EpiSensor ZDR-10 User manual

User Guide

Wireless Demand Response Controller

Applies to: ZDR-10, ZDR-15, ZDR-16

EPI-078-02

© EpiSensor

Table of Contents

Safety Information 4

Electrical Installation 4

Intended Use 6

Related Documents 6

Introduction 7

Benefits 7

Features 7

Data Feeds & Settings 8

Frequency Response Settings 8

Meter Configuration, Property 6036 9

System State Sensors 9

Event Response Sensors 9

User Interface Sensors 10

Electricity Metering Sensors 10

Analogue & Digital Inputs 12

Frequency Response Specification 12

Reaction Time 13

User Interface 13

Status LED 13

Mode Button 14

Install Mode 15

Front Panel 15

Demand Response Logic 16

Rules Engine 17

Remote Management 17

Gateway API 17

Page 2

of 37

Firmware Updates 18

Hardware Features 18

Power Supply 20

Communications 21

Wireless Communications 22

Electricity Metering 23

Electricity Metering 23

Current Transformers 23

Rogowski Coils 24

Supported 3-phase configurations 25

Voltage Reference 26

Switch Output 27

Analogue Inputs 27

Digital Inputs 28

Pulse Info 28

Pulse Operation 29

Dry Pulse 29

Open Collector Pulse 29

Active Pulse 30

Mechanical 30

Enclosure & Label Material 30

Mounting Instructions 30

Opening the Enclosure 31

Tamper Evident Seals 32

Compliance Label 33

Ordering Information 35

Troubleshooting & Support 36

Warranty 36

Glossary 36

Page 3

of 37

Safety Information

Please read these instructions carefully before trying to install, operate, service or maintain the ZDR. The

following special notes may appear throughout the user guide (or on the equipment labels) to warn of potential

hazards or to call attention information that clarifies or simplifies a procedure for users.

Symbol

Description

The addition of either symbol to a “Danger” or “Warning” safety label indicates that an

electrical hazard exists which will result in personal injury if the instructions are not

followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

This symbol notes that Electrostatic discharge (ESD) events can harm electronic components

inside this product. Protect against ESD and discharge static electricity from your body

before you interact with this product.

Electrical Installation

Electrical equipment should be installed, operated, serviced and maintained only by qualified personnel. No

responsibility is assumed by EpiSensor for any consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction, installation, and operation of

electrical equipment and has received safety training to recognize and avoid the hazards involved.

Installation, wiring, testing and service must be performed in accordance with all local and national electrical

codes.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

➔NEVER work alone.

➔Use appropriate personal protective equipment (PPE) and follow safe electrical work practices.

➔Only qualified electrical workers should install this equipment. Such work should be performed only

after reading the entire set of installation instructions.

Page 4

of 37

➔If the equipment is not used in a manner specified by EpiSensor, the protection provided by the

equipment may be impaired.

➔Before performing visual inspections, tests, or maintenance on this equipment, disconnect all sources

of electric power. Assume that all circuits are live until they have been completely de-energized,

tested, and tagged. Pay particular attention to the design of the power system. Consider all sources of

power, including the possibility of backfeeding.

➔Turn off all power supplying the meter and the equipment in which it is installed before working on it.

➔Always use a properly rated voltage sensing device to confirm that all power is off.

➔Before closing all covers and doors, inspect the work area for tools and objects that may have been

left inside the equipment or panel.

➔When removing or installing metering or other equipment, do not allow it to extend into the

energised bus.

➔The successful operation of this equipment depends upon proper handling,

➔Neglecting fundamental installation requirements may lead to personal injury as well as damage to

electrical equipment or other property.

➔Before performing Dielectric (Hi-Pot) or Megger testing on any equipment in which the energy meter

is installed, disconnect all input and output wires to the energy meter.

➔High voltage testing may damage electronic components contained in the meter.

➔Failure to follow these instructions will result in death or serious injury.

Installation & Safety Notes

➔EpiSensor equipment should be installed, operated, serviced and maintained only by qualified

personnel. EpiSensor does not assume any responsibility for any consequences arising out of the use

of this equipment.

➔The ZDR voltage measurement inputs are rated for up to 250 V L-N or 433 V L-L. For any voltage

exceeding 250 V L-N, an auxiliary power source must be used. Consult the ZDR datasheet for more

information on available product variants. For voltages exceeding 433 V L-L, a voltage transformer

must be used.

