Epple Maschinen SBS 32 400 V User manual

26.01.07, SBS 32, Drills Page 1 from 33

User manual

Drill SBS 32 400 V

Keep for future reference!

26.01.07, SBS 32, Drills Page 2 from 33

Table of contents

1SAFETY.............................................................................................................. 5

1.1 Safety notes (warning notes).............................................................................6

1.1.1 Classification of hazards........................................................................... 6

1.1.2 More, used pictograms.............................................................................. 7

1.2 Proper use...........................................................................................................7

1.3 Danger, which can emanate from drill ..............................................................8

1.4 Qualification of personnel..................................................................................9

1.4.1 Target group............................................................................................... 9

1.4.2 Authorised personnel................................................................................ 9

1.4.3 The operator must.....................................................................................10

1.4.4 The user must ...........................................................................................10

1.4.5 Special claims to the qualification...........................................................11

1.5 Operator position..............................................................................................11

1.6 Safety equipment..............................................................................................11

1.6.1 Main switch lockable ................................................................................12

1.6.2 Chip protection .........................................................................................12

1.6.3 Safe belt cover ..........................................................................................12

1.6.4 Prohibition, instruction and warning signs.............................................12

1.7 Safety check at the machine............................................................................13

1.8 Personal protective equipment for special work............................................14

1.9 Safety during the use of the machine .............................................................15

1.10 Safety during general maintenance work .......................................................16

1.10.1 Breaking and assuring the machine........................................................16

1.10.2 Use of hoisting devices for attendance work..........................................16

1.10.3 Mechanic attendance work at the machine.............................................17

1.11 Accident report.................................................................................................17

1.12 Electricity ..........................................................................................................17

2TECHNICAL DATA .......................................................................................... 18

2.1 Electrical connection data ...............................................................................18

2.2 Machine data.....................................................................................................18

2.3 Dimensions.......................................................................................................18

2.4 Necessary working room .................................................................................18

2.5 Environmental conditions................................................................................18

2.6 Emissions..........................................................................................................18

3ASSEMBLY...................................................................................................... 19

3.1 Delivery volume................................................................................................19

3.2 Transport...........................................................................................................19

3.3 Storage..............................................................................................................19

3.4 Positioning and assembly................................................................................20

3.4.1 Claims to installation location..................................................................20

3.4.2 Assembly...................................................................................................20

26.01.07, SBS 32, Drills Page 3 from 33

3.4.3 Anchor - free assembly ............................................................................20

3.4.4 Anchor free assembly...............................................................................20

3.4.5 Positioning ................................................................................................20

3.5 First initiation....................................................................................................21

3.5.1 Cleaning.....................................................................................................21

3.5.2 Sight check/ mnaual function check........................................................21

3.5.3 Electrical connection................................................................................21

3.5.4 Function check..........................................................................................21

4HANDLING....................................................................................................... 22

4.1 Safety.................................................................................................................22

4.2 Control and inidcator elements .......................................................................23

4.2.1 Control elements electrical ......................................................................23

4.2.2 Control elements mechanical ..................................................................23

4.3 Activating the machine.....................................................................................24

4.3.1 Release EMERGENCY STOP control.......................................................24

4.3.2 Main switch ...............................................................................................24

4.3.3 Turning direction choice ..........................................................................24

4.3.4 Driving speed choice................................................................................24

4.3.5 Close chip protection ...............................................................................24

4.3.6 Close belt cover ........................................................................................24

4.3.7 Activating ..................................................................................................25

4.3.8 Deactivating...............................................................................................25

4.4 Hand drive.........................................................................................................25

4.5 Adjust depth arrester........................................................................................25

4.6 Table height adjustment...................................................................................25

4.7 Turn, swivel, tilt table .......................................................................................25

4.8 Machine light.....................................................................................................25

4.9 Centre sleeve fetching......................................................................................26

4.10 Working notes...................................................................................................26

4.10.1 General notes............................................................................................26

4.10.2 Fixing the work part in the vice................................................................26

4.10.3 Eject a tool.................................................................................................26

5MAINTENANCE ............................................................................................... 27

5.1 Safety.................................................................................................................27

