USER’S MOUNTING INSTRUCTIONS

After the initial set-up assembly is completed use the following procedure to mount the attachment to the loader.

Coupler wedges or pins must extend through holes in attachment. Levers must be fully

down and locked. Failure to secure wedges or pins can allow the attachment to come off and cause injury

or death.

1. Use the step, safety treads, and grab handles to

get on and off the loader and attachment.

2. Sitting in the operator’s seat, lower the seat bar (if

so equipped) and fasten the seat belt.

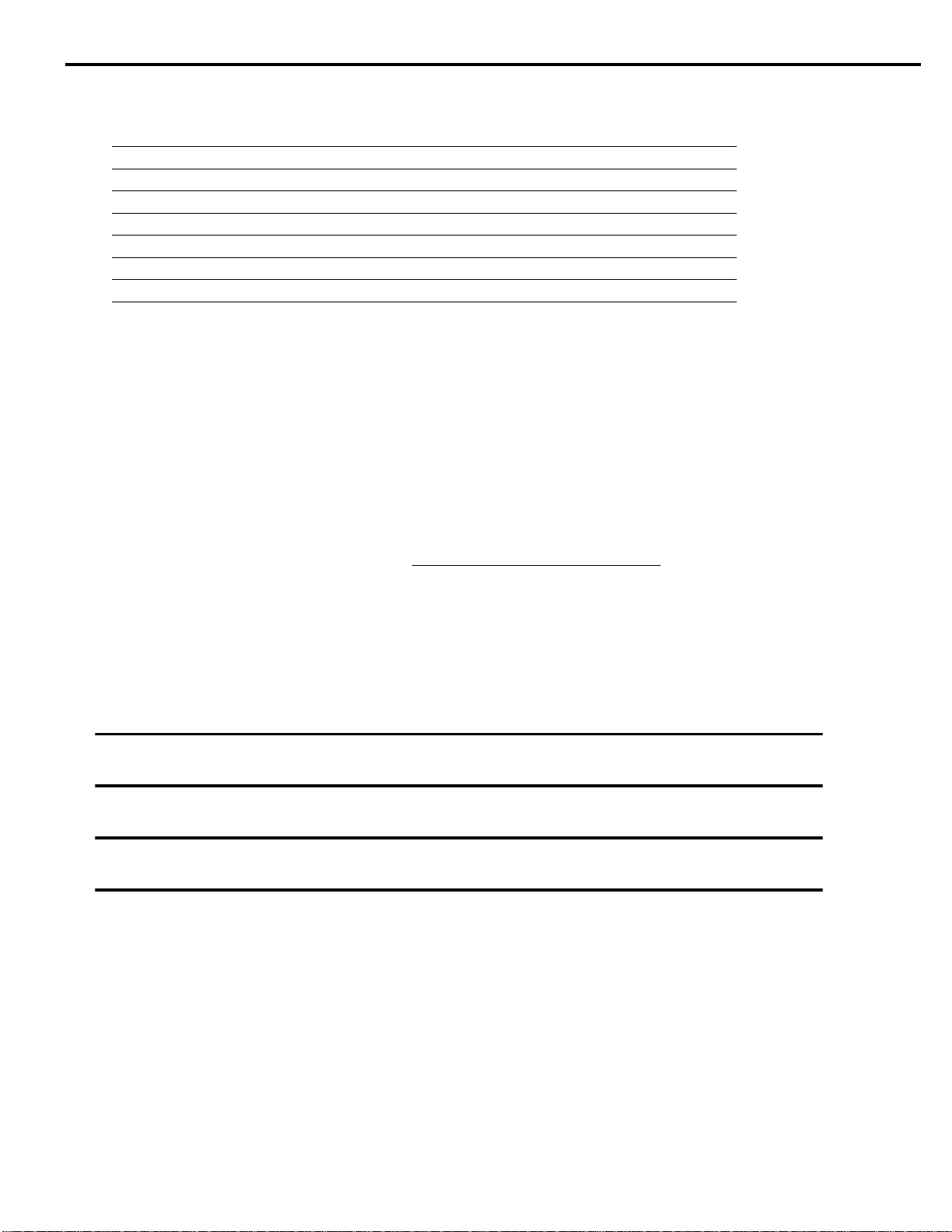

3. Drive the loader to the rear of the adapter and put

the loader mounting plate into the adapter mount

bracket.

4. Tilt the loader coupler backward a small amount

until it is fully engaged in the adapter mounting

bracket.

