Ernex AS MaxiCut 1500 User manual

1

2

CONTENTS

1. Safety instructions 3

2. General instructions/Dust and Noise 4

3. Directions for assembly/Power Supply 5

4. Control functions/Transport 9

5. Operation 10

6. Maintenance/Repair 14

7. Troubleshooting 16

8. Warranty 17

9. Technical data 18

10. Standard/optional equipment 19

11. Spare part list/drawings 20

12. Wiring diagaram 25

13. Conformity declaration 26

14. Product marks 27

Original Manual: Norwegian 520102

3

1. SAFETY INSTRUCTIONS

1. This machine is designed and constructed by Ernex AS and has been submitted for test

and found in conformity with the Machine Directive 2006/42/EF, 2006/95/EF and EN 1870-5:

2002.

2. The Health and Safety at Work places duties on designers, manufacturers and supp-liers to

ensure that among other things: 1. articles supplied for use at work are, so far as is reason-

ably practicable, safe and without risks to health during setting, cleaning and maintenance

and 2. persons supplied with the articles are provided with ade-quate information about the

use for which they are designed and about conditions necessary to ensure that they will be

safe and without risks to health.

3. These duties will apply to you if you re-supply the machine by way of sale, lease, hire or hire

purchase.

4. Persons who install this machine for use at work have a duty under the Health and Safety

at Work to ensure, so far as is reasonably practicable, that nothing about the way in which it

is installed makes it unsafe or a risk to health at all times during setting, use, cleaning and

maintenance. This includes such aspects as correct assembly, electrical installation, con-

struction of enclosures, fitting of guards and exhaust ventilating equipment. When installing

this machine, consideration must be given to the provision of adequate lighting and working

space.

5. This machine is supplied complete with all necessary safeguards to enable the user to

comply with the Woodworking Machines Regulations and the Provision and use of Work

Equipment Regulations. Details of correct installation and use, together with guidance on

fitting and proper adjustment of guards are described in this manual.

6. The Woodworking Machines Regulations place absolute legal duty on employers and em-

ployees to ensure that guards and the Provision and use of Work Equipment Regulations and

any other safety devices are securely fitted, correctly adjusted and properly maintained.

7. Repairs and maintenance must only be undertaken by competent technicians. Ensure that

all power supplies are isolated before maintenance work commences. Instructions for routine

maintenance are included in this manual.

8. Machine operators must have received sufficient training and instructions as to the dangers

arising in connection with the machine, the precautions to be observed and the requirements

of the Woodworking Machines Regulations which apply, except where they work under the

adequate supervision of a person who has a thorough knowledge and experience of the

machine and the required safeguards.

9. Persons under the age of eighteen years must have successfully completed an approved

HSE course of training before operating this machine at work, unless participating in a course

of training under adequate supervision. (NB. This paragraph is only relevant to: circular

sawing machines, any sawing machine fitted with a circular blade, any planing machine for

surfacing which is not mechanically fed or any vertical spindle moulding machine).

The saw can be used for sawing wood, plywood and chipboard.

The saw must not be used on plasterboard, polysterene and tarred paper (for roofing).

WARNING: Safety equipment such as riving knife, blade guard and push sticks must not be

removed, but have to be used.

4

2. GENERAL INSTRUCTIONS

2.1 General safety precautions:

• IMPORTANT! According to the CE-regulations, rollertables must always be used.

• IMPORTANT! Note that the sawblade moves up and forward the entire length of the

slot. This is the essence of the MaxiCut concept.

• Ensurethatthereisadequateroomaroundthesaw.

• Forbeststability,placesawonalevelandevensurface.

• Keepsawtable,sawbladecoverandareaaroundsawfreeforoffcutsandexcessive

sawdust.

• Theworkingareashouldbewellventilatedandasawdustextractororcollectormustbe

used.

• Usegoodlightingandadequatehearingandeyesightprotection.

• Whensawinglongerpiecesusetheextraoutfeedtableorsuitablesupport.

• Alwayslowertopguardwhensawing.

• Usepushstickswhenrippingsmallmaterialsandwhenthedistancebetweensawblade

and rip fence is less than 120 mm (approx. 5”).

• Whentiltingthesawblade,theblademustalwaysbeloweredunderthetableandthe

motor should be switched off.

• Lowersawbladewhennotinuse.

• Alwaysuserivingknife.

• Disconnectmaincablewhenchangingsawbladeorperformingothermaintenancework.

• Useonlycarbide-tippedsawbladewhichisproperlysharpened.Neveruseacrackedor

deformed sawblade.

• Thesawisequippedwithanautomaticmotor-brake.Ifthesawcontinuestorotatefor

more than 10 seconds after the off-button has been pressed, the braking mechanism

must be replaced.

• Ensurethatthesawbladecoverisclosedaftersawbladehasbeencleanedand/or

changed or if riving knife has been changed or adjusted.

• Wornaluminiumedgingstripsinturntableshouldbereplaced.

Dust and noise:

Dust and noise measurements have been performed for work with the materials and saw

blades for which the machine is intended (see section 1 Safety Instructions).

Measurement uncertainty is related to local conditions and can vary with the saw blade/

transmission characteristics. Follow the maintenance instructions (see Section 6 Mainte

nance/Repair).

Ear protection must be used, and a dust mask is recommended.

For indoor use, the machine must be connected to an extractor

that provides a minimum air speed of 30 m/s i.e. 1.8 kPa.

