E+E Elektronik HTS801 User manual

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 2

Content

1 General Information........................................................................................................................................... 4

1.1 Explanation of Warning Notices and Symbols ............................................................................................ 4

1.2 Safety Instructions ..................................................................................................................................... 5

1.2.1. General Safety Instructions ............................................................................................................................... 5

1.2.2. Alarm Module with Voltages >50V (Option AM2) ............................................................................................... 5

1.2.3. Integrated power supply 100 - 240 V AC (Option AM3)...................................................................................... 5

1.2.4. Intended Use..................................................................................................................................................... 5

1.2.5. Mounting, Start-up and Operation...................................................................................................................... 6

1.3 Environmental Aspects............................................................................................................................... 7

1.4 ESD Protection ......................................................................................................................................... 7

2 Scope of Supply ................................................................................................................................................ 7

3 Product Description .......................................................................................................................................... 8

3.1 General...................................................................................................................................................... 8

3.2 Product Design .......................................................................................................................................... 8

3.3 Configuration Interface............................................................................................................................... 9

3.4 Operation and Heating Modes ..................................................................................................................10

3.4.1. Overview Operation Modes and Types ............................................................................................................ 10

3.4.2. Automatic ReCovery (ARC) against Chemical Pollution .................................................................................. 10

3.4.3. Condensation Guard (CG) against Temporary Condensation .......................................................................... 12

3.4.4. High Humidity Guard (H2G) against Continous High Humidity and Condensing Conditions............................. 13

3.5 Optional Features .....................................................................................................................................13

3.5.1. TFT Colour Display.......................................................................................................................................... 13

3.5.2. rapidX Smart Probe (Option PC7) ................................................................................................................... 15

3.5.3. ARC Module (Option AM1) .............................................................................................................................. 16

3.5.4. Alarm Module (Option AM2) ............................................................................................................................ 17

3.5.5. Integrated Power Supply 100 - 240 V AC (Option AM3)................................................................................... 19

3.5.6. RS485 Module - Modbus RTU (Option J3) ...................................................................................................... 20

3.5.7. Ethernet Module - Modbus TCP (Option J4) .................................................................................................... 20

3.6 Dimensions ...............................................................................................................................................22

4 Mounting and Installation ................................................................................................................................23

4.1 Sensor Enclosure......................................................................................................................................23

4.2 General Information for Mounting HTS801 Sensing Probes......................................................................24

4.3 Remote Sensing Probe Type T5 ...............................................................................................................25

4.4 Remote Sensing Probe Type T7 ...............................................................................................................25

4.4.1. Installation at normal pressure......................................................................................................................... 25

4.4.2. Pressure-tight Installation ................................................................................................................................ 26

4.5 Remote Sensing Probe Type T9 ...............................................................................................................27

4.6 Remote Sensing Probe Type T10 .............................................................................................................29

4.6.1. Installation of the Probe directly in the Process ............................................................................................... 29

4.6.2. Installation of the Probe with Ball Valve Set..................................................................................................... 30

4.7 Remote Sensing Probes Type T17............................................................................................................31

4.7.1. Installation at Normal Pressure........................................................................................................................ 31

4.7.2. Pressure-tight Installation ................................................................................................................................ 32

4.8 Remote Sensing Probes Type T28............................................................................................................32

5 Electrical Connection .......................................................................................................................................32

5.1 Electrical Connection and Wiring Overview...............................................................................................33

5.2 With Cable Glands ....................................................................................................................................36

5.3 Plug Options .............................................................................................................................................36

5.4 ARC Module (Option AM1)........................................................................................................................36

5.5 Alarm Module (Option AM2) ......................................................................................................................36

5.6 Integrated Power Supply 100 - 240 V AC (Option AM3) ............................................................................37

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 3

6 Setup and Configuration ..................................................................................................................................38

6.1 PCS10 Product Configuration Software ....................................................................................................38

6.1.1. General ........................................................................................................................................................... 38

6.1.2. Simulation Mode.............................................................................................................................................. 39

6.1.3. Analogue outputs ............................................................................................................................................ 39

6.2 RS485 Digital Interface .............................................................................................................................39

6.2.1. Modbus RTU Setup ......................................................................................................................................... 39

6.2.2. Modbus Register Map ..................................................................................................................................... 41

6.2.3. Freely Configurable Custom Modbus Map....................................................................................................... 42

6.2.4. Device Status Indication .................................................................................................................................. 43

6.2.5. Module Status Indication ................................................................................................................................. 44

