ERME T3P User manual

Vacuum packaging machines

Table models professional

(T3P, T5P, T7P)

Translation of the original instructions

Before starting work, read these instructions!

ERME AG SWISS VACUUM SOLUTIONS

Grossmattstrasse 25

CH-8964 Rudolfstetten

T +41 (0)56 633 74 18

F +41 (0)56 633 75 18

erme.ch

Revision status: 1.0

Date of issue: March 2017

This manual is protected by copyright and is exclusively for internal purposes. Transfer of this manual

to third parties, reproductions in any manner and form – in full or in part – as well as exploitation

and/or communication of content without written permission from the manufacturer, except for

internal purposes, is prohibited.

Erme AG Table of contents

Table models professional iii

Table of contents

1 General information..............................................................................................................................................6

1.1 Subject of these instructions..........................................................................................................................................................................6

1.2 Target group ...........................................................................................................................................................................................................6

1.3 Information about these instructions......................................................................................................................................................... 7

1.3.1 Information about the content...................................................................................................................................................... 7

1.3.2 Instructions for use..............................................................................................................................................................................8

1.3.3 Used symbols..........................................................................................................................................................................................9

1.3.4 Structure of the warning messages ..........................................................................................................................................10

1.4 Additional sources of information.............................................................................................................................................................. 12

1.5 Limitations of liability ....................................................................................................................................................................................... 12

1.6 Copyright protection..........................................................................................................................................................................................13

1.7 Warranty provisions ...........................................................................................................................................................................................13

1.8 Customer service .................................................................................................................................................................................................13

1.9 Product monitoring.............................................................................................................................................................................................13

2 Safety................................................................................................................................................................... 14

2.1 General information .......................................................................................................................................................................................... 14

2.2 Intended use.......................................................................................................................................................................................................... 14

2.2.1 Foreseeable misuse ...........................................................................................................................................................................14

2.3 Basic safety instructions...................................................................................................................................................................................15

2.4 Special dangers / residual risks.................................................................................................................................................................... 16

2.4.1 Danger due to electrical current.................................................................................................................................................16

2.4.2 Danger due to hot surfaces........................................................................................................................................................... 16

2.4.3 Danger due to pressurised components..................................................................................................................................17

2.4.4 Danger due to oxygen-displacing gases ...................................................................................................................................17

2.4.5 Risk of crushing.....................................................................................................................................................................................17

2.5 Emissions................................................................................................................................................................................................................. 18

2.5.1 Noise emission......................................................................................................................................................................................18

2.6 The operator's responsibility.........................................................................................................................................................................18

2.7 Personnel requirements.................................................................................................................................................................................. 19

2.7.1 Personnel qualifications .................................................................................................................................................................. 19

2.7.2 Unauthorised personnel .................................................................................................................................................................20

2.7.3 Instruction..............................................................................................................................................................................................20

2.8 Personal protective equipment................................................................................................................................................................... 21

2.9 Safety equipment on the machine.............................................................................................................................................................22

2.10 Signage on the machine ..................................................................................................................................................................................23

2.11 Conversions prohibited................................................................................................................................................................................... 24

2.12 Spare parts............................................................................................................................................................................................................ 24

2.13 Auxiliary and operating materials.............................................................................................................................................................. 24

2.14 Accident prevention measures.....................................................................................................................................................................25

2.14.1 Preventative measures.....................................................................................................................................................................25

Table of contents Erme AG

iv Table models professional

2.14.2 Response measures in case of accidents................................................................................................................................25

2.15 Environmental protection ..............................................................................................................................................................................25

3 Technical data......................................................................................................................................................26

3.1 Machine data ....................................................................................................................................................................................................... 26

3.1.1 Technical data......................................................................................................................................................................................26

3.2 Ambient conditions........................................................................................................................................................................................... 29

3.3 Type plate.............................................................................................................................................................................................................. 29

4 Structure and function .......................................................................................................................................30

4.1 Functional description.....................................................................................................................................................................................30

4.2 Machine overview................................................................................................................................................................................................31

