ePropulsion DCAC230026 User manual

2023.08 Version 1.0

Copyright © ePropulsion ePropulsion. All Rights Reserved

DC-AC Inverter 96 V - 230 V

6 kW User manual

Mode: DCAC230026(50)

English

1

Acknowledgement

Thanks for choosing ePropulsion products, your trust and support in our company are sincerely

appreciated. We are dedicated to providing high-performance electric outboards, electric

inboards, sup/kayak motors, reliable lithium batteries and accessories.

Welcome to visit www.epropulsion.com and contact us if you have any concerns.

Using This Manual

Before use of the product, please read this user manual thoroughly to understand the correct

and safe operations. By using this product, you hereby agree that you have fully read and un-

derstood all contents of this manual. ePropulsion accepts no liability for any damage or injury

caused by operations that contradict this manual.

Due to ongoing optimization of our products, ePropulsion reserves the rights of constantly ad-

justing the contents described in the manual. ePropulsion also reserves the intellectual property

rights and industrial property rights including copyrights, patents, logos and designs, etc.

This manual is subject to update without prior notice, please visit our website www.ePropulsion.

com for the latest version. If you nd any discrepancy between your products and this manual,

or should you have any doubts concerning the product or the manual, please visit www.ePropul-

sion.com.

ePropulsion reserves the rights of nal interpretation of this manual.

This manual is multilingual, in case of any discrepancy in the interpretation of different language

versions, the English version shall prevail.

Warning

Do not dismantle any of the inverter’s housings or components. There is a danger of lethal

voltages or high energy levels in the internal parts of the device!

Do not touch the input and output terminals of this product directly with your hands while

it is energised!

Symbols

ePropulsion considers safety of great importance and recommends that anyone that comes

into close contact with its products, such as those who install, operate, maintain or service ePro-

pulsion products, exercise care, common sense and comply with the safety information in this

manual and on the machine’s safety decals.

The following are the relevant information marks in the user manual or the product labels:

Hazardous or warning signs indicate a potentially hazardous or hazardous situation which, if not

90mm

86mm

60mm

56mm

13mm

90mm

86mm

60mm

56mm

13mm

English

2

avoided, will result in death or serious injury. Special attention and attention should be paid to

the safety of you or the products involved.

Important warning:

Tips or important informations help quickly grasp the use of the inboard motor and improve e-

ciency.

Caution:

When installing, operating, maintaining or serving ePropulsion products, there are many safety

risks in the process. You need to be alert, perform relevant operations reasonably, and pay atten-

tion to safety. when installing, operating, maintaining or serving ePropulsion products, there are

many safety risks in the process. You need to be alert, perform relevant operations reasonably,

and pay attention to safety.

Electric shock hazard:

The areas or equipment may be at risk of electric shock. The equipment uses 230V AC power.

When operating electricity-related electrical connectors, switches, cables and other electricity-re-

lated items, power off operation to prevent electric shock.

This user manual provides users with instructions for installation, debugging, operation,

and troubleshooting of the product. Please keep it safe and read it carefully before using

the product.

• Do not install, operate, maintain, or inspect the product until you have thoroughly read

and understood this manual.

• Follow the warnings and instructions indicated in the product and accompanying printed

materials.

110mm

76mm

22mm

100mm

88mm

90mm

86mm

60mm

56mm

13mm

3

Table of Contents

Acknowledgement.................................................................................................. 1

Instructions for use ................................................................................................ 1

warning .................................................................................................................. 1

Symbols ................................................................................................................. 1

1 Product Overview ................................................................................................ 4

1.1 In the Package .......................................................................................................4

1.2 Parts and Diagram.................................................................................................5

1.3 Product Dimensions ..............................................................................................6

1.4 Specifications ........................................................................................................7

1.5 Operating Environment..........................................................................................8

2 Installation and Operation.................................................................................... 9

2.1 Installation Preparation .........................................................................................9

2.2 Installation Location..............................................................................................9

2.3 Cable Connection, Startup, and Shutdown........................................................ 10

2.3.1 Cable Connection ..................................................................................... 10

2.3.2 Operating................................................................................................... 13

3 Warnning ........................................................................................................... 14