5

3. DIRECTIONS FOR ASSEMBLY

3.1 Top guard adjustment

• Adjustthetopguard(Fig. 2) so that the wooden strip on the inside of the guard

is 3 mm from the saw blade. See Fig. 1.

3 mm (1/8")

Fig. 1

Fig. 2

6

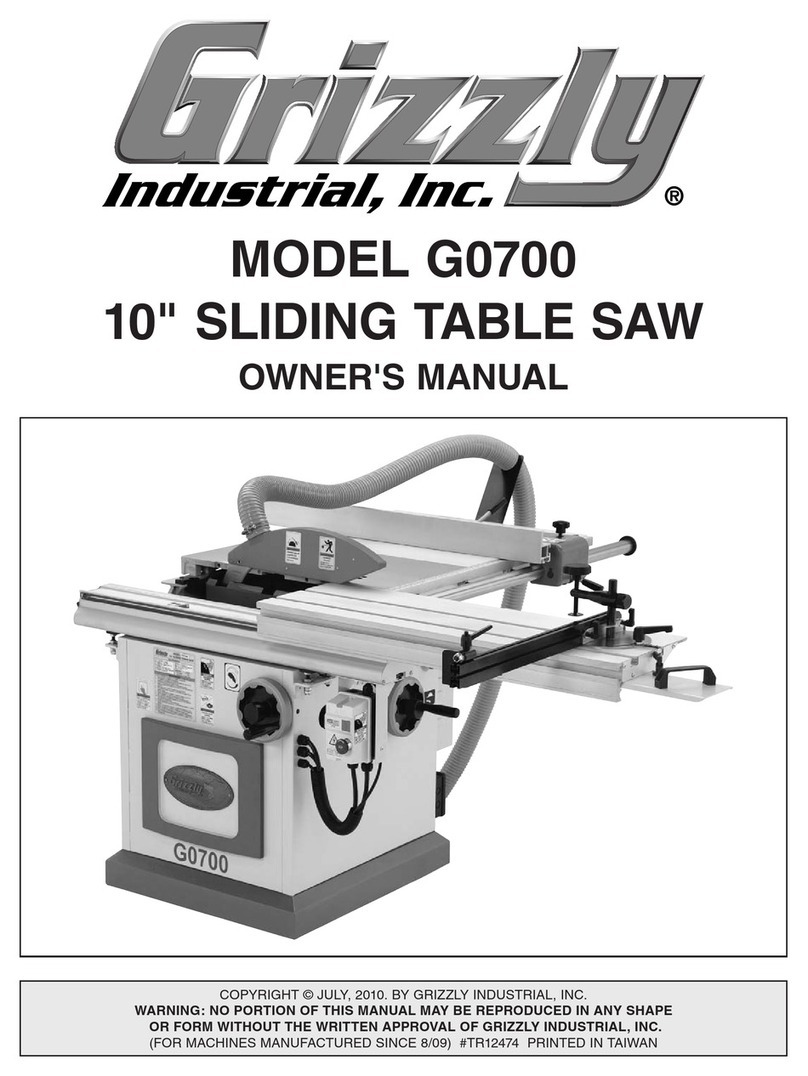

3.2 Mounting rollerbox and adjustable rollertable

• Attachguidebartosawbyturninglockinghandle.See Fig. 3.

• RemovestopscrewAat the end of the guide bar and insert the end of the roller-

box into the guide bar. Retighten stop screw A.

• Setuprollertablesupporttrestleandadjustatapproximateheight.Attachthe

rollertable to the rollerbox with screws. Now adjust correct trestle height L

Fig. 3a.

• Adjustrollerboxheight,bringingitushwiththeturntablebylooseningthelock-

nuts on the guide bar fastening screws B, adjusting the screws and locknuts

Fig. 3. Check rollerbox height by laying the rip fence across the turntable, roller-

box and rollertable. Tighten the locknuts and re-check the height.

• FitripfenceasillustratedinFig. 4a/4b.

• AdjustguidebaranglebymeansofscrewsB. Set turntable at 90° and use a

carpenter’s square to check the angle between the rip fence and the sawblade

Fig. 4b. Tighten screws and re-check angle Fig. 3.

A

B

C

C

Fig. 3

L

Fig. 4a

Fig. 3a

Fig. 4b

7

3.3 Attaching support roller

• AttachsupportrollertothesawusingM10x16screws.SeeFig. 5.

Fig. 5

3.4 Assembling the fixed table w/board support

Assemble as illustrated in Fig. 6a/6b.

M10 x 16

Fig. 6a

Fig. 6b

8

3.4 Connecting mains supply - direction of rotation

• Whenconnectingasawwithathree-phasemotortothemains,checktosee

that the sawblade rotates in the right direction (away from the riving knife). The

direction of blade rotation is indicated on the sawblade cover under the table.

If the blade rotates in the wrong direction, two of the phases must be switched.

This should be done by an electrician. Three-phase saws which run on 400 V

have a change of phase switch which is operated by a screwdriver. These saws

are fitted with a neutral wire, i.e. 5-prong plugs. Note the placement of the neutral

prong in Fig. 7. Check also to see that the blade is mounted correctly with re-

gards to the direction of rotation.

• NOTE! For single-phase motors, supply cables must have at least 2.5 mm2

conductors. Recommended cablelength max. 20 feet.

• Extensioncordsmusthavegroundprotection.

• For3-phasemotors,thisdimensionisrequiredforcablesover10feetin

length.