4.3 Control panel........................................................................................................................................................................................................33

4.4 Options ................................................................................................................................................................................................................... 34

4.4.1 GreenVac................................................................................................................................................................................................ 34

4.4.2 Inert gas.................................................................................................................................................................................................. 34

5 Transport ............................................................................................................................................................. 35

5.1 Safety instructions .............................................................................................................................................................................................35

5.2 Personnel qualifications ................................................................................................................................................................................. 36

5.3 Transport inspection ........................................................................................................................................................................................ 36

5.4 Packaging ............................................................................................................................................................................................................... 36

6 Installation .......................................................................................................................................................... 37

6.1 Safety instructions .............................................................................................................................................................................................37

6.2 Electrical connection........................................................................................................................................................................................ 38

6.3 GreenVac connection (option).................................................................................................................................................................... 39

7 Control/operation .............................................................................................................................................. 40

7.1 Safety instructions ............................................................................................................................................................................................40

7.2 Requirements for the installation site ....................................................................................................................................................40

7.3 General instructions .......................................................................................................................................................................................... 41

7.4 Information about packaged goods........................................................................................................................................................... 41

7.4.1 Basic machine settings .....................................................................................................................................................................41

7.4.2 Instructions on storage times...................................................................................................................................................... 42

7.4.3 Packaging liquids................................................................................................................................................................................ 43

7.5 Switching on the machine ............................................................................................................................................................................. 43

7.6 Switching off the machine ............................................................................................................................................................................ 43

7.7 Preparing the machine ....................................................................................................................................................................................44

7.8 Preparing the machine for injection of inert gas ............................................................................................................................... 45

7.9 Operation of the controller CP-E3 ...........................................................................................................................................................46

7.9.1 General operation of the controller CP-E3 ..........................................................................................................................46

7.9.2 Editing preinstalled programs.....................................................................................................................................................49

7.9.3 Editing your own programs..........................................................................................................................................................50

7.9.4 Using the USB function ..................................................................................................................................................................50

Erme AG Table of contents

Table models professional v

7.10 Performing the vacuum procedure.............................................................................................................................................................51

7.11 Using the GreenVac option............................................................................................................................................................................52

7.12 Activities after use..............................................................................................................................................................................................52

8 Troubleshooting.................................................................................................................................................. 53

8.1 Safety instructions .............................................................................................................................................................................................53

8.2 Instructions on troubleshooting................................................................................................................................................................. 54

8.3 Fault displays....................................................................................................................................................................................................... 54

8.4 Localising faults...................................................................................................................................................................................................55

9 Cleaning ...............................................................................................................................................................56

9.1 Safety instructions ............................................................................................................................................................................................ 56

9.2 Personnel qualifications ..................................................................................................................................................................................57

9.3 Cleaning the machine .......................................................................................................................................................................................57

10 Maintenance ........................................................................................................................................................58

10.1 Safety instructions............................................................................................................................................................................................ 58

10.2 Personnel qualifications ................................................................................................................................................................................. 59

10.3 Measures prior to maintenance ................................................................................................................................................................. 59

10.4 Service reminder ................................................................................................................................................................................................ 59

10.5 Maintenance report..........................................................................................................................................................................................60

10.6 Description of the maintenance work...................................................................................................................................................... 61

10.6.1 Service program...................................................................................................................................................................................61

10.6.2 Checking the oil level ...................................................................................................................................................................... 62

10.6.3 Cleaning the piston rods................................................................................................................................................................ 62

10.7 Replacing wearing parts................................................................................................................................................................................. 63

10.7.1 Replacing the input fuse ................................................................................................................................................................ 63

11 Decommissioning and disposal ..........................................................................................................................64

11.1 Safety instructions ............................................................................................................................................................................................64

11.2 Personnel qualifications ................................................................................................................................................................................. 65

11.3 Decommissioning............................................................................................................................................................................................... 65

11.3.1 Temporary decommissioning....................................................................................................................................................... 65

11.3.2 Final decommissioning / disassembly...................................................................................................................................... 65

11.4 Disposal .................................................................................................................................................................................................................. 65

12 Declaration of Conformity..................................................................................................................................66

1 | General information Erme AG

6 / 66 Table models professional

1 General information

1.1 Subject of these instructions

The vacuum packaging machine described here was manufactured and placed on the

market by:

ERME AG / SWISS VACUUM SOLUTIONS

Contact data (see Legal notice page 2)

1.2 Target group

In addition to the operator, the target groups for these operating instructions

include:

– Operating personnel — operation and cleaning instructions.

