ES Aeon CLR 2 Series User manual

JA06062019 www.elitescreens.com U-00147 1

Aeon CLR® 2 Series

EDGE FREE® Ceiling/Ambient Light Rejecting Fixed Frame Screen

USER’S GUIDE

Product Description:

The Aeon CLR® 2 Series is a fixed frame projection screen that uses Elite’s EDGE FREE® technology. The

EDGE FREE® design resembles a giant size flat panel TV display. The Aeon includes a bezel trim to further

enhance the frame appearance and absorb projector overshoot. An optional LED kit is available for

backlighting. The screen material included is our ISF Certified CLR® 2 (Ceiling Light Rejecting) which is a

front projection material designed for ultra and short throw projectors, precisely formulated for environments

with minimal control of overhead room lighting. Its multi-layer structure enhances picture brightness,

maintain color purity and improves contrast levels in ambient light room environments. The CLR® 2 is best

for family rooms, educational facilities, conference rooms, house of worship or any applications in which

incident light is a factor.

Screen Maintenance: Dust, dirt and scratches on the projection screen surface will affect the quality and

performance of the projection image. For optimal results we advise to pay attention to the following

instructions.

•Use a dry microfiber cloth or soft brush to remove dust from the screen’s surface.

•When cleaning, use a damp microfiber cloth with warm water to remove any marks.

•Never rub or apply pressure when cleaning the surface.

•Don’t point to the screen material with a fingertip or other sharp objects to prevent damage to the

material.

•The screen surface has a horizontal lens structure. DO NOT wipe the screen up and down or in a

circular motion. Wipe very gently from left to right only.

▪Don’t scratch the material, as it will leave permanent markings on the screen’s surface.

▪Don’t use acetone, benzene, alcohol and any other organic solvents to clean the screen material. Using

such chemicals will permanently damage the screen.

JA06062019 www.elitescreens.com U-00147 2

1. Frame and Edge Trim Parts List

Qty

item

2 pcs

Main Frame Parts

Qty

item

2 pcs

Edge Trim Parts

Part A.

vertical frame

Part D.

Part B.

½ horizontal frame

Part E.

Part C.

½ horizontal frame

Part F.

2. Hardware Parts List

a. M4*4

b. D5*4

c. M4*4

d. D5*4

e. M4*4

f. M4*4

g.

h.

i.

j.

k.

l.

m.

n.

o.

p.

q.