Page 5

of 37

➔Fuse for neutral terminal is required if the source neutral connection is not grounded.

➔Clearly label the device’s disconnect circuit mechanism and install it within easy reach of the operator.

➔The fuses / circuit breakers must be rated for the installation voltage and sized for the available fault

current.

➔If Voltage Transformers are used, the power consumption values must be adjusted in ZDR settings

accordingly.

➔Each ZDR meter is individually calibrated and the current transformer cables should not be extended

or interchanged.

Intended Use

Do not use this device for critical control or protection applications where human or equipment safety relies on

the operation of the control circuit. Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Related Documents

Related installation and configuration documents are listed in the following table:

Document

Reference No.

EpiSensor ZDR Datasheet

EPI-066-00

Install Sheet for ZDR

EPI-065-00

Gateway API User Guide

ESE-009-08

Bootloading on a live Gateway

EPI-064-00

Configuring the High Speed Data Module on ZDR

EPI-131-02

Application Note - Demand Response Event Data

EPI-124-01

Page 6

of 37

Introduction

EpiSensor’s ZDR enables customers to participate in multiple Demand and Frequency response programs. It

includes best-in-class functionality to accurately monitor electrical load (via CT’s or pulse inputs), frequency and

can take action to shed load or engage backup generators based on frequency set points or commands sent

from a remote network operations centre.

The system is capable of streaming data securely to a Network Operations Centre (NOC) to arm the system,

detect low frequency events, override the system remotely, and switch loads both automatically and manually.

With a wide range of additional sensors available, EpiSensor’s platform can also be used for energy

management, environmental monitoring and many other applications.

This guide discusses features of the EpiSensor ZDR series demand response controller and provides installation

and configuration instructions.

For the most up-to-date version of this document and others, please visit www.episensor.com

Benefits

●Significantly lower cost and physical size than other solutions

●Can be expanded to multiple ‘apps’ with additional sensors available

●Multiple ZDR’s can communicate to a single Gateway

Features

●4 relays for asset control

●2-channel high frequency pulse inputs

●2-channel 4-20mA analog inputs

●100ms reaction time for under frequency events

●Live stream (1-second) data for 3-phase power consumption, current and frequency

●Modbus (RS-485) communications capability

Page 7

of 37

Data Feeds & Settings

The list of parameters that are available to monitor on the ZDR are listed below. Data reporting can be enabled

or disabled as required for each of the ‘sensors’ below.

Frequency Response Settings

The following table lists the settings on the ZDR that related to frequency response. They define how the ZDR

should respond to under-frequency events and how the current state of the hardware. These items are

configured as properties on the ZDR rather than sensors.

Property ID

Setting

Description

Unit

Resolution

Reporting

Default

Read/Write

6500

Event Sensor

The sensor ID for which the system

is monitoring to generate events.

Initially this is only configurable for

“none” indicating no events are

generated locally, or “Line

Frequency - 342” for frequency

monitoring.

-

-

-

none

Read/Write

6501

Enter Event Value

The value at which the system will

trigger the start of an event.

Raw Sensor

Units

1

-

49700

Read/Write

6502

Exit Event Value

The value at which the system will

exit the event.

Raw Sensor

Units

1

-

49800

Read/Write

6503

Auto Exit

Defines whether the site will exit a

trip state automatically after an

event, or if it should waits for a ‘soft

reset’ from a user via the

pushbutton.

TRUE

/FALSE

1

-

0

Read/Write

6504

Minimum Event

Time

The minimum amount of time the

unit must remain in an event.

Sec

1

-

0

Read/Write

6505

Event Reset Time

After an event, this is the minimum

amount of time the unit must

remain in the non-event state before

another event will trigger

Sec

1

-

0

Read/Write

6550

CT Ratio

A multiplier on the CT input channel

which is applied to the calibration

constants within the metering

section of the ZDR System. It allows

for 100:1 or 100:5 (20:1) type Ratios

to be applied to the CTs

-

-

-

1

Read/Write

6551

VT Ratio

A multiplier on the VT input channel

which is applied to the calibration

constants within the metering

section of the ZDR System. It allows

the ZDR be connected to MV

systems with (for example) 11kV

inputs using VTs that output 110V.

-

-

-

1

Read/Write

6036

Configuration

The American ANSI C12.10 standard

defines the different configurations

of the meter. This defines how the

active power accumulated in each

watt-hour register is calculated.