– Maintenance personnel — troubleshooting and maintenance instructions.

– Specialists who are tasked by the operator with performing tests and

maintenance work.

Erme AG General information | 1

Table models professional 7 / 66

1.3 Information about these instructions

1.3.1 Information about the content

These operating instructions contain important information about handling the

machine during installation, commissioning, operation, maintenance and servicing as

well as disassembly and disposal.

Compliance with all specified warning messages and instructions is a prerequisite for

safely, correctly and efficiently working on and with the machine.

Observing the above information helps to prevent dangers, reduce repair costs and

downtimes and increase the reliability and service life of the machine.

In addition, the local accident prevention regulations and general safety regulations

applicable at the site where the machine is operated must also be observed.

Carefully read through the operating instructions before starting all work. They are

part of the product and must be stored at a location where they are always

accessible to the personnel.

In addition to these operating instructions, the instructions for the installed

components provided by the respective supplier are located in the overall

documentation. See chapter Additional sources of information [}12].

1 Observe the information — in particular, the warning messages — contained

therein.

1 | General information Erme AG

8 / 66 Table models professional

1.3.2 Instructions for use

Instructions and system reactions

The work steps to be carried out by the operating personnel are described

consecutively. The order of the steps must be observed. The system reactions to the

respective operational steps are marked by an arrow.

Example:

üRequirement

1 Work step 1

ðReaction to work step 1

Lists

Lists without a mandatory order are displayed as a list with a preceding bullet point.

Example:

– Item 1

– Item 1, sub-item A

– Item 2

Lists with a mandatory order are displayed as a list with a preceding number.

Example:

1. First

2. Second

References to chapters/pages

References to specific chapters in which procedures and instructions are described

are illustrated as active links.

Example: (see chapter A [}8])