JA06062019 www.elitescreens.com U-00147 3

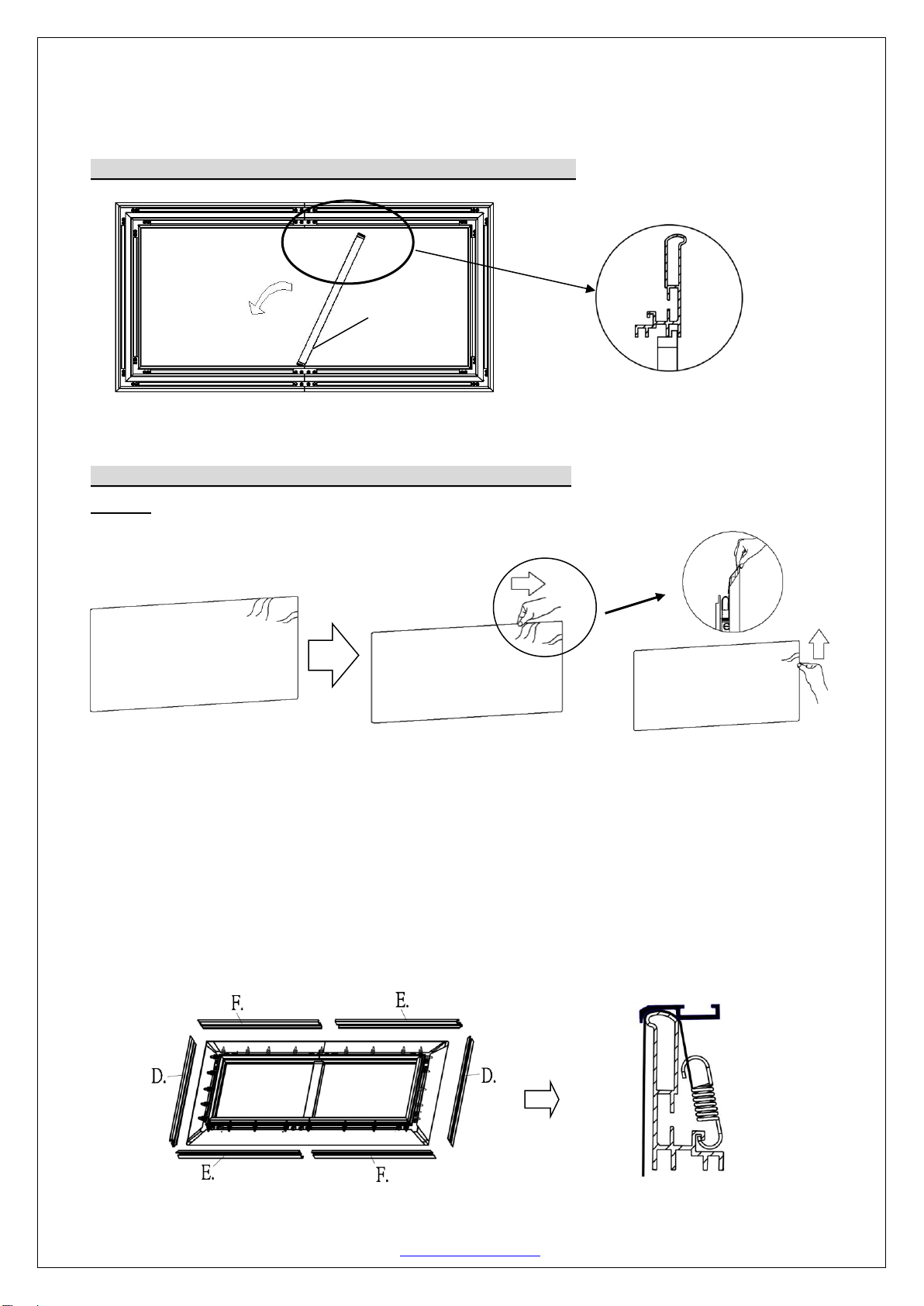

Frame Assembly

Step 1: Place the included soft padded EPE sponge sheet on a clean area where the screen will be assembled.

Step 2: Position the pieces of the frame on the EPE sponge in the arrangement shown below

Step 3: Insert center joint (a/b) connectors into one-half of the horizontal frame (B/C) and secure with the

M4x7 screws (M) as shown in the illustration below.

Tip: The center joint (b) with the larger diameter holes should be on top.

Item

Parts List

AR103H-CLR2

a.

Center Joints- M4 (bottom position)

4

b.

Center Joints-D5 (top position)

4

c.

Elbow Joints M4 (bottom position)

8

d.

Elbow Joints D5 (top position)

8

e.

Side cover Center Joints- M4

2

f.

Side cover Elbow Joints M4

4

g.

M4x7 Screws

48

h.

Spring

88

i.

Spring Hook

2

j.

wall brackets

4

k.

Φ5x50 Wall Screws

6

l.

Hollow Wall anchors

6

m.

M4x4 Screws

32

n.

Angle cover

4

o.

Center Support Bar

1

p.

White gloves

2

q.

Spring

4

b.

a.

a.

b.

g.

…

JA06062019 www.elitescreens.com U-00147 4

Step 4: Connect the elbow joints (c/d) to the top and bottom sections of the vertical frame. Once inserted,

connect the vertical sections to the horizontal frame sections. Make sure all holes are in alignment and the

frame pieces are flush (no gaps). They should form perfect right angles.

Tip: The elbow joint (d) with the larger diameter holes should be on top.

Step 5: Secure the elbow joints by fastening them with M4x7 screws (M), 4 at each corner.

Screen Material

Step 6: Put on the white gloves (p) and carefully unroll the screen material on a clean surface from the roller

to the other side as shown below. The back side of the screen material should be placed upwards.

Step 7: Carefully and gently place the assembled frame on top of the screen material in the marked areas as

shown below. Make sure to not allow the angle edge of the frame to come in direct contact with the screen

material to avoid puncturing it.

2. Hardware Parts List

a.

b.

c.

d.

e.

f.

g.

h.

i

j.

k.

l.

m.

Back side

RFront

*Make sure the frame corners are positioned

in the marked areas of the material.

Back Side

c.

d.

g.