S2 T3

R1 N

3P+N+

Kobl. 400V (5 pins)

Fig. 7

9

4. CONTROL FUNCTIONS/TRANSPORT

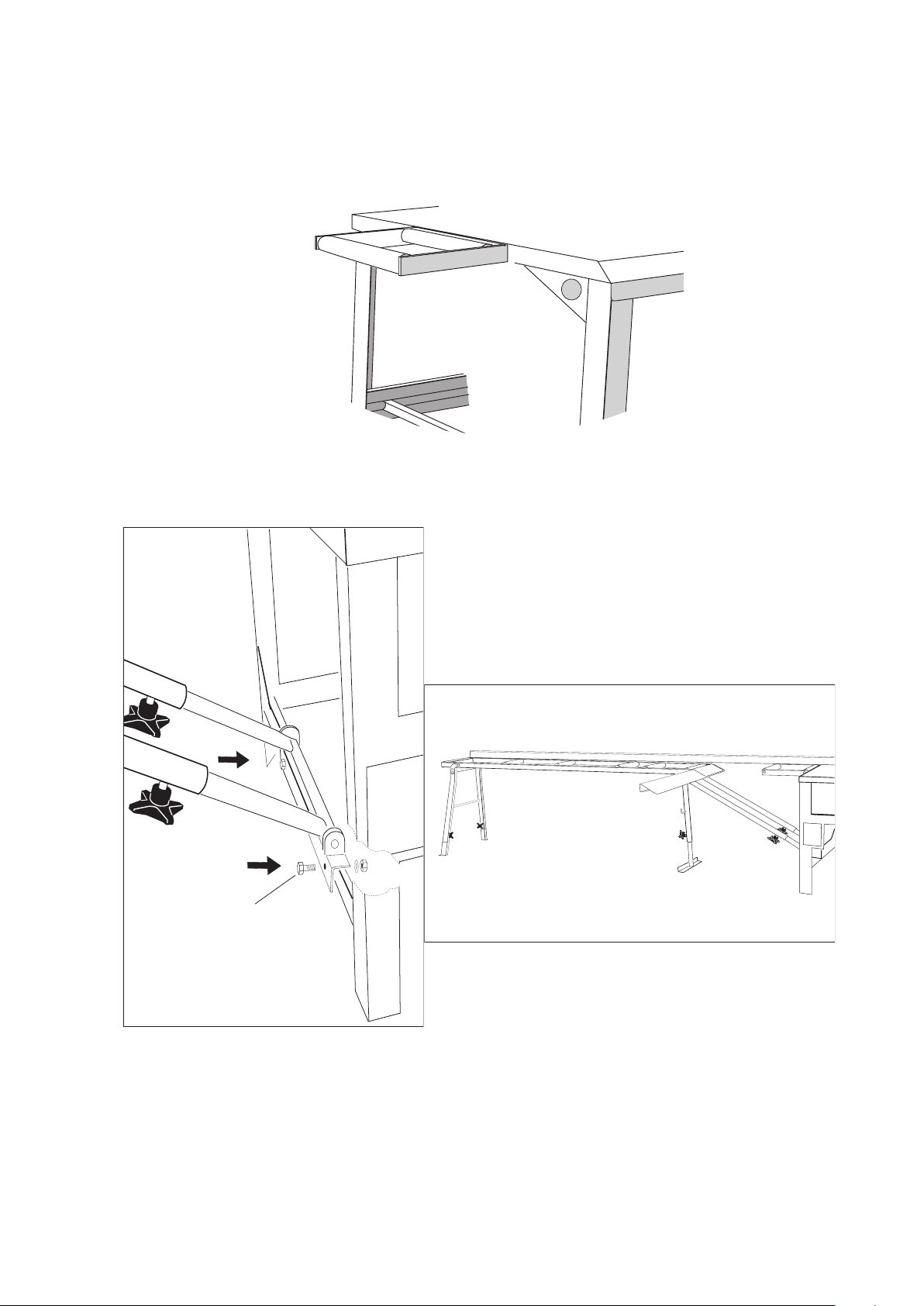

4.1 Raising and lowering transport wheels

• Topositionthewheelsfortransport,liftthesawbythehandlessothattheaxle

drops into the bottom notch, and lower the saw again.

• Thesawshouldnotbeleftstandingonitswheelsduringmotorvehicletransport

orwhileinuse.Liftsawandpushaxleupintothenotchtotherear.SeeFig. 8.

4.2 Accessories

• OnthefrontofthesawisatoolboxG

which may be locked.

• Thesawisprovidedwith4handlesfor

lifting.

• Oneofthesawlegshasareceptaclefor

push sticks.

• Whenliftingthesawwithacrane,place

slings in the holes on either side of the

saw.

4.3 Starting and stopping motor

An On/Off switch Cis located on one of the legs.

A cover which can be locked with a padlock is

mounted over the switches. See Fig. 9. Incor-

porated into the switch is a zero-voltage switch

which prevents the motor from starting unexpect-

edly after a power-out. If the motor is overloaded,

the built-in overload feature will disconnect the

power. After a short cooling-off period the motor

may be started again by pressing the start but-

ton. Avoid overloading the motor.

D

E

20

0°

45°

C

F

G

Fig. 8

Fig. 9

10

4.4 Raising and lowering saw blade

The saw blade is raised and lowered by means of the elevation arm illustrated in D,

Fig. 9. The blade may be locked at the desired height by means of the elevation locking clamp

illustrated in D, same figure.