6.2.6. Device Operating Conditions Indication........................................................................................................... 44

6.3 Modbus RTU Example ..............................................................................................................................45

7 Maintenance and Service .................................................................................................................................46

7.1 Self Diagnosis and Error Messages ..........................................................................................................46

7.1.1. Error Messages on the Display........................................................................................................................ 46

7.1.2. Status and Error Messages via LEDs .............................................................................................................. 46

7.2 Cleaning the Sensing Head and Filter Cap Replacement..........................................................................47

7.3 Automatic ReCovery (ARC) ......................................................................................................................47

7.4 RH and T Calibration and Adjustment .......................................................................................................47

.......................................................................... 49

7.4.2. RH and T Adjustment and Calibration for Type T7 ........................................................................................... 49

............................................................................... 49

7.5 Fuse Replacement for Integrated Power Supply 100 - 240 V AC (Option AM3) ........................................50

8 SpareParts / Accessories ................................................................................................................................50

9 Technical Data ..................................................................................................................................................51

10 Conformity ........................................................................................................................................................54

10.1 Declarations of Conformity........................................................................................................................54

10.2 FCC Part 15 Compliance Statement .........................................................................................................54

10.3 ICES-003 Compliance Statement..............................................................................................................54

11 Appendix:DisplayMenuStructure..................................................................................................................55

11.1 Overview...................................................................................................................................................55

11.2 Detailed Information..................................................................................................................................55

11.3 Optional Menus.........................................................................................................................................59

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 4

1 General Information

This user manual serves for ensuring proper handling and optimal functioning of the device. The user manual

shall be read before commissioning the equipment and it shall be provided to all staff involved in transport,

installation, operation, maintenance and repair. E+E Elektronik Ges.m.b.H. does not accept warranty and liability

claims neither upon this publication nor in case of improper treatment of the described products.

This document may contain technical inaccuracies and typographical errors. The content will be revised on a

regular basis. These changes will be implemented in later versions. The described product(s) can be improved

and changed at any time without prior notice.

The user manual may not be used for the purposes of competition without the written consent of E+E Elektronik

Ges.m.b.H. and may not be forwarded to third parties. Copies may be made for internal purposes. All information,

technical data and diagrams included in these instructions are based on the information available at the time of

writing.

PLEASENOTE

Find this document and further product information on our website at .

1.1 ExplanationofWarningNoticesandSymbols

Safety precautions

Precautionary statements warn of hazards in handling the device and provide information on their prevention.

The safety instruction labeling is classified by hazard severity and is divided into the following groups:

DANGER

Danger indicates hazards for persons. If the safety instruction marked in this way is not followed, the hazard

will verly likely result in severe injury or death.

WARNING

Warning indicates hazards for persons. If the safety instruction marked in this way is not followed, there is a

risk of injury or death.

CAUTION

Caution indicates hazards for persons. If the safety instruction marked in this way is not followed, minor or

moderate injuries may occur.

NOTICE

Notice signals danger to objects or data. If the notice is not observed, damage to property or data may

occur.

Informational notes

Informational notes provide important information which stands out due to its relevance.

INFO

The information symbol indicates tips on handling the device or provides additional information on it. The

information is useful for reaching optimal performance of the device.

The title field can deviate from “INFO” depending on the context. For instance, it may also read “PLEASE

NOTE”.

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 5

1.2 Safety Instructions

1.2.1. General Safety Instructions

NOTICE

Improper handling of the device may result in its damage.

The HTS801 enclosure, the sensing probe and the sensing module shall not be exposed to unnecessary

mechanical stress.

Do not apply the supply voltage to the RS485 data lines.

The HTS801 electronics is sensitive to electrostatic discharge (ESD), appropriate protective measures shall

be taken when touching it.

When replacing the filter cap make sure not to touch the sensing elements.

The device must be operated with the filter cap on at all times.

For sensor cleaning and filter cap replacement please see “Cleaning Instructions” at www.epluse.com.

Installation, electrical connection, maintenance and commissioning shall be performed by qualified

personnel only.

The devices are designed for the operation with class III supply (EU) and class 2 supply (NA).

The power supply must be switched off before opening the housing.

Use the HTS801 only as intended and observe all technical specifications.

An existing Ethernet connection must be disconnected before opening the enclosure.

1.2.2. AlarmModulewithVoltages>50V(OptionAM2)

WARNING

Notice signals danger to objects or data. If the avoidance instructions are not observed, damage to property

or data may occur.