5. Stop the engine and engage the park brake.

6. Secure the coupler locking mechanism that

attaches the attachment to the loader.

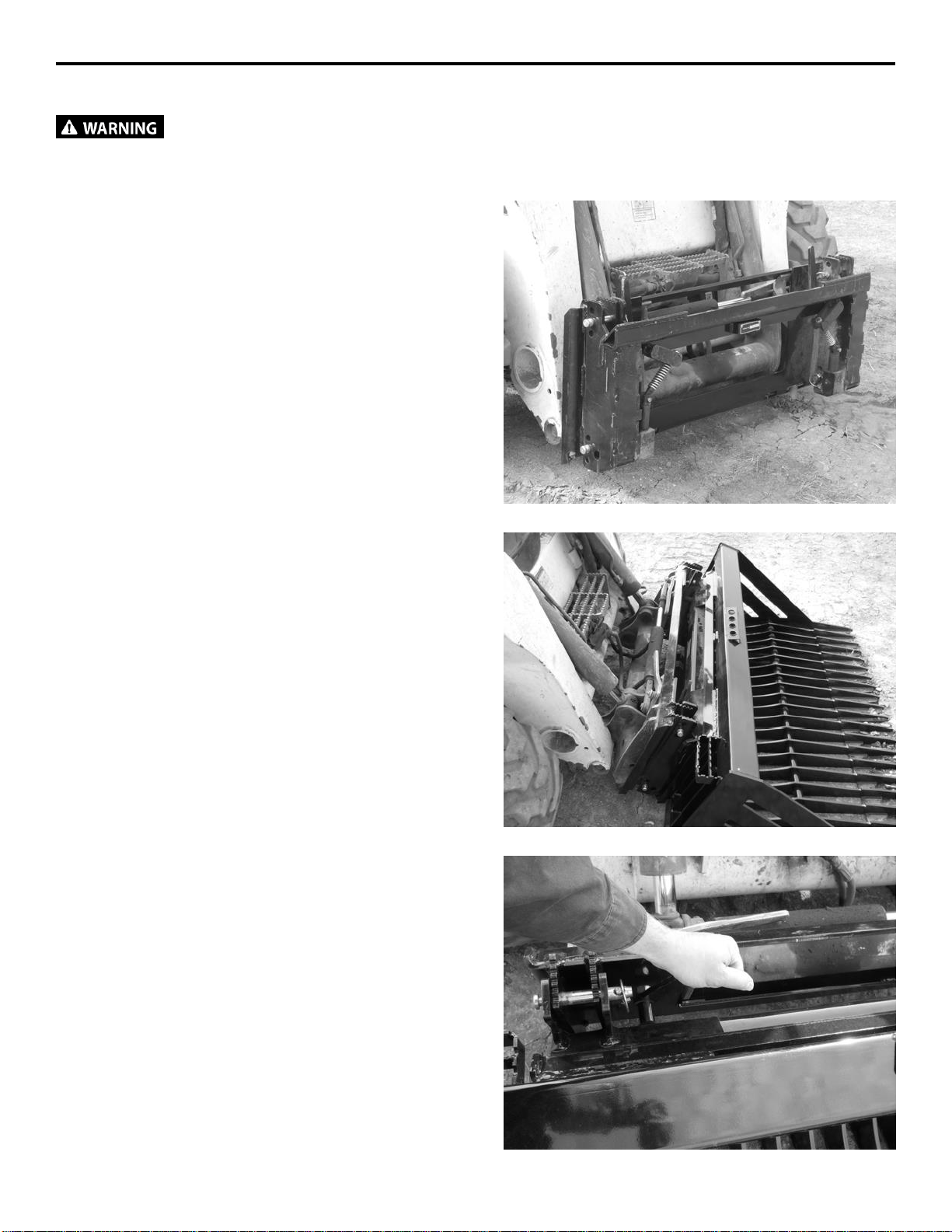

7. Drive the loader to the rear of the primary

attachment and put the adapter mount wedge into

the attachment mounting bracket.

8. Tilt the loader coupler back a small amount until

the adapter mount is fully engaged in the

attachment mounting bracket.

9. Stop the engine and engage the park brake.

10. Secure the coupler locking levers that attach the

attachment to the adapter mount.

NOTE: If the primary attachment being mounted to

the adapter has hoses, follow the hydraulic

connection instructions in the primary attachment’s

operator’s manual.

Mounting is now complete, and the attachment is

ready for operation. Use the reverse order of the

above instructions to dismount the attachment and

adapter mount from the loader.