Ernex AS Norsaw 250 User manual

2

CONTENTS

Side

1. Safety instructions 3

2. General instructions/Dust and Noise 4

3. Mounting/Power Supply/Transport 6

4. Functions 10

5. Operation 12

6. Maintenance/Repair 14

7. Troubleshooting 16

8. Warranty 17

9. Technical data 18

10. Standard/Optional equipment 18

11. Spare part lists/Drawings 19

12. Wiring diagram 23

13. Product Marks 24

14. Conformity declaration 25

Original manual: Norwegian 525053

3

1. SAFETY INSTRUCTIONS

The European Union Machinery Directive 2006/42/EF, 2006/95/EF and EN 1870-5:2,

requires manufacturers, importers, suppliers and dealers to ensure that machines are

designed and built to avoid causing injury to users and others by accident or inappropri-

ate work posture or strain. Machinery used at a workplace must - wherever practicable - be

secured and pose no risk to operator health during installation, operation, cleaning or mainte-

nance.

Persons who will use the equipment must receive the necessary information on operation,

usage and precautions necessary for safe operation without risk to life or health.

The Directive applies to purchase, resale (wholesale, retail), leasing, short and extended

hire, and hire-purchase.

Persons installing the machines at a workplace are required under the regulations to ensure

that - wherever practicable - no aspect of the installation has rendered the machine unsafe

or causes it to pose a hazard at any time during assembly, use, cleaning or maintenance.The

Directive also covers assembly, electrical hookups, accessories, safety features and extrac-

tor fans/ ventilators. Make sure there is sufcient light and space before commencing instal-

lation.

The Norsaw 2003 comes complete with the safety features enabling the operator to comply

with the regulations. Details on correct installation and use, combined with a guide to instal-

lation and proper adjustment of the safety systems, are described in this User Guide.It is an

absolute requirement under the Directive that the employer and employee shall ensure

themselves that all safety features are properly installed, adjusted and maintained and that

personal protective gear is worn.

Repairs and maintenance must only be done by a competent person. Be sure to check that the

power supply is off and the plug is out before starting a maintenance procedure. Instructions

for maintenance procedures are included in this User Guide.

The machine operator must receive adequate training and instruction on the hazards of the

machine and the precautions that must be observed and the actions that the law requires of

him, or alternatively must work under the close supervision of a person thoroughly familiar

and experienced with the machine who knows and understands the proper precautions to be

taken.

Persons under the age of 18 years must take and pass an approved HSE course before us-

ing the machine at the workplace except when on a training course under adequate supervi-

sion and guidance.

The saw is ideal for use with wood, plywood and chipboard.

The saw must not be used on plasterboard, polysterene and tarred paper (for roong).

WARNING: Safety equipment such as riving knife, blade guard and push sticks must not be

removed, but have to be used.

4

2. GENERAL INSTRUCTIONS/DUST AND NOISE

2.1 General safety precautions:

• IMPORTANT! According to the CE-regulations an extension table should

be used wherever possible.

• IMPORTANT! Note that the saw blade moves up and forward the entire length of the slot.

• Ensure that there is adequate room around the saw.

• For best stability, place saw on a level and even surface.

• Keep saw table, saw blade cover and area around saw free of off cuts and excessive saw-

dust.

• The working area should be well ventilated and a sawdust extractor or collector should be

used.

• Use this machine in a well lit area and wear adequate hearing and eye sight protection.

• When sawing longer pieces of timber use an extension table or suitable support.

• Always lower top guard as close as possible to the work piece when sawing.

• Use push sticks when ripping small materials and when the distance between

saw blade and rip fence is less than 120 mm (approx. 5").

• When tilting the saw blade, the blade must always be lowered under the table and the mo-

tor should be switched off.

• Lower saw blade when not in use.

• Always use riving knife (See Section 6.2 for adjusting).

• Disconnect main cable when changing saw blade or performing other maintenance work.

• Use a carbide-tipped saw blade which is properly sharpened. Never use a cracked or de-

formed saw blade.

• The saw is equipped with a motor-brake.

• Ensure that the saw blade cover is closed after the saw blade has been cleaned and/or

changed or if riving knife has been changed or adjusted.

• For ripping, always push saw blade to rear of slide travel and lock it in position, before

rotating the table and the blade to the ripping position.

• The saw should not be exposed to rain, wet- or dampness. It should be stored in a dry

environment.

• The saw must not be started close to gas or other explosives (electrical sparkles will

occur by start/stop).

• IMPORTANT! The saw blade must run freely when starting the saw.

2.2 Main connection

The saw is delivered with cable and plug (230V). 110V machines only with cable.

Supply cables must have ground protection and a conductor cross-section of 2,5

mm². Recommended length max. 25 m.

5

•Dust and noise measurements have been performed for work with the materials and saw

blades for which the machine is intended (see section 1 Safety Instructions).

Measurement uncertainty is related to local conditions and can vary with the saw blade/

transmission characteristics. Follow the maintenance instructions (see Section 6 Mainte-

nance/Repair).

Ear protection must be used, and a dust mask is recommended.

For indoor use, the machine must be connected to an extractor that provides a minimum

air speed of 30 m/s i.e. 1.8 kPa.

2.3 Dust and Noise

6

Fig. 1

3. MOUNTING/POWER SUPPLY/TRANSPORT

3.1 Mounting the saw

The saw is delivered in a carton box with the table top downwards Fig. 1.

Pull out/Unfold the legs Fig. 2 and tighten the locking wheels Fig. 3.

Fig. 3

Fig. 2

For best stability place saw on a level, even surface. If the machine still needs to be level

led, this can be achieved by adjusting one or more of the legs Fig. 4.

