EpiSensor ZDR-17 User manual

Install Sheet

ZDR-16, ZDR-17 // Wireless Demand Response Controller

Document Ref. EPI-065-02

Installation & Safety Notes

➔NEVER work alone.

➔Use appropriate personal protective equipment (PPE) and follow safe electrical work practices.

➔Only qualified electrical workers should install this equipment. Such work should be performed only after

reading the entire set of installation instructions.

➔If the equipment is not used in a manner specified by EpiSensor, the protection provided by the equipment

may be impaired.

➔Before performing visual inspections, tests, or maintenance on this equipment, disconnect all sources of

electric power. Assume that all circuits are live until they have been completely de-energized, tested, and

tagged. Pay particular attention to the design of the power system. Consider all sources of power, including

the possibility of backfeeding.

➔Turn off all power supplying the meter and the equipment in which it is installed before working on it.

➔Always use a properly rated voltage sensing device to confirm that all power is off.

➔Before closing all covers and doors, inspect the work area for tools and objects that may have been left

inside the equipment or panel.

➔When removing or installing metering or other equipment, do not allow it to extend into the energised bus.

➔The successful operation of this equipment depends upon proper handling,

➔Neglecting fundamental installation requirements may lead to personal injury as well as damage to

electrical equipment or other property.

➔Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the energy meter is

installed, disconnect all input and output wires to the energy meter.

➔High voltage testing may damage electronic components contained in the meter.

➔Failure to follow these instructions will result in death or serious injury.

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

➔EpiSensor equipment should be installed, operated, serviced and maintained only by qualified personnel.

EpiSensor does not assume any responsibility for any consequences arising out of the use of this

equipment.

➔The ZDR voltage measurement inputs are rated for up to 277 V L-N or 480 V L-L. For any voltage

exceeding 277 V L-N, an auxiliary power source must be used. Consult the ZDR-16 datasheet for more

information on available product variants. For voltages exceeding 480 V L-L, a voltage transformer must

be used.

➔Fuse for neutral terminal is required if the source neutral connection is not grounded.

➔Clearly label the device’s disconnect circuit mechanism and install it within easy reach of the operator.

➔The fuses / circuit breakers must be rated for the installation voltage and sized for the available fault

current.

➔Depending on the type of current transformers used with the EpiSensor ZDR, shorting links may be

required. Please consult the user guide for more information.

➔If Voltage Transformers are used, the VT ratio setting should be adjusted on the ZDR settings page on the

Gateway.

➔By default, there will not be a cable included for mains reference voltages

➔ZDR’s using Rogowski coil or milliamp Current Transformers are individually calibrated and the current

transformer cables should not be extended or interchanged.

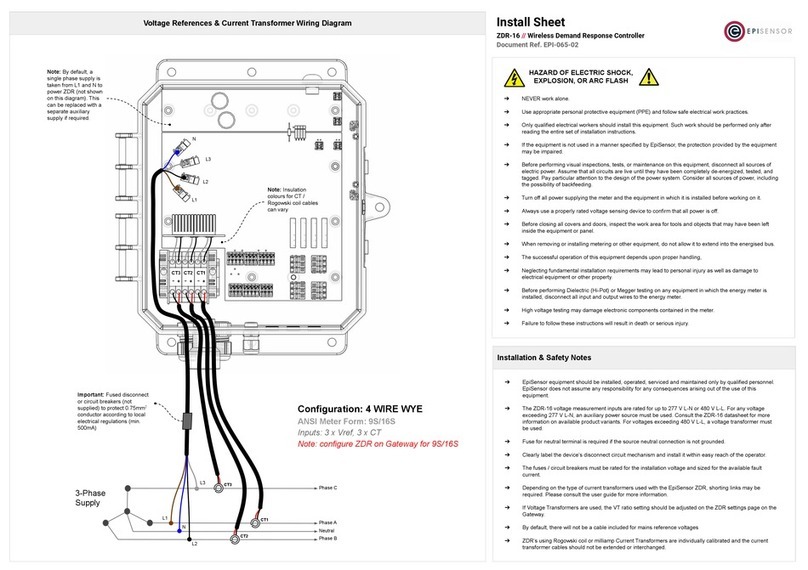

CT1

Voltage References & Current Transformer Wiring Diagram

Important: Fused disconnect

or circuit breakers (not

supplied) to protect 0.75mm2

conductor according to local

electrical regulations (min.

