ERS®Manual / AirCool®

plus

-System / SP72_TA1C8 / -55°C +200°C / Ver. 02.02 8

3.2 Description of the system

The AirCool®

plus

System provides rapid temperature adjustment and a precise

environment for probing semiconductor wafers.

The system operation temperature ranges from -55°C to + 200°C. The AirCool®

plus

System, as the name implies, uses exclusively air for cooling down to lowest

temperatures. There is no need for any water or other liquid coolants and there are

no peltier devices inside the chuck, heating is done with high reliable resistance

heater. Therefore the AirCool®

plus S

ystem is offered to the costumer as a fully

developed and field experienced product, convincing in respect to precision, high

quality and highest reliability.

The chuck model has been designed to fit perfectly into all common manual, semi-

automatic or fully automatic wafer probers.

The main components of the AirCool®

plus

Chuck System are the Controller SP72

and the Chuck TA1C8.

The AirCool®

plus

Chuck TA1C8 uses air and an accurate PT100 temperature

sensor in order to provide a precise hot or cool temperature and a precise

temperature transmission to the wafer.

The experience of more than 30 years in the area of temperature transmission and

semiconducter measurement demands are embodied in the AirCool®

plus

Chuck.It

offers especially the combination of highest mechanical precision (surface planarity),

remakable temperature uniformity and excelent electrical characteristics (low noise,

low leakage).

The top surface of the AirCool®

plus

Chuck is lapped and polished in order to

provide a maximum contact area for heat transfer to or from the wafer. Vacuum holes

and notches are located in a way that ensures an accurate fixation of the wafer and a

close contact of the chuck to the wafer.

The chuck bottom is provided with a standard interface for easy installation into the

probe station.

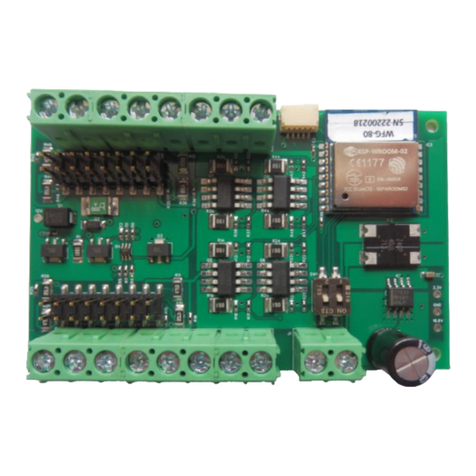

The Controller SP 72 continuously monitors the chuck surface temperature using a

precise platinum RTD sensor which is connected to a microprocessor controlled

close loop temperature management. It is operated via an ergonomically arranged

front panel with a very bright LED displays. It is designed for 19" standard rack

system for easy integration at the customer‘s site.

For a remote operation via PC or prober software RS232C and IEEE-488 interfaces

are available.