Erme AG General information | 1

Table models professional 9 / 66

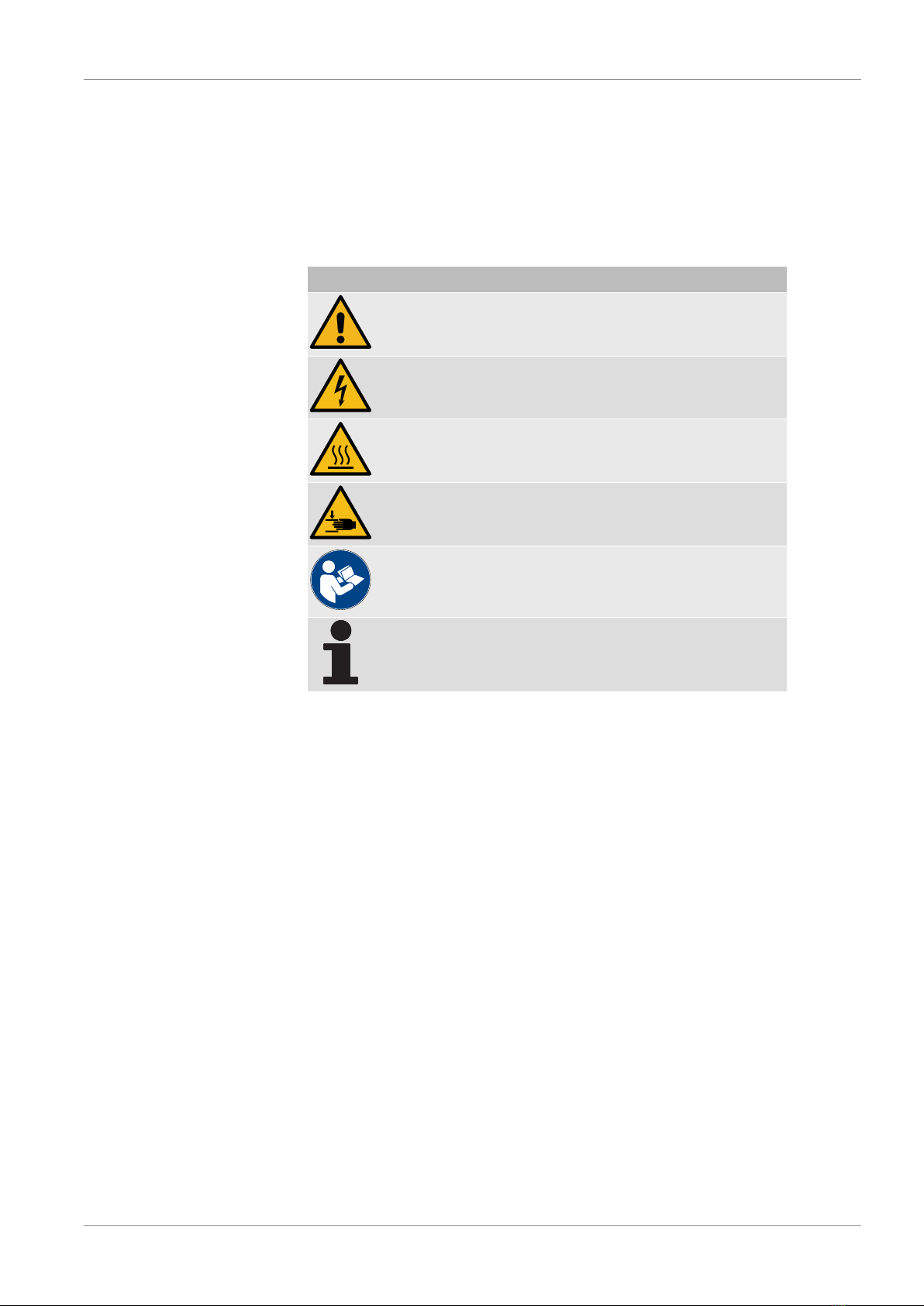

1.3.3 Used symbols

Pictograms

The warning messages used in these operating instructions are also provided with

pictograms to clarify the type of the possible hazard.

The following pictograms are used:

Symbol Meaning

General warning message

Danger due to electricity

Danger due to hot surfaces

Risk of crushing

Observe the operating instructions

General information and helpful tips on handling

1 | General information Erme AG

10 / 66 Table models professional

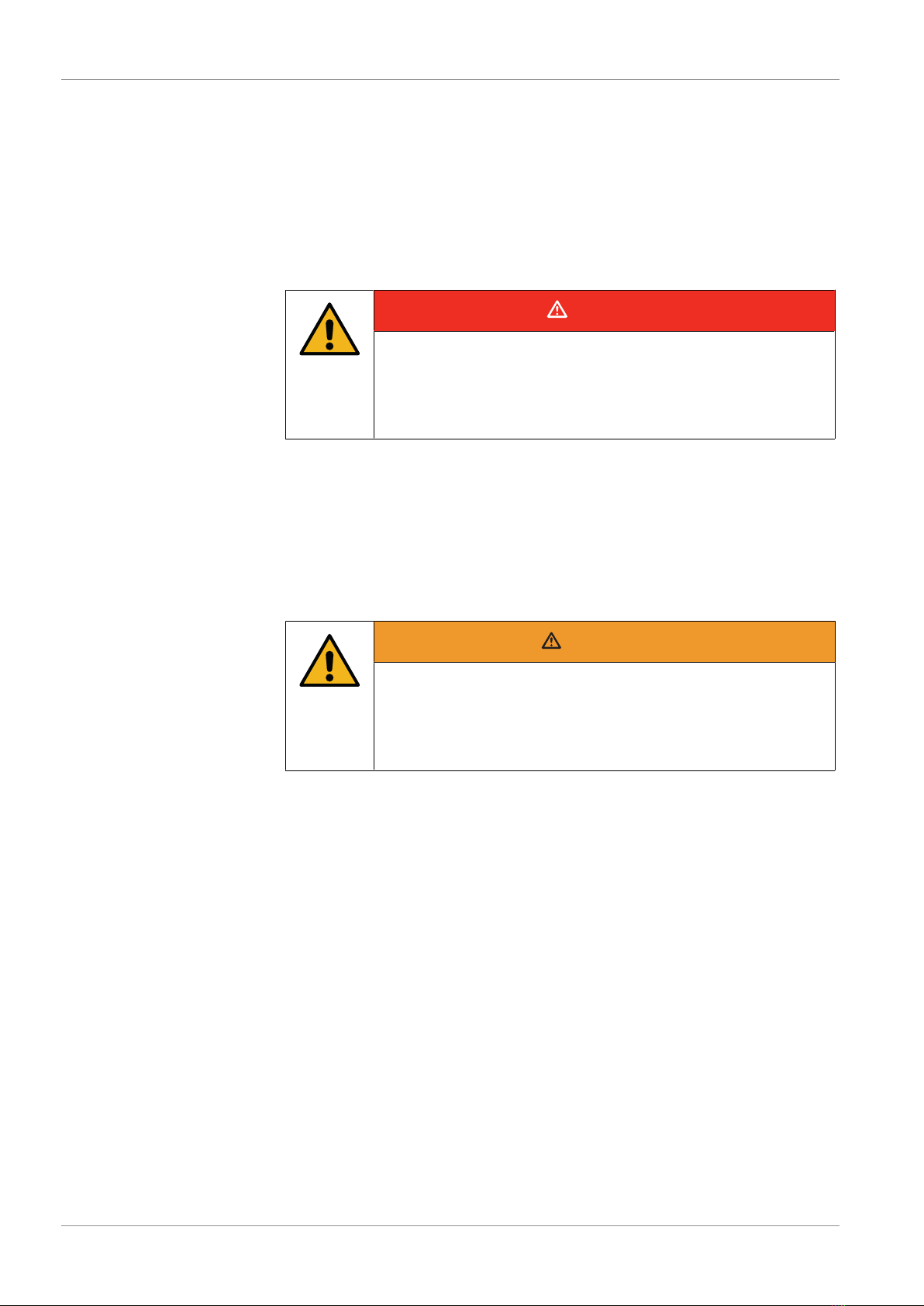

1.3.4 Structure of the warning messages

The warning messages in these operating instructions are introduced by the signal

words DANGER, WARNING, CAUTION and ATTENTION that express the extent of

the hazard. A warning symbol also indicates the nature of the hazard.

The following warning messages are used in these operating instructions:

Risk to life

DANGER

Risk to life!

Consequences of non-compliance...

4Instructions about prevention.

A warning message of this danger level indicates an impending dangerous situation.

If the dangerous situation is not prevented, it will result in death or severe,

irreversible injuries.

Follow the instructions in this warning message to prevent the risk of death or

severe personal injuries.

Risk of injury

WARNING

Risk of injury!

Consequences of non-compliance...

4Instructions about prevention.

A warning message of this danger level indicates a potentially dangerous situation.

If the dangerous situation is not prevented, it may result in death or serious injuries.

Follow the instructions in this warning message to prevent the possible risk of death

or serious personal injuries.

Erme AG General information | 1

Table models professional 11 / 66

Personal injuries

CAUTION

Personal injuries due to...

Consequences of non-compliance...

4Instructions about prevention.

A warning message of this danger level indicates a potentially dangerous situation.

If the dangerous situation is not prevented, it may result in light or moderate

injuries.

Follow the instructions in this warning message to prevent personal injuries.

Material damage

NOTICE

Material damage due to...

Consequences of non-compliance...

4Instructions about prevention.

A warning message of this danger level indicates possible material damage.

If the situation is not prevented, it may result in material damage.

Follow the instructions in this warning message to prevent material damage.