JA06062019 www.elitescreens.com U-00147 5

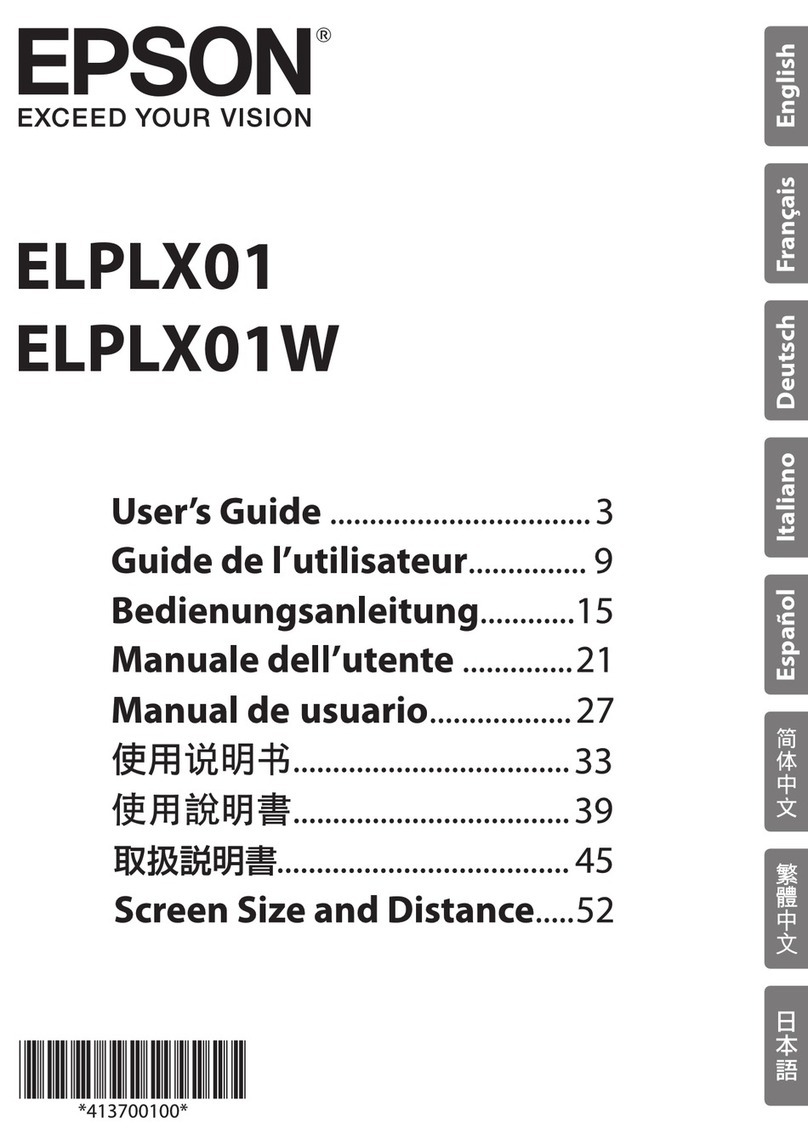

Step 8: Hook one end of the spring and secure inside the groove of the frame, use the spring hook (h) to

attach the spring to the hole located on the screen material’s outer edge in the following order.

Begin by first attaching the center points on both vertical (left/right) sides, steps 1-2. Then the center points

on both horizontal (top/bottom) sides, steps 3-4. Once all center points have been secured, make sure the

screen material is still within the marked areas before proceeding to attach the next springs.

Continue attaching the rest of the springs to the material in the following order in steps 5-12.

Note (after all springs have been attached):

Correct material installation –Corners of the screen material are properly wrapped around the corner edges

of the frame and material is evenly tensioned and flat, creating a nicely taut surface.

Incorrect material installation –The corners of the screen material are not properly wrapped along the edge

of the frame leaving the material with unbalanced tension and an uneven finish. To correct, detach springs

from material at the corner(s) where material does not lie flat along the edge of the frame, reposition the

material so that it lies flat and wraps along the edge of the frame, and reattach springs to the material.

Note: Please make note of the yellow label and spring in the center of the frame. This is an indicator to start

the screen material installation process from the middle area of the frame.

h.

i.

5

6

7

8

9

11

10

12

1

2

3

4

To avoid ripples forming in the material it is imperative that all of the corners are properly wrapped around

the edges as illustrated in the check mark diagrams.