3.1 Protection............................................................................................................ 14

3.2 Indicator Light..................................................................................................... 14

3.3 Common Fault Causes and Solutions............................................................... 15

4 Maintenance...................................................................................................... 16

5 Warranty............................................................................................................ 17

5.1 Out of Warranty................................................................................................... 18

5.2 Limited Warranty Claim Procedures.................................................................. 19

English

4

1 Product Overview

This product is a converter that transforms direct current energy into fixed-frequency fixed-

voltage alternating current, providing 230V AC power supply for daily equipment use on

boats. This product is equipped with thermal sensing devices and features functions such as

overheat protection, short-circuit protection, and overload protection.

1.1 In the Package

During transportation, please avoid strong vibrations, falls, and impacts on the product. Do

not invert the packaging box, and make sure not to lose accessories and product manuals

when unpacking or moving. If any items are missing, please contact your dealer immediately.

Items Qty. Figure Function

Converter main part 1 supply power to 230V

devices.

AC output cable 1 Connect to AC devices

DC input cable 1 Connect to the DC power

source

Communication cable 1 Communicate with the

system

Hexagon cross-slot

three combination

screw

4 304 M8X25 Used to Install the converter.

Hexagon nut 4 304 M8 /

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极-1

负极-2

+

-

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A向脚位示意图 B向脚位示意图

1

2

4

3

此处缺一张图

Ground Connect

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极-1

负极-2

+

-

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A向脚位示意图 B向脚位示意图

1

2

4

3

此处缺一张图

Ground Connect

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极-1

负极-2

+

-

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A向脚位示意图 B向脚位示意图

1

2

4

3

此处缺一张图

Ground Connect

5

T-Terminal 1 /

User manual 1 /

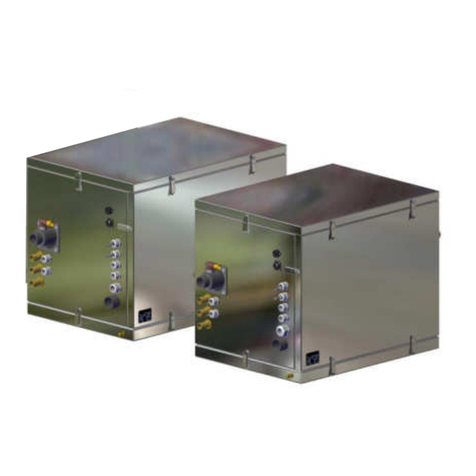

1.2 Parts and Diagram

No. Name No. Name

1 DC input connector 6 ON/OFF button

2 Ventilation outlet 7 /

3 AC output port 8 /

4CAN communication

port 9/

5 LED indicator 10 /

Figure 1-1

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极-1

负极-2

+

-

123 4 5 6

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A向脚位示意图 B向脚位示意图

1

2

4

3

此处缺一张图

English

6

1.3 Product Dimensions

The inverter's dimensions are: Length 485 * Width 366 * Height 157mm

When storing the product, please pay attention to the following points to avoid potential

adverse effects:

Keep away from corrosive gases and liquids. If the product is left Without uses for a

long period, it needs to be powered on every six months.

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极-1

负极-2

+

-

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A向脚位示意图 B向脚位示意图

1

2

4

3

此处缺一张图

Ground Connect

Figure 1-2

7

1.4 Specifications

Actual parameters please refer to the model number

Model DCAC230026(50)

DC input

Rated input voltage 102.4Vdc

Input voltage range 80 - 120Vdc

AC output

Rated power(kW) 6KW

Rated voltage(V) 230Vac

Rated current(A) 26

Voltage deviation ±2%

Frequency(Hz) 50/60

Frequency deviation ±0.5%

Total harmonic distortion (THD)

(linear load) ≤5%

Dynamic response (load 0←→100%) 5%

Environment

Operating temperature -30℃ - +85℃

Storage temperature -25℃ - +55℃

Relative humidity 5% - 95%

IP protection level IP56

Model DCAC230026(50)

English

8

1.5 Operating Environment

To ensure the product's optimal performance, The operating environment should at

least satisfy the below requirements:

1.Place the product in a clean, dry, and well-ventilated area. (When installing the product in a

spacious cabin, make sure to provide ventilation.)