5.1.1 Preparation................................................................................................27

5.1.2 Recommissioning.....................................................................................27

5.2 Inspection and attendance...............................................................................28

5.2.1 Daily work..................................................................................................28

5.2.2 Weekly work..............................................................................................28

5.2.3 Monthly work.............................................................................................28

5.2.4 Semi –yearly work....................................................................................28

5.3 Maintenance......................................................................................................28

6FAILURES........................................................................................................ 29

7APPENDIX........................................................................................................ 30

26.01.07, SBS 32, Drills Page 5 from 33

1 Safety

Glossary of symbols

Symbol

account

Reference to another

page

Calls on you to get in

action

enumerations

This first part of the operating manual:

Explains the meaning and use of the warning references contained in the

operating manual

Highlights the dangers that might arise for you and others if these instructions are

not followed

Explains how to use the machine properly

Tells you how to avoid dangers

In addition to this operating manual please observe:

Legal regulations for accident prevention

Applicable laws and regulations

The prohibition, warning and mandatory lables as well as the warning notes

You are liable to follow the european norms by installation, operation, maintenance and

reparation of the machine.

If european norms still are outstanding you are liable to use the country –specific

effectual norms.

If necessary you have to take some in –company actions before the use of the machine

to follow the country –specific instructions.

Always keep this document close to the machine.

Support / Information

If you are unable to solve a problem using this manual, please contact us for advice:

Epple Maschinen GmbH

Service und Support

Auf der Breite 2-14

D-73349 Wiesensteig

26.01.07, SBS 32, Drills Page 6 from 33

1.1 Safety notes (warning notes)

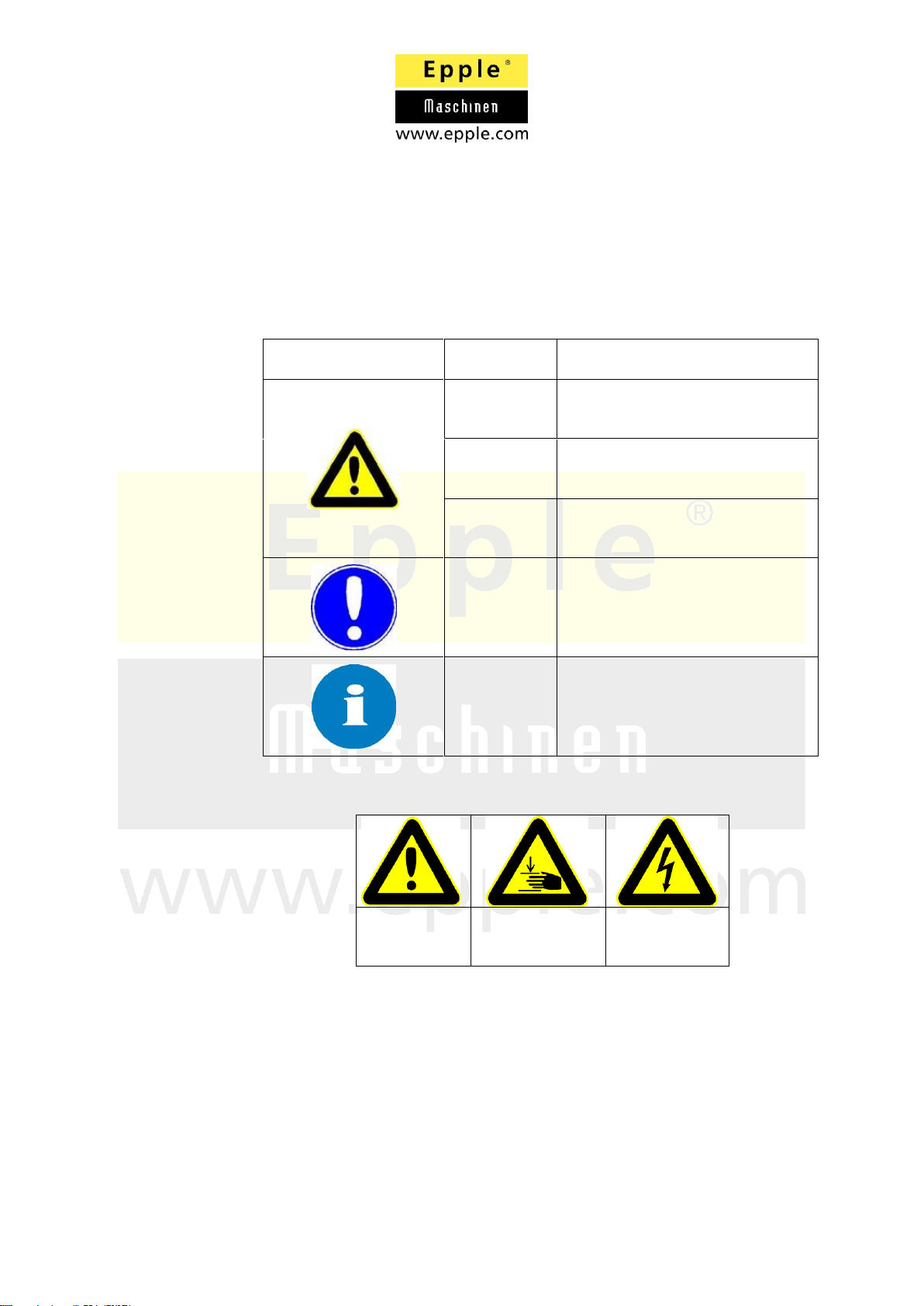

1.1.1 Classification of hazards

We classify the safety warnings into various levels. The table below

gives an overview of the classification on symbols (pictograms) and

warning labels fort he specific danger and is (possible) consequences.

Symbol

Warning

alert

Definition/ Consequences

Danger!

Imminent danger that will cause

serious injury or death to

personnel.

Warning!

Risk: a danger that might cause

serious injury of death to

personnel.

Caution!

Risk: a danger that might cause

serious injury of death to

personnel.

Attention!

Situation that could cause

damage to the machine or

products and other types of

damage. No risk of injury

personnel.

Information!

Application tips and other

important or useful information

and notes. No dangerous or

harmful consequences for

personal or objects.