4.5 Tilting saw blade

Thesawblademustbeinlowpositionwhenadjustingtiltingangle.Loosentiltinglocking

clamp Fto tilt saw blade from 0° to 45°. See Fig. 9. The angle of tilt is indicated on the

scale in the turn table.

4.6 Turning turn table

The turn table may be turned horizontally from 0° (ripping) to 135°, though it is limited to

90° when the short rollertable is attached. The angle is indicated by means of a scale on

theturntableandamarkonthesawtable.Lockturntableindesiredpositionbypush-

ing stop handle Eto the left. Free turn table by pushing stop handle to the right. The saw

is also provided with pre-stops at 0° - 45° - 90° and 135°. See Fig.9.

5. OPERATION

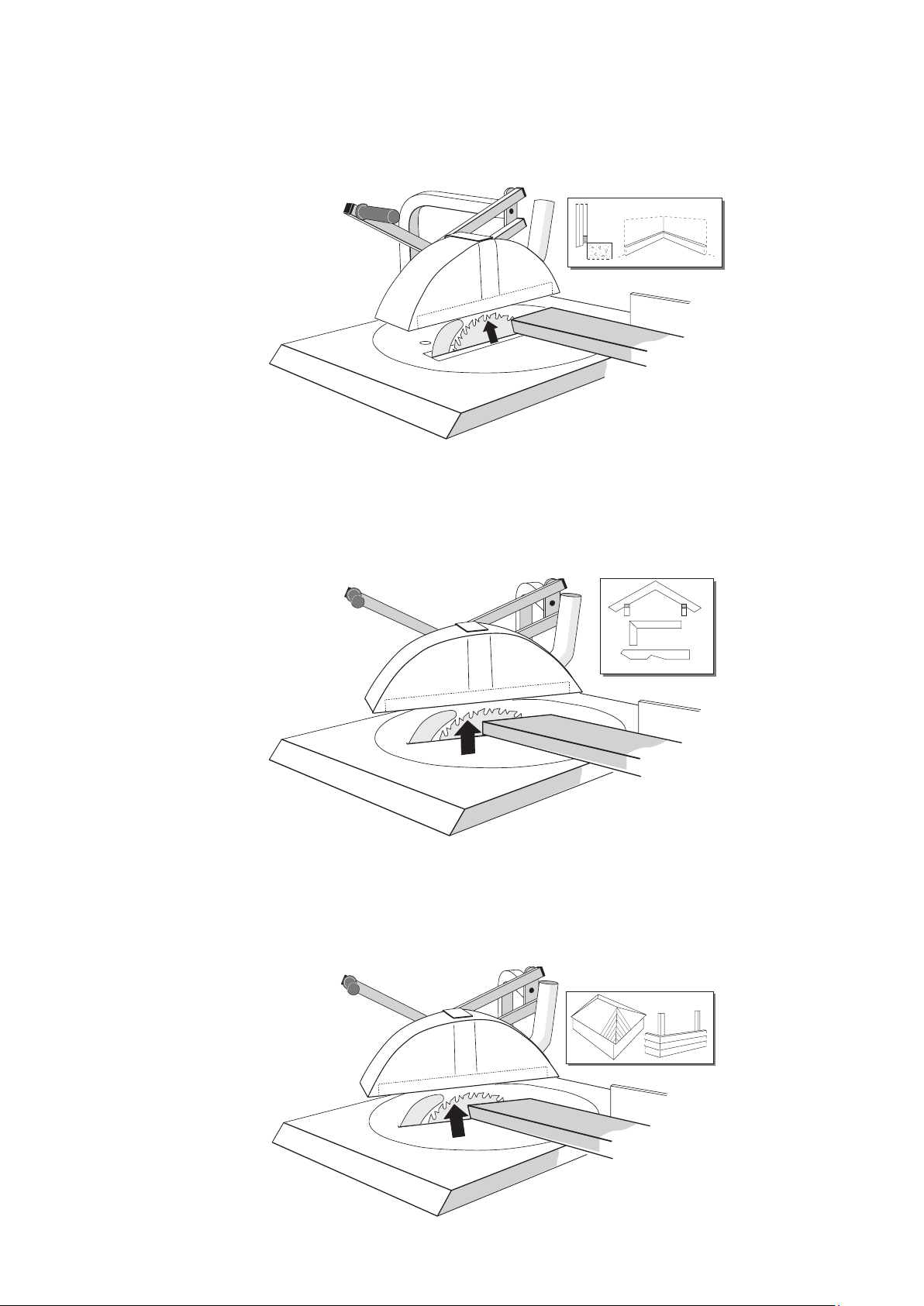

5.1 Crosscutting

There are two methods for making crosscuts (with the turntable at 90°).

A • Holdmaterialagainstfenceandraisesawbladetomakecut.

IMPORTANT! Note that the saw blade moves up and forward the entire length

of the slot. This is the essence of the MaxiCut concept.