Maintain an appropriate ambient temperature. (The inverter can operate in an environment

ranging from -25°C to +55°C; operating in high temperatures is strictly prohibited.)

Maintain the relative humidity within the range of 5% to 95%, avoiding condensation.

2.Altitude ≤2500m. If the altitude exceeds 1000 meters, it's recommended to reduce the rated

capacity of the machine. (For altitudes above 3000 meters, the rated output current decreases

by 3% for every 100 meters of altitude increase.)Ensure there are no corrosive gases or other

corrosive substances nearby, and no flammable or explosive items.

3.Ensure the input power supply complies with safety regulations.

9

2 Installation and Operation

The installation of this product requires careful planning, including selecting the installation

location, properly configuring the load, choosing appropriate cables, and ensuring correct

connections to ensure safe and normal operation of the product.

2.1 Installation Preparation

1. Before using this product, carefully consider the power of the load equipment to avoid

overloading the inverter.

2. Under normal operating conditions, the actual power consumption of the load equipment,

especially in standby mode, may be lower than the specified power. Users should use the

nominal power of the equipment as the basis for calculations and consider the startup

current to ensure sufficient power margin for reliable inverter power supply.

2.2 Installation Location

1. Choose the installation location based on principles of heat dissipation, easy wiring, and

compliance with the requirements of the product's operating environment. Select a stable

installation location whenever possible.

2. Keep the air inlet and outlet unobstructed. Maintain at least 300mm of clearance around

the air inlet and outlet. Ensure there is enough operating and maintenance space based on

the installation conditions.

3. When installing vertically, pay attention to foreign objects falling into the air duct to avoid

blocking the product inlet and outlet

4. Ensure the product is securely installed to prevent shaking or falling.

5. Use M8x15 combination bolts to secure the product in place using the designated mounting

holes. The tightening torque of the bolts should be at least 18Nm.

Figure 2-1

English

10

The installation position should be far from water, steam, and other liquids. Keep away

from flammable and explosive materials.

Avoid installing or storing the inverter in environments with high corrosiveness, high

dust levels, high temperatures, high humidity, and especially environments with metal

substances that could fall into the enclosure.

Do not place any objects on top of the enclosure. Parallel operation is not supported.

2.3 Cable Connection, Startup, and Shutdown

Prior to connecting cables, disconnect the upstream power source.

• Ensure reliable grounding of the inverter. Use thicker ground cables if possible and connect

them close to the inverter. Keep the grounding cable short.

• Use cables that meet the requirements. Avoid using cables that are overloaded to prevent fire

or electric shock accidents. Even after cutting off the input power supply, there will still be high

voltage inside the inverter. Do not open the enclosure to touch internal components, as this

could cause harm to operators and the product.

2.3.1 Cable Connection

DC input cable and port definition:

• ①is the DC input socket of the inverter (meaning of ①detailed in 1.2 Parts and Diagram).

The connector of the DC cable is designed with an anti-reverse lock to match the inverter's DC

input port. Pay attention to the direction of the lock when connecting.

• Ensure the polarity of the DC cable input terminals is correct. After connecting the connectors,

tighten them securely.

• Make sure to disconnect the power source before connecting..

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极-1

负极-2

+

-

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A向脚位示意图 B向脚位示意图

1

2

4

3

此处缺一张图

Ground Connect

Figure 2-2

11

• Maintain a natural curve on the cable. Avoid forcefully bending it.

• Maintain a natural curve on the cable. Avoid forcefully bending it

Pin Definition

1 Positive (+) /

2 Negative (-) /

AC Output Cable and Port Definition:

• ③ is the AC output port of the inverter (the significance of position ③is detailed in section

1.2 Parts and Diagram). The AC cable connector and the inverter's AC output port are

designed with anti-reverse locking mechanisms. Please pay attention to the phase sequence

and numbering of the AC cable connectors when connecting them to the inverter's AC

output port.

• During installation, ensure the correct phase sequence of the AC cable output end. After

connecting the connectors, tighten or secure them.

• Make sure to perform the connection after disconnecting the power source.

• The cables should be bent naturally and not forcefully folded.