In case of specific dangers, we replace the pictogram by

General

danger

Injuries to hand

Dangerous,

electrical

tension

26.01.07, SBS 32, Drills Page 7 from 33

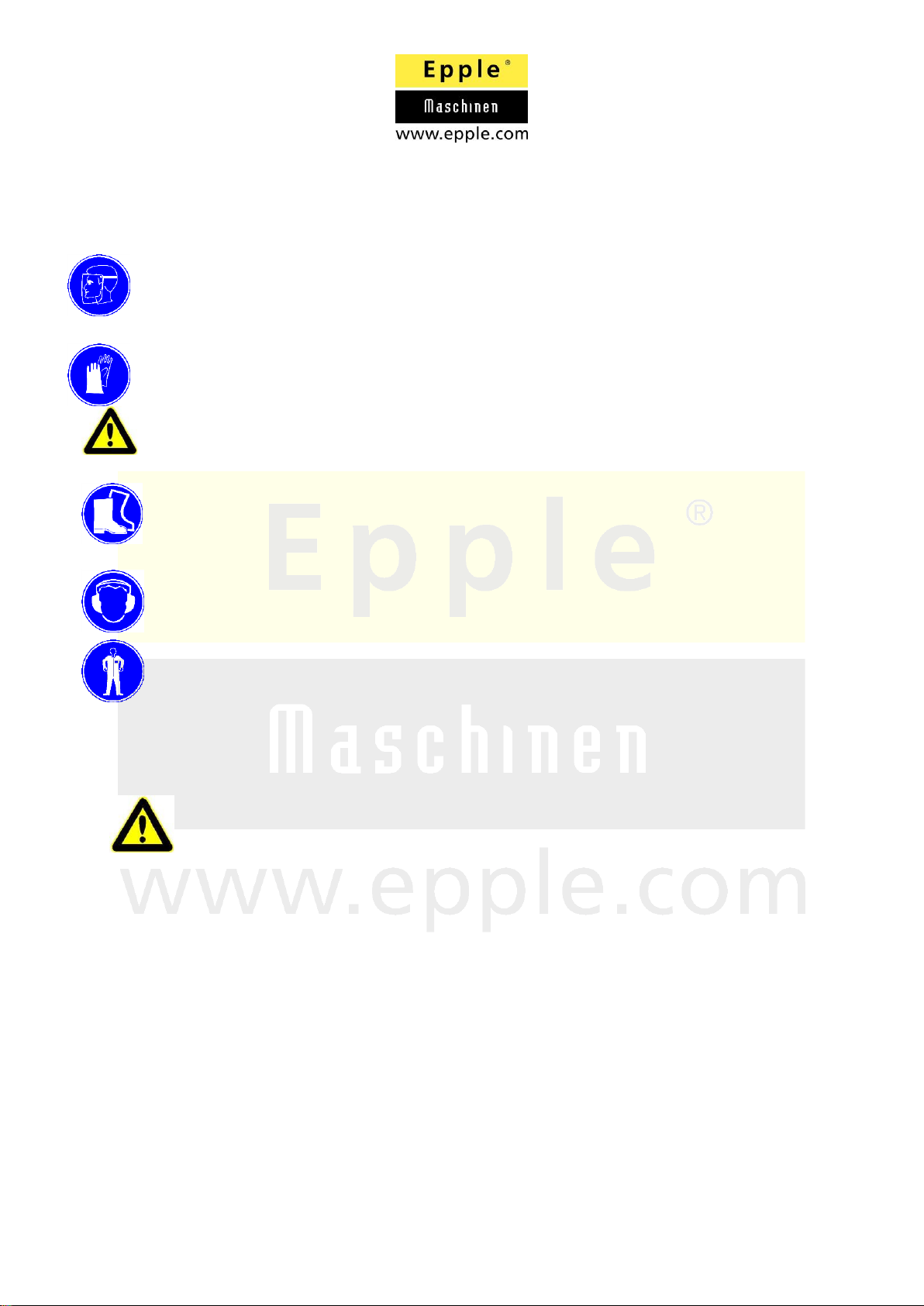

1.1.2 More, used pictograms

Engaging

forbidden

Draft mains

plug

Wear

protection

gloves

Wear

protection

glasses

Wear ear

protection

Wear

protective

suit

Wear safety

shoes

Mind the

environment

Your contact

person

1.2 Bestimmungsgemässe Verwendung der Maschine

Warning!

In the event of improper use, the machine

Will endanger employees,

Will endanger the machine and other material property of the operator,

may affect proper operation of the machine

The machine may not be in an explosive environment.

The machine was built and construed for the following utilisations

This drill only is for working with metal, wood and plastic.

Working with flammable materials is forbidden.

Any other use is improper.

The use and positioning of the machine only is allowed in dry and well aired

rooms

If the machine is used in any way other than as described above, modified

without authorisation of Epple Maschinen GmbH or operated with different

process data, then it is being used improperly.

We do not take any liabilities for damage caused by improper use. We would like

to point out that any modifications to the construction, or technical or

technological modifications that have not been authorised by Epple Maschinen

GmbH will also render the guarantee null and void.

It is also part of proper use that

For an optimal efficiency, you have to observe the following:

The correct choice of the tool, according to the material

26.01.07, SBS 32, Drills Page 8 from 33

The correct clamping of the tool

The correct clamping of the work part

The correct cutting pressure and cutting speed

The adequate coolant lubricant

Warning!

An improper use can lead to heaviest injuries.

The rebuilding or the change of the performance data is forbidden and

endangers personnel and machine.

1.3 Danger, which can emanate from drill

Construction and building of the machine equate to level of technique. The

machine was checked of operating safety.

However there exist risks and dangers by the use:

Improper use and non –observance of safety instructions can cause

extensive injuries like bruises, crops, fractures or separation of members

Risk of injury by kickback or derailing of work parts and/ or tool

Danger of electric shock by damaged and electric units

Risk of stumbling by about lying work parts or work part rests

A cant of work parts can cause heavy injuries

Danger for ears by loud noise (from 85 dB(A))

The running drill can capture work wear or long hair insert

Danger of cutting by arris work parts

Danger of accidents by damaged tool (f. e. stump, loose, chapped etc.)

During use of coolant lubricant exists the danger of skin diseases

By the maintenance and use of the machine dangers because of false use or

improper maintenance may encounter you.

Information

To avoid errors and dangers, all users who are assigned with the

assembly, the use and maintenance have to be qualified and read plus

understand the operating manual.

By improper use of the machine may:

Danger for body and life exist

The machine and other property can be endangered

The safe function of the machine can be affected

It is very important that you disconnect the machine for cleaning and maintenance

work.

Warning!