500mA)

CT3

CT2

Phase C

Phase A

Neutral

Phase B

L1

L2

L3

N

Configuration: 4 WIRE WYE

ANSI Meter Form: 9S/16S

Inputs: 3 x Vref, 3 x CT

Note: configure ZDR on Gateway for 9S/16S

3-Phase

Supply

L1

L2

L3

N

CT1

- +

CT2

- +

CT3

- +

Note: Insulation

colours for CT /

Rogowski coil cables

can vary

Note: By default, a

single phase supply is

taken from L1 and N to

power ZDR (not shown

on this diagram). This

can be replaced with a

separate auxiliary

supply if required.

Install Sheet

ZDR-16, ZDR-17 // Wireless Demand Response Controller

Document Ref. EPI-065-02

Installation & Safety Notes

➔NEVER work alone.

➔Use appropriate personal protective equipment (PPE) and follow safe electrical work practices.

➔Only qualified electrical workers should install this equipment. Such work should be performed only after

reading the entire set of installation instructions.

➔If the equipment is not used in a manner specified by EpiSensor, the protection provided by the equipment

may be impaired.

➔Before performing visual inspections, tests, or maintenance on this equipment, disconnect all sources of

electric power. Assume that all circuits are live until they have been completely de-energized, tested, and

tagged. Pay particular attention to the design of the power system. Consider all sources of power, including

the possibility of backfeeding.

➔Turn off all power supplying the meter and the equipment in which it is installed before working on it.

➔Always use a properly rated voltage sensing device to confirm that all power is off.

➔Before closing all covers and doors, inspect the work area for tools and objects that may have been left

inside the equipment or panel.

➔When removing or installing metering or other equipment, do not allow it to extend into the energised bus.

➔The successful operation of this equipment depends upon proper handling,

➔Neglecting fundamental installation requirements may lead to personal injury as well as damage to

electrical equipment or other property.

➔Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the energy meter is

installed, disconnect all input and output wires to the energy meter.

➔High voltage testing may damage electronic components contained in the meter.

➔Failure to follow these instructions will result in death or serious injury.

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

➔EpiSensor equipment should be installed, operated, serviced and maintained only by qualified personnel.

EpiSensor does not assume any responsibility for any consequences arising out of the use of this

equipment.

➔The ZDR voltage measurement inputs are rated for up to 277 V L-N or 480 V L-L. For any voltage

exceeding 277 V L-N, an auxiliary power source must be used. Consult the ZDR-16 datasheet for more

information on available product variants. For voltages exceeding 480 V L-L, a voltage transformer must

be used.

➔Fuse for neutral terminal is required if the source neutral connection is not grounded.

➔Clearly label the device’s disconnect circuit mechanism and install it within easy reach of the operator.

➔The fuses / circuit breakers must be rated for the installation voltage and sized for the available fault

current.

➔Depending on the type of current transformers used with the EpiSensor ZDR, shorting links may be

required. Please consult the user guide for more information.

➔If Voltage Transformers are used, the VT ratio setting should be adjusted on the ZDR settings page on the

Gateway.

➔By default, there will not be a cable included for mains reference voltages

➔ZDR’s using Rogowski coil or milliamp Current Transformers are individually calibrated and the current

transformer cables should not be extended or interchanged.

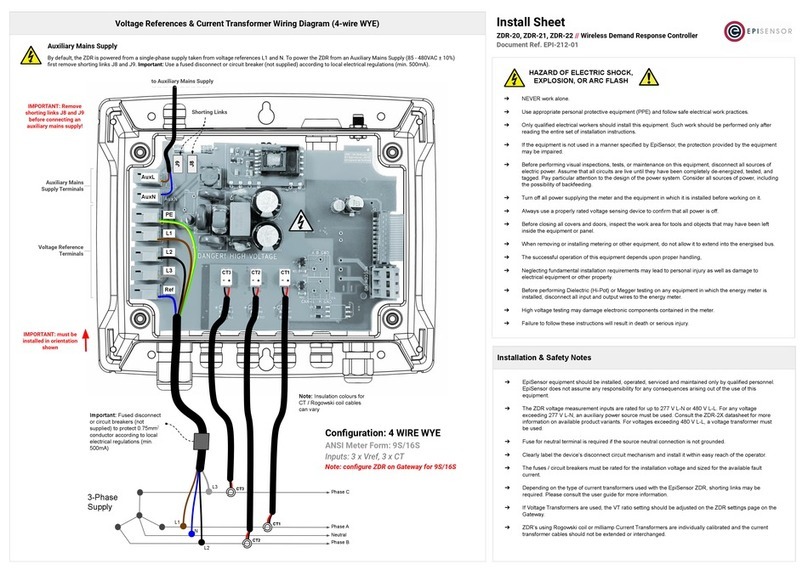

CT1

Voltage References & Current Transformer Wiring Diagram

Important: Fused disconnect

or circuit breakers (not

supplied) to protect 0.75mm2

conductor according to local

electrical regulations (min.