Tips and suggestions

NOTE

Message text…

Consequences

1 | General information Erme AG

12 / 66 Table models professional

1.4 Additional sources of information

In addition to the instructions contained in these machine operating instructions, the

information contained in the sources of information specified below must also be

taken into consideration:

– Information about the signage on the machine

– Operating instructions for the assemblies and purchased parts that are in use

– Instructions from the operator

– Safety data sheets for auxiliary and operating materials

– Local accident prevention regulations and regional regulations at the machine

operating site

– Data sheets for installed components

1 Observe the information — in particular, the safety instructions — contained

therein.

1.5 Limitations of liability

All information and instructions provided in these operating instructions were

compiled taking into consideration the applicable standards and regulations, the

technological state-of-the-art as well as knowledge and experience acquired over

many years.

We reserve the right to make technical modifications in the course of further

developing the machine that is the subject of these operating instructions. No claims

can be derived from the information, figures and descriptions provided in these

operating instructions.

The manufacturer assumes no liability for damage and malfunctions due to:

– Non-compliance with these operating instructions

– Unintended use

– Personnel who are not sufficiently trained or trained at all

– Use of impermissible equipment

– Faulty connection

– Non-use of original spare parts and accessories

– Technical modifications and conversions unless they have been coordinated with

the manufacturer

– Non-performance of the required maintenance work

– Performance of welding work on the machine

The manufacturer is liable for any faults or failures on our part, not including further

claims arising within the context of the warranty obligations specified in the

contract. Claims for compensation, regardless of the legal grounds, will be excluded.

Erme AG General information | 1

Table models professional 13 / 66

1.6 Copyright protection

This documentation is protected by copyright.

We reserve all rights, including the rights of photomechanical reproduction,

duplication and the distribution through special procedures (for example, data

processing, data carriers and data networks), also in part, as well as the right to

make content-related and technical modifications.

1.7 Warranty provisions

According to the Purchase Agreement, the company ERME AG provides the

corresponding warranty from the delivery date of the machine.

The warranty extends to the material and manufacturing defects, which occur during

normal load (single-shift operation).

The warranty excludes improper operation, incorrect electrical installations and wear

parts.

Our "General Terms and Conditions" apply.

1.8 Customer service

Please keep the following information readily available for all contact with our

customer service department:

– Machine type (see type plate on the machine)

– Purchase date (see proof of purchase)

Contact data (see Legal notice page 2)

NOTE

We recommend that the operator conclude a maintenance

agreement with ERME AG.

This ensures that the machine will be regularly maintained by our

service personnel and also ensures the supply of necessary wear

and spare parts without long delivery times.

1.9 Product monitoring

The company ERME AG monitors its machines up to and after delivery.

Therefore, please provide us with the following information:

– Any accidents that have occurred;

– Problems that have occurred when using the machine;

– Malfunctions that occur during specific operational situations;

– Experiences that could be important for other users.

Contact data (see Legal notice page 2)

2 | Safety Erme AG

14 / 66 Table models professional

2 Safety

2.1 General information

This chapter provides important information about all safety aspects to ensure the

optimum protection of personnel as well as safe and smooth operation.

Non-compliance with the safety instructions and handling instructions specified in

these operating instructions may result in significant hazards.

1 Make sure to observe the warning messages and instructions specified in the

operating instructions.

2.2 Intended use

The vacuum packaging machine is only suitable for packaging solid and liquid food as

well as technical products. The machine must not be used in electrostatic discharge-

protected (ESD) areas.

The machine may only be used within the technical specifications and under the

operating conditions defined by the manufacturer.

Any other use beyond this scope is not considered as the intended use.

The permissible values specified in the "Technical data [}26]" section must be

observed.

2.2.1 Foreseeable misuse

Any use for purposes other than that specified above is not intended.

The operator solely bears the risk of unintended use or misuse.

Misuse occurs, for example, if

– The machine is not used for its intended purpose.

– The information provided in these operating instructions is not strictly observed.

– Modifications are made to the machine.

– The machine is used in a potentially explosive area.