Fig. 4

7

Fig. 8

Fig. 7

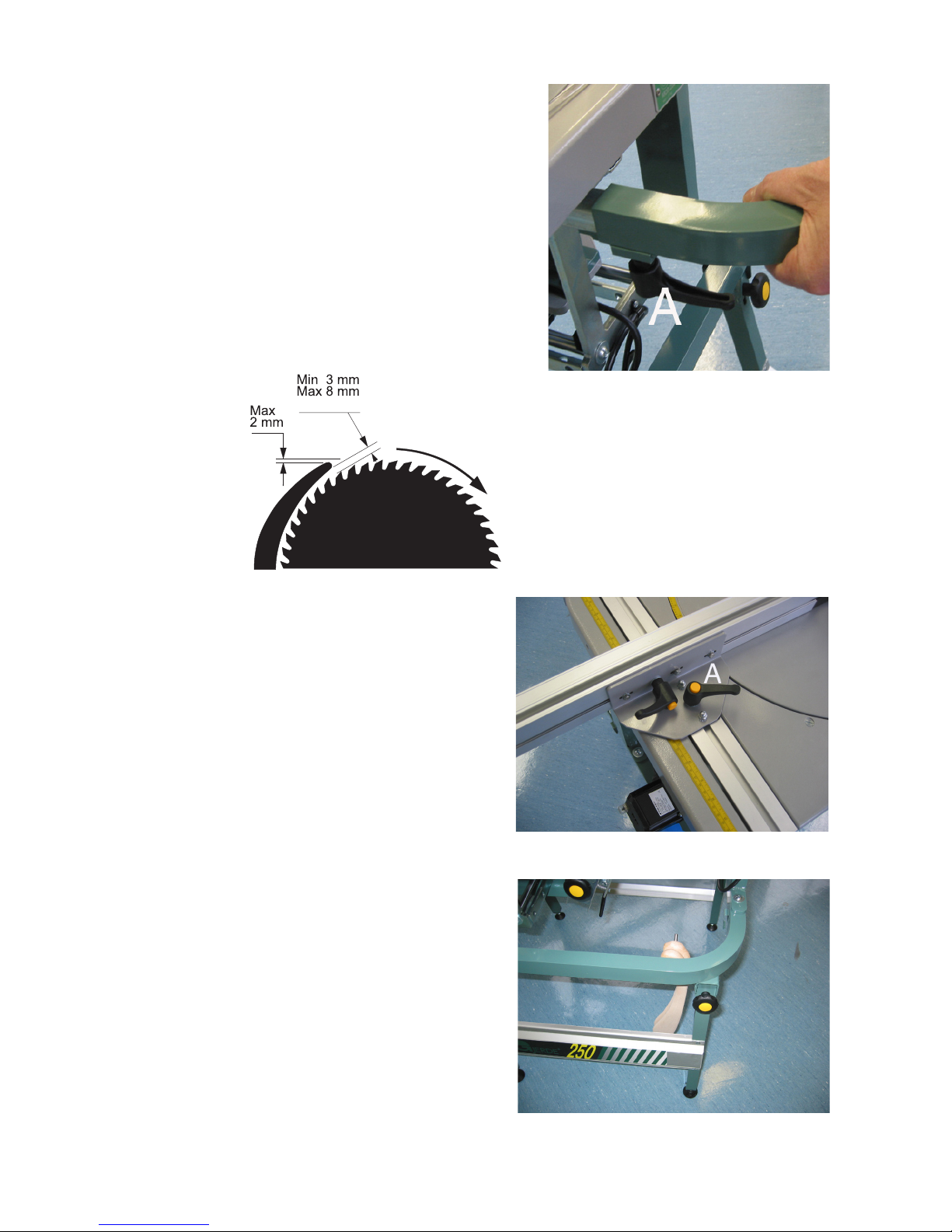

Check saw blade and riving knife and

assemble according to illustration Fig. 6.

Fig. 6

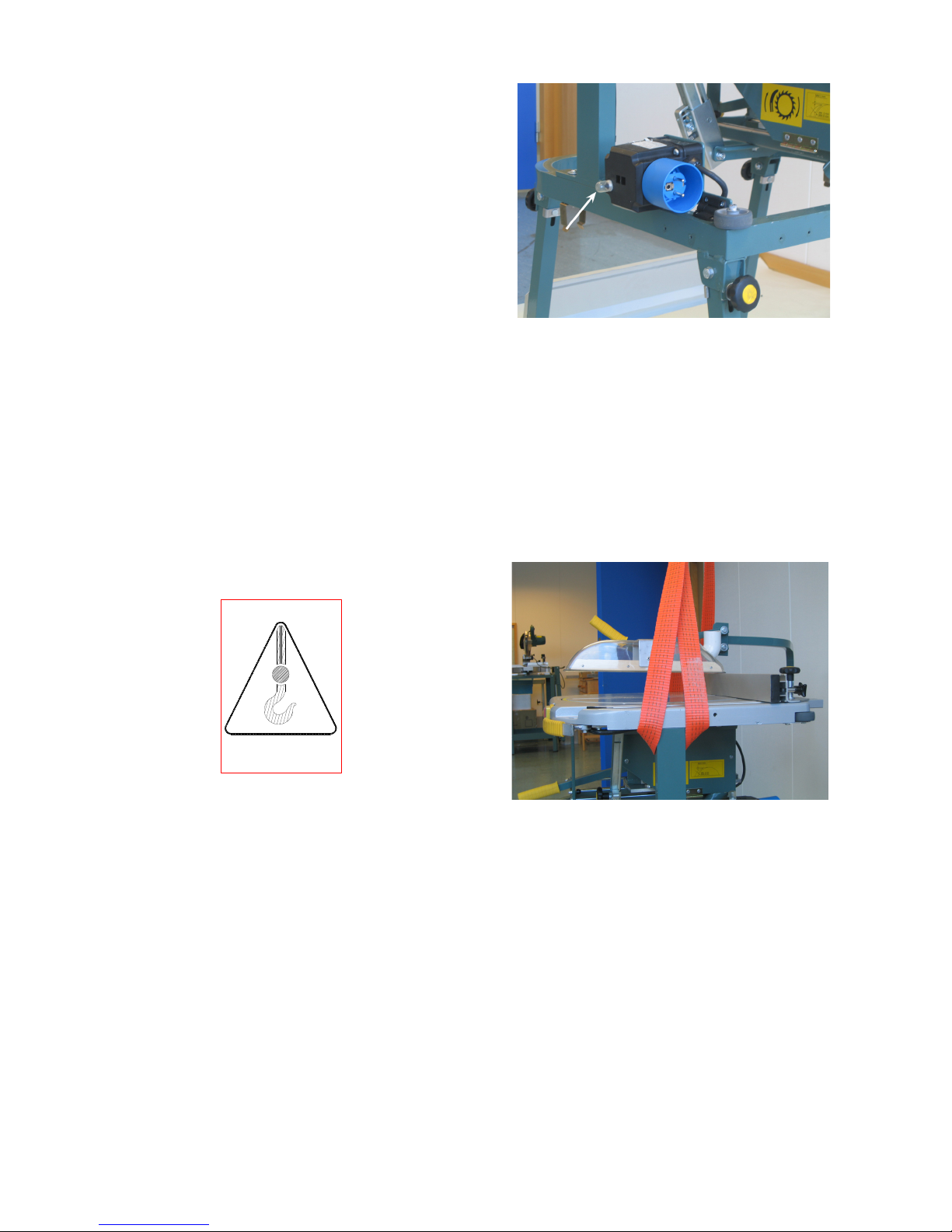

Mount the fence by loosening the handle

Aand lead the nut underneath the fence

into the slot of the aluminium prole.