500mA)

CT3 Phase C

Phase A

Phase B

L1

L2

L3

Configuration: 3 WIRE DELTA

ANSI Meter Form: 5S/13S

Inputs: 3 x Vref, 2 x CT

Note: configure ZDR on Gateway for 5S/13S

3-Phase

Supply

L1

L2

L3

N

CT1

- +

CT2

- +

CT3

- +

Note: Insulation

colours for CT /

Rogowski coil cables

can vary

Note: By default, a

single phase supply is

taken from L1 and N to

power ZDR (not shown

on this diagram). This

can be replaced with a

separate auxiliary

supply if required.

Note: L2 is used as the

reference phase with

this configuration, so

the L2 voltage

reference should be

connected to terminal

marked ‘N’

Note: CT2 can

be disconnected

in this mode

Install Sheet

ZDR-16, ZDR-17 // Wireless Demand Response Controller

Document Ref. EPI-065-02

Installation & Safety Notes

➔NEVER work alone.

➔Use appropriate personal protective equipment (PPE) and follow safe electrical work practices.

➔Only qualified electrical workers should install this equipment. Such work should be performed only after

reading the entire set of installation instructions.

➔If the equipment is not used in a manner specified by EpiSensor, the protection provided by the equipment

may be impaired.

➔Before performing visual inspections, tests, or maintenance on this equipment, disconnect all sources of

electric power. Assume that all circuits are live until they have been completely de-energized, tested, and

tagged. Pay particular attention to the design of the power system. Consider all sources of power, including

the possibility of backfeeding.

➔Turn off all power supplying the meter and the equipment in which it is installed before working on it.

➔Always use a properly rated voltage sensing device to confirm that all power is off.

➔Before closing all covers and doors, inspect the work area for tools and objects that may have been left

inside the equipment or panel.

➔When removing or installing metering or other equipment, do not allow it to extend into the energised bus.

➔The successful operation of this equipment depends upon proper handling,

➔Neglecting fundamental installation requirements may lead to personal injury as well as damage to

electrical equipment or other property.

➔Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the energy meter is

installed, disconnect all input and output wires to the energy meter.

➔High voltage testing may damage electronic components contained in the meter.

➔Failure to follow these instructions will result in death or serious injury.

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

➔EpiSensor equipment should be installed, operated, serviced and maintained only by qualified personnel.

EpiSensor does not assume any responsibility for any consequences arising out of the use of this

equipment.

➔The ZDR voltage measurement inputs are rated for up to 277 V L-N or 480 V L-L. For any voltage

exceeding 277 V L-N, an auxiliary power source must be used. Consult the ZDR-16 datasheet for more

information on available product variants. For voltages exceeding 480 V L-L, a voltage transformer must

be used.

➔Fuse for neutral terminal is required if the source neutral connection is not grounded.

➔Clearly label the device’s disconnect circuit mechanism and install it within easy reach of the operator.

➔The fuses / circuit breakers must be rated for the installation voltage and sized for the available fault

current.

➔Depending on the type of current transformers used with the EpiSensor ZDR, shorting links may be

required. Please consult the user guide for more information.

➔If Voltage Transformers are used, the VT ratio setting should be adjusted on the ZDR settings page on the

Gateway.

➔By default, there will not be a cable included for mains reference voltages

➔ZDR’s using Rogowski coil or milliamp Current Transformers are individually calibrated and the current

transformer cables should not be extended or interchanged.

Connecting an auxiliary supply to the ZDR mains power supply

Note: By default, a single

phase supply is taken

from L1 and N to power

ZDR. To power ZDR from

an auxiliary supply,

remove these links and

connect as shown in this

diagram.

Important: Fused disconnect

or circuit breakers (not

supplied) to protect 0.75mm2

conductor according to local

electrical regulations (min.

500mA)

Live

Neutral

L

N

Install Sheet

ZDR-16, ZDR-17 // Wireless Demand Response Controller

Document Ref. EPI-065-02

Installation & Safety Notes

➔NEVER work alone.