The optional alarm module is isolated from the low-voltage side of the HTS801 by a special partition; this

must remain fitted at all times in the back section of the enclosure.

The HTS801 enclosure must be tightly closed during operation. An open enclosure corresponds to IP00

and exposes components carrying dangerous voltage. Any work (maintenance for instance) on the device

may be performed by qualified staff only.

1.2.3. Integratedpowersupply100-240VAC(OptionAM3)

WARNING

Notice signals danger to objects or data. If the avoidance instructions are not observed, damage to property

or data may occur.

The HTS801 enclosure must be tightly closed during operation. An open enclosure corresponds to IP00

and exposes components carrying dangerous voltage. Any work (maintenance for instance) on the device

may be performed by qualified staff only.

1.2.4. IntendedUse

The HTS801 sensors are designed to meet the highest demands of stable and highly accurate measurements of

relative humidity (RH) and temperature (T) under the most challenging conditions The RH and T sensor handles a

environmental conditions such as constant high humidity and chemical contamination.

With different intelligent operating modes, HTS801 can be perfectly tailored to the specific needs of each

measurement task. Depending on the type and duration of the exposure (humidity, chemicals), the monolithic RH

and T sensing element is exposed to an appropriate heating strategy.

The use of the HTS801 in any other way than described in this manual bears a safety risk for people and the

entire measurement installation and is therefore not allowed.

The manufacturer cannot be held responsible for damages as a result of incorrect handling, installation, and

maintenance of the equipment.

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 6

The device may only be powered as described in this manual.

In order to avoid damage to the instrument or health hazards, the measuring equipment must never be

manipulated with tools that are not specifically described in this manual. The sensor may only be utilized in

accordance with the conditions defined in the technical data. Otherwise, measurement inaccuracies will occur and

equipment failures cannot be ruled out. The steps recommended by the manufacturer for installation, inspections

and maintenance work must be observed and carried out for the safety of the user and for the functionality of the

equipment.

Unauthorized product modification leads to loss of all warranty claims. This may be accomplished only with an

explicit permission of E+E Elektronik!

WARNING

Non-compliance with the product documentation may cause safety risk for people and the entire

measurement installation.

The manufacturer cannot be held responsible for damages as a result of incorrect handling, installation and

maintenance of the device.

Do not use HTS801 in explosive atmosphere or for measurement of aggressive gases.

This device is not appropriate for safety, emergency stop or other critical applications where device

malfunction or failure could cause injury to human beings.

The device may not be manipulated with tools other than specifically described in this manual.

NOTICE

Failing to follow the instructions in this user manual may lead to measurement inaccuracy and device

failures.

The HTS801 may only be operated under the conditions described in this user manual and within the

specification included in chapter 9 Technical Data.

Unauthorized product modification leads to loss of all warranty claims. Modification may be accomplished

only with an explicit permission of E+E Elektronik Ges.m.b.H.!

1.2.5. Mounting,Start-upandOperation

The HTS801 humidity and temperature sensor has been produced under state of the art manufacturing

conditions, has been thoroughly tested and has left the factory after fulfilling all safety criteria. The manufacturer

has taken all precautions to ensure safe operation of the device. The user must ensure that the device is set up

and installed in a way that does not impair its safe use. The user is responsible for observing all applicable local

and international safety guidelines for safe installation and operation of the device. This user manual contains

information and warnings that must be observed by the user in order to ensure safe operation.

PLEASENOTE

The manufacturer or his authorized agent can be only be held liable in case of willful or gross negligence.

In any case, the scope of liability is limited to the corresponding amount of the order issued to the

manufacturer. The manufacturer assumes no liability for damages incurred due to failure to comply with the

applicable regulations, operating instructions or the specified operating conditions. Consequential damages

are excluded from the liability.

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 7

WARNING

Non-compliance with the product documentation may cause accidents, personal injury or property damage.

Mounting, installation, commissioning, start-up, operation and maintenance of the device may be

performed by qualified staff only. Such staff must be authorized by the operator of the facility to carry out

the mentioned activities.

The qualified staff must have read and understood this user manual and must follow the instructions

contained within.

All process and electrical connections shall be thoroughly checked by authorized staff before putting the

device into operation.

Do not install or start-up a device supposed to be faulty. Make sure that such devices are not accidentally

used by marking them clearly as faulty.

A faulty device may only be investigated and possibly repaired by qualified, trained and authorized staff. If

the fault cannot be fixed, the device shall be removed from the process.

Service operations other than described in this user manual may only be performed by the manufacturer.