Lock lever Fig. 7.

3.2 Mount the push sticks

The push sticks should be placed on the

(enclosed) hook at front of machine Fig. 8.

Mount the top guard by pushing the tube to

the bottom and make sure that the handle A

is locked into position Fig. 5.

Fig. 5

8

3.3 Mounting the tables

The same table can be used on both sides of the saw.

Length: 1 m - Weight: 3 kg

9

Fig. 9

Fig. 10

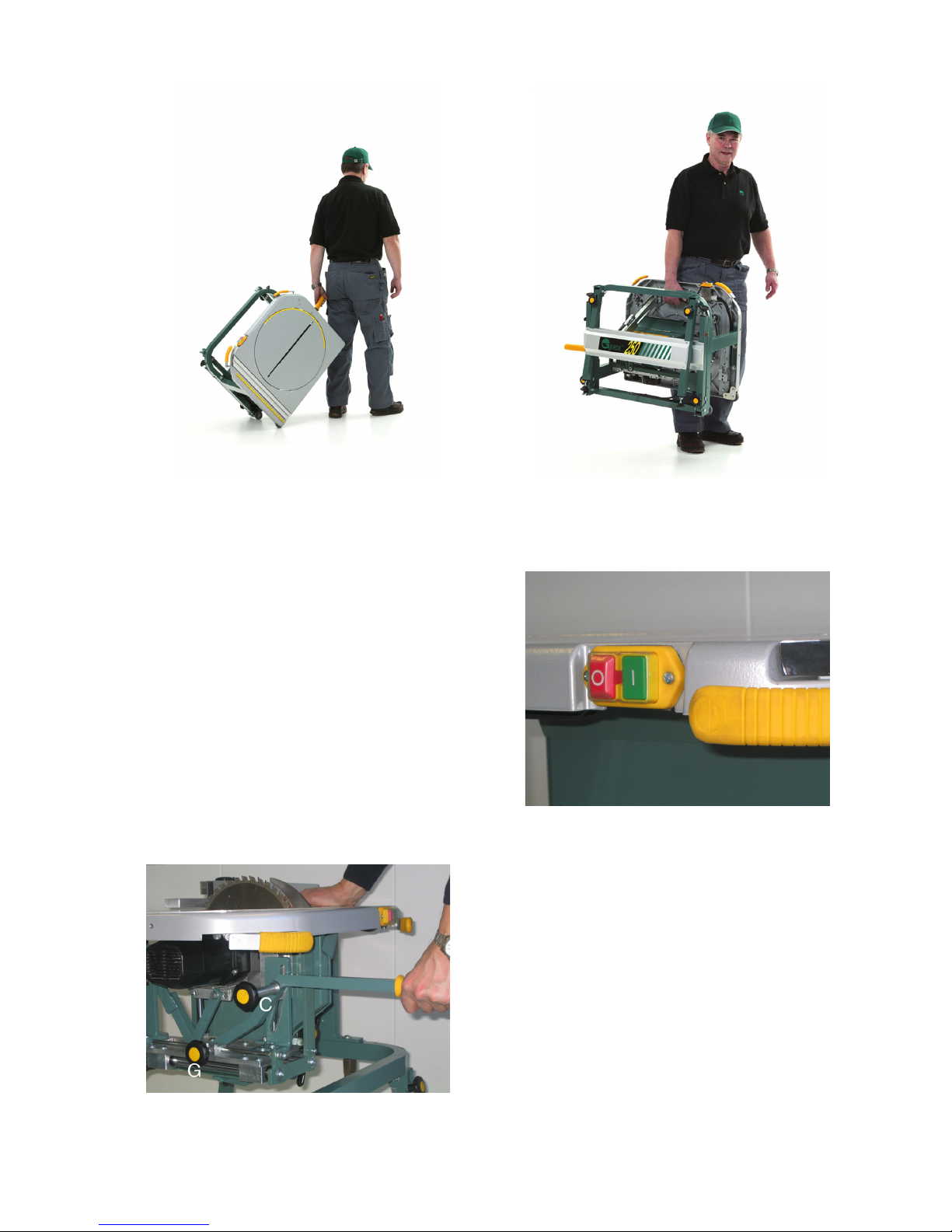

3.3 Connecting main supply

Use an approved extension cord with

ground protection/earth wire diam.

2,5 mm², max. length 25 m.

Tilt the switch and connect power supply

cable.

NB! The switch should always stay in this

position when the saw is in use Fig. 9.

3.4 Connecting of Dust Collector

A dust collector must always be connected to the top guard and the lower blade cover

when using the saw indoors. The extractor should have a capacity of at least 234 m /h -

28 m/sec. The suction connector has a diam. of 38 mm. Remember to cut off the top of

the nozzle on the top guard.

3.5 Transport - carrying-/wheel transport

When lifting the saw with a crane, place slings around the legs on either side of the

machine Fig. 10.

1. Remove extension table (if any) and its locking handles, also remove the push sticks.

2. Remove the fence and make sure that the alu. prole in the table top doesn't stick out on

either side.

