ESAB ARC400i User manual

Other ESAB Welding System manuals

ESAB

ESAB Caddy Mig C160i User manual

ESAB

ESAB MXH 300PP User manual

ESAB

ESAB Aristo Robust Feed U6 User manual

ESAB

ESAB LAF 1000 User manual

ESAB

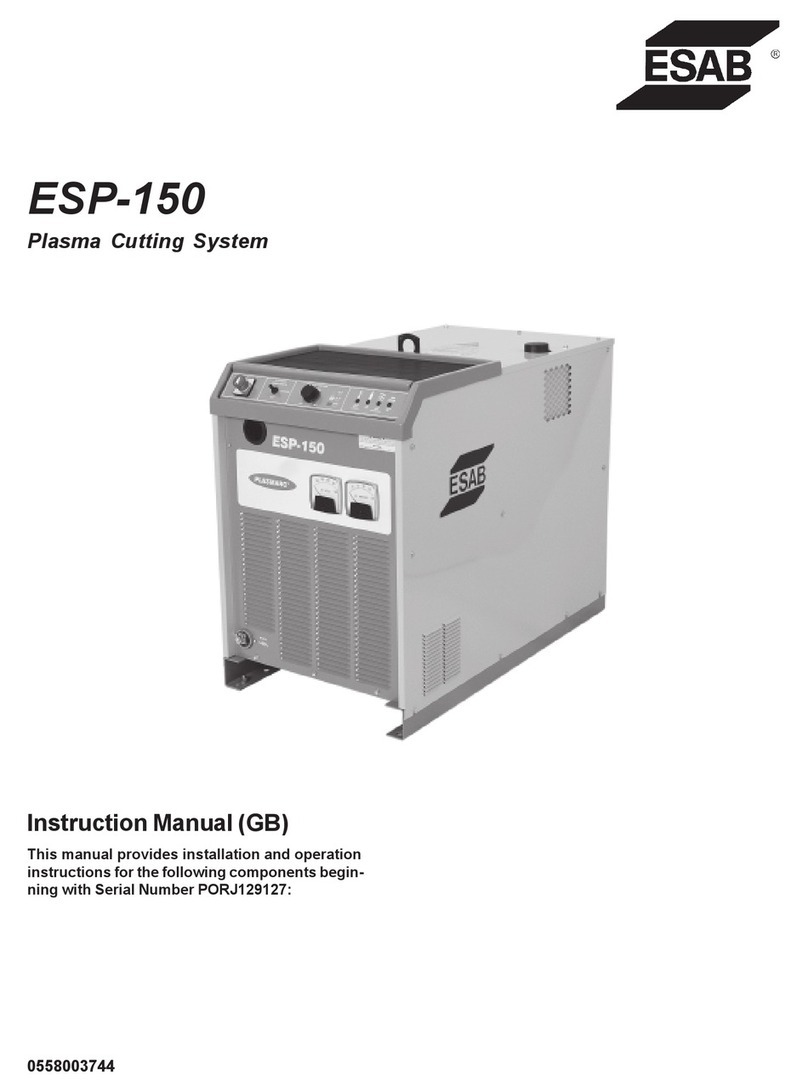

ESAB ESP-150 User manual

ESAB

ESAB Warrior 400i CC/CV User manual

ESAB

ESAB A2 Multitrac User manual

ESAB