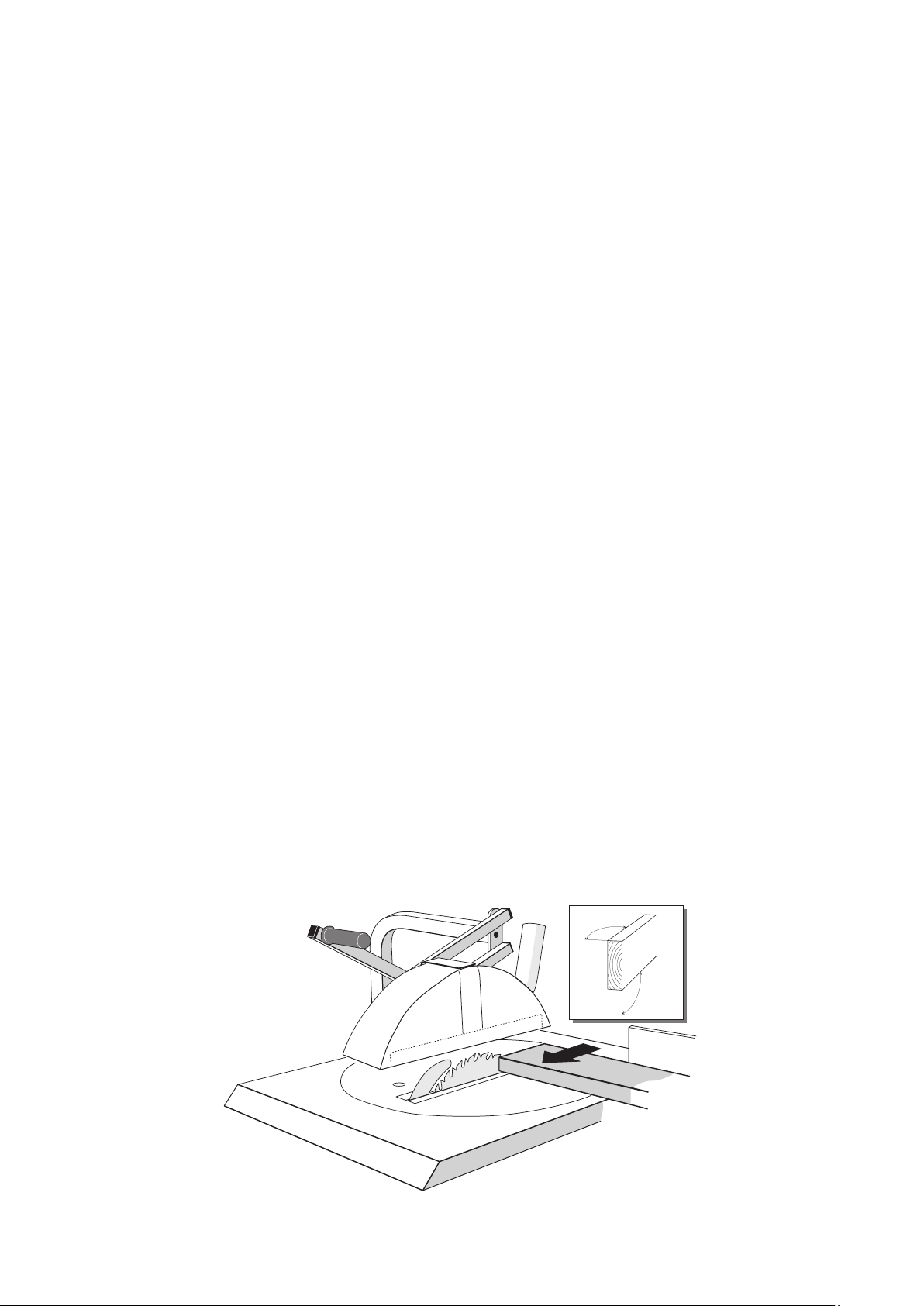

B • Raisesawbladetodesiredheightandlockintoplace.Placematerialagainst

fence behind saw blade and feed material into sawblade by pulling fence.

See Fig. 10.

CAUTION! Crosscutting as described in Bcan only be done with saw blade set

at a 90° angle. Never saw more pieces at one time than can be held securely

against the fence.

CAUTION! Never stack boards higher than the rip fence provides support for.

90°

90°

Fig. 10

11

5.2 Bevelled crosscutting (tilted blade)

• Tiltsawbladetodesiredangleandtightenlockingclamp.

• Placematerialagainstfenceandcutbyliftingsawblade.See Fig. 11.

5.3 Angled crosscutting

• Turnturntabletodesiredangleinrelationtofence.

• Holdmaterialagainstfenceandcutbyliftingsawblade.See Fig. 12.

5.4 Compound angle cutting

• Setturntableasforanangledcrosscut.

• Tiltsawbladetodesiredangleandlock.

• Holdmaterialagainstfenceandcutbyliftingsawblade.See Fig. 13.

Fig. 11

Fig. 12

Fig. 13

12

5.5 Ripping

• Locksawbladeatdesiredheight.Theblademustbeparalleltothefence.

• Positionthefencelengthwisesothatitsendisinlevelwiththecentreofthesaw-

blade.

• Lockfenceatdesireddistancefromsawbladetoobtainwidthrequired.

• Feedmaterialalongfenceandintosawblade.Usepushstickswhenthedistance

between sawblade and fence is less than 120 mm (5”) and the remaining length is

less than 120 mm (5”). See Fig.14.

5.6 Ripping with bevelled cuts

• Setturntableandfenceforrippingandadjustsawbladetodesiredverticalangle

and lock. Perform operation as described in 5.5. See fig. 15.

5.7 Cutting grooves lengthwise

• Setsawbladeinverticalposition,raiseandlockatdesiredheight.Theblademustbe

parallel to the fence.

• Lockfenceatdesireddistancefromsawblade.

• Feedmaterialalongfencetowardsthesawblade,usingpushstickswhenthe

distance between fence and sawblade is less than 120 mm (5”) and trailing end of

material is less than 120 mm (5”) from sawblade.

• Adjustfenceandrepeatoperationuntilgrooveistherequiredwidth.See Fig. 16.