JA06062019 www.elitescreens.com U-00147 6

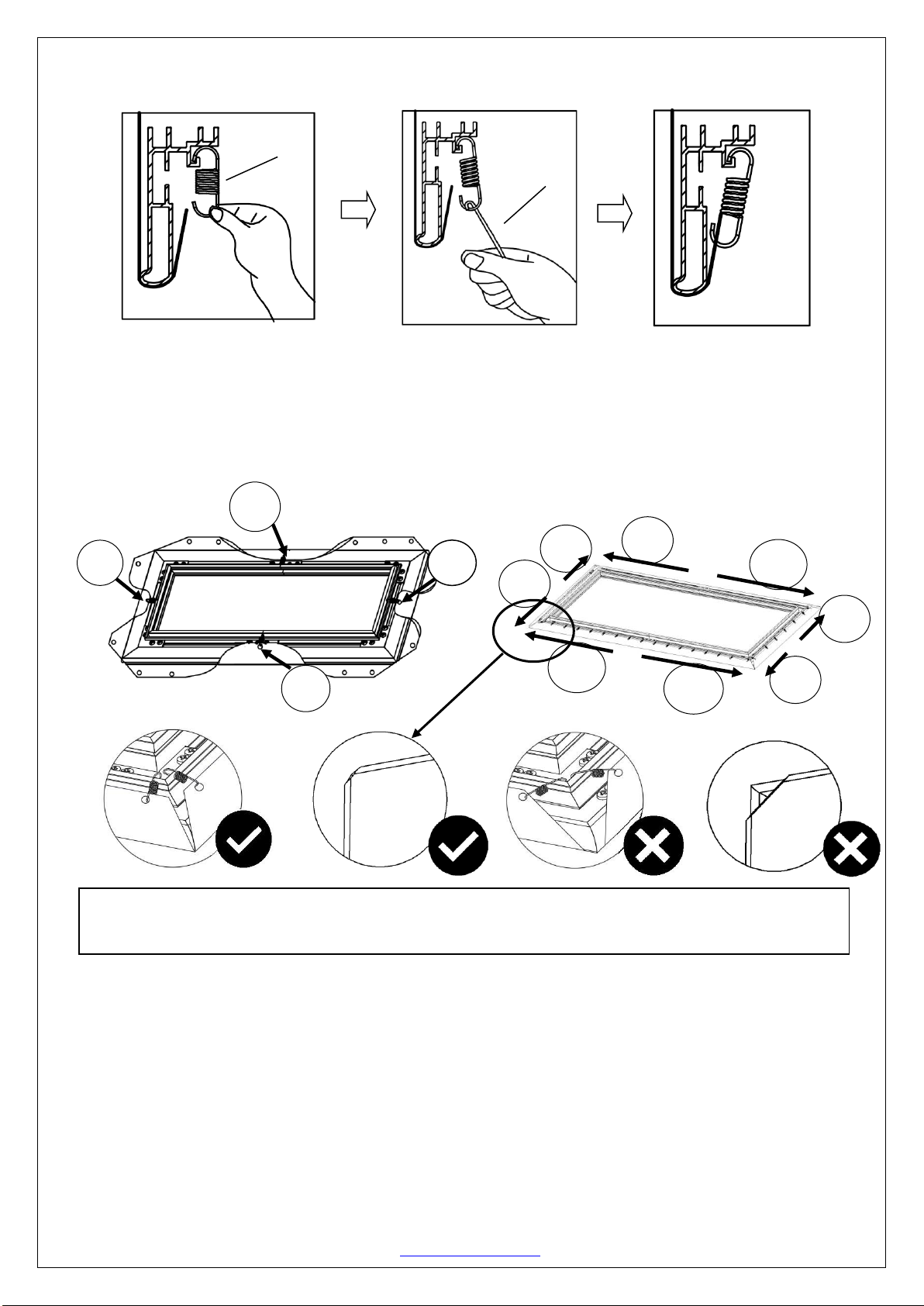

Center Support Bar

Step 9: Insert the Center Support Bar (o) into the upper top groove on the back of the frame with the bottom

end near the approximate center point of the frame and rotate it in at an angle so that both ends of the bar are

in alignment with the groove.

Diagonal Sizes of 150” and below use 1 x Center Support Bar

Attention: Do not proceed with the Edge Trim installation until making sure there are no ripples in the material.

How to avoid getting ripples on the screen’s material surface

Solution: Pull and smooth out the material using your hand from the center to the corners, creating a nicely

taut surface as shown below.

Edge Trim Installation

ATTENTION: ON THE BACK OF THE MATERIAL THERE ARE LABELS INDICATING THE TOP

AND BOTTOM. THE TOP EDGE TRIM PIECE WITH THE LOGO SHOULDBE INSTALLED ON THE

TOP. THE MATERIAL ISDIRECTIONAL SO IT WILL NOT PROPERLY REFLECT IF THE BOTTOM

SIDE IS PROJECTED ON.

Step 10: Place the edge trim frame pieces over each end of the frame.

p.