1.3 EnvironmentalAspects

PLEASENOTE

Products from E+E Elektronik Ges.m.b.H. are developed and manufactured in compliance with all relevant

environmental protection requirements. Please observe local regulations for the disposal of the device.

For disposal, the individual components of the device must be separated according to local recycling

regulations. The electronics shall be disposed of correctly as electronics waste.

1.4 ESD Protection

The sensing elements and the electronics board are ESD (electrostatic discharge) sensitive components

of the device and must be handled as such. Failure to do so may damage the device by electrostatic

discharge when touching exposed sensitive components.

2 Scope of Supply

Included in all versions Withoption

HTS801 according to ordering guide

Manual HTS801

Inspection certificate according to

Mating plug for integrated power supply AM3

E6

Mating plug HPP V4 RJ45 Cat5 J4

M16 cable gland

Cut-in fitting HTS801-M1T9

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 8

3 Product Description

3.1 General

environmental condition like high humidity and chemical pollution. It offers various probe and cable lengths (for

the dimensions, please refer to chapter 3.6 Dimensions)

ProbeType Description

T5 Remote probe up to 180 °C (356 °F)

T10 Remote probe, pressure-tight up to 20 bar (300 psi) and 180 °C (356 °F), with sliding fitting

T9 Remote probe, pressure-tight up to 300 bar (4 350 psi) and 180 °C (356 °F), with cut-in

fitting

T17 Two remote probes, pressure-tight up to 20 bar (300 psi) and 180°C (356 °F),

with optional cut-in fitting

T7 Remote probe for cut-in fitting, pressure-tight up to 20 bar (300 psi) and 180 °C (356 °F),

with optional cut in fitting, for dew point (Td) measurement

T28 Two remote probes, for meteorological applications

The employed high-end E+E RH and T sensing element is heated autonomously and enables reliable and

long-term stable measurements in extremely humid or chemically polluted environments. The monolithic

contamination. In addition, it is perfectly protected by the E+E proprietary coating.

Different heating modes of the monolithic RH and T sensing element allow for best adaption to the specific

needs of each measuring task. Furthermore, types T7, T17 and T28 offer a dual heating system (probe body

and sensing element are heated) to prevent condensation on the RH sensing element and on the probe body for

continuous high humidity operation.

The measured data is available on two freely scalable analogue outputs, on the RS485 (Modbus RTU) or

Ethernet-PoE (Modbus TCP) interface and on the alarm (relay) outputs. The configuration and the RH and T

adjustment of the HTS801 can be performed with the free PCS10 Product Configuration Software. An optional

3.5” colour display with push-buttons is available for configuration and visualisation.

The HTS801 with PC7 option (see ordering guide) features the intelligent pluggable rapidX probe, which enables

a plug-and-play probe exchange.

The optional Automatic ReCovery (ARC) module allows for external triggering of the heating functionality.

3.2 Product Design

3.5" TFT colour display

Standard cable gland / connector*)

Back section

Front section

USB service interface

Front section with electronics,

display*) and probe cable

Back section with electrical connection,

additional module*) and mounting holes

5 push-buttons for configuration menu

Probe connection / socket*)

Standard cable glands / connectors*)

Back section

Front section

*) Optional

*) Depending on electrical connection options

Fig. 1 HTS801 perspective view

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 9

3.5" TFT colour display

Standard cable gland / connector*)

Back section

Front section

USB service interface

Front section with electronics,

display*) and probe cable

Back section with electrical connection,

additional module*) and mounting holes

5 push-buttons for configuration menu

Probe connection / socket*)

Standard cable glands / connectors*)

Back section

Front section

*) Optional

*)

Depending on electrical connection options

Fig. 2 HTS801 connector-side view

Connection terminal block

RS485 add-on chip

Mounting plate

Space for optional modules

Back section

Front section

Fig. 3 HTS801 modular polycarbonate enclosure inside view

3.3 Configuration Interface

The HTS801 is ready to use and does not require any configuration by the user. The factory setup of HTS801

corresponds to the type number ordered. Please refer to the datasheet at . If needed, the

user can change the factory setup with the

Free PCS10 Product Configuration Software.

Please refer to chapter 6.1 PCS10 Product Configuration Software.

Display and push-buttons (if the optional display is selected)

Please refer to chapter 1.2.1. General Safety Instructions.

Modbus RTU protocol (if the RS485 option is selected).

Please note that configuration is limited to the Modbus communication settings.

Please refer to chapter 6.2 RS485 Digital Interface.