The machine only can be used with functioning safety equipment. The machine

must be disconnected directly if you notice damaged or failure safety equipment.

All special units that are mounted from the operator have to include the

accordant safety units. You are not allowed to derogate or avoid the safety units

of machine. The responsibility therefore is the operators.

26.01.07, SBS 32, Drills Page 9 from 33

1.4 Qualification of personnel

1.4.1 Target group

This manual is addressed to the operators, users and maintenance staff.

The warning notes therefore refer to both operation and maintenance of

the machine.

Determine clearly and irrevocably who will be responsible for the

different activities on the machine (operation, maintenance and repair).

1.4.2 Authorised personnel

Warning!

Incorrect use and maintenance of the machine constitutes a danger for

personnel, objects and environment.

Only authorized personnel may operate the machine.

Authorised personnel for the use and maintenance are:

Trained and instructed operators

Trained and instructed experts of the retaile

26.01.07, SBS 32, Drills Page 10 from 33

1.4.3 The operator must

The operator is bound to instruct the personnel in regular intervals (at

least once a year) on

Monitoring all safety standards that apply to the machine

Maintaining the operation

Obtaining accredited technical guide lines

Furthermore the operator is bound to:

Document training/ instructions

Require the staff to confirm participation in training/ instruction by

means of a signature

Control whether the personnel observes the operation manual

and whether it is close to the machine

Check that the staff is aware of safety and dangers in the

workplace and that they observe the operating manual

1.4.4 The user must

Observe commands of superiors and sentinels

Do not remove safety equipment during work

Avoid contact with tool

Use personal protective equipment (incl. Skin protection)

Wear close work wear

Remove chips with equipment and not by hand

Do not use damaged thread, wood, HSS drills

Work parts have to be clamped safe and feast

Assure order and cleanness at the work place

Never work with damaged machine parts

Announce defects directly to your superior

Read and understood the user manual

To be familiar with all safety regulations and safety arrangements

Use the machine

26.01.07, SBS 32, Drills Page 11 from 33

1.4.5 Special claims to the qualification

For the work with electric units or operating materials more claims to the

qualification are efficient.

Only electronic experts are allowed to do work at electric units. If the

instruct and oversee you, you are allowed, too.

Before you accomplish work at electric units or operating material you

have to keep the following instructions in this order:

Disconnection

Assure against resetting

The unit must be de - energized

Please observe the effective regulations of the insurance association

and the accident prevention.

1.5 Operator position

The operator position is straight standing in front of the profile roll. Every other

position can lead to danger of personnel.

1.6 Safety equipment

The use of the machine is only allowed with correct functioning safety devices.

The machine is to decommission directly if a safety device is deficient or

effectless. Therefore you are responsible as an operator/ user. After response,

defect or falling out of a safety device, the profile roll may not be in use until:

The failure/ cause of the failure is abolished

You have checked the machine and fell confident that there is no danger

for personnel or property values

Warning!

If you remove the destined safety devices or abrogate them by bridging you

endanger yourself and other personnel working at the machine.

Consequences can be heavy injuries until death.

The drill includes the following safety devices:

Main switch lockable with EMERGENCY STOP function

Chip protection

Belt protection cover with safety switch

26.01.07, SBS 32, Drills Page 12 from 33

1.6.1 Main switch lockable

At the front side of the machine is a lockable

switch with an optional u –lock.

Release a used emergency Stop control

by pushing the button in direction of

arrow to jump out of the catch

mechanism to let it open and

consequently it is possible to activate

the machine again.

1.6.2 Chip protection

You can fold up the chip protection. Additionally the

chip protection is height adjustable. Springs keep it

in its particular position. The chip protection has no

control function. During drilling you have to click the

chip protection in front of the tool.

1.6.3 Safe belt cover

The safe belt cover has a safety switch. In opened position the current entry to the motor

is break.

1.6.4 Prohibition, instruction and warning signs

Observe additionally to the user manual the safety and warning notes at the

machine. Warning notes that only are to find in the user manual and not at the

machine have additionally absolute validation and are to observe implicitly.

26.01.07, SBS 32, Drills Page 13 from 33

1.7 Safety check at the machine

You are bound to check the machine at least once pro shift. Announce scarcities

and defects directly. You have to check alle arrangements

Before every shift

By disconnected use before every use

After every maintenance

Check that all warning notes and signs are complete and good readable at the

machine.