Fig. 14

Fig. 15

13

5.8 Cutting rabbets and grooves across material

• Settheturntableat90°tothefenceandlockthesawbladeatthedesiredheight.

• Holdmaterialagainstthefenceandfeeditthroughthesawbladebypullingthe

rollertable towards you.

• Advancematerialslightlyalongthefenceandrepeattheoperationuntiltherab-

bet or groove has the proper width. See Fig. 17.

Fig. 16

Fig. 17

14

6. MAINTENANCE/REPAIR

CAUTION! Make sure power supply is disconnected while performing mainte-

nance operations. A minimum of maintenance is required to ensure satisfactory

performance and a long service life.

• Lubricatemovingparts,linkagesandthebearingscarryingtheturntableatregu-

lar intervals. It is also important to lubricate the moving rings at the ends of the

sawblade spindle.

• Checkallscrewsandnutsregularlyfortightness.

• Topguardshouldbeclean.Ifdamageditshouldbereplaced.

• Keepsawandsawbladecoverfreefromsawdust.Payparticularattentiontomo-

tor ventilation openings and cooling fins.

• Keepsawbladecleanandinorder.Replacebladeifthereareanycracksor

missingteeth.Removeresindepositswithasuitablecleaninguid.

• Thesawisequippedwithanautomaticmotor-brake.Ifthesawcontinuestoro-

tate for more than 10 seconds after the off-button has been pressed, the braking

mechanism must be replaced.

• Thesawmaybeconnectedtoasawdustextractorwithaminimumcapacityof

1100 m3/h.

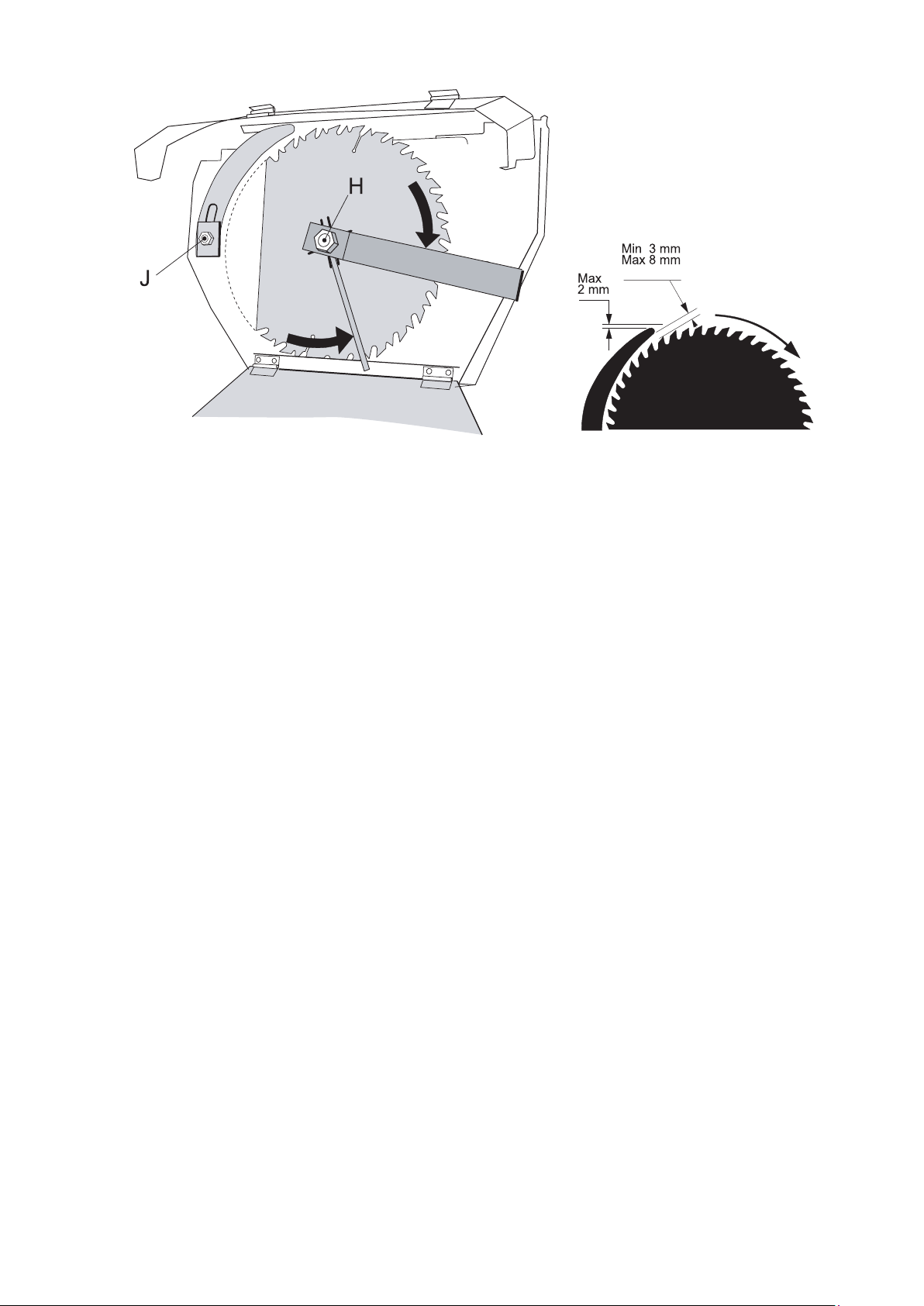

6.1 Replacing sawblade

• Sawblademustbeinlowerpositionwhenbeingremoved.