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 10

3.4 OperationandHeatingModes

3.4.1. OverviewOperationModesandTypes

OperatingMode HTS801 Type Useinenvironmentswith FunctionTrigger

Condensation Guard (CG) Temporary condensation RH setpoint1)

High Humidity Guard (H2G) Continous high humidity and

condensation Always on

1) Factory setting: acc. to ordering guide

3.4.2. AutomaticReCovery(ARC)againstChemicalPollution

When capacitive humidity sensing elements are exposed to chemical pollution (e.g. detergent residues), the presence

of foreign molecules can distort the measurement reading of the sensor. With the ARC function foreign molecules

can be evaporated from the sensing element by brief and intensive heating.

All HTS801 types support the ARC function.

PLEASENOTE

Before a recalibration is done after an ARC cycle, reconditioning of the sensing element is recommended.

For best reconditioning, please allow 2 free calibration cycles between 15 %RH and 90 %RH in steps of

~20 %RH and 20 min stabilisation time.

The start of the ARC function can be triggered as follows:

Manual: by using PCS10 or via display and push-buttons. A manual start of the ARC function is recommended when

measurement readings deviate significantly from a calibration reference.

Cyclic: by using PCS10 or order code option ARC1 (24 h), ARC can be configured to start periodically at a

certain time interval.

The cyclic option can be extended to include an automatic start at power on. This function can be switched on

and off via PCS10, display and push-buttons or using order code option ARC2 (24 h power on).

Periodic heating shall be used to minimize drift effects in applications with high chemical pollution. The ideal cycle

time depends on the type of pollution and its concentration and has to be determined empirically.

heating

time

cool-down

time

freezing

heating 1 heating 2

definable interval time

T [°C]

T [°F]

t [min]

Fig. 4 ARC cycle

External: by using the optional ARC module the function can be activated using an external signal see chapter

3.5.3. ARC Module (Option AM1). RS485 or Ethernet with Modbus commands can be used to start ARC as well.

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 11

The ARC parameters can be configured via PCS10 or display and push-buttons:

Heatingduration: Defines the time in which the monolithic measurement cell is intensively heated. A heating

time of at least 20 minutes (20 min = factory setting) is recommended if chemical pollution has occurred.

Recoveryduration: The cool-down time is necessary for the sensing element to cool back down to ambient

temperature. The cool-down time should be >3 minutes (3 min = factory setting) in order to prevent measurement

errors.

During the ARC process (heating and cool-down time) the values on the outputs are frozen. In other words, the

measuring values at the outputs are kept constant during the ARC cycle.

The orange LED D5 at the main PCB near the USB interface is permanently lit during the ARC process. An

orange frame and text on the display also indicates the ARC process. On the status page of the display, the

remaining ARC process time in seconds is displayed.

T [°C]

T [°F]

start ARC

heating time

chem. loads (> 20 min)

cool-down time

min. > 3 min

freezing period of output signals

ambient temperature

t [min]

Fig. 5 ARC process in detail

PLEASENOTE

If the defined cool-down time is too short, the measurements may be incorrect.

heating time

chem. loads (> 20 min)

cool-down time

e.g. 2 min

freezing period of output signals

T [°C]

T [°F]

t [min]

humidity output

temperature output

ambient humidity

ambient temperature

RH [%]

Fig. 6 ARC cycle with cool-down time too short

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 12

3.4.3. CondensationGuard(CG)againstTemporaryCondensation

Temporary condensation on the sensing element in highly humid environments is eliminated when a specified

RH set point (factory setting: acc. to order code) is reached. By intensive heating of the sensing element for 10

seconds occurring dew is evaporated. Due to its monolithic structure, the sensing element cools off quickly within

approximately 3 minutes and returns to its measurement function.

If condensation is still detected after the CG process, it restarts immedately or after a predefined lock time.

During the complete heating and cool-down process, the values on the outputs are frozen. In other words, the

measuring values at the analog outputs are kept constant during the CG cycle.

PLEASENOTE

The lock time has to be set according to the application needs. A too short lock time might result in

permanent freezing of the outputs.

The CG function can be preconfigured using the order code options. The lock time is configurable.

T [°C]

T [°F]

start CP cycle

RH > RH setpoint

heating time

temp. condensation (10 s)

cool-down time

min. > 3 min

freezing period of output signals

ambient temperature

t [min]

Fig. 7 CG process in detail

RH [%] start CG cycle

heating time

10 s

cool-

down time

3 min

definable threshold e.g. 99 %

ambient humidity

ambient temperature

T [°C]

t [min]

t [min]

Fig. 8 CG cycles with a lock time of 30 min

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 13

PLEASENOTE

When heating has ended, the system blocks any subsequent heating for 30 minutes. In other words, if the

ambient humidity remains above the defined set point after the initial heating, the next heating starts again

after 30 minutes.