Document your security check in an adequate way.

Checking in general

Safety equipment

Operation

OK

Chip protection

Fixed mounted, flap smooth

Safety notes

All safety notes are located and undamaged at

the machine

Function check of the safety elements

Element

Operation

OK

EMERGENCY

STOP control

Stop the machine directly after use of the

emergency Stop control.

Belt protection

cover

If you open the belt cover the motor

disconnects or rather the motor does not start

with opened cover.

26.01.07, SBS 32, Drills Page 14 from 33

1.8 Personal protective equipment for special work

Use for your work always the necessary personal protective.

Protect your face and your ears: Wear a safety helmet with a face guard for

every work, especially for any kind of work where your face and eyes are

exposed to hazards.

Use protective gloves when lifting or handling pieces with sharp edges.

CAUTION!

Do not wear protective gloves, if you have to hold work parts with the hands.

Hooking work parts can cause heaviest injuries that can lead to constrictions and/

or breaks.

Wear safety shoes when fitting, dismanteling or transporting heavy components.

Use ear protection over 80dB

Wear closely safety suit.

Do not wear long hair open, wear hairnet or cap

Check before start of work whether the required protective is complete and intact.

Broken protective has to be modernized. Always announce missing protective

and only begin to work if the protective is complete.

CAUTION!

Contaminated, defiled protectives can release indispositions. Clear them up after

every use and at least once a week.

26.01.07, SBS 32, Drills Page 15 from 33

1.9 Safety during the use of the machine

Warning!

Assure before activating the machine that no person or property value is

endangered.

Do not accomplish work at the machine that is dangerous:

Assure that other people are not endangered by you

Observe the maximum drilling cap of the machine

Clamp the work parts before connection correct and feast

Do not try to break the run –down drill chuck with the hand

Always break the machine for control measures at the work part

Wear adequate protective equipment

Do not wear long hair open, work with hairnet or cap

Wear close wear, no cravats, jewellery, rings etc.

Do not remove chips with hands, use adequate means of work

Never work at the machine if your concentration is limited (f. e. through

medicaments)

Follow the using, attendance and maintenance instructions of this user

manual

Observe the accident prevention regulations that are effective for your

business

Announce damages directly to your superior

Only leave the machine after deactivating if it stopped completely

26.01.07, SBS 32, Drills Page 16 from 33

1.10 Safety during general maintenance work

Before you begin with maintenance work at the machine you are bound to inform

the operating personnel.

Announce and document changes which are safety relevant. Do not execute

changes without consultation with the manufacturer. Refresh the operation

manual only in consultation with the manufacturer. Only instruct the operation

personnel if all changes are approved.

Document the instruction in an adequate way.

1.10.1 Breaking and assuring the machine

Deactivate the machine before the beginning of attendance and maintenance

work with the main switch. Assure the main switch with a u –lock and retain the

key. If applicable brew the mains plug.

Mark and assure the machine clearly against unauthorised resetting.

After unplug of the mains plug all dangerous tensions are disabled.

Excluded are areas at the machine that are marked with the adjoining symbol. At

these areas dangerous tensions can be possible although a deactivated main

switch (f. e. connecting line).

Warning!

Moves of machine parts and electric machine parts can hurt you and

others heavy. Act very careful if it is not necessary to unplug the

machine because of working. Inform personnel around you about your

cycle and the possible dangers.

1.10.2 Use of hoisting devices for attendance work

Warning!

If the lifting tool is not stable enough it can burst what may cause heavy

or deadly injuries.

Check before working with lifting tool whether it is admitted for the load

and undamaged. Assure that the load is fixed correctly. Never step

under lifted loads. Please observe the effective accident prevention

regulations for your business.

26.01.07, SBS 32, Drills Page 17 from 33

1.10.3 Mechanic attendance work at the machine

Before or after attendance work:

Replace all protection and safety units that are especially for attendance

work and activate the machine with the machine –own protection and

safety units. Check the protection and safety units after every

attendance or maintenance work about completeness and correct

function.

1.11 Accident report

Inform your superior directly about accidents or “nearly accidents”.

So –called „nearly accidents“ can have different causes and need an detailed

analysis.

1.12 Electricity

You are bound to let the electrical equipment of the machine check regularly.