• Usetoolstoopensawbladecover.Restrainuppercoverusingchainundersawta-

ble.Usetoolssuppliedwithsawtoremovesawblade.ArbornutHhas a left-hand

threadandisunscrewedbyturningclockwise.Useanothertooltokeepsawb-

lade from rotating while removing arbor nut. Close cover when finished. See Fig.

18.

6.2 Replacing and adjusting riving knife

• Therivingknifemustalwaysbettedwhenthesawisbeingused.Adjustriving

knife as illustrated in Fig. 18 and 19.

• Whenreplacingsawbladewithabladeofadifferentthickness,therivingknife

mustbereplacedaswell.LoosennutJ to free riving knife. The thickness of the

riving knife should be 0.2 mm wider than the kerf width of the sawblade. Be sure

to close the saw blade cover when finished.

6.3 Replacing top guard and push sticks

• Thetopguardandpushsticksareimportantsafetyfeatureswhichmustbe

replaced immediately if damaged in any way.

15

Fig. 18 Fig. 19

REPAIR

Routines at repair:

* The machine must only be repaired by qualified electricians or authorised

service workshops.

Testing the brakes:

* The brake for the saw blade rotation should be tested regularly.The stop-time

must be max. 10 sec. Start/stop the saw 10 times in a row and check the

stop-time.

16

7. TROUBLESHOOTING

The saw does not start:

* check the power supply

* do not use the cable with several machines at the same time

* check that the cable is not too long, and that the cross-section is not too small

* contact an electrician

The saw vibrates and is weak

* check that the blade box under the bench does not contain chips and sawdust

* check the spindle

* check the saw blade for eccentricity, and that all the teeth are whole and sharp

* check that the motor brake is clean and that it loosens when starting up, clean

it by removing the fan cover and for instance use compressed air to purify.

The saw blade is heavy to lift and does not go down completely

* check that nothing is stuck in the blade box

* check that the bearings in the universal joint and the movable glide rings at either

end of the spindle are not stuck

17

8. WARRANTY

Notwithstanding any statutory requirements, Ernex AS provide warranty in accordance with the

legislation of the customer‘s own country of residence, but in all cases for a minimum of 3 years,

except for electrical parts which still has a 1-year warranty commencing from the date on which

the machine is sold to the end user. Ernex AS/The importer promise to repair, or at our op-

tion, replace with like grade and quality any product determined to be faulty due to the failure of

parts, material or workmanship.

The warranty covers defects in material and/or workmanship only. When making a claim under

the warranty, proof of purchase bearing the original date of purchase must be submitted. The

repairs under warranty may only be carried out by Ernex AS, or by authorized Ernex warranty

service agents or the importer.

The warranty will not apply in cases of:

- incorrect use, overloading of the machine or fitting non-approved accessories

-useofforce,damagecausedbyexternalinuences,orforeignbodies

- damage caused by non-observance of the instructions for use, such as connection to an

unsuitable mains supply or voltage or non-compliance with the installation instructions

- normal wear and tear

The warranty also does not cover machines which have been partially or completely dismantled.

18

9. TECHNICAL DATA

MaxiCut 1500

Manufacturer: Ernex AS, Norway.

NS-ISO 9001

Model: Norsaw MaxiCut 1500.

Table: 650 mm x 790 mm.

Height: 885 mm.

Weight: 124 kg.

Sawblade: Carbide-tipped, Z=32.

Diam. 360 mm.

Arborhole30mm.(USA31.75mm.)

Kerfwidth3.5mm.

Riving knife: Hardened steel, thickness 3.0 mm.

Cutting height: 104 mm at 90° (vertical)

80 mm at 45° (tilted).

Motor: 2.2 kW-230V single phase.

1.6 kW-110V single phase.

2.2 kW-230/400V three phase.

Motorspeed: 2700rpm.(USA3240rpm.)

Peripheralspeed: 52.5m/swithstandardblade.(USA58m/s.)

Cable dimension: Single phase: minimum 2.5 mm2

max length: 15 m

Three-phase: minimum 1.5 mm2.

Fuse: 230V single phase 16 A time-lag

230V three phase 13 A time-lag

110V single phase 25 A time-lag

400V three phase 10 A time-lag

Motor protection: 230V single phase: 16 A

110V single phase: 20 A

230V three phase: 12 A

400V three phase: 7 A

Thermoelement: Thermal relay in motor 140° Celsius

Noise as per 2006/42/EC: No-load: 85,0 dB.

Loaded:87,5dB.

-certification: Certified by Dansk Teknologisk Institut,

Aarhus. Identification number: 0396,

approval certificate number TI-09-MD-0311.

19

10. STANDARD EQUIPMENT

• GuideBar

• Rollerbox

• Supportroller

• Carbide-tippedsawblade

• 2pushsticks

• Topguard

• Wheels

• Handtools

OPTIONAL EQUIPMENT

• Adjustableinfeedrollertablewithsupporttrestle

• Fixedoutfeedrollertablewithboardsupport

• Aluminiumfencewithlengthstopforadjustableinfeedrollertable

• Aluminiumfenceforxedoutfeedrollertable

• Telescopeextension

• Shortaluminiumfence

• Sawdustextractor

• Fittingsandexiblehoseforsawdustextractor

Standardequipmentmayvaryineachcountryduetocurrentlegislation!

* According to the CE-regulations rollertables must always be used.