JA06062019 www.elitescreens.com U-00147 7

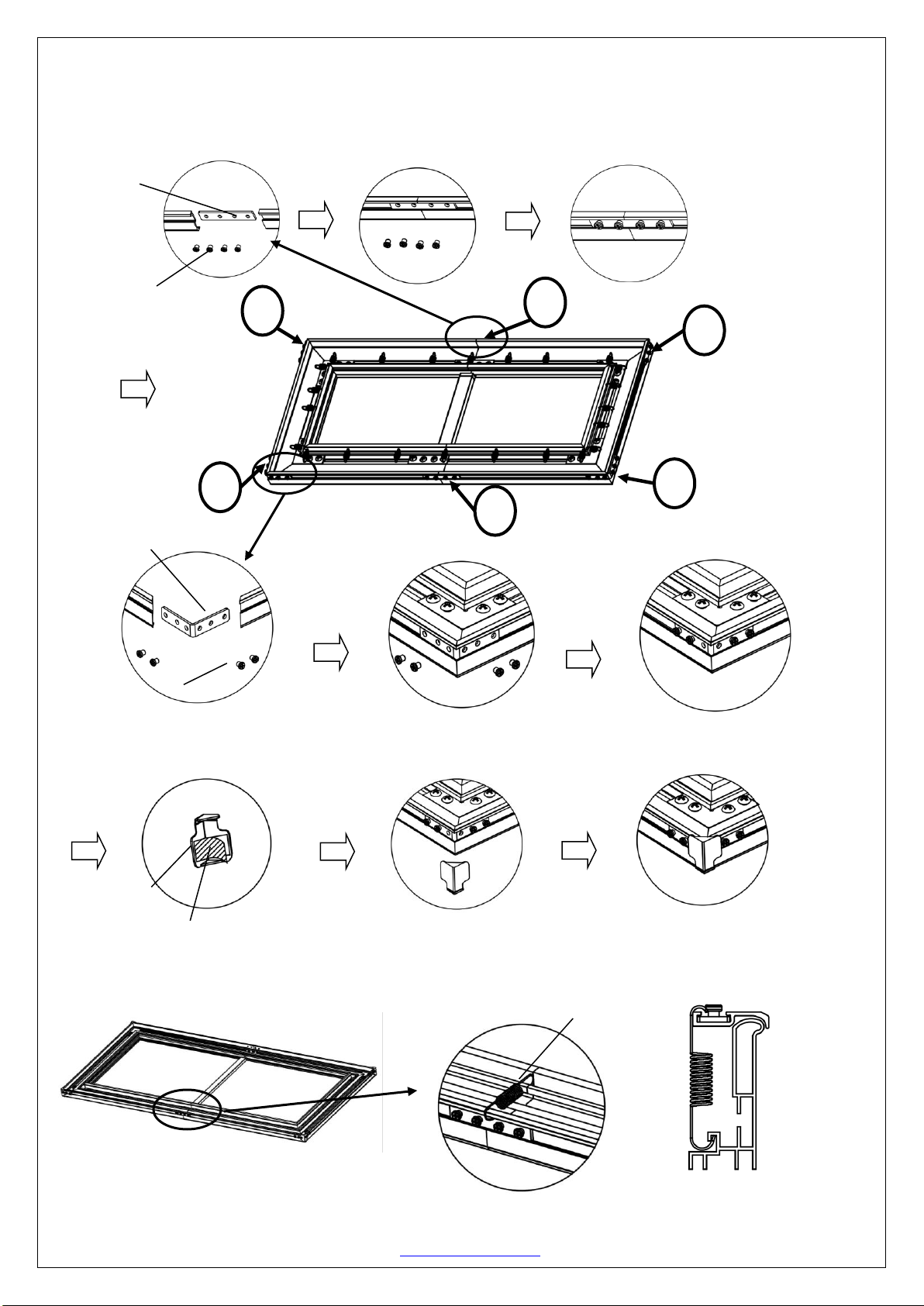

Connect edge trim frames (e/f) together using the M4 center joint (e) and secure with four of the M4x4 screws

(m) as show in Step 1. Repeat for other side.

Once both top and bottom edge trim frames have been connected, attach the vertical (left/right) sides edge trim

frames (d) using the elbow joints (f) and secure with four M4x4 screws (m) on all corners, Step 2.

Step 11: Install the angle cover (n) on each corner of the frame using the M4x4 screws (m).

Note: The angle cover screws holes align with the screw holes on the elbow joint.

Step 12: Install the springs (q) in each middle area to further support the bezel trim edge frame.

f.

1

1

2

2

2

2

m

e.

m

.

q.

o.

Tear off the double-sided tape.

JA06062019 www.elitescreens.com U-00147 8

Notice to Installer:

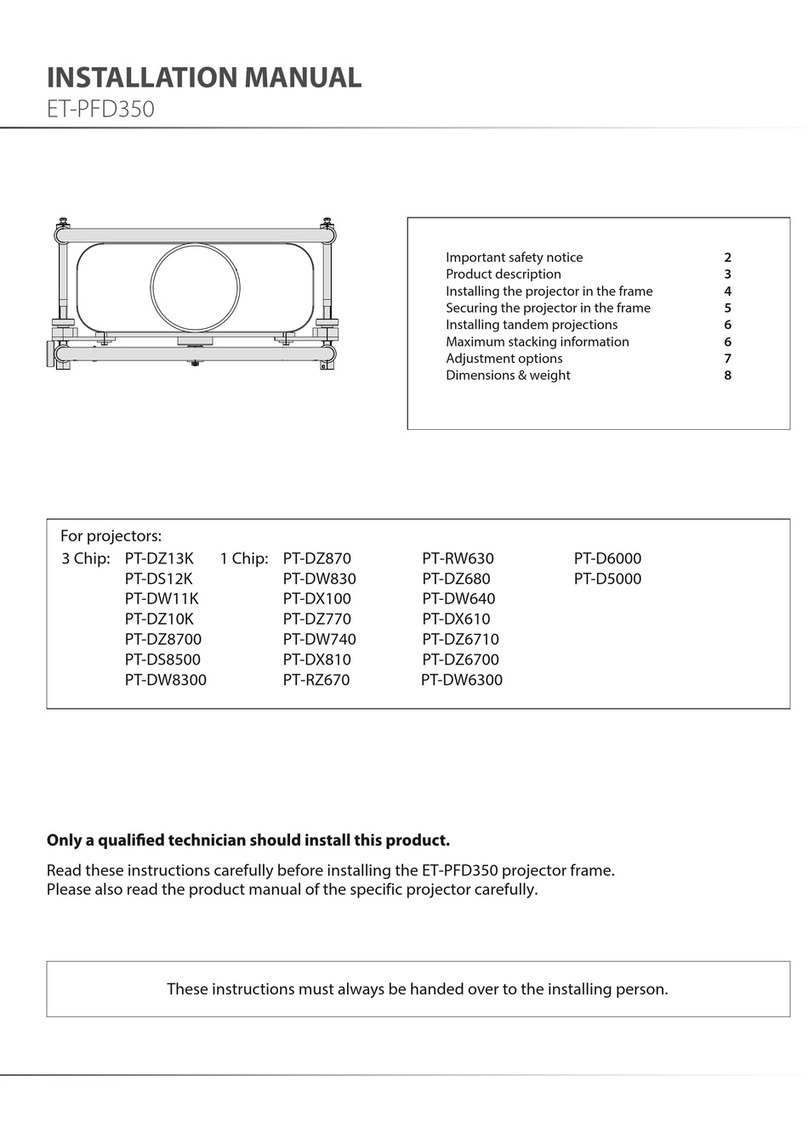

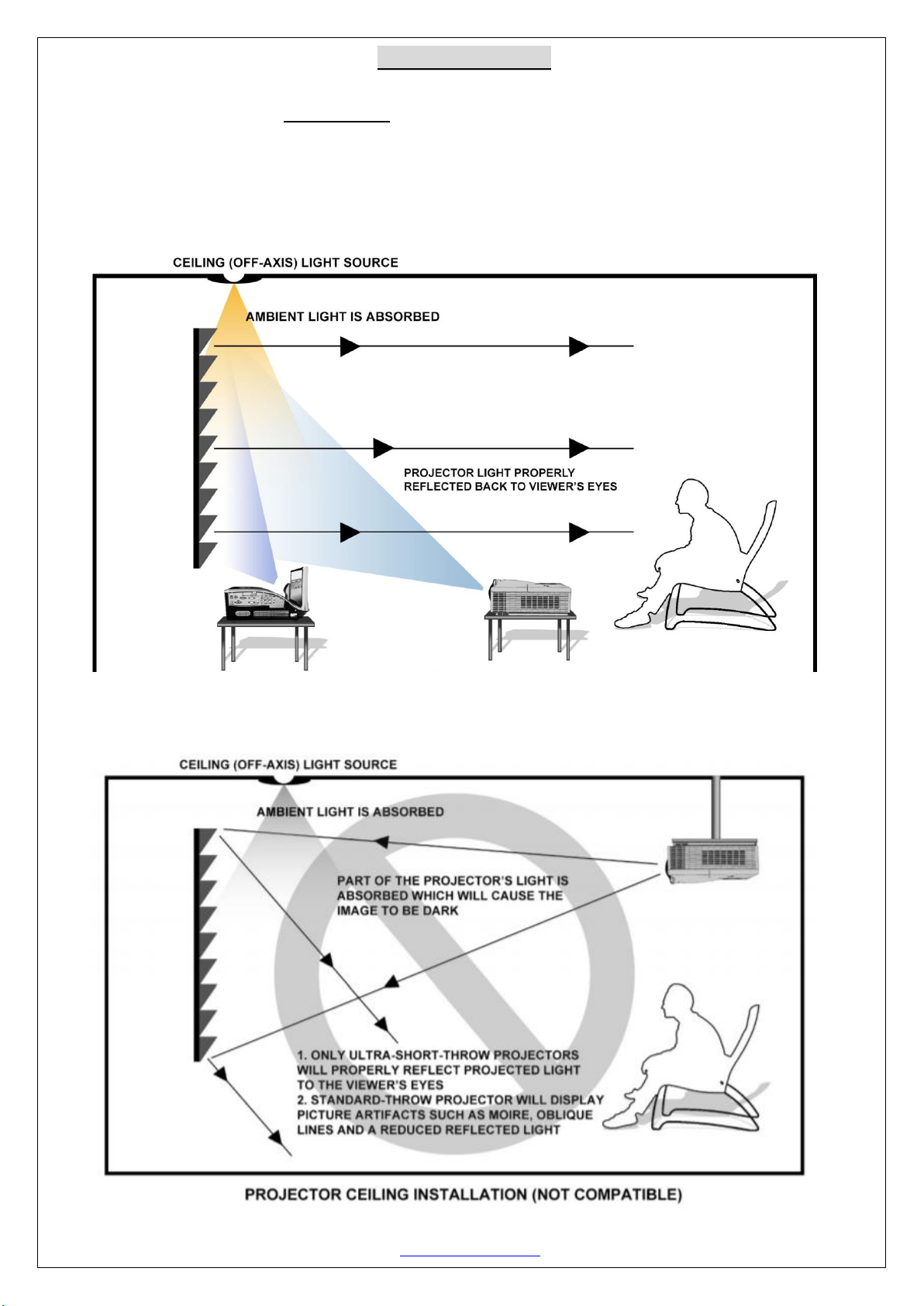

Material Tip: Proper Projector Placement for CLR®2

The CLR®2 is exclusively for table-mounted ultra and short throw projectors as illustrated in the graphics

below. Overhead placement or a standard throw projector will make the image very dark, on account of

the screen’s absorbent layer deflecting light that is not aligned with its reflective angle.

Correct projector installation: Ultra-short and Short throw projector aligns with reflective layer.