-

-

-

9S/16S

4-wire

Wye

Read/Write

Page 8

of 37

Meter Configuration, Property 6036

The active power accumulated in each watt-hour sensor depends on the configuration of the Meter. Choose the

appropriate value from the table below depending on how the ZDR is connected to a 3-phase system. This is

based on the ANSI C12.10 standard.

Ansi Meter Form

Configuration

Phase A Watt Hours

Phase B Watt Hours

Phase C Watt Hours

9S/16S

4-wire wye

VA x IA

VB x IB

VC x IC

5S/13S

3-wire delta

VA x IA

0

VC x IC

6S/14S

4-wire wye

VA x IA

VB × IB

Where VB = −VA − VC

VC x IC

8S/15S

4-wire delta

VA x IA

VB × IB

Where VB = −VA

VC x IC

System State Sensors

These sensors provide data on the state of the ZDR State Variables and can be used to trigger state changes at

the NOC or for audit/compliance purposes.

Sensor ID

Data Feed

Description

Unit

Resolution

Reporting

Default

Read/Writ

e

24

Armed

Set to 1 when the Key Switch is in

the Armed position AND the ZDR

system is actively monitoring an

Event Sensor. Set to 0 otherwise.

1/0

1

Interval

and Delta

-

Read Only

25

Opt Out

Set to 1 when the Gateway or API

removes a device from an active

event with the Opt Out command

OR when a user on site has removed

the site from an event by the Opt

Out key sequence on the front panel

- Press and hold the Exit button and

turn the key switch to Disarm.

1/0

1

Interval

and Delta

-

Read Only

Event Response Sensors

The following sensors produce data on the state of the ZDR showing whether an event is currently in progress,

or if the ZDR has been triggered remotely by the NOC.

Sensor ID

Data Feed

Description

Unit

Resolution

Reporting

Default

Read/Writ

e

27

Event Response

Notifies that an event is currently in

progress. Will be reset if a user takes

the site out of trip with the

pushbutton and keylock, or with

1/0

1

Interval

and Delta

-

Read Only

Page 9

of 37

remote override. Or if the event

ends and the system is configured to

Auto Exit

26

Demand Response

Notifies that a demand response

event is currently in progress. Will be

reset either by the manual override

push button, or remote override. Or

if the event ends and the system is

configured to Auto Exit

1/0

1

Interval

and Delta

-

Read Only

359

Switch

The position of the switch. Writing 1

to the switch initiates a DR Event,

while writing 0 to the switch ends a

DR Event. Note that the switch could

be ON, when no event is in progress

if the system is waiting for a manual

Exit.

1/0

1

Interval

and Delta

-

Read/Write

User Interface Sensors

These sensors provide data on the state of the user interface and can be used to trigger state changes at the

NOC or for audit/compliance purposes.

Sensor ID

Data Feed

Description

Unit

Resolution

Reporting

Default

Read/Writ

e

41

Key Switch

The position of the key switch. 1 =

Armed, 0 = Not Armed

-

1

Interval

and Delta

-

Read Only

42

Exit Button

The position of the Exit Button, 1 =

pressed, 0 = released

-

1

Interval

and Delta

-

Read Only

250

Enter Event Value

An Echo of the Enter Event Value

Property 6501 which allows this to

be exported as a Sensor in the

normal fashion

-

1

Snap to

Clock

-

Read Only

251

Exit Event Value

An Echo of the Exit Event Value

Property 6502 which allows this to

be exported as a Sensor in the

normal fashion

-

1

Snap to

Clock

-

Read Only

Electricity Metering Sensors

These read-only ‘sensors’ provide data on the power consumption and frequency of the 3-phase system that the

ZDR is monitoring.

Sensor ID

Data Feed

Description

Unit

Resolution

Reporting

Default

Read/Writ

e

300

Phase A kWh

Phase A kWh value. This is a

continually increasing kWh reading.

kWh

0.01

Off

-

Read/Write

301

Phase B kWh

Phase B kWh value. This is a

continually increasing kWh reading.

kWh

0.01

Off

-

Read/Write

Page 10

of 37

302

Phase C kWh

Phase C kWh value. This is a

continually increasing kWh reading.

kWh

0.01

Off

-

Read/Write

303

Phase A RMS

Current

Instantaneous Phase A RMS Current.

A

0.1

Off

-

Read Only

304

Phase B RMS

Current

Instantaneous Phase B RMS Current.