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

DC cable connector DC input terminal

WOER

A

12

SC25-6 SC25-6

Positive -1

Negative -2

+

-

123 4 5 6

157mm 485mm

306mm

366mm

366mm

AC cable Connector AC cable Output End

1

2

3

LLT

N

L

GND

Communication cable Connector Remote Control Connector

8

7

6

5

4

1

2

3

BA

Pin A Illustration Pin B Illustration

1

2

4

3

此处缺一张图

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

DC cable connector DC input terminal

WOER

A

12

SC25-6 SC25-6

Positive -1

Negative -2

+

-

123 4 5 6

157mm 485mm

306mm

366mm

366mm

AC cable Connector AC cable Output End

1

2

3

LLT

N

L

GND

Communication cable Connector Remote Control Connector

8

7

6

5

4

1

2

3

BA

Pin A Illustration Pin B Illustration

1

2

4

3

此处缺一张图

Figure 2-3

Figure 2-4

Figure 2-5

English

12

Pin Definition Note

1 Line (L) /

2 Neutral (N) /

3 Ground (GND) /

CAN Communication cable and Port Definition:

• ④is the CAN communication port of the inverter (the significance of position ④is detailed in

section 1.2 Parts and Diagram). The communication cable connectors are designed with anti-

reverse locking mechanisms. After connecting the connectors, make sure to tighten or secure

them.

• Make sure to perform the Remote ControlConnector to the T-terminal after disconnecting the

power source.

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极

-1

负极

-2

+

-

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A

向脚位示意图

B

向脚位示意图

1

2

4

3

此处缺一张图

Ground Connect

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极

-1

负极

-2

+

-

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A

向脚位示意图

B

向脚位示意图

1

2

4

3

此处缺一张图

Ground Connect

12

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

直流线束连接器 直流线束输入端

WOER

A

12

SC25-6 SC25-6

正极-1

负极-2

+

-

157mm 485mm

306mm

366mm

366mm

直流线束连接器 直流线束输入端

1

2

3

LLT

N

L

GND

通讯线束连接器

8

7

6

5

4

1

2

3

BA

A向脚位示意图 B向脚位示意图

12

4

3

此处缺一张图

Ground Connect

Figure 2-6

Figure 2-7

Figure 2-8 Figure 2-9

1

2

4

3

1

2

3

交流输出线束

SC25-6 SC25-6

+

-

直流输入线束

逆变器通信线束

LLT

N

L

GND

DC cable connector DC input terminal

WOER

A

12

SC25-6 SC25-6

Positive -1

Negative -2

+

-

123 4 5 6

157mm 485mm

306mm

366mm

366mm

AC cable Connector AC cable Output End

1

2

3

LLT

N

L

GND

Communication cable Connector Remote Control Connector

8

7

6

5

4

1

2

3

BA

Pin A Illustration Pin B Illustration

1

2

4

3

此处缺一张图

Output End cable Numbering Output End cable Color Definition

1 Brown L L (Line)

2 Blue N N (Neutral)

3 Yellow-Green GND GND (Ground)

Figure 2-10

13

Pin Figure 2-8 Definition Pin Figure 2-9

1 CAN-H 4

2 CAN-L 5

3 / 1

4 / 2

/ / 3

/ / 6

Figure after connecting:

Proper operation of the inverter can better ensure its service life and provide high-quality input

power to your load equipment.

2.3.2 Operating

1.Startup for the Inverter:

(1) Turn on the DC input power of the primary stage; connect the AC output cable of the

secondary stage.

(2) Close the inverter switch by pressing it to ON.

(3) The startup process will take about 10 seconds. When the "Inverter" indicator light is ON, it

indicates normal operation.

(4) Turn on the load device switches one by one.

2.Shutdown for the Inverter:

(1) Turn off the load device switches one by one.

(2) Turn off the inverter switch by pressing The power button.

(3) Wait for the "Inverter" indicator light to go off.

(4) Disconnect the input power.

CAN bus

AC loads

Figure 2-11

English

14

3 Warnning

3.1 Protection

This product has comprehensive protection functions. In the event of faults listed in the table

below, the product will enter a protection state and shut off the output to ensure that the load is

not damaged, and the product itself is protected.

