Install Sheet

ZDR-20, ZDR-21, ZDR-22 // Wireless Demand Response Controller

Document Ref. EPI-212-01

Installation & Safety Notes

➔NEVER work alone.

➔Use appropriate personal protective equipment (PPE) and follow safe electrical work practices.

➔Only qualified electrical workers should install this equipment. Such work should be performed only after

reading the entire set of installation instructions.

➔If the equipment is not used in a manner specified by EpiSensor, the protection provided by the equipment

may be impaired.

➔Before performing visual inspections, tests, or maintenance on this equipment, disconnect all sources of

electric power. Assume that all circuits are live until they have been completely de-energized, tested, and

tagged. Pay particular attention to the design of the power system. Consider all sources of power, including

the possibility of backfeeding.

➔Turn off all power supplying the meter and the equipment in which it is installed before working on it.

➔Always use a properly rated voltage sensing device to confirm that all power is off.

➔Before closing all covers and doors, inspect the work area for tools and objects that may have been left

inside the equipment or panel.

➔When removing or installing metering or other equipment, do not allow it to extend into the energised bus.

➔The successful operation of this equipment depends upon proper handling,

➔Neglecting fundamental installation requirements may lead to personal injury as well as damage to

electrical equipment or other property.

➔Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the energy meter is

installed, disconnect all input and output wires to the energy meter.

➔High voltage testing may damage electronic components contained in the meter.

➔Failure to follow these instructions will result in death or serious injury.

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

➔EpiSensor equipment should be installed, operated, serviced and maintained only by qualified personnel.

EpiSensor does not assume any responsibility for any consequences arising out of the use of this

equipment.

➔The ZDR voltage measurement inputs are rated for up to 277 V L-N or 480 V L-L. For any voltage

exceeding 277 V L-N, an auxiliary power source must be used. Consult the ZDR-2X datasheet for more

information on available product variants. For voltages exceeding 480 V L-L, a voltage transformer must

be used.

➔Fuse for neutral terminal is required if the source neutral connection is not grounded.

➔Clearly label the device’s disconnect circuit mechanism and install it within easy reach of the operator.

➔The fuses / circuit breakers must be rated for the installation voltage and sized for the available fault

current.

➔Depending on the type of current transformers used with the EpiSensor ZDR, shorting links may be

required. Please consult the user guide for more information.

➔If Voltage Transformers are used, the VT ratio setting should be adjusted on the ZDR settings page on the

Gateway.

➔ZDR’s using Rogowski coil or milliamp Current Transformers are individually calibrated and the current

transformer cables should not be extended or interchanged.

CT1

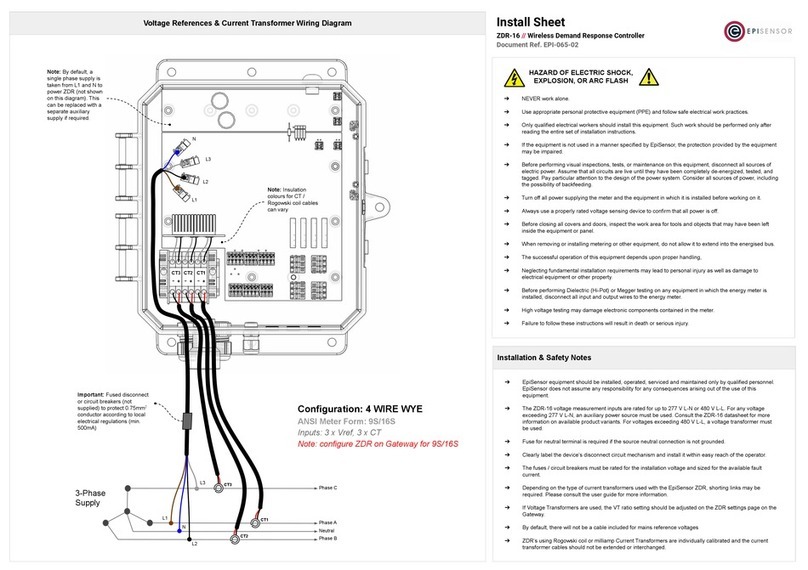

Voltage References & Current Transformer Wiring Diagram (4-wire WYE)

Important: Fused disconnect

or circuit breakers (not

supplied) to protect 0.75mm2

conductor according to local

electrical regulations (min.

500mA)

CT3

CT2

Phase C

Phase A

Neutral

Phase B

L1

L2

L3

N

Configuration: 4 WIRE WYE

ANSI Meter Form: 9S/16S

Inputs: 3 x Vref, 3 x CT

Note: configure ZDR on Gateway for 9S/16S

3-Phase

Supply

Note: Insulation colours for

CT / Rogowski coil cables

can vary

By default, the ZDR is powered from a single-phase supply taken from voltage references L1 and N. To power the ZDR from an Auxiliary Mains Supply (85 - 480VAC ± 10%)

first remove shorting links J8 and J9. Important: Use a fused disconnect or circuit breaker (not supplied) according to local electrical regulations (min. 500mA).

CT3

- +

CT2

- +

CT1

- +

Ref

L3

L2

L1

J9

J8

Auxiliary Mains

Supply Terminals

PE

IMPORTANT: Remove

shorting links J8 and J9

before connecting an

auxiliary mains supply!

Auxiliary Mains Supply

Voltage Reference

Terminals

Shorting Links

to Auxiliary Mains Supply

AuxN

AuxL

IMPORTANT: must be

installed in orientation

shown