A

0.1

Off

-

Read Only

305

Phase C RMS

Current

Instantaneous Phase C RMS Current.

A

0.1

Off

-

Read Only

306

Phase A RMS

Voltage

Instantaneous Phase A RMS Voltage.

V

0.1

Off

-

Read Only

307

Phase B RMS

Voltage

Instantaneous Phase B RMS Voltage.

V

0.1

Off

-

Read Only

308

Phase C RMS

Voltage

Instantaneous Phase C RMS Voltage.

V

0.1

Off

-

Read Only

324

Phase A Active

Power

Instantaneous Active Power on

Phase A

W

1

Off

-

Read Only

325

Phase B Active

Power

Instantaneous Active Power on

Phase B

W

1

Off

-

Read Only

326

Phase C Active

Power

Instantaneous Active Power on

Phase C

W

1

Off

-

Read Only

330

Phase A Power

Factor

Power Factor on Phase A

%

1%

Off

-

Read Only

331

Phase B Power

Factor

Power Factor on Phase B

%

1%

Off

-

Read Only

332

Phase C Power

Factor

Power Factor on Phase C

%

1%

Off

-

Read Only

333

Total kWh

The sum of Phase A, B and C kWh,

sensors 300, 301 and 302

kWh

0.1

Off

-

Read/Write

335

Total Active Power

The instantaneous sum of Phase A, B

and C Active Power, sensors 324,

325 and 326

KW

0.001

Off

-

Read Only

338

Interval Phase A

kWh

The kWh on Phase A since the

previous data point.

kWh

0.01

Off

-

Read/Write

339

Interval Phase B

kWh

The kWh on Phase A since the

previous data point.

kWh

0.01

Off

-

Read/Write

340

Interval Phase C

kWh

The kWh on Phase A since the

previous data point.

kWh

0.01

Off

-

Read/Write

341

Interval Total kWh

The total kWh on all phases since

the previous data point.

kWh

0.1

Off

-

Read/Write

342

Line Frequency

The Line Frequency of the 3 Phase

system. This is read from the Phase

A voltage channel

Hz

0.001

Live

Stream

-

Read Only

Page 11

of 37

Analogue & Digital Inputs

These data feeds show the number of pulses counted by the ZDR and average 4-20mA analogue input readings.

Sensor ID

Data Feed

Description

Unit

Resolution

Reporting

Default

Read/Writ

e

394

4-20 MilliAmps

Now 1

The Instantaneous Milli Amp value

on channel 1 of the 4-20 Milliamp

input.

mA

0.001

Off

-

Read Only

396

4-20 MilliAmps

MIn 1

The number of pulses recorded on

channel 2 during the previous

reporting interval.

Ma

0.001

Off

-

Read Only

397

4-20 MilliAmps

Max 1

The average 4-20mA value of

channel 1.

mA

0.001

Off

-

Read Only

494

4-20 MilliAmps

Now 2

The Instantaneous Milli Amp value

on channel 1 of the 4-20 Milliamp

input.

mA

0.001

Off

-

Read Only

496

4-20 MilliAmps

MIn 2

The number of pulses recorded on

channel 2 during the previous

reporting interval.

Ma

0.001

Off

-

Read Only

497

4-20 MilliAmps

Max 2

The average 4-20mA value of

channel 1.

mA

0.001

Off

-

Read Only

450

Pulse Count

The total Pulse Count on Channel 1

of the Pulse Input

pulses

1

Off

-

Read/Write

462

Interval Pulse

Count

The total number of Pulses on

channel 1 during the previous

reporting interval

pulses

1

Off

-

Read Only

444

Pulse Rate 1

The instantaneous Pulse Rate on

Channel 1

Hz

0.001

Off

-

Read Only

463

Pulse Count 2

The total Pulse Count on Channel 2

of the Pulse Input

pulses

1

Off

-

Read/Write

464

Interval Pulse

Count 2

The total number of Pulses on

channel 2 during the previous

reporting interval

pulses

1

Off

-

Read Only

447

Pulse Rate 2

The instantaneous Pulse Rate on

Channel 2

Hz

0.001

Off

-

Read Only

Frequency Response Specification

This section describes the parameters of the ZDR that are particularly important for fast frequency response

programs.

Page 12

of 37

Reaction Time

The reaction time for frequency response programs is defined as the amount of time between an

under-frequency event, and when a relay is latched / asserted.