– The machine is used in electrostatic discharge-protected (ESD) departments.

– Aggressive, combustible liquids, such as petroleum, benzol, benzene, (explosive

vapours!) as well as infectious substances, living beings and material whose

processing violates laws or social standards are packaged.

Erme AG Safety | 2

Table models professional 15 / 66

2.3 Basic safety instructions

The machine is built according to the current directives, the technological state-of-

the-art and the established safety rules and regulations.

Hazards and adverse effects may, however, occur when operating the machine:

– To life and limb of the user or third parties

– To life and limb of the maintenance personnel

– To the machine itself

– To other equipment

Knowledge of the safety and user instructions set out in these instructions provides

the basis for safe handling and smooth operation of the machine.

Set up the machine where it is out of the reach of children.

Regularly clean the machine.

Only have service and repair work performed by the ERME customer service

department or an authorised dealer.

2 | Safety Erme AG

16 / 66 Table models professional

2.4 Special dangers / residual risks

2.4.1 Danger due to electrical current

There is a risk of death when making contact with lines or components that carry

current.

– Do not use the machine if electrical lines, plugs or the insulating housing are

damaged. Perform checks according to the intervals for recurring tests/

inspections specified in the operating instructions.

– Work on electrical equipment must only be carried out by qualified electricians

or personnel under the guidance and supervision of a qualified electrician in

accordance with electrical engineering regulations.

– Defects identified on the electrical components/equipment must be corrected

immediately. If there is an acute danger up until that point, the machine,

component or equipment must not be used in a defective condition.

– Machine parts on which inspection, maintenance and repair work are performed

— if required — must be de-energised. First check that parts that have been

disconnected from the power are free of voltage, then earth and short circuit

them and isolate adjacent live parts.

– If work is required on live parts, involve a second person who can disconnect the

main power switch in case of an emergency. Block off the work area with a red

and white security chain and a warning sign. Only use insulated tools.

2.4.2 Danger due to hot surfaces

Hot surfaces can cause serious injuries.

The machine reaches high temperatures during operation.

– Take safety precautions against fires, burns and overheating.

– Wear personal protective equipment.

– Do not touch the machine and, in particular, the sealing bar.

– After stopping operation, let the machine sufficiently cool down.

Erme AG Safety | 2

Table models professional 17 / 66

2.4.3 Danger due to pressurised components

Serious injuries may occur due to components under high pressure.

– Maintenance and repair work on the inert gas equipment must only be

performed by personnel especially trained for this.

– Prior to maintenance and repair work, depressurise all machine components that

are under pressure (take the pressure accumulator into consideration here).

– Regularly check the pressurised components.

– Regularly replace hose lines during preventative maintenance, even if no damage

is detected.

– Observe the warning messages and instructions specified in the operating

instructions.

– Wear personal protective equipment when working on the machine.

2.4.4 Danger due to oxygen-displacing gases

Risk of suffocation due to high inert gas concentrations.

Higher concentrations of inert gas can result in suffocation, since they displace the

atmospheric oxygen.

– Only operate the machine at a well-ventilated location.

If necessary, install a device for monitoring the ambient air.

– Keep the air slots and openings free and clean.

– Make sure that the inert gas equipment is regularly checked for leaks.

– To ensure safe handling, observe the safety data sheet for the inert gas.

2.4.5 Risk of crushing

There is a risk of crushing between the lid and the machine.

– Never use the machine without a gas pressure cylinder or lid lifter.

– When closing the lid, make sure that body parts do not get caught.

2 | Safety Erme AG

18 / 66 Table models professional

2.5 Emissions

2.5.1 Noise emission

Refer to the technical data for the machine's noise emission (see "Technical data

[}26]").

To evaluate the overall noise level at the machine's operating site, observe the local

noise control regulations and measure the noise if necessary.

2.6 The operator's responsibility

When using the machine in the commercial sector, the operator is subject to the

legal obligations on occupational safety.

In addition to the occupational safety instructions provided in these operating

instructions, the safety, accident prevention and environmental protection

regulations applicable for the location where the machine is operated must be

observed.