We advise you at least a checking every 6 months. Deficiencies like damaged

cables or not fixed connections you have to correct always immediately

underneath observance of the safety measures. During work at live parts a

second person always has to be attendant who can switch –off the machine in

an emergency.

The machine must be out off gear immediately by failure in the electrical supply.

You will find more information in chapter maintenance.

26.01.07, SBS 32, Drills Page 18 from 33

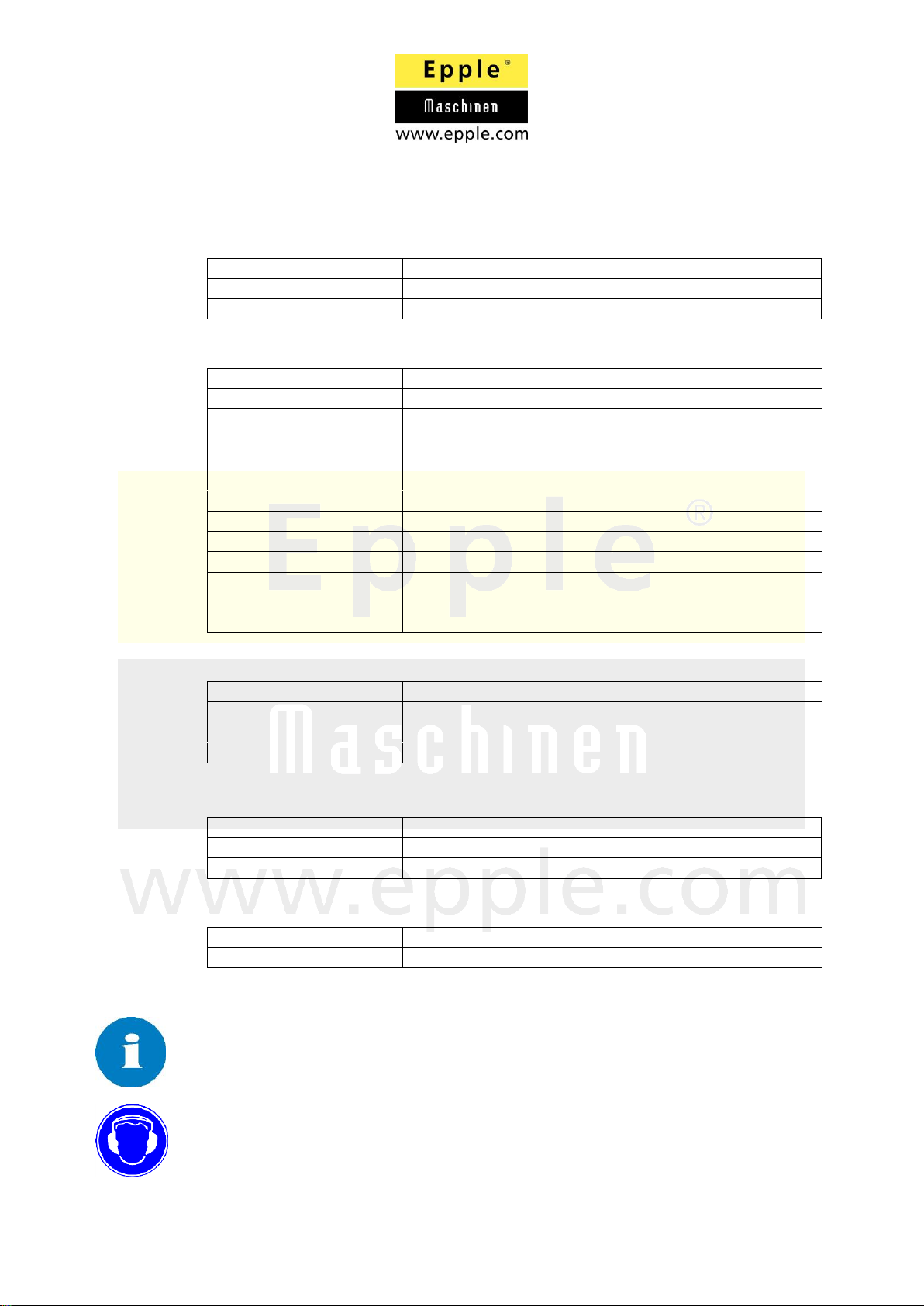

2 Technical data

2.1 Electrical connection data

Connection

400V 50Hz 16A CEE

Connection power

1,1kW

Main motor

1,1kW

2.2 Machine data

Drilling cap in steel

32 mm

Centre sleeve hub

120 mm

Spindle taper

MT3

Driving speed range

150 –2.700 U/min

DRiving speed steps

12

Drehrichtungsumkehr

yes

Working range

255 mm

Table size

470 x 420 mm

Table swiveling range

+/- 90°

Table tilting range

+/- 45°

Table travelling

distance

850 mm

Column diameter

90 mm

2.3 Dimensions

Width

500 mm

Depth

700 mm

Height

1.750 mm

Weight

120 kg

2.4 Necessary working room

Width

1.500 mm

Depth

1.500 mm

Height

2.500 mm

2.5 Environmental conditions

Temperature range

5 –45°C

Air humidity

Up to max. 75%

2.6 Emissions

The noise emission of the machine is accordant to work.

If you use more machines at one time it is possible that the acoustic emissions

cross the allowed extreme value (over 80 db(A)). Constancy of the emissions,

character of the working place and more machines influence the noise level at

the working place.

Therefore we advise to wear always ear protection.

26.01.07, SBS 32, Drills Page 19 from 33

3 Assembly

3.1 Delivery volume

After receipt of the delivery you have to check directly of shortfalls. Compare the

scope of delivery with the information at the packing slip.

Check whether the machine has damages in transit

3.2 Transport

Warning!

If the lifting tool is not stable enough it can burst what may cause heavy or deadly

injuries. Please observe the following instructions for the carrier box/ palette:

Rope stops

Weight

Balance point

Prescribed means of transport

Warning!

If the lifting tool is not stable enough it can burst what may cause heavy or deadly

injuries. Check before working with lifting tool whether it is admitted for the load

and undamaged. Observe the effective accident prevention regulations for your

business. Never step under lifted loads for your own safety. See that the load is

fixed correctly.

3.3 Storage