3. Remove the top guard by loosening the handle and pull out.

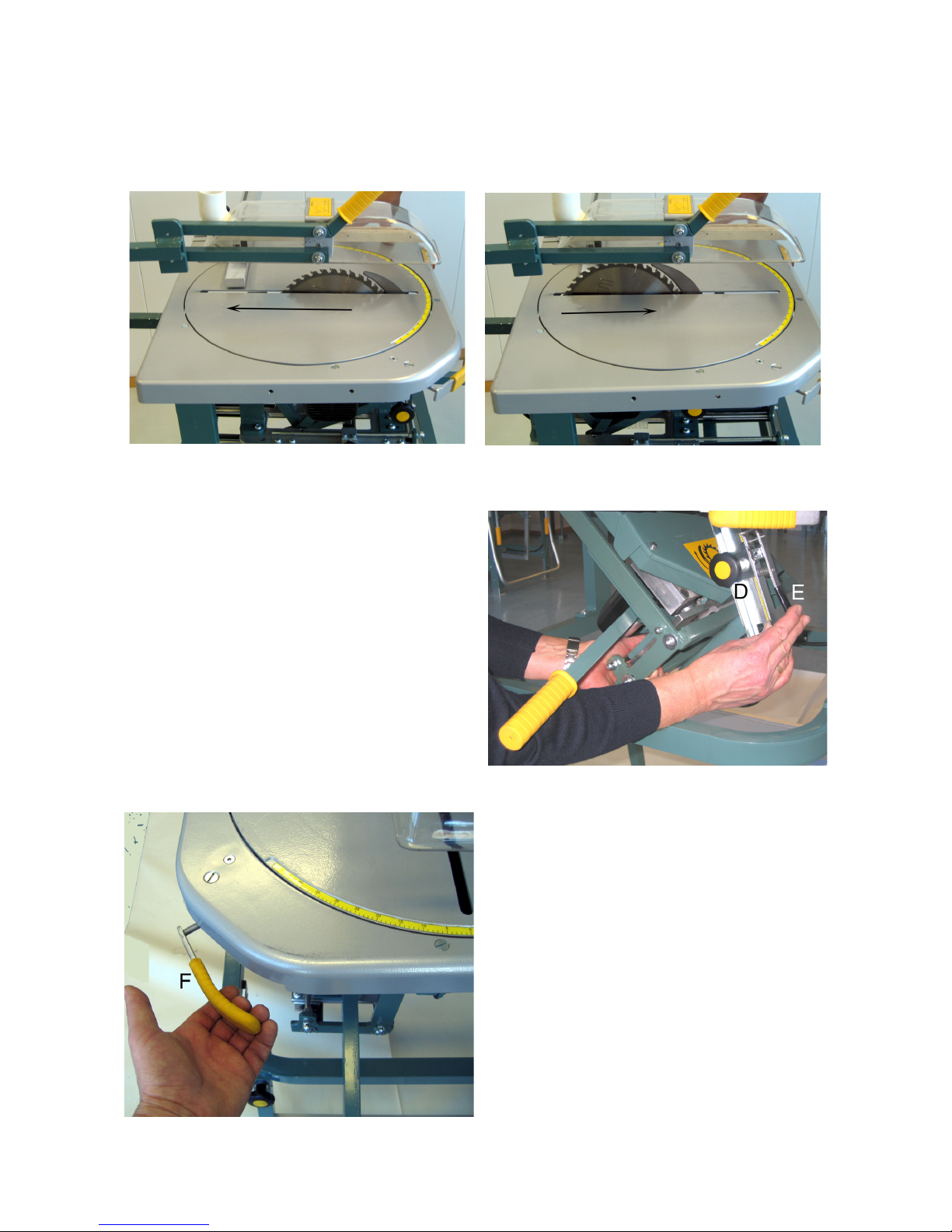

4. Tilt the switch into transport position, lower the saw blade and lock it. Set the saw in

ripping position 90° and lock it in the forward position (seen from the operating side).

5. Tilt the saw down on its wheels (right side) and loosen the locking wheels on the legs.

Fold the front legs rst and secure other legs in the clips. Remember to tighten the

locking wheels.

6. You can now pull the saw by means of the handle or carry it by the black handle beneath

the table top Fig. 11 and 12.

10

Fig. 13

Fig. 14

Fig. 11 Fig. 12

4. FUNCTIONS

4.1 On/off switch

On the front side of the saw there is a green

ON- and a red STOP button. The switch has

an overload protection and a low-volt cut out

which will automatically stop the motor. If the

overload protection comes into operation, wait

until the motor cools down and restart.

Try to avoid this situation Fig. 13.

To reset the overload protection, press

the button on the plug Fig. 9.

4.2 Raising/lowering the saw blade

Loosen the lifting handle by turning the

locking wheel C. The blade can then be

lifted and lowered. It can be locked at

any height by turning the wheel Fig. 14.

11

Fig. 15 Fig. 16

4.3 Pushing/pulling of saw blade

The blade can be pushed or pulled along the slot in the turntable Fig. 15 and 16. The