3.4.4. HighHumidityGuard(H2G)againstContinousHighHumidityandCondensingConditions

In environments with continuous high humidity even the smallest deviations between the temperature of

influences the measurement accuracy and increases the risk of deposits on the active sensor surface that lead to

parallel resistances and parasitic capacitances.

The dual heating system of the HTS801 prevents both: condensation on the RH sensing element and on the

probe body by a regulated heating strategy. This leads to very short response time and fast recovery after

condensing conditions. Furthermore, it enables accurate RH measurement even under continuously high humidity

and condensing conditions. RH and T can be determined precisely with the help of the heated monolithic sensing

element and the calculated dew point.The relative humidity near condensation is determined with the T value of

The following HTS801 types incorporate the dual heating system:

T17: with additional T Sensor included for RH measurement

T28: with additional T Sensor included for RH measurement in meteorological applications

T7: one probe design for Td measurement only

3.5 OptionalFeatures

3.5.1. TFTColourDisplay

This option includes a 3.5" TFT colour display and push-buttons for full configuration.

Configuration Menu

Detailed information on the configuration menu see chapter 11 Appendix: Display Menu Structure.

Menu

Data logging

Display settings Display layout - measurands | brightness | orientation | display alarm

Analogoutput

Heating mode settings

Alarmoutput*

Customer

adjustment

reset to factory adjustment | calibration status

Modbussettings*

IPsettings*

Device settings Settings - language | date, time | parameters | password protection

Status Status and device information

* Menu only available with the corresponding optional module.

Fig. 9 Principal configuration menu structure

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 14

CONFIGURATIONHINT

Display alarms can be configured via display and push-buttons only. Configuration is to be done in the

“Display settings” menu.

calculated quantity.

During the first 5 seconds after display start-up, the data logger and the configuration menu are initialized.

1

2

3

4

5

Chart + data logger

Configuration menu

Status information

Buzzer ON / OFF

Error indication / information

Fig. 10 Control panel with display and push-buttons

Data Logging

The TFT display with the integrated data logging function saves all measured and calculated values to the internal

memory. The data logger has a real time clock (UTC time) with a battery back-up.

NOTICE

Changing the UTC time erases all stored data.

second to 12 hours. The data logging menu is also used to select the data points that make up the graph and for

scaling, see chapter 11.2, Fig. 48 Data logging.

1 Home button

2 Configuration incl. data logger menu

3 Time scale for the graph (5 min - 3 months)

4 Cursor

Axis 1 value

(cursor position)

Axis 1

Axis 2

Axis 2 value

(cursor position)

Date

(cursor position)

Time

(cursor position)

Fig. 11 Data logging

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 15

Each point in the graph represents a logged value. The points are connected by linear interpolation.

One point

Fig. 12 Data logger graph

The data logger memory works according to the first in first out (FIFO) principle: new data is stored while the

The logged data can be downloaded with PCS10 Product Configuration Software as .csv file by choosing the

measurands and the time period.

Status Information

The status information shows all actual HTS801 settings and measured values.

Fig. 13 Status information

Buzzer

If a previously configured limit value is violated, a buzzer sounds periodically. This buzzer can be switched off or

on here. Factory default is on.

Error Indication

As soon as an error occurs, an indication shows the error code.

3.5.2. rapidXSmartProbe(OptionPC7)

The HTS801 with PC7 option features the intelligent pluggable rapidX probe. The rapidX smart probe enables

a plug-and-play probe exchange during operation without any configuration, adjustment or calibration. The

sensing element data of the rapidX smart probe is determined in the E+E RH factory calibration systems. Upon

connection to the HTS801, the probe automatically uploads its specific parameters to the HTS801 electronics.

This enables simple maintenance procedures at the customer’s site without “down time” due to cost-intensive

quick replacement without any tools at any time, even during operation (hot-swap).

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 16

PLEASENOTE

Replacing a rapidX probe results in an additional uncertainty in the RH measurement. This is due to the

variation of the capacitive coupling at the connector.

To ensure the initial accuracy of the HTS801, an adjustment after the rapidX smart probe exchange is

recommended.