Some frequency response programs (or the certification for some programs) will require sub-second response

times. The metering chip used in the ZDR samples the voltage waveform regularly to determine the frequency.

The frequency register on the metering chip is polled directly from the ZigBee SoC every 2-3 cycles, which at

50Hz would be every 40ms to 60ms. The main processor then compares the value to the frequency set point,

checks the armed state, and if the ZDR is in fact armed, takes an action to latch a relay.

The overall reaction time for the ZDR is 100 milliseconds.

User Interface

There are two user interfaces on the ZDR - the front panel, and

the mode button & LED. The front panel user interface is

intended to inform local users about the state of the ZDR,

whether it is armed / participating in DR programs, and if an

event is currently in progress. The status button and LED are

located on the top of the ZDR enclosure, as shown on the

diagram to the right. This section describes the user interface

of the ZDR and what each state means.

A node must be in “command mode” before users can interact

with the product. To put the node in Command Mode, press

and hold the “MODE” button for 2 seconds, then release. At

this point the ZDR Status LED will flicker then switch the LED

On Solid, then transition into showing a node’s status.

Status LED

The red status LED will flash in different sequences depending on the current state of the ZDR. This table below

lists all possible LED flash sequences and their meaning.

Flash Sequence

Description

Diagram

Heartbeat

The node is operating correctly and has

successfully joined a wireless network.

Page 13

of 37

Inverse Heartbeat

The node is has received valid security keys, but

is not connected to a Gateway.

Square Wave

The node is operating correctly but has lost

contact with the Gateway.

On Solid, or Off

If the LED is On Solid, the node is searching for a

Gateway to join. If it is Off, the node may not be

powered, or there is a problem with the node.

Check the power supply, and if the problem

persists, contact EpiSensor support.

Mode Button

The following options are available with Command Mode. The button should be pressed and then released to

register a valid button press. If no further button presses are made, the device will terminate “command mode”

4 seconds after the last button press.

Press

Description

0

Send a PING message disable any active Install Mode or Range Test Mode. If the node is not joined,

try and join a network.

1

Send a DATA message to the Gateway for any enabled sensors that are not reporting in

‘snap-to-clock’ mode.

2

Leave the current network. Mains powered Nodes will automatically try and join a new network

once they have left and will periodically retry the join. Battery powered nodes will go to sleep.

4

Start “Install Mode”. Node sends a PING message every 15 seconds, with the LED pulse speed

indicating the wireless signal strength of the reply. Automatically expires after 5 minutes.

6

Reboot the node. Security keys for the wireless network the node is joined to will not be erased, and

all other settings will remain the same.

8

Factory-reset the node and perform a reboot. All settings and security keys will be lost. The node

will be returned to its factory default state.

12

Start “Range Test” mode. Node will send a PING message every 5 seconds. The LED pulse speed

indicates the wireless signal strength of the reply. Automatically expires after 5 minutes.

Page 14

of 37

Install Mode

Issuing a press sequence on the Mode button of a powered node can enable either “Install Mode” or “Site

Survey Mode” on that node. In this mode, the LED will flash at a rate that indicates the wireless signal strength

(Link Quality Indicator) of that node, based on the following table:

Flash Rate

Flashes per Second

Wireless Signal Strength

LQI

Very Fast

10 flashes / second (Light on 50ms, off 50ms)

Very good Signal

> 200

Fast

2 flashes / second (LED on 250 ms, off 250 ms)

Good Signal

> 150

Slow

1 flash / 2 seconds (LED on 1 sec, off 1 sec)

OK Signal

> 100

Very Slow

1 flash / 6 seconds (LED on 3 sec, off 3 sec)

Poor Signal

< 100

This mode expires after 15 minutes for Install Mode and 5 minutes for Site Survey Mode.