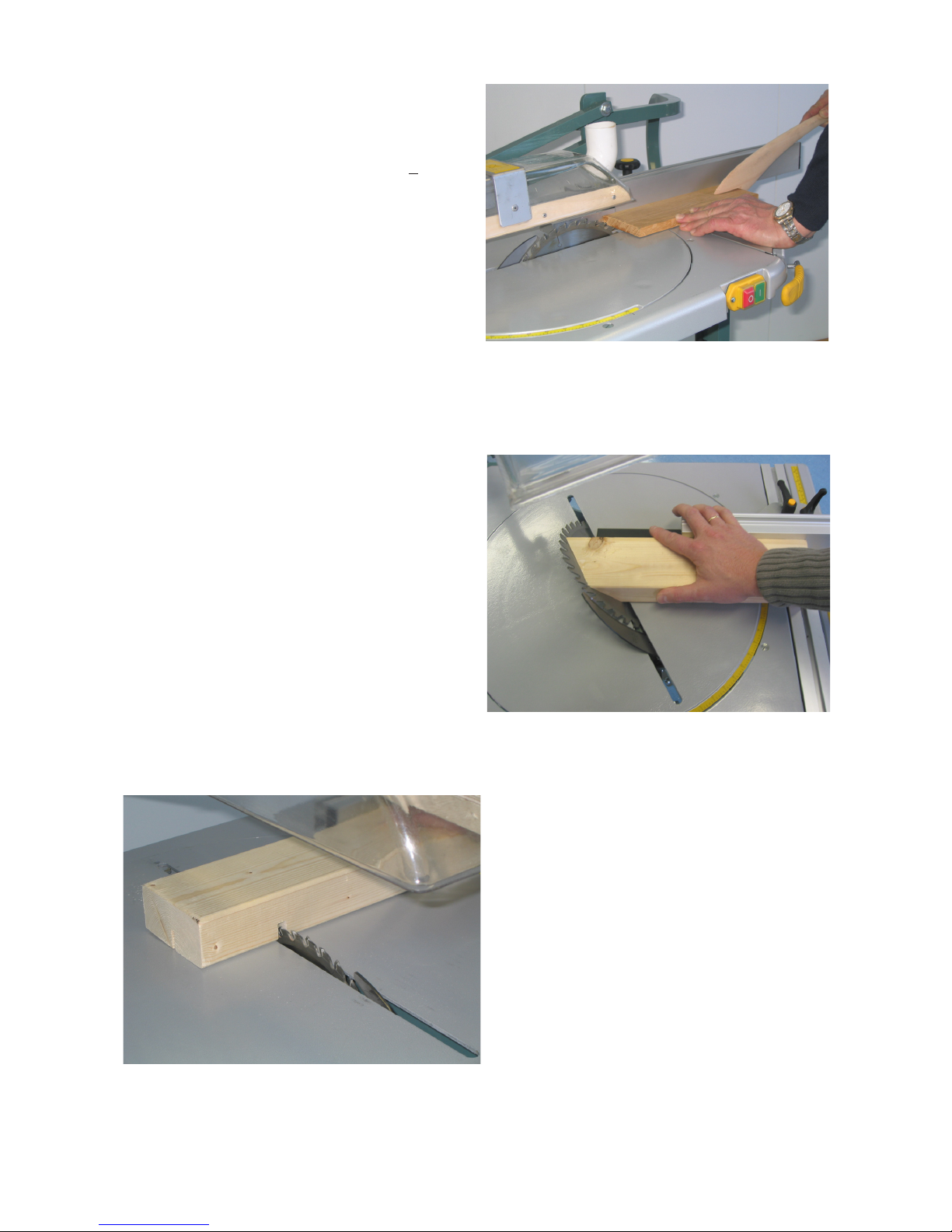

slide mechanism can be locked with the locking wheel G below the table top Fig. 14.

4.4 Tilting of saw blade

Before tilting, the blade must be lowered.

By loosening the locking wheel Dand

push the arm Efor tilt securing (position

handle), the blade can be tilted from -2° to

- 47° Fig. 17.

Position and lock the blade in desired

tilting angle. Set the degrees on the scale

and tighten the locking wheel.

Attention: Locking wheel D must also be

tightened in 0 and 45° (the pre-stop

function).

4.5 Rotating the turntable

The turntable can be rotated both ways

and set at the desired cutting angle. The

turntable is released by pulling the lock-

ing handle F to the left Fig. 18. Turn the

turntable by gripping the lifting handle

and set the saw blade in desired cutting

position (read on the table). Lock the

turntable by pushing the locking handle

to the right. For mitre cutting of the most

used angles (90° - 45° - 22,5° and 0°),

there is a pre-stop function. The turn-

table must be locked by use of the handle

F(including the pre-stop positions).

NB! When setting the blade the motor

has to be turned off. This is to avoid

damage to the saw or the operator.

Fig. 18

Fig. 17

12

Fig. 20 Fig. 21

Fig. 19

5. OPERATION

5.1 Cross cutting

* Set the desired cutting angle - Section 4.4. and 4.5.

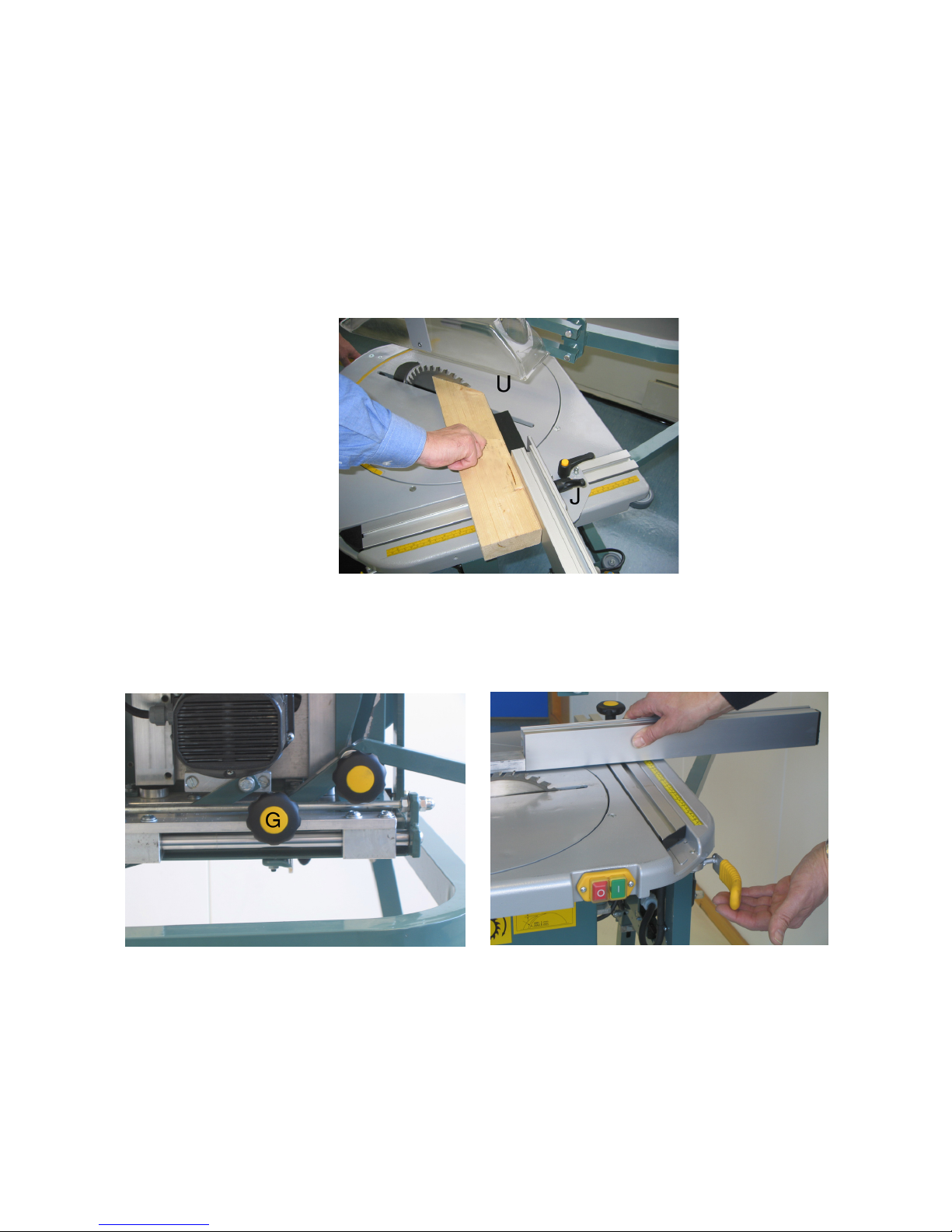

* Adjust the position of the fence and lock with locking handle JFig. 19.