Status Protection Recovery

Condition Notes

Normal Operation Normal Output / /

Overvoltage

Protection Turn off output Automatically

recoverable

Undervoltage Recovery

(85V)

Undervoltage

Protection Turn off output Automatically

recoverable

Overvoltage Recovery

(115V)

Overload

Protection

Turn off output after

reaching overload

alarm threshold

Resume

operation after

restart

/

Short-Circuit

Protection

Turn off output

(200ms)

Resume

operation after

restart

/

Overtemperature

Protection Turn off output Automatically

recoverable

Overtemperature protection

start temperature: 85℃

Normal operation

temperature recovery: 75℃

When the inverter is first started and the input voltage is exactly between the protection

and recovery points (80/85V, 120/115V), the machine will be in protection state. The

protection state will be canceled when the input voltage is between the undervoltage

recovery value and the overvoltage recovery value.

3.2 Indicator Light

The front panel of this product has 2 indicator lights. Since the inverter itself has comprehensive

protection functions, once abnormalities or faults occur, the inverter will shut off or stop output.

The indicator lights will respectively indicate the corresponding abnormal information and the

operating status of the inverter.

Status Green Light Red Light Output Status

Normal Operation Steady On Steady Off Normal Output

Overvoltage Protection Steady Off Steady On Output Stopped

Undervoltage

Protection Steady Off Steady Off Output Stopped

Power Loss/Shutdown Steady Off Steady Off Output Stopped

15

Overload Warning Steady On Off 2S On 1S Output Stopped

Overload Protection Steady Off Steady On Output Stopped

Short-Circuit Protection Steady Off Steady On Output Stopped

Overtemperature

Protection Steady Off Steady On Output Stopped

3.3 Common Fault Causes and Solutions

Before using this product, carefully consider the power of the load equipment to avoid

overloading the inverter. The actual power of the load equipment in general operating

conditions, especially in standby mode, is slightly lower than the labeled power. Users should

rely on the nominal power of the device when using it and consider the impact current when the

device starts. Provide sufficient power margin to ensure reliable power supply from the inverter.

Fault Cause Solution

All lights are off, the

inverter does not

start

Switch failure Check if the switch is working

properly or damaged

Input undervoltage Check if the input voltage is normal

Reverse connection Check if the DC input is reversed

Internal fault Contact your dealer for

maintenance

Red light flashes Output overload warning Remove some devices and check

the status of the red light

Green light steady

on, no output

Device does not start Check if the output lines L, N, GND

are connected correctly

No voltage at output port Contact your dealer for

maintenance

Green light off, red

light steady on

Overvoltage protection

Check if the input voltage is

normal; normal operation can be

restored when the input voltage is

within the recovery range

Overload protection Remove some devices and then

power on again

Overtemperature protection

Temporarily stop using the

inverter.

Resume operation after the

inverter temperature drops

Short-circuit protection After eliminating the line fault,

power on again

English

16

4 Maintenance

To ensure the continuous and proper operation of this product, regular maintenance and

inspection are required.

When conducting maintenance, adhere to the nominal power of the equipment and consider the

surge current during startup. Sufficient power margin should be retained to ensure the reliable

power supply of the inverter.

1. Regularly inspect whether the connection cables are aging and whether cable connection

points are securely fastened and safe.

2. Periodically open the enclosure to clean dust and any debris that might hinder ventilation

from the cooling fans. Also, check the normal operation of the fans. Refer to point 3 for

guidance on opening the enclosure.

3. Opening the enclosure for maintenance requires the expertise of a professional:

Before opening the enclosure for maintenance, the power supply should be completely

disconnected, and the system should be powered down for at least 10 minutes or longer. This

waiting time is necessary to allow the capacitors to discharge fully (there are high-capacity

capacitors inside the machine that require a certain amount of time for discharge). During

disassembly, take care not to damage components and parts, and pay attention to the order

of connecting wires. Specific maintenance requirements include:

- Clean dust and debris inside the enclosure.

- Check if the terminals and screws inside the enclosure are securely fastened.

- Inspect for any traces of overheating and damaged components left inside the enclosure.

- Check if the wires inside the enclosure have aged.