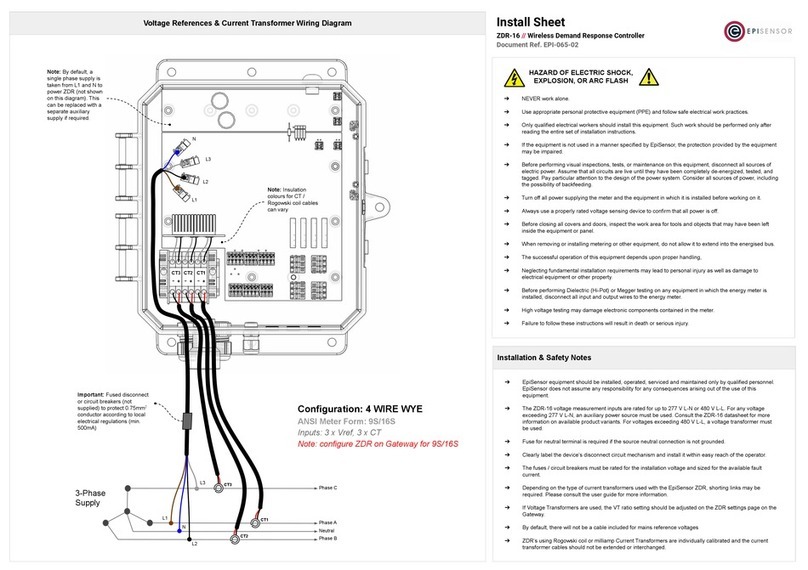

Front Panel

The ZDR has a simple user interface consisting of a Key Lock, an Exit button, and three LED indicators for

‘Power’, ‘Armed’ and ‘Event’.

The ‘POWER’ light is connected to the panel’s power supply, and will show that the panel is powered on.

The ‘ARMED’ light indicates that the system is armed for a sensor event OR demand response event. Once the

Key Switch is in the ARM position, the ZDR is always available for a Demand Response Event. This ‘ARMED’ light

will be ON solid if the key switch is set to the ‘ARM’ position, and the ZDR is monitoring a sensor. The light will

PULSE once every 2 seconds when the key switch is set to the ‘ARM’ position, but the ZDR is not monitoring a

sensor. When an event ends, and a Manual Reset is required to restore the ZDR, the ‘ARMED’ light will PULSE

every 1 second while the ‘EVENT’ light remains on. Pressing the ‘EXIT’ button executes the Manual Reset,

restoring the unit to a state determined by the Key Switch.

The ‘EVENT’ light indicates that a sensor or DR event is in progress. It will switch off when the relays switch off at

the end of an event. When an event ends, and a Manual Reset is required to restore the ZDR, the armed light

will PULSE every 1 second while the Event light remains on. Pressing the EXIT button executes the Manual Reset.

To “Opt Out” of any event, Press the EXIT button and switch the key to the DISARM position. This forces the

relays back to the reset position. Alternatively, use the remote Opt Out function available through the gateway

to achieve the same thing. Both the Armed and Event lights will FLASH every second until there are no events

active on the ZDR.

Page 15

of 37

Amber LED

Red LED

Description

Diagram

Off

Off

The system is disarmed with the

Key Switch and is not available for

either Event Or Demand Response

programs

Off

Flashing

The system is disarmed, but

would trigger an Event Response

if Armed. The system must have a

Sensor configured for Event

Monitoring for this status to arise.

Flash every 2

seconds

Off

The system is armed but is only

available for Demand Response

Programs, No Sensor is configured

for Event Monitoring

On

Off

The system is fully armed and is

monitoring a sensor for an Event

program and is available for

Demand Response.

On

On

The system has triggered either

an Event Response and/or

Demand Response

Flashing

On

All Event Response and Demand

Response events have ended, but

a manual Exit is required. Press

the EXIT button.

Flashing

Flashing

The system has been Opted Out

of an event. The system waits for

the Event to end before returning

to a state specified by the key

switch and other internal settings.

Demand Response Logic

This section describes the various states the ZDR can be in, and how it moves between them taking the various

inputs and outputs into account.

Page 16

of 37

Rules Engine

The table below lists all the states the ZDR can be in. Having the relay in the ‘ON’ position means that it’s in an

asserted position, as would happen during a sensor or demand response event.

Key

Switch

DR In

Progress

Event

Monitoring

Event In

Progress

Event

Over

Opt

Out

Manual

Exit

ARMED

light

EVENT

Light

Relay

DISARM

-

No

No

-

-

-

OFF

OFF

OFF

DISARM

-

No

Yes

-

-

-

OFF

PULSING

OFF

ARM

No

No

-

-

-

-

PULSING

OFF

OFF

ARM

Yes

No

-

-

-

-

OFF

ON

ON

ARM

Yes

No

-

-

Yes

-

PULSING

PULSING

OFF

ARM

-

Yes

No

No

-

-

ON

OFF

OFF

ARM

-

Yes

Yes

No

-

-

ON

ON

ON

ARM

-

Yes

No

Yes

-

No

ON

OFF

OFF

ARM

-

Yes

No

Yes

-

Yes

PULSING

ON

ON

ARM

-

Yes

-

-

Yes

-

PULSING

PULSING

OFF

Remote Management

It is possible to manage all aspects of the ZDR remotely from a Network Operations Centre, for initial setup,

ongoing operation, maintenance and troubleshooting. The following section describes the features available for

remotely managing ZDR installations.