* Set the upper guard Uapprox. 5 mm above the height of material.

* Lift and (gently) push the blade if you need to increase the cutting width/length.

5.2 Ripping

Turn the blade to the 90° mark so it is parallel to the fence. Lock the turn table as in

Section 4.5 Fig 18. Push the saw blade forward to the end position and lock with wheel G.

Fig. 20.

Tilt the saw blade to the desired angle as in Section 4.4.

Position the blade slightly higher than the thickness of timber you are going to rip, and then

lock in place Fig. 14.

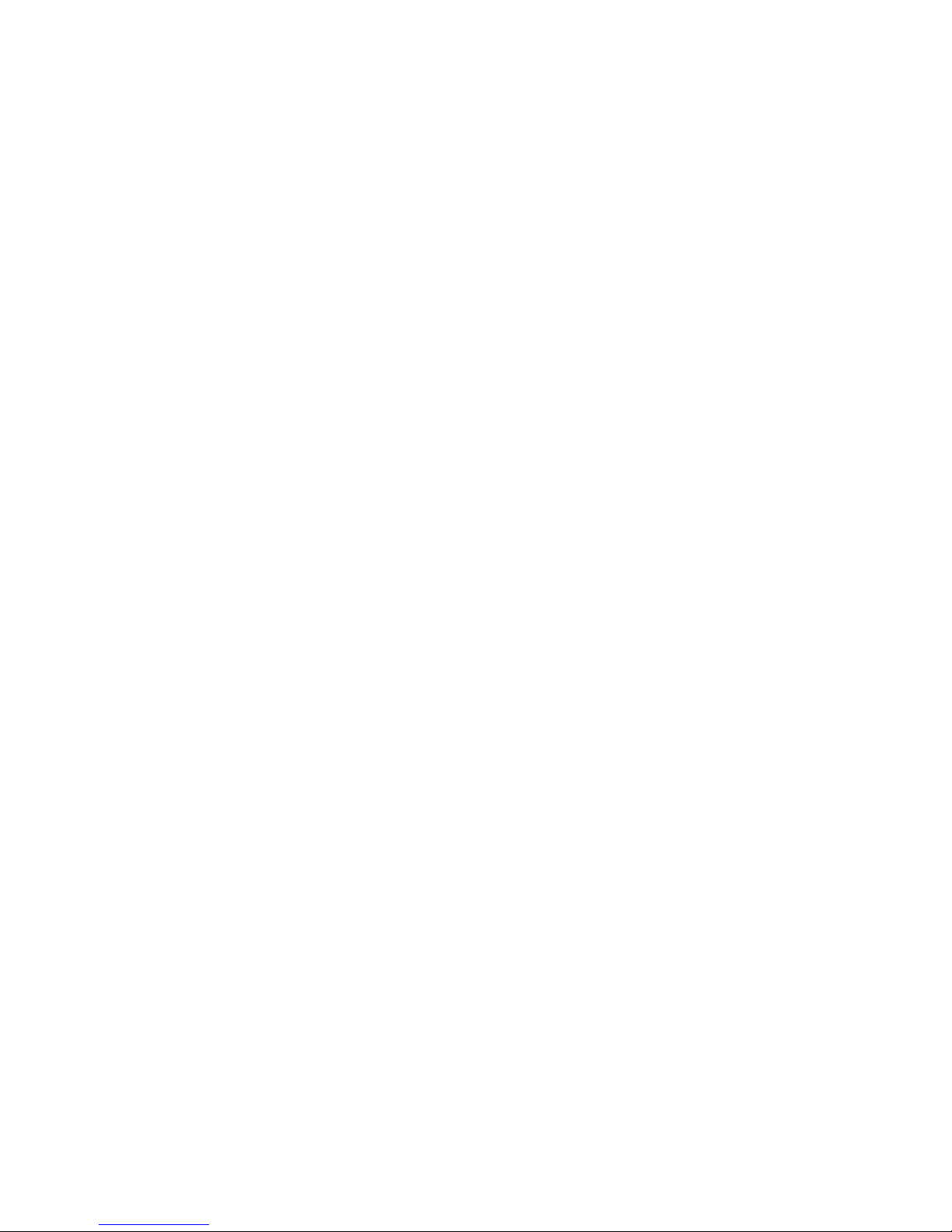

Set the fence for the desired ripping width and lock with the handle Fig. 21.

13

Fig. 22

Start the motor and feed the material

through the blade along the fence Fig. 22.

Use push sticks when the distance

between fence and saw blade is < 120 mm.

NB! The riving knife is always to be

used when ripping. Make sure that

it is correctly tted and adjusted see

Fig. 6, Section 6.2 for settings.

Push gently (reduce the pressure if the motor is working hard) to achieve a clean, neat cut.

5.3 Compound angle cutting

Set the turn table at the desired cutting

angle. Section 4.5.

Tilt the saw blade to the desired angle.

Section 4.4.

Adjust the fence Section 5.2 and

lift the saw blade to complete the

cutting operation Fig. 23.

Fig. 23

Fig. 24

5.4 Cutting grooves

Set the turn table at 0° (square to the

fence) and lock it in position.

Set the saw blade at the desired height

(depth of groove) and adjust the fence

to the correct position.

Place the material against the fence.

Feed material along the fence and

repeat the operation until the grooveis

the desired width Fig. 24.

14

6. MAINTENANCE/REPAIR

CAUTION! MAKE SURE POWER SUPPLY IS DISCONNECTED WHILE PERFORMING

MAINTENANCE OPERATIONS. A minimum of maintenance is required to ensure

satisfactory performance and a long service life.

• Lubricate moving parts at regular intervals.

• Check all screws and nuts regularly for tightness.

• Top guard should be clean. If damaged it should be replaced.

• Keep saw and saw blade cover free from sawdust. Pay particular attention to motor venti-

lation openings and cooling ns.

• Keep saw blade clean and in order. Replace blade if there are any cracks or missing teeth.

Remove resin deposits with a suitable cleaning uid.

• Repairs to electric parts must be carried out by qualied electricians only!