If rapidX smart probes with different cable lengths are exchanged on an HTS801 (e.g. smart probe change

from 10 m to 1 m cable length), an adjustment must be carried out.

For Type T17 only the RH probe is exchangeable. The T probe is fixed.

3.5.3. ARCModule(OptionAM1)

The additional circuit board located in the lower part of the HTS801 enclosure offers the possibiliy to start the

ARC heating function with external signal.

Fig. 14 ARC module in polycarbonate enclosure

During the ARC process the orange LED 5 at the main PCB near the USB interface is permanently lit (refer to

Fig. 43). An orange frame and text on the display also indicates the ARC process. The remaining time span of the

ARC process is indicated in seconds in a device information register. Please refer to chapter 6.2.1. Modbus RTU

Setup. On the status page of the optional display, the remaining seconds of the ARC process are displayed.

Heating process and trigger parameters can be set and changed with the PCS10 and via the display and push-

buttons.

Electrical Connection

Terminal“Input”:Externalsignaltrigger

IN1 signal (24 V DC; 10 mA)

IN2 GND

Terminal“Status”:Feedbacksignaltotheexternalcontrol

The NO contact is closed during the heating process, otherwise opened.

open

closed

IN1 +24 V Input

NO

Output

Relais

ARC

Freezed outputs

>0.5 s

Fig. 15 ARC timing

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 17

3.5.4. AlarmModule(OptionAM2)

The module offers two freely configurable relay outputs for alarm or control purposes. Various operation modes

are available including switch hysteresis, switch window and error indication. The error modes can be configured

independently from each other. The measurands at the outputs as well as switching points, hysteresis and the

buttons (see chapter 11.3 Optional Menus, Fig. 55 Alarm output).

SwitchHysteresisMode

The switching behavior is determined by entering a switching point and an associated hysteresis value.

t

closed

open

closed

open

Normal state: Standard

Normal state: Standard

Terminal 1-2 / 4-5

Terminal 2-3 / 5-6

Switching point

Hysteresis

RH [%]

Fig. 16 Example hysteresis mode on both alarm outputs using normal state standard

Additionally, detected errors are signaled at the alarm output.

t

closed

open

closed

open

Error occurs

No error

RH [%]

Switching point

Hysteresis

Terminal 2-3

Terminal 5-6

Normal state: Standard

Normal state: Inverted

Fig. 17 Example of hysteresis mode with error occurring.

SwitchWindowMode

The switching behavior is determined by entering two switching points and two associated hysteresis values.

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 18

t

closed

open

closed

open

Normal state: Standard

Normal state: Standard

Terminal 1-2 / 4-5

Terminal 2-3 / 5-6

Switching point 2

Hysteresis 2

Switching point 1

Hysteresis 1

RH [%]

Fig. 18 Example window mode on both alarm outputs using normal state standard

Additionally, detected errors are signaled at the alarm output.

Error Indication Mode

When error indication mode is selected, various errors will trigger the alarm output.

t

closed

open

Error occurs

No error

Terminal 5-6 Normal state: Inverted

Fig. 19 Example of error mode on relay 1 using normal state inverted.

PLEASENOTE

An alarm output in this operation mode is used for error indication only (no combination with switching points

possible).

ElectricalConnectionandSwitchLoad

NO

NC

C

NC 6

NO 4

C5

NC 3

NO 1

C2

NO

NC

C

Normal state:

Standard

Normal state:

Inverted

REL 1

REL 2

RELAY 2RELAY 1

PROTECTIVE CONDUCTOR TERMINAL:

Maximum wire cross section: 1.5 mm2

Fig. 20 Alarm module (option AM2)

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 19

WARNING

The metal enclosure must be grounded during operation. National regulations for installation must be observed!

SwitchLoad

Max. switch load

Min. switch load

Tab. 1 Maximum and minimum switch loads

WARNING

No overcurrent and short circuit protection. Both relays shall be connected to either high oder low voltage.

3.5.5. IntegratedPowerSupply100-240VAC(OptionAM3)

Polycarbonate enclosure Stainless steel enclosure

Fig. 21 Power supply module (option AM3)

WARNING

The AM3 option includes a 1.25 A fuse on the 100 - 240 V side. This fuse must not be replaced by the user,

only by the E+E after sales service.

The protection of the supply cable against excess current and short-circuit must be designated to a wire

cross section of 0.8 mm2(AWG 18) (6 A fuse).

The metal enclosure must be grounded during operation.

All national regulations for installation shall be observed!