Gateway API

EpiSensor’s Gateway has a RESTful API which can be used to send commands to the ZDR node, change settings

and query data.

For more detailed information on the Gateway API, and the functional available, please refer to the Gateway API

User Guide (EpiSensor Document Ref. No. ESE-008-08)

Page 17

of 37

Firmware Updates

The firmware of the ZDR can be updated both locally (via a serial communications cable) and over-the-air via the

ZigBee wireless network.

Important Note

All parts of the circuit within the enclosure must be considered to be at dangerously high

mains voltage when the unit is connected to a mains voltage source.

For detailed instructions on updating the ZDR (and other EpiSensor nodes) over-the-air please refer to the

document “How to Bootload on a Live Gateway” (EpiSensor Document Ref. EPI-064-00).

For additional advice and support, please email [email protected]

Hardware Features

This section has an overview of the various features / components of the ZDR. For more detailed information on

any part, please email [email protected]

Page 18

of 37

Function

Description

A

Mains power supply

B

Voltage Reference Terminals

C

Front Panel Interface (Indicator LED’s)

D

Current Transformer Terminals

E

Modbus Terminals

F

Front Panel Interface (Key Switch and Push Button)

G

Dual Pulse Input Terminals

H

Relay Terminals

I

Dual 4-20mA Terminals

J

ZigBee Wireless Module

K

Mode Button & Status LED

Page 19

of 37

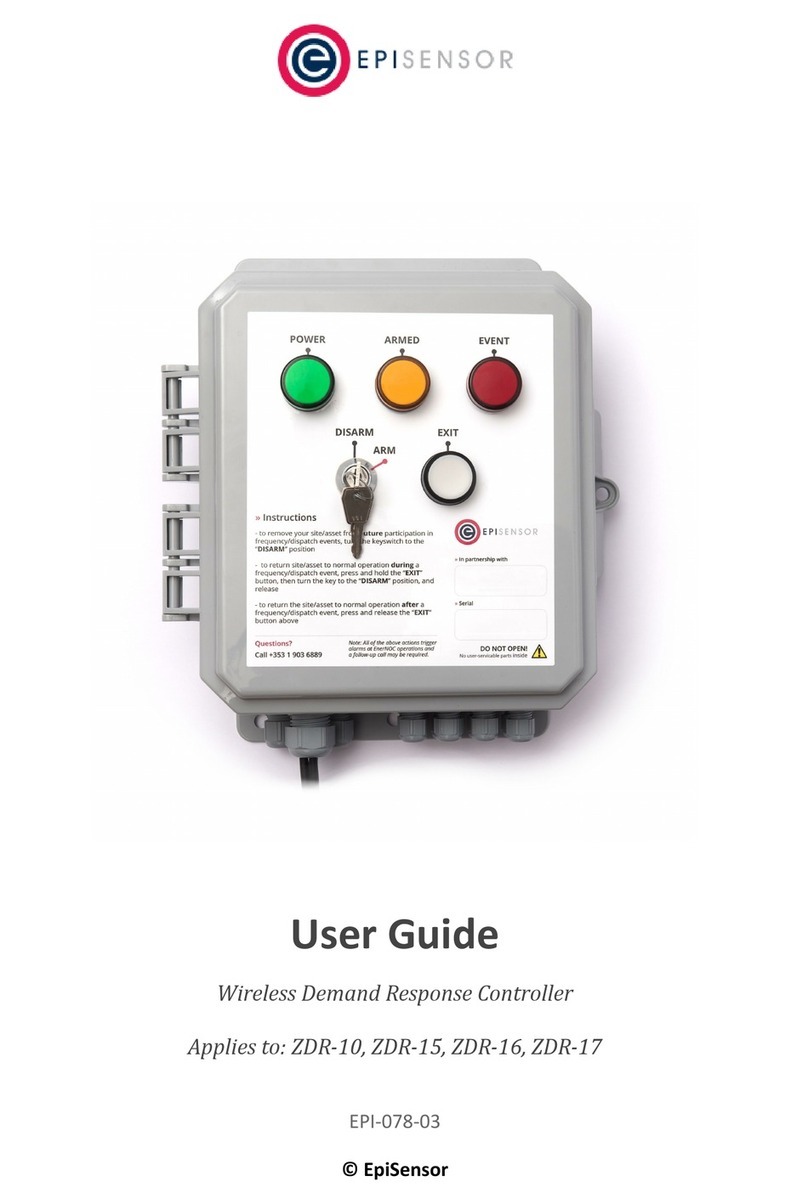

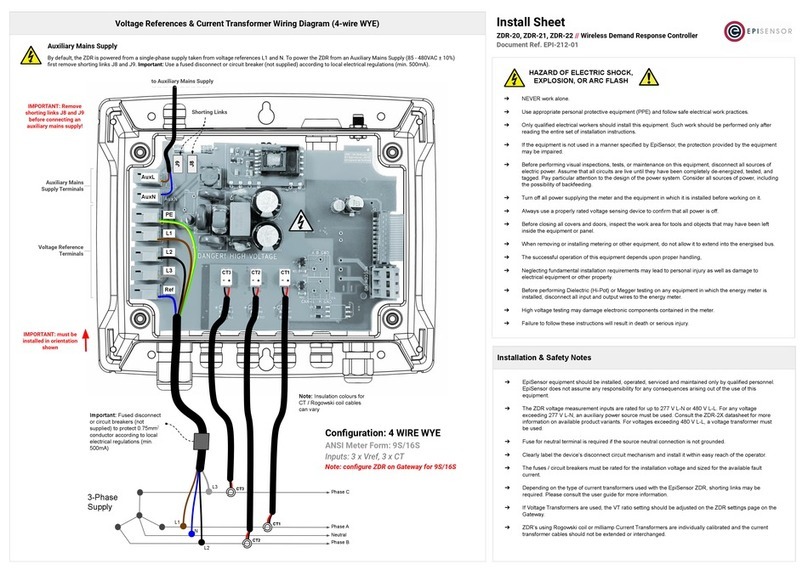

Power Supply

There is an on-board mains power supply in the ZDR that provides 12V, 5V and 3.3V DC to various parts of the

product. This section describes how to connect an AC supply to the ZDR safely, and how to protect the cable and

the product.

Power Supply Wiring

The on-board mains power supply in the ZDR is designed to accept a single phase voltage from 85 VAC to 265

VAC at either 50Hz or 60Hz.

Important Safety Note