• The motor brushes must be checked evenly and replaced when necessary.

• Do NOT clean the motor with dissolvents.

6.1 Replacing saw blade

• Lower the blade and lock it in the forward position.

• Open the cover by loosening the two screws and the nut at the front of the guard Fig. 25.

• Use tools (13 mm spanner) supplied with saw Fig. 26 to remove saw blade. Loosen the

spindle screw whilst blocking the ange with the supplied tool.

Remove outer ange and saw blade. NB! The spindle screw is left-hand thread.

• The saw blade is mounted the opposite way. Be sure to close cover when nished.

The saw is only to be used with saw blades of 250 mm diameter with a bore diameter

of 30 mm, kerf 3,2 mm and a thickness of 2,2 mm. Select a blade with the correct number

of teeth suitable for the work you are performing.

Fig. 25 Fig. 26

15

6.2 Replacing and adjusting riving knife

• Pull the plug and lower the blade cover as in Section 6.1.

• Loosen the screws and nut Fig. 27 and remove or reposition the riving knife (by replacing

riving knife).

• The riving knife is mounted using same method in reverse.

The thickness of the riving knife should be the nearest thickness but slightly less than

the kerf width of the saw blade. Adjust the riving knife as shown in Fig. 6 and check that

screws and nut are tight. Be sure to close the saw blade cover when nished.

Fig. 27

6.4 Testing of stop function

The saw blade will stop less than 10 seconds after pushing the red STOP button.

This should be checked regularly.

6.3 Adjusting turn table locking

• Set the locking handle in neutral position.

• Loosen lock nut P.

• Screw the set screw 0 against the turn

table until sufcient locking is achieved

whilst the locking handle is turned to the

locking position.

• Tighten the lock nut PFig. 28.

Fig. 28

16

6.5 Repair

Routines at repair:

* The machine must only be repaired by qualied electricians or authorised service

workshops.

Testing the brakes:

* The brake for the saw blade rotation should be tested regularly. The stop-time

must be max. 10 sec. Start/stop the saw 10 times in a row and check the stop-

time.

7. TROUBLESHOOTING

The saw does not start:

* check the power supply

* do not use the cable with several machines at the same time

* check that the cable is not too long, and that the cross-section is not too small

* contact an electrician

The saw vibrates and is weak:

* check that the blade box under the bench does not contain chips and sawdust

* check that the toothed belt is whole and undamaged

* check the spindle

* check the blade for eccentricity, and that all the teeth are whole and sharp

The saw blade is heavy to lift and does not go down completely:

* check that nothing is stuck in the blade box

* check that the bearings in the universal joint and the movable glide rings at either

end of the spindle are not stuck

17

8. WARRANTY SERVICE

Notwithstanding any statutory requirements, Ernex AS provide warranty in accordance

with the legislation of the customer‘s own country of residence, but in all cases for a mini-

mum of 3 years, except for electrical parts which still has a 1-year warranty commencing

from the date on which the machine is sold to the end user. Ernex AS/The importer prom-

ise to repair, or at our option, replace with like grade and quality any product determined to

be faulty due to the failure of parts, material or workmanship.

The warranty covers defects in material and/or workmanship only. When making a claim

under the warranty, proof of purchase bearing the original date of purchase must be sub-

mitted. The repairs under warranty may only be carried out by Ernex AS, or by authorized

Ernex warranty service agents or the importer.

The warranty will not apply in cases of:

- incorrect use, overloading of the machine or tting non-approved accessories

- use of force, damage caused by external inuences, or foreign bodies

- damage caused by non-observance of the instructions for use, such as connection to an

unsuitable mains supply or voltage or non-compliance with the installation instructions

- normal wear and tear

The warranty also does not cover machines which have been partially or completely dis-

mantled.

18

9. TECHNICAL DATA

Gjerde®250

Manufacturer: Ernex AS, Norway.

Model: Norsaw 250.

Table size: 670 mm x 565 mm.

Height: 860 mm.

Transport height: 430 mm.

Weight: 37 kg.

Saw blade: Carbide tipped, Z=40

Diam. 250 mm.

Bore diam. 30 mm.

Kerf width 3,2 mm.

Riving knife: Hardened steel; std. thickness 2,5 mm.

Cutting height: 80 mm 90° (vertical).

60 mm 45° (tilted)

Slide/push travel: 130 mm

Max. cutting width: 310 mm

Tilt range (stepless): -2° - +47°

Turn table rotation: 0-135° (+ 90° - -45°)

Motor w/Brake: 1.6 kW 110 V/50 Hz 1-phase.

1.8 kW 230 V/50 Hz 1-phase.

Spindle speed: 4.500 rpm.

Peripheral speed: 59 mps.

Cable diam: 1-phase 3 x 2.5 mm2.

Fuse: 16A time-lag.

Switch: On/Off with overload and low-volt cutout

Noise as per 2006/42/EC: No-load 94 dB

Under load 92,4 dB.

-certication: Certied by Dansk Teknologisk

Institut, Aarhus. Identikasjonsnr: ID-No.: 0396

Approval certicate No.: TI-09-MD-0308.