User Manual HTS801

Humidity and Temperature Sensor for High Humidity and Chemically Polluted Conditions | 20

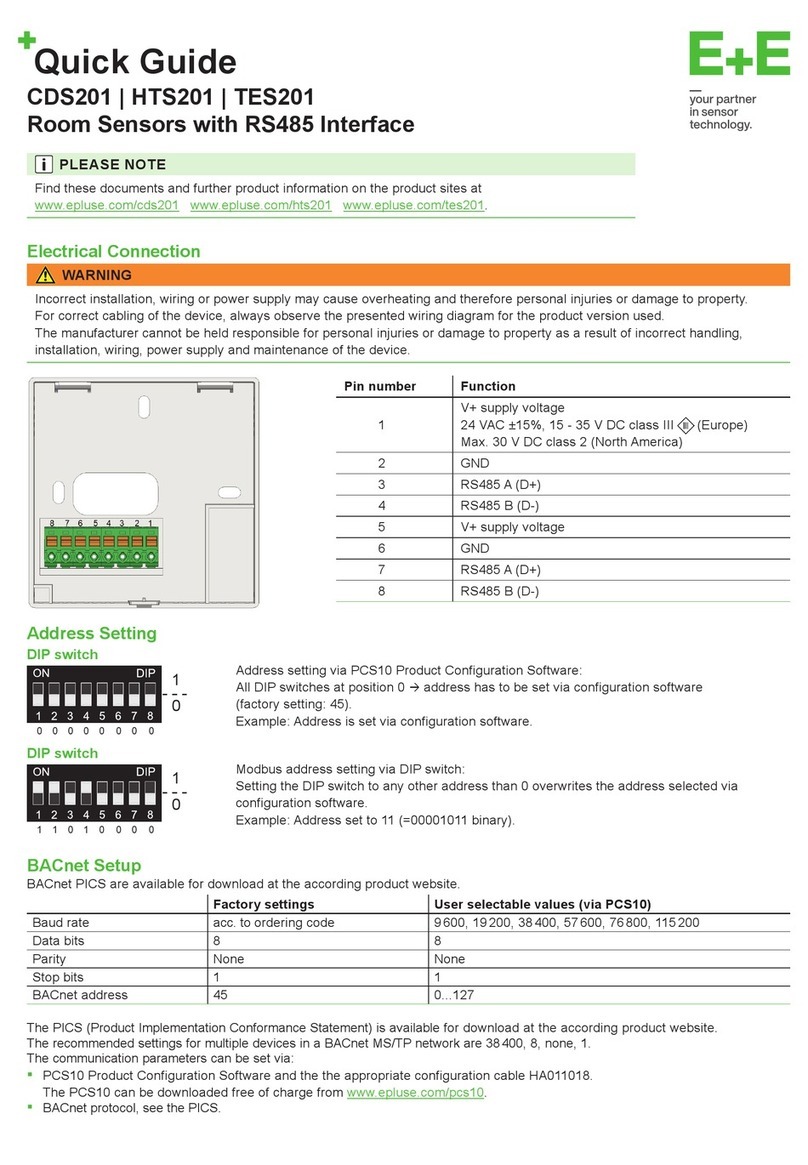

3.5.6. RS485Module-ModbusRTU(OptionJ3)

Up to 32 HTS801 sensors with Modbus RTU interface can be connected in an RS485 bus system (1 unit load).

Slave n

(max. 32) Slave 2

Slave 1

Slave 3

Modbus RTU Master

Fig. 22 2-wire RS485 bus

PLEASENOTE

Both ends of the bus shall be terminated with a resistor Ra

The setup of the Modbus RTU communication can be performed via PCS10 Product Configuration Software or via

display and push-buttons, see chapter 11.3, Fig. 56 Modbus settings.

ModbusRTUprotocolsettings

Factorysettings Userselectablevalues(viaPCS10)

Baud rate

Data bits 8 8

Parity Even None, odd, even

Stop bits 11, 2

Modbus address 230 (0xE6) 1...247

Tab. 2 Modbus RTU protocol settings

PLEASENOTE

3.5.7. EthernetModule-ModbusTCP(OptionJ4)

The Ethernet module features power over Ethernet (PoE) and RJ45 connector with IP65 protection rating.

PLEASENOTE

The Ethernet connection shall be disconnected before opening the enclosure.

AvailableTCPandUDPPorts

Modbus TCP: Port 502

.

The unit identifier of the MBAP header is not used and can be any value from 0 to 255.

Table of contents

Other E+E Elektronik Security Sensor manuals