The ZDR should be connected via a switched junction box and breaker to protect the cable.

Also, please ensure that the live connection is made on the same circuit as the neutral

connection where residual-current devices (RCD’s) are used.

Installation should only be carried out only by personnel qualified in the installation of

electrical equipment. All parts of the circuit within the enclosure must be considered to be

at dangerously high mains voltage when the unit is connected to a mains voltage source.

The power consumption of the ZDR at full load is less than 10 Watts. 1.5mm2 single phase mains cable rated at

600 Volts should be used to make the connection.

Please refer to the document “Mains Power Supply, Voltage References & Current Transformers” (EpiSensor

Document Ref. No. EPI-065-00) for detailed wiring instructions.

It is possible to use the same mains supply for the voltage reference and to power the ZDR by looping one phase

of the 3-phase supply between the voltage reference terminals (Function “B” above) and the mains power

supply terminals (Function “A”).

However, care should be taken, particularly for Demand Response applications, that the power supply is

constant and won’t be interrupted during a DR event - as this would affect the operation of the ZDR.

For more information on the technical specification of the ZDR power supply, please refer to EpiSensor ZDR

Datasheet.

Protection

This section will be completed in a future release of the user guide. Information to be included:

Page 20

of 37

This manual suits for next models

2

Table of contents

Other EpiSensor Controllers manuals

Popular Controllers manuals by other brands

KiWi Lighting

KiWi Lighting TopLedLight BY-CON-DR1903B manual

Sferalabs

Sferalabs Strato Pi UPS Advanced configuration guide

Ebmpapst

Ebmpapst CN1090 Operating and maintenance instructions

ICON

ICON P1-NANO quick start guide

Zero88

Zero88 Chilli Master operating manual

Data Video

Data Video RMC-300C instruction manual