By an improper storage the machine or machine parts can be damaged. Never

store the machine under other environmental conditions than in the operation

manual denoted. The warranty claim declines by improper storage.

26.01.07, SBS 32, Drills Page 20 from 33

3.4 Positioning and assembly

3.4.1 Claims to installation location

The machine may not be in an explosive area. The machine is therefore

not construed. The acceptable environmental conditions have to be

followed at the installation location. Organise the installation location

according to the safety regulations for the use of this machine. See that

the installation location is not limited for the use, attendance and

maintenance.

Guarantee a boundless and free amenability of the mains plug and all

operation unit of the machine.

3.4.2 Assembly

Install the stand

Install the column in the stand and screw both parts

Lay in the gear rack into the table adjustment

Impose on the beam with gear rack about the column

Mount the end ring of the gear rack at the column

Mount the table and adjust it

Mount the head at the column and screw both parts

Mount the chip protection at the centre sleeve

3.4.3 Anchor - free assembly

Attention!

An anchor –free positioning is not allowed because of safety causes

and therefore it is forbidden!

3.4.4 Anchor free assembly

Observe that the machine is anchored safe and correctly. Assure that you respect

the internal safety regulations.

Attract the anchor screws across balanced and not too feast, to avoid a break of

the stand. Adjust the machine perpendicular.

3.4.5 Positioning

See that the bottom/ ceiling at the installation location are stable enough. If the

rigidity is not enough, it can come to oscillation between machine and ground.

This can lead to failures at the machine or at the adjoining equipment.

See during positioning of the machine that the working place is designed

ergonomic.

Observe during position the machine the accident prevention regulations for your

business. The use, attendance and maintenance may not be limited. Bethink: A

cramped work place retrieves accident risks.

Table of contents

Other Epple Maschinen Drill manuals

Popular Drill manuals by other brands

Hilti

Hilti SF 6H-A22 Original operating instructions

Narex

Narex EVP 13 H-2C Original operating manual

Makita

Makita 8270D instruction manual

Bosch

Bosch PSB 1080 LI-2 Original instructions

Milwaukee

Milwaukee 14.4V HAMMER/DRIVER DRILL Operator's manual

Parkside

Parkside PSBM 500 A1 - 3 Operation and safety notes