Improper projector installation

JA06062019 www.elitescreens.com U-00147 9

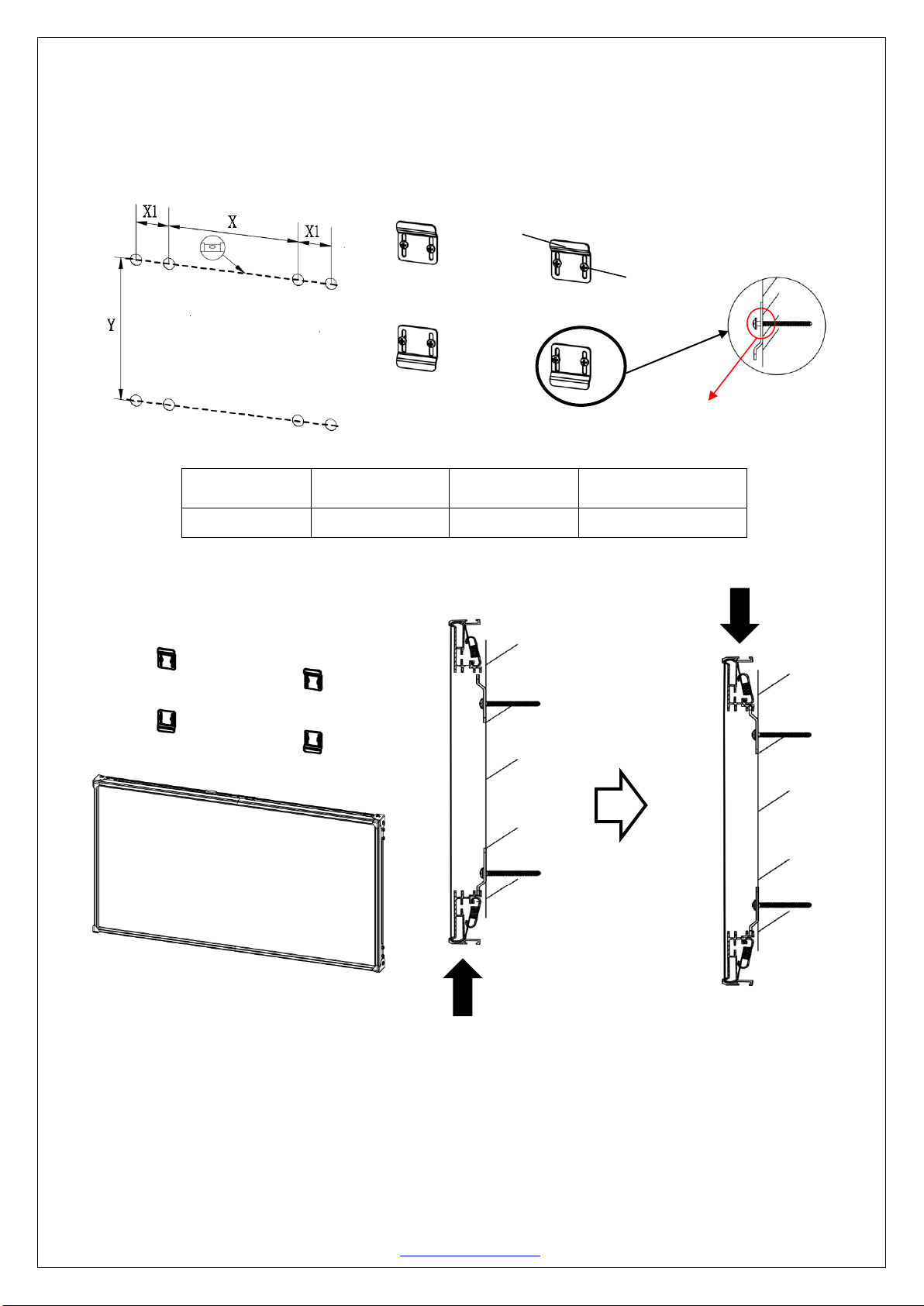

Wall Installation

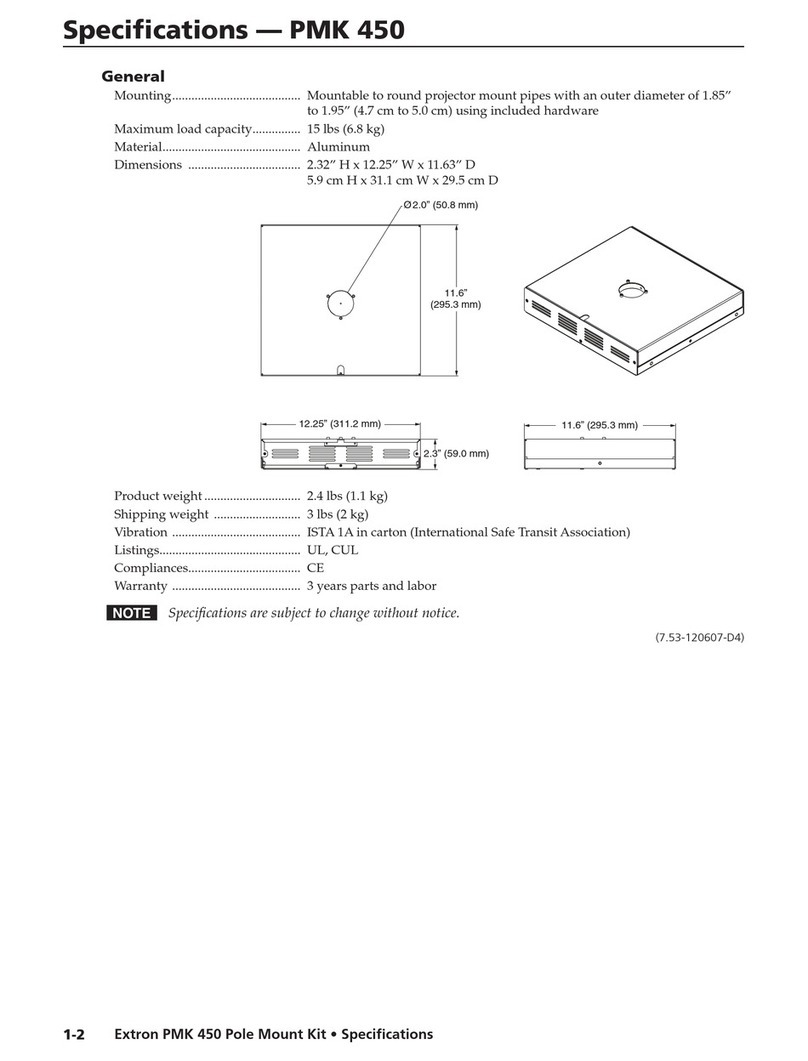

Step 13: Measure the overall length and height of the frame and drill holes for the top brackets. Line up the

wall brackets with the drilled holes on the installation location and screw them in using a Phillips screwdriver.

If not installing into a structural wood stud, use a hollow wall anchor then screw in the M5x50 wood screws

with a screwdriver. Make sure the brackets are leveled.

Step 14: Position the fixed frame screen onto the top wall brackets as shown below and push down at the

center of the top of the frame to secure.

For Technical Support or an Elite Screens contact in your area, visit

www.elitescreens.com

Item

X = Wall

bracket distance

X1 = Bracket

hole distance

Y = Top/Bottom

Wall Bracket Height

AR103H

1200mm(47.24”)

35mm(1.37”)

1110mm(43.7”)

Don’t lock the screw to the bottom.

l.

k.

This manual suits for next models

1

Table of contents