10. STANDARD EQUIPMENT

• Top guard

• Carbide tipped saw blade

• Push sticks

OPTIONAL EQUIPMENT

• Extension table, Aluminium 1m long

• Wheels

19

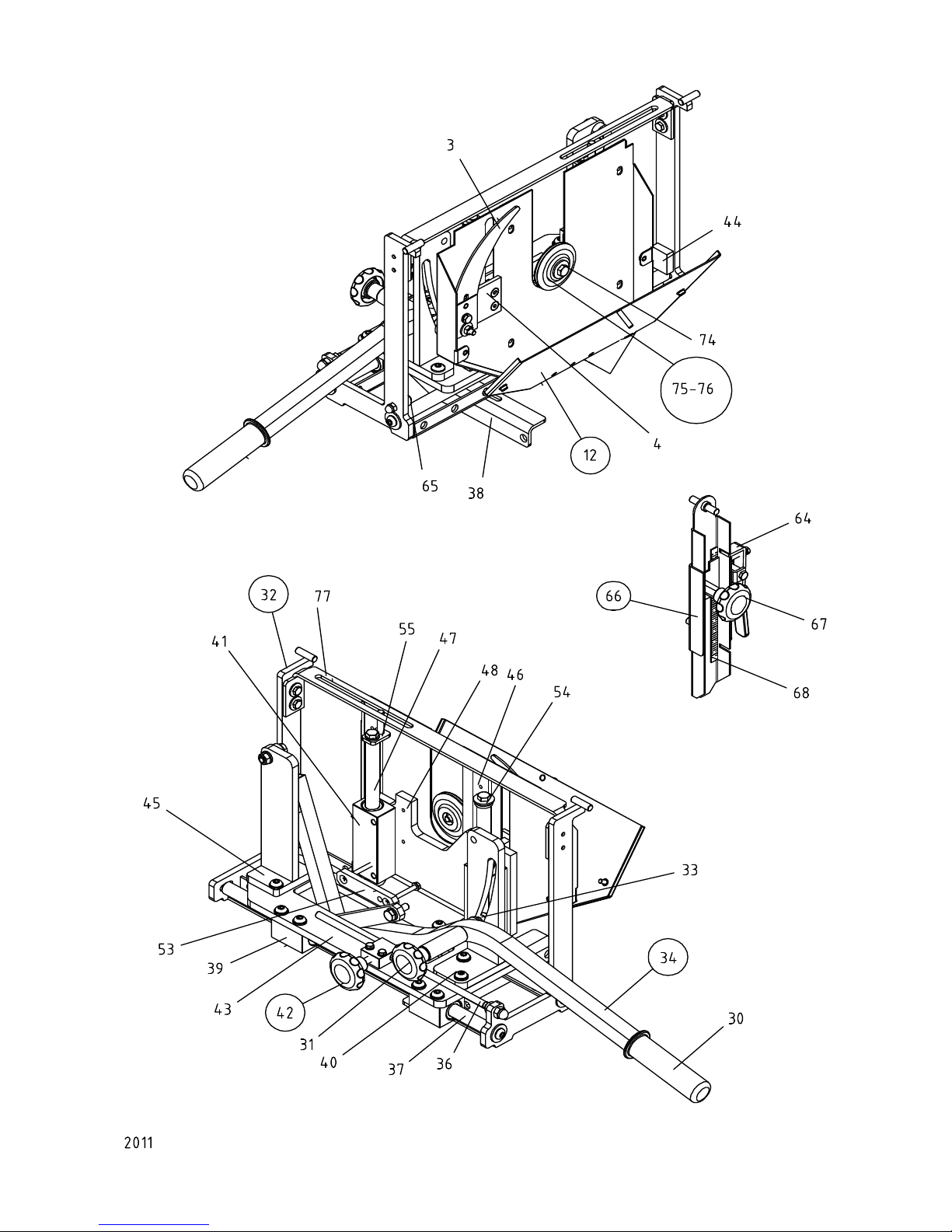

Ernex AS

Spare Part List Gjerde 250

Pos. Art.No. Text

1 725 179 Sawtable top

2 725 178 Turntable w/scale

3 725 019 Riving knife 2.5mm w/clamp

4 725 216 Bracket f/riving knife compl.

5 725 183 Plastic hood w/bracket

6 725 206 Adjusting bar w/handle

7 725 182 Guard arm w/handle

8 725 186 Upper guard compl.

9 725 011 Leg f/frame (1)

10 745 441 Spring stud

11 725 155 Locking handle M8x15

12 725 062 Blade cover compl.

13 725 030 Bottom frame

14 725 207 Foot (set 4) adj.

15 725 208 Rear leg-pair

16 725 209 Locking wheel

17 725 210 Wheel set compl. (2)

18 725 089 Switch 230V/1-phase

19 725 212 Gliding blocks f/alu.profile (3)

20 725 211 Front leg-pair

21 720 075 Plastic sleeve 25x5 (93-99)

22 725 213 Short fence w/extension

23 725 130 Angle fence compl.

24 725 214 Angleplate f/fence

25 725 025 Measure

26 725 027 Plug f/alu.profile (table top)

27 725 121 Alu.profile w/plugs

28 725 024 Tilting scale f/turntable

29 725 151 Extension, plastic

30 720 073 Plastic sleeve Ø22 f/elev.arm (99-)

31 725 101 Locking wheel f/height adj.

32 725 038 Suspension f/axles

33 745 033 Elevation slider

34 725 217 Elevation arm compl.

35 707 019 Hook f/push stick

36 725 043 Locking bar f/push

37 725 023 Tracking axle L=430mm

38 725 144 Angle f/tilting bar

39 725 108 Ballbearing housing, short 50mm

40 725 081 Locking bracket f/lift

41 725 107 Ballbearing housing, long 100mm

42 725 218 Locking device f/push

43 725 109 Bottom plate

44 725 219 End cushion f/push

45 725 077 Bracket f/suspension of lift

46 725 059 Bracket f/blade cover

47 725 022 Tracking axle L=208mm

48 725 110 Plate f/motor suspension

49 725 254 Brushes compl. (2) (1/3-07)

50 760 043 Brushes compl. (2)

51 725 090 Motor 230V/1-phase w/o switch

52 725 092 Motor protection 8Amp

53 725 040 Bracket f/motor lift

54 725 220 End cushion f/elev.

55 725 240 Guide pin

56 725 074 Locking handle f/alu.profile

57 725 073 Locking device f/alu.profile compl.

58 725 020 Carrying handle

59 725 120 Pre-stop plate compl.

60 725 065 Hinge plate compl.

61 725 124 Bracket f/guard arm

62 725 221 Locking f/turntable compl.

63 725 222 Ballbearing set f/turntable (5)

64 725 134 Locking handle f/tilting

65 725 156 Rubber cap

66 725 223 Lock f/tilting compl.

67 725 103 Locking wheel f/tilting

68 725 141 Tilting scale

69 725 224 Switch plate w/hinge

70 725 249 Foot, telescopic

71 725 228 Alu. profile

72 725 241 Plug f/alu. profile

73 725 250 Bearings f/fence

74 760 017 Screw M8x25 lefthanded

75 725 247 Clamps

76 725 255 Clamps (1/3-07)

77 725 236 Rail

78 760 019 Arbor/Gear compl.

79 725 253 Arbor/Gear compl. (03-07-)

80 725 261 Arbor/Gear compl. (10/07-)

81 725 258 Tools f/motor (03/07-)

82 725 245 Start/stop panel

83 725 305 Relay f/switch (725089)

84 725 174 Motor w/switch 230V/1

145 745 099 Push stick

2011

20

Table of contents

Other Ernex AS Saw manuals