4. When reopening the enclosure of a previously maintained inverter, a trial run should be

conducted before putting it back into operation to ensure reliable power supply from the

inverter.

17

5 Warranty

Guangdong ePropulsion Technology Co., Ltd. (“ePropulsion”), China, warrants its products to

be free of defects in material and workmanship under normal usage with proper installation

and routine maintenance for a period of twenty-four (24) months from date of delivery of

products to end customers (the “Limited Warranty Period”), the I series motor and G battery

will have another extend 36 months warranty period after registration on the official website.

The Limited Warranty is provided to the first end customer of ePropulsion products ONLY.

The Customer is entitled to free repair or replacement of defective or non-conform parts. Any

warranty claim must be made within six (6) months of discovery of issues as provided below.

If the Limited Warranty Period expires, you can still enjoy maintenance services from dealers/

distributors authorized by ePropulsion (the “ePropulsion Service Partners”) with minimum

maintenance charge per occurrence.

In all warranty cases, ePropulsion will only bear the repair cost and other costs (such as those

related to product installation, disassemble, transportation, financing, rental, etc.) as a direct

result forof issues covered by the Limited Warranty only. Any costs irrelevant to or out of the

scope of the Limited Warranty will be born by the Customer alone., which shall NOT include

costs irrelevant such as those related to product installation, disassemble, transportation,

financing, rental, etc.

Beyond the Limited Warranty, the Customer may have statutory rights in your jurisdiction

according to applicable laws. Nothing in this Limited Warranty affects such rights. The

Customer may have warranty claim rights arising from the purchase contract with ePropulsion

Service Partners in addition to the rights granted by this Limited Warranty.

Products for commercial/professional use, even if only temporarily, are not covered by the

Limited Warranty. Instead, the statutory warranty in your jurisdiction shall apply. You are

encouraged to consult with ePropulsion Service Partners for applicable warranty and advice

before engaging in such use.

* Commercial/professional Use refers to application cases that have high use frequency,

high-reliability requirement or aim for money making, etc.

English

18

To keep your warranty valid, you shall follow:

Keep the product label intact and record the Serial Number shown on the label. Never tear

the label off the product. A product without the original product label is not covered by the

Limited Warranty provided by ePropulsion;

The Limited Warranty is not transferable and will not be reissued;

The Limited Warranty may change from time to time. Pls visit our website

(http://www.epropulsion.com) for the latest version.

Capacity guarantee for high-voltage batteries

A guarantee of the capacity of the high-voltage batteries, in addition to the standard guarantee.

Depending on the long-term average temperature and the usage profile, this guarantee runs for

a period of up to 5 years.

Comment on average temperature:

The average temperature is calculated using the Arrhenius equation; this means that higher

temperatures are given a greater weighting.

5.1 Out of Warranty

ePropulsion may refuse a warranty claim if:

• Any improper operation contradicts what is written in the user manual;

• Accident, misuse, dropping, improper care or storage, willful abuse, physical damage,

overcharging, over discharging, or unauthorized repair;

• Water ingress caused by external sources such as fishing nets, submerging underwater, etc;

• Product modification, alternation, disassembly, or parts/accessories attachment, which are

not expressly permitted or recommended by ePropulsion;

• Failure of, or damage caused by, any 3rd party products;

• Repositioning of the high-voltage batteries in the boat;

• The battery incorrectly charging, overcharging, over-discharging, operating in temp out of

scope described in the user manual;

• Consumables are out of warranty scope (like propeller, anode...etc.);

• Purchases of product from unauthorized dealers or seller;

• Normal wear and tear and routine servicing are excluded from the warranty;

This manual suits for next models

1

Table of contents

Popular Inverter manuals by other brands

Mitsubishi Electric

Mitsubishi Electric FR-D740-012SC-EC Installation guidelines

enphase

enphase AC Combiner Box Quick install guide

Sealey

Sealey TIG175HF instructions

tbs electronics

tbs electronics Powersine Combi PSC1600-12-60 owner's manual

FLOWTECH

FLOWTECH flowcon Operation and maintenance manual

Riello

Riello RPS 25/2 EVO INSTALLER, Technical Assistan ce Service AND USER MANUAL