➔Use appropriate personal protective equipment (PPE) and follow safe electrical work practices.

➔Only qualified electrical workers should install this equipment. Such work should be performed only after

reading the entire set of installation instructions.

➔If the equipment is not used in a manner specified by EpiSensor, the protection provided by the equipment

may be impaired.

➔Before performing visual inspections, tests, or maintenance on this equipment, disconnect all sources of

electric power. Assume that all circuits are live until they have been completely de-energized, tested, and

tagged. Pay particular attention to the design of the power system. Consider all sources of power, including

the possibility of backfeeding.

➔Turn off all power supplying the meter and the equipment in which it is installed before working on it.

➔Always use a properly rated voltage sensing device to confirm that all power is off.

➔Before closing all covers and doors, inspect the work area for tools and objects that may have been left

inside the equipment or panel.

➔When removing or installing metering or other equipment, do not allow it to extend into the energised bus.

➔The successful operation of this equipment depends upon proper handling,

➔Neglecting fundamental installation requirements may lead to personal injury as well as damage to

electrical equipment or other property.

➔Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the energy meter is

installed, disconnect all input and output wires to the energy meter.

➔High voltage testing may damage electronic components contained in the meter.

➔Failure to follow these instructions will result in death or serious injury.

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

➔EpiSensor equipment should be installed, operated, serviced and maintained only by qualified personnel.

EpiSensor does not assume any responsibility for any consequences arising out of the use of this

equipment.

➔The ZDR voltage measurement inputs are rated for up to 277 V L-N or 480 V L-L. For any voltage

exceeding 277 V L-N, an auxiliary power source must be used. Consult the ZDR-16 datasheet for more

information on available product variants. For voltages exceeding 480 V L-L, a voltage transformer must

be used.

➔Fuse for neutral terminal is required if the source neutral connection is not grounded.

➔Clearly label the device’s disconnect circuit mechanism and install it within easy reach of the operator.

➔The fuses / circuit breakers must be rated for the installation voltage and sized for the available fault

current.

➔Depending on the type of current transformers used with the EpiSensor ZDR, shorting links may be

required. Please consult the user guide for more information.

➔If Voltage Transformers are used, the VT ratio setting should be adjusted on the ZDR settings page on the

Gateway.

➔By default, there will not be a cable included for mains reference voltages

➔ZDR’s using Rogowski coil or milliamp Current Transformers are individually calibrated and the current

transformer cables should not be extended or interchanged.

Connecting a GPS Antenna to ZDR (only needed if High Speed Data Module installed)

to active GPS Antenna

Note: Isolate power to ZDR before connecting the

GPS antenna

Recommended Antenna:

Manufacturer: Taoglas

Part No.: A.03.C.1001111

Description: Hercules A.03 GPS/GALILEO

Permanent Mount, 10M RG-174 Note: SMF (F) connector

panel mounted on top

side of ZDR enclosure

Install Sheet

ZDR-16, ZDR-17 // Wireless Demand Response Controller

Document Ref. EPI-065-02

Input Voltage

If the mains power supply of the ZDR is powered directly from the 3-phase voltage reference,

ensure that the voltage does not exceed 480V AV L-L

Installation Checklist

1

High Speed Data Module Connection

Check that the high speed data module (if present) has been aligned with its terminals

correctly, and it mating properly with the female terminals on the main PCB

2

Enclosure Contamination & Integrity

Ensure that there is no swarf or other dirt inside the ZDR enclosure, and that the enclosure has

not been drilled or modified (other than to add IP68 glands in standard positions)

3

GPS Signal

If a high-speed data module has been installed, confirm (using a mobile app, or other

handheld test device) that there is a good GPS signal available at the GPS antenna of ZDR.

Line-of-sight view to the sky is needed for ZDR to synchronise time with GPS satellites.

4

This manual suits for next models

1

Table of contents

Other EpiSensor Controllers manuals

Popular Controllers manuals by other brands

Emerson

Emerson Asco 642 Series Installation and maintenance instructions

ADLINK Technology

ADLINK Technology COM Express Express-HLE user manual

modec

modec JA73 instruction manual

Webasto

Webasto Diavia MCP Instructions for use

Sentiotec

Sentiotec K2-NEXT Installation and operating instructions

Mohlenhoff

Mohlenhoff OEM-Actuator 24 V technical information