20

2011

Ernex AS Spare Part List Gjerde 1500

Pos. Art.No. Text

1 720 101 Saw frame

2 720 078 Tabletop

3 720 242 Foot

4 720 008 Turntable

5 720 224 Packing strips R/L (2)

6 720 252 Guide bar

7 720 271 Guide bar w/brackets compl. (10/05-)

8 720 320 Bracket f/guide bar (1)

9 745 746 Measure f/guide bar

10 745 901 End plug f/guide bar

11 745 927 Roller box compl. (91-)

12 717 548 Handle

13 745 919 Guide roller w/bearings (4)

14 745 965 Caster w/screw f/roller box (1)

15 720 205 Nut w/screw f/guidebar

16 745 685 Adjustment bolt M8x35

17 745 961 Indicator f/roller box

18 745 960 Locking system f/roller box compl.

19 720 185 Ball jointed arm

20 745 929 Handle f/r.box locking

21 720 075 Plastic sleeve 25x5 (93-99)

22 745 959 Fixing brackets f/roller box

23 720 226 Bracket f/ball jointed arm

24 707 710 Short work support compl.

25 707 711 Roller

26 720 168 Elevation frame

27 720 222 Elevation arm compl.

28 720 221 Sleeve nut

29 720 181 Handle top guard (short) compl.

30 720 073 Plastic sleeve Ø22 f/elev.arm (99-)

31 720 248 Roller f/elev. arm

32 720 287 Arm f/turntable lock

33 720 288 Lifting handle (bent)

34 720 286 Lifting handle (99-)

35 707 019 Hook f/push stick

36 720 329 Bracket f/push stick

37 720 098 Pre-stop

38 720 155 Handle f/pre-stop

39 720 264 Pre-stop arm f/tilting

40 720 253 Spring f/pre-stop

41 720 321 Ball bearings f/turntable (7)

42 720 107 Turntable locking bolt

43 720 108 Bracket f/turntable lock

44 707 398 Brass pc. f/locking screw

45 720 092 Tilting scale

46 720 228 Glass lens

47 720 292 Tilting scale compl.

48 720 195 Tilting device

49 720 200 Bracket f/tilting scale

50 720 104 Eccenter disk

51 707 604 Suction connector w/rivets

52 720 276 Upper guard compl.

53 720 274 Hood w/dust conn.

54 720 174 Guard arm compl.

55 720 144 Bracket f/upper guard

56 720 172 Adjusting bars

57 720 260 Riving knife 3mm -Std.

58 720 245 Riving knife bracket

59 720 259 Clamps & bolts f/riving knife

60 720 347 Clamp f/sawblade, inner

61 720 396 Clamp f/sawblade, inner EMG

62 820 165 Clamp f/sawblade, outer

63 820 166 Spindle nut (left handed)

66 720 390 Motor 230V/1-ph. 2kW EMG

67 720 391 Motor 230V/3-2.2kW EMG

68 720 392 Motor 400V/3-ph. 2.2kW EMG

69 720 393 Motor 110V/1-ph. 1.6kW EMG (-01)

70 720 394 Motor 230V/1-w/o switch & susp. EMG

71 720 397 Motor 400V/3-w/o bracket EMG

72 720 398 Motor 230V/3-w/o bracket EMG

73 720 019 Bracket f/motor

74 720 231 Bracket nut f/motor

75 720 261 Spring f/elev. arm

76 720 013 Suspension f/motor

77 720 156 Connecting arm f/motor

78 720 160 Connecting arm w/nut

79 720 090 Capacitor 40MF Hanning

80 720 091 Capacitor 110MF Hanning

81 720 333 Capacitor 120MF

82 708 333 Capacitor 40MF EMG

83 720 336 Brake EMG

84 720 348 Motor brake f/Hann. motor

85 720 335 Fan EMG

86 720 349 Fan f/Hann. motor

87 720 350 Fan cover f/Hann. motor

88 720 794 Fan cover EMG

89 720 060 Switch 230V/1-ph. 2.2kW K&B

90 720 061 Switch 230V/3-ph. 2.2kW K&B

91 720 062 Switch 400V/3-ph. 2.2kW K&B

92 720 063 Switch 110V/1-ph. 1.6kW K&B

93 720 099 Switch plate

94 708 018 Switch cover 6x6cm K&B (-06/01)

95 708 020 Switch cover K&B (06/01-) w/PVC cove

96 708 076 Relay 2.2.kW K&B

100 720 409 Blade cover Ø360 complete

101 720 405 Blade cover (01-)

102 720 306 Blade cover (-99)

103 720 386 Blade cover (00-)

104 720 268 Cover plate (-99)

105 720 388 Cap f/blade cover (00)

106 720 071 Safety plate

107 720 411 Cover plate outside

108 720 382 Cover plate inside

109 720 176 Height locking clamp

110 720 293 Tool box compl.

111 720 097 Cover f/tool box

112 720 139 Tilting handle

113 720 210 Mounting hinge front

114 720 002 Mounting hinge rear

115 720 163 Wheel shaft

116 720 161 Wheel device R.

117 720 162 Wheel device L.

118 720 072 Wheel (1)

119 720 395 Locking device, set (4)

120 720 265 Tool f/Hanning motor

144 707 328 Push stick

145 745 099 Push stick

146 820 134 Tool f/arbor nut

147 717 555 Spindle tool

148 720 305 Carton w/std. parts

149 720 376 Handle f/tilting (long)

170 708 789 Sleeve f/ball jointed arm

Table of contents

Other Ernex AS Saw manuals