The operator must

– obtain information about the applicable occupational safety regulations and

carry out a risk assessment to identify additional dangers, which arise due to the

special working conditions at the machine's operating site. This assessment must

be implemented in the form of operating instructions for the machine.

– check during the entire operating time of the machine whether the operating

instructions prepared by the operator correspond with the current status of the

regulations, and adapt them as necessary.

– secure dangerous areas that are created between the machine and other

equipment provided by the customer.

– clearly regulate and define the responsibilities for installation, operation,

maintenance and cleaning.

– define the machine operator's responsibility and authorise it to reject

instructions from third parties that are detrimental to safety.

– ensure that all personnel who handle the machine have read and understood

the operating instructions.

In addition, it must also train the personnel at regular intervals and notify them

of the dangers.

– ensure that these operating instructions and all other applicable regulations are

readily available to the operating and maintenance personnel.

– regularly check that the personnel are working in a safe manner while remaining

aware of the dangers in compliance with these operating instructions.

– provide the personnel with the required personal protective equipment.

– ensure that hearing protection is worn if the permissible noise level (85 dB(A)) is

exceeded at the operating site.

The operator is also responsible for ensuring that the machine is in perfect working

order. The following therefore applies:

Erme AG Safety | 2

Table models professional 19 / 66

– The operator must ensure that the cleaning and maintenance intervals defined

in these operating instructions are observed.

– The operator must have all safety equipment regularly checked for proper

functioning and completeness.

2.7 Personnel requirements

2.7.1 Personnel qualifications

Improper handling can result in significant personal injuries and material damages.

– Have all activities performed by appropriately qualified personnel only.

The following qualifications for various areas of activities are specified in these

operating instructions:

Instructed person

– The instructed person has been trained using instructions provided by the

operator about the work assigned to him/her and the possible hazards in case of

improper behaviour.

Skilled personnel

– The specialised personnel can, as a result of his/her technical training,

knowledge and experiences as well as knowledge of the relevant regulations,

perform the work to which he/she has been assigned and independently identify

and avoid possible hazards.

Qualified electricians

– can, as a result of his/her technical training, knowledge and experience as well as

knowledge of the relevant standards and regulations, perform work on electrical

machines and independently identify and avoid possible hazards.

The qualified electrician is trained for the particular operation site where he/she

works and knows the relevant standards and regulations.

Only persons who can be expected to reliably perform their work are permitted to

work as operating personnel. Persons whose responsiveness is impaired, e.g. by

drugs, alcohol or medicines, are not permitted.

Personnel who are yet to be trained, taught, instructed or are undergoing general

training may only work on the machine under constant supervision of an experienced

person.

The machine may be used by persons with limited physical, sensory or mental

capabilities or with insufficient experience if they are supervised or have been

instructed in its safe use and have understood the associated dangers.

NOTE

Observe the age and occupational-specific regulations that apply

at the operating site when selecting personnel.

2 | Safety Erme AG

20 / 66 Table models professional

2.7.2 Unauthorised personnel

Unauthorised personnel who do not fulfil the described requirements are not aware

of the dangers in the work area.

– Keep unauthorised personnel away from the work area.

– In case of doubt, address the personnel and direct them out of the work area.

– Stop working as long as unauthorised personnel are in the work area.

2.7.3 Instruction

The personnel must be regularly instructed by the operator.

NOTE

For better tracking, document the performance of the training

programs and have the participants confirm their participation

with their signature.

This manual suits for next models

2

Table of contents

Other ERME Kitchen Appliance manuals

Popular Kitchen Appliance manuals by other brands

Nostalgia Electrics

Nostalgia Electrics DFF-310 owner's manual

ELICA

ELICA EWS52SS1 instruction manual

river systems

river systems Mistral 50L Use and maintenance manual

Breville

Breville Fresh Keeper BVP700 Instruction booklet

CDA

CDA RC9300 Operating & installation instructions

Silhouette

Silhouette Select DOBC7070SSST owner's manual