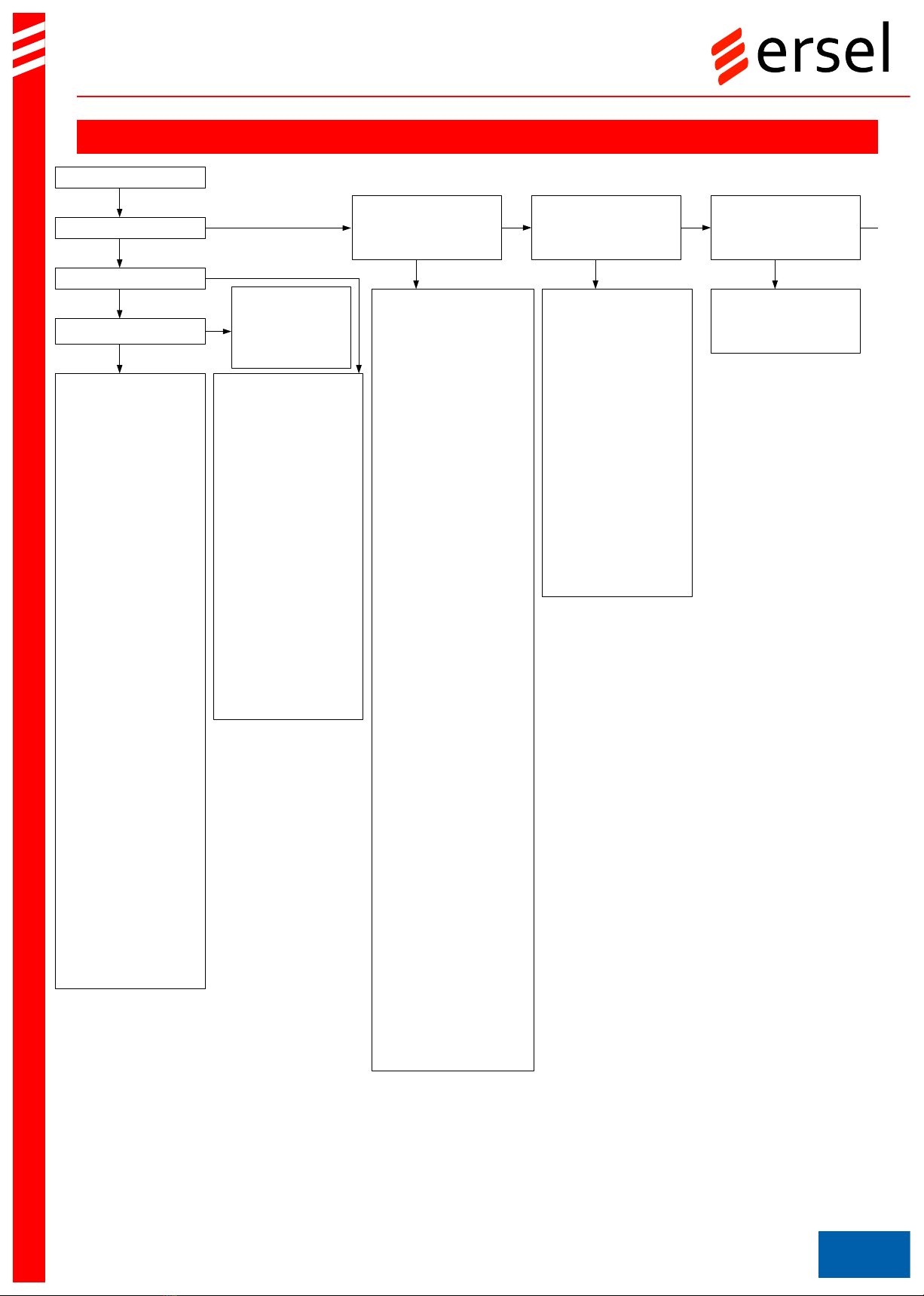

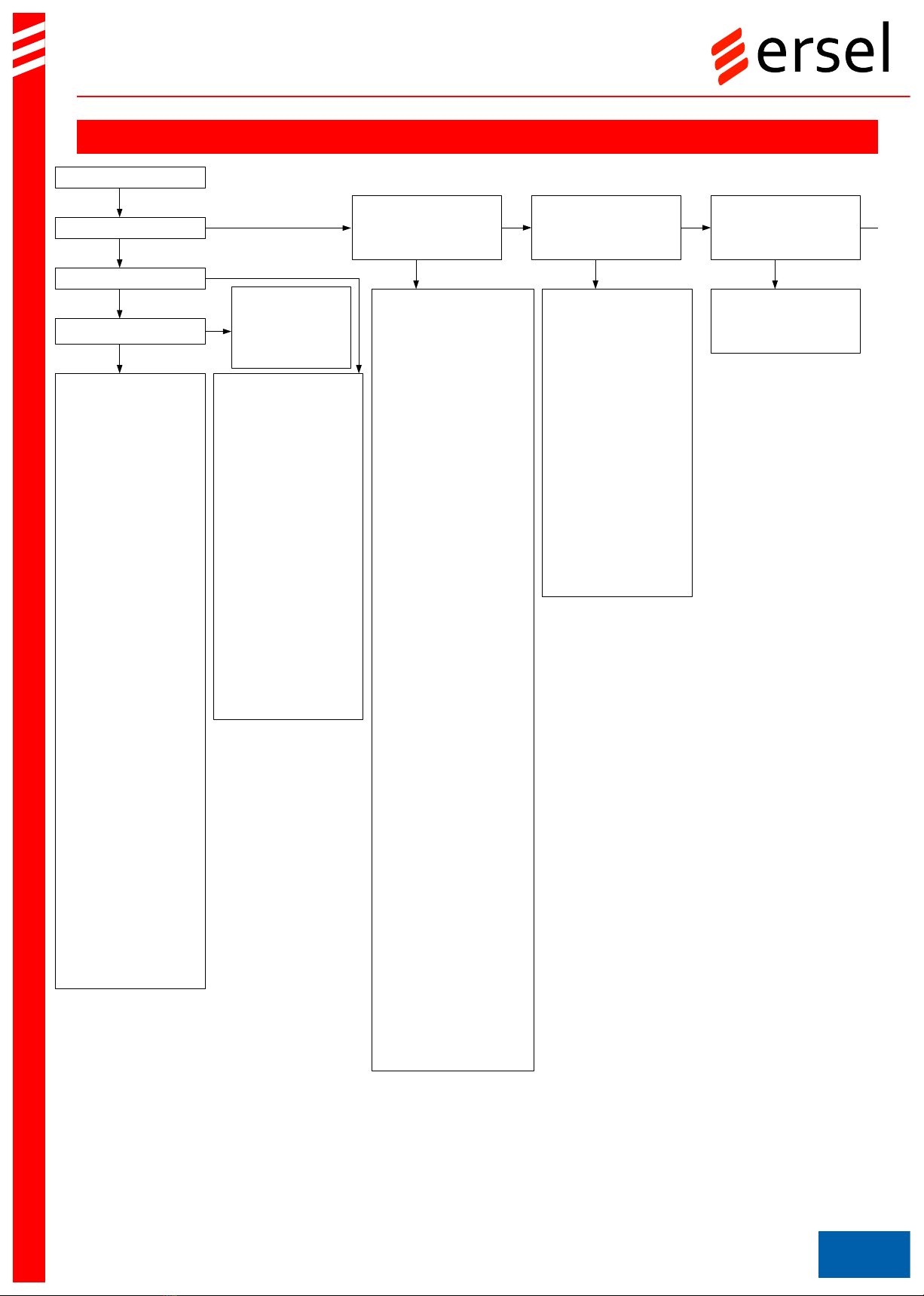

APPENDIX 1. DIAGNOSIS OF MALFUNCTIONS

Start

2.01. Can pilot be lit? 2.06. Pilot can be lit.

Does it stay alight?

2.08. Does main burner ignite

immediately?

2.10. Does main burner ignite

smoothly and across its/their full

length after first ignition by pilot

burner?

2.11 No proper cross lighting

of main burner.

Go to box 2.09 and take actions

act as described for 'retarded

ignition of main burner'.

No

Yes

No

Yes

Yes Yes Yes

Yes

No

No No No

2.09 Ignition procedure

– Oval knob on gas control is on

"MAN". Set to "ON" and restart.

Retarded ignition of main

burner(s)

Gas to main burner opens ca. 3-5

seconds after servo motor,

operating the gas valve, starts

running (sound of motor!). After

this the main burner is to ignite

(at least partially) within 10

seconds and not with a firm noise

WHOOF. If not: no or delayed

cross lighting of main burner.

Hazardous situation.

Stop ignition procedure straight

away and first check for:

– Position of logs or pebbles.

– Burner holes (locally) blocked.

Remove vermiculite dust.

– Vermiculite missing.

– Chips on burner.

– Vermiculite not distributed

evenly across burner(s).

2.02. Sparking?

2.03. Only one spark?

2.03a

– Loosen and retighten

earthing screw on gas

control.

– If this does not work:

replace receiver.

2.04 Check:

Receiver

- Replace missing, weak or

rechargeable batteries (not

enough power to open

thermoelectric valve).

Presence of gas on pilot burner

Check pilot on presence of gas at

normal ignition cycle or in Manual

Mode (turn oval knob on gas

control to MAN and keep safety

shut off valve opened with a

screwdriver) and ignite pilot with

a lighter.

- Pilot flame not on: Step 1.

- Pilot flame on: Step 2.

Step 1: Pilot has no gas

Check:

- Gas tap open?

- Gas at gas control (line pressure

at measuring point on gas

control).

- Gas flowing out of gas control?

(By loosening pilot tube at gas

control). If not: check adjustment

screw pilot flame (under black

cover): sealing

not to be broken.

Sealing broken: screw should be

fully open.

- Blocking of pilot tube (kink or

dirt).

- If this does not help: replace gas

control.

Step 2: Pilot has gas, but no

ignition

- Electrode with 90° bended tip:

bend tip 1 mm higher.

- Spark too weak (thin and

reddish). Act as if 'no spark' in box

2.05 and perform actions

described for ignition cable and

ignition electrode.

- Pilot flame too weak (dirty).

Remove injector (remove gland

nut and the pilot tube). See that it

does not fall away. Clean with

compressed air. Rectify. Retry.

2.07

Pilot out when servomotor starts to

run? Check the thermocouple

system.

– Measure thermocouple voltage in

mV just after servomotor starts to

run and the voltage goes down.

– Measure between red dot on

receiver and earth point on gas

control (fig. 23).

– 0 mV

– 2-3 mV

– 3-5 mV

– 6 mV and higher

– Requirement: after rectification

actions thermocouple voltage should

be 6 mV at least, just after motor

starts running!

Voltage 0 mV

– Thermocouple defective. Check by

replacing or measuring voltage at

end whilst heating (tip: with a

lighter).

– Short circuiting or interruptions in

circuit:

Check:

– thermocouple tight in interruptor;

– interruptor tight in gas control;

– black wires (yellow/red end)

connected to interruptor + receiver;

– interruptor (mount thermocouple

directly in gas control and ignite in

Manual Mode (see 2.04).

If pilot stays on: interruptor

defective.

Voltage 2-3 mV

– Check pilot flame.

Too small:

– pilot dirty.

Clean up (see 2.04).

– check for pilot gas tube tightness;

– pilot tube kinks or dirt inside;

– line pressure too low.

– Tip: thermo couple not in

(correct!) pilot flame.

Bend into flame.

Voltage 3-5 mV

– Appliance may work, but is too

critical.

Perform actions as described for

2-3 mV.

Voltage 6 mV and higher

Voltage OK, so different cause.

– Receiver defective. Check by

dismounting black-red and yellow

control cables from receiver and link

together. Ignite fire in Manual Mode

(see 2.04). Pilot stays on: receiver

defective.

– Gas control defective if receiver is

not defective. Replace gas control.

2.05 Kontrol:

Ignition cable

– Present and connected.

– Being free from metal parts or

concrete.

– Too long: cut away all excessive

length at receiver end, and

reconnect.

– Shorting out to earth: replace

ignition cable.

– Spark in wrong position:

– slide rubber sleeve on ignition

cable over ceramic of electrode.

– Replace electrode if neccessary.

Ignition electrode

– Straight electrode:

– oxidation (roughen electrode

with file or sand paper);

– position (4 mm from pilot

burner).

– Cracks in ceramic (not always

visible): replace electrode.

Starting procedure

After switching off/going out the

remote is locked for 120 sec.

(older versions 60 sec). Wait 2

minutes before reigniting.