in a few minutes.

4. heck that the red alarm indicator on the control unit has not been activated.

5. onfirm that all doors and covers are closed and latched.

6. Ensure that the container is stored in accordance with the specified limits and ambient

conditions.

Refer to chapter 2. Limits, Ambient Conditions.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 12 (42)

Operations Manual 6. GENERAL CONTAINER HANDLING

GUIDELINES

Envirotainer RKN e1 Container

6. GENERAL CONTAINER HANDLING GUIDELINES

6.1 FORKLIFT REQUIREMENTS

• The container should be lifted using forklifts when empty and loaded.

NOTE:

• The container can only be forklifted from the door side and the rear side.

• The container SHOULD NOT touch the ground when moved by forklift.

6.2 ROLLER BEDS

Fig. 6

Use the straps ( ig. 6 ) outside the corners of

the container to handle the container on roller

beds.

6.3 AMBIENT CONDITIONS

Ensure that the container is handled in accordance with the specified limits and ambient

conditions.

Refer to chapter 2. Limits, Ambient Conditions.

6.4 SHIPMENT DURATION

If the duration of the shipment is longer than 30 hours charging of the container should be

considered whenever it is in a warehouse.

6.5 WRAPPING

Wrapping MUST NOT be applied to the container. If the container is wrapped the air inlets

and outlets are blocked and the container can not work properly.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 13 (42)

Operations Manual 6. GENERAL CONTAINER HANDLING

GUIDELINES

Envirotainer RKN e1 Container

6.6 GROUND TRANSPORT PRECAUTIONS

• Ensure that the container is transported in an environment where temperatures are between

-10° and +30° (+14°F and +86°F) and limit exposure to other temperatures.

Refer to chapter 2. Limits, Ambient Conditions.

6.7 AIRCRAFT TRANSPORT PRECAUTIONS

Limit time on the tarmac during aircraft loading (to avoid temperature extremes and direct

sunlight).

6.8 UNLOADING

• Before unloading the container, check for damage.

• Unload the container by unlocking and opening the doors.

6.8.1 AFTER UNLOADING:

Switch off the container by pressing and holding down or for about 3 seconds.

6.9 STORAGE

It is recommended that the RKN e1 container be stored on flat ground. The storage

temperature should be between -40° and +50° (-40°F and +122°F).

IMPORTANT

No container, cargo or other must be stored on top of a RKN e1.

6.10 BATTERY SWITCH

The battery switch is located behind the adapter case.

The battery switch disconnects the batteries from the container system. I.e. the container cannot

run on battery power when the switch is off ( ig. 8 ).

IMPORTANT

The refrigeration system can still run and the batteries can still be charged when the container is

connected to an electrical outlet.

Doc No. MO-RKN-3009

Version 2.2: 2017-08-31 14 (42)

Other manuals for RKN e1

4

Table of contents

Popular Farm Equipment manuals by other brands

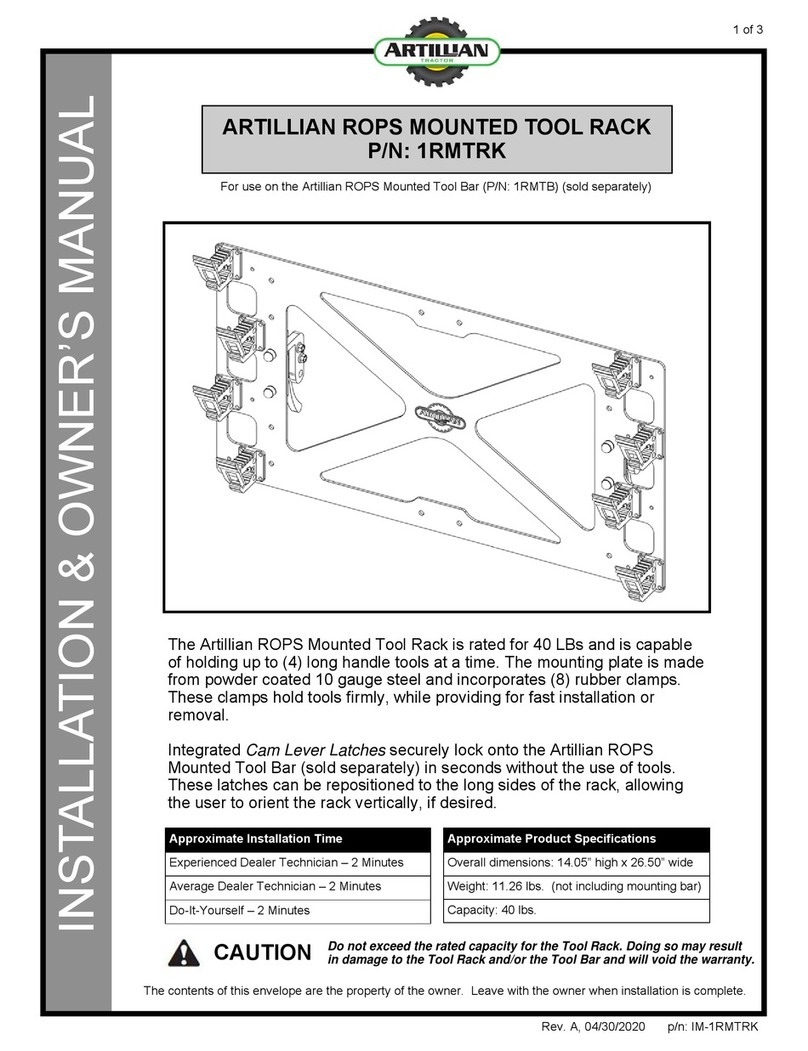

Artillian

Artillian 1RMTRK Installation & owner's manual

DuraTech Industries

DuraTech Industries HAYBUSTER CMF-1150 Operating Instructions and Parts Reference

Toro

Toro Sitework 22447 Operator's manual

DFE

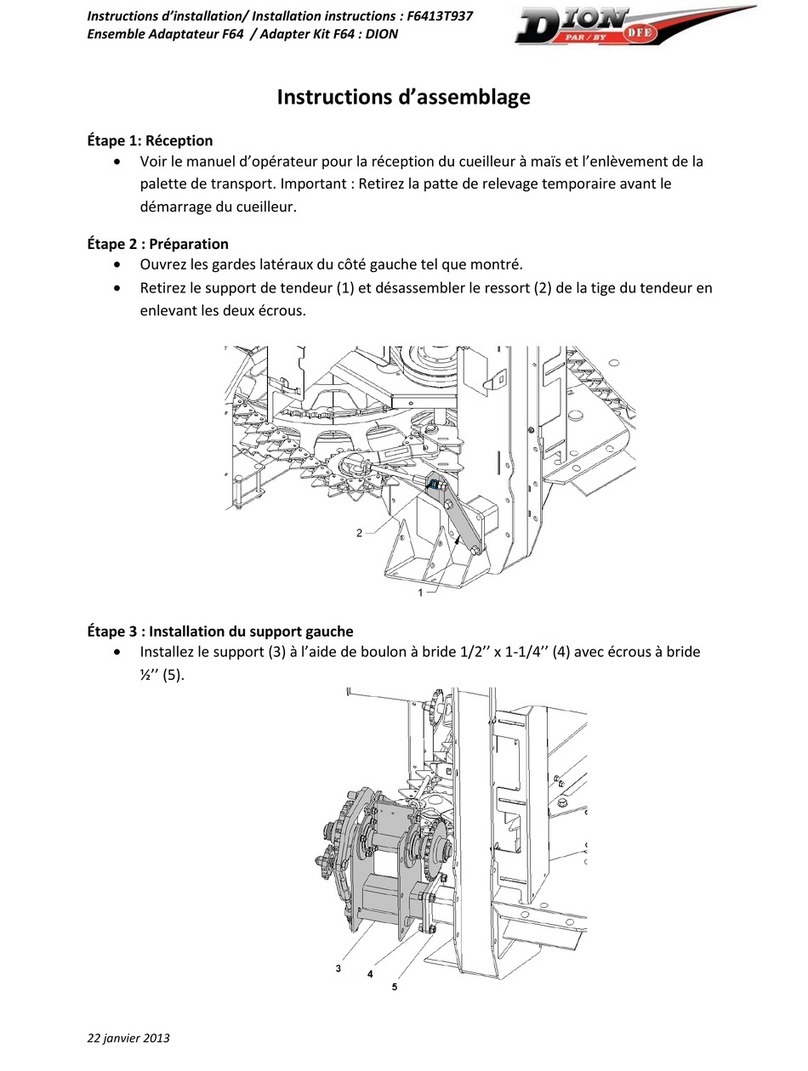

DFE DION F64 installation instructions

Ferrari

Ferrari FX Operating and service manual

KUHN

KUHN HR 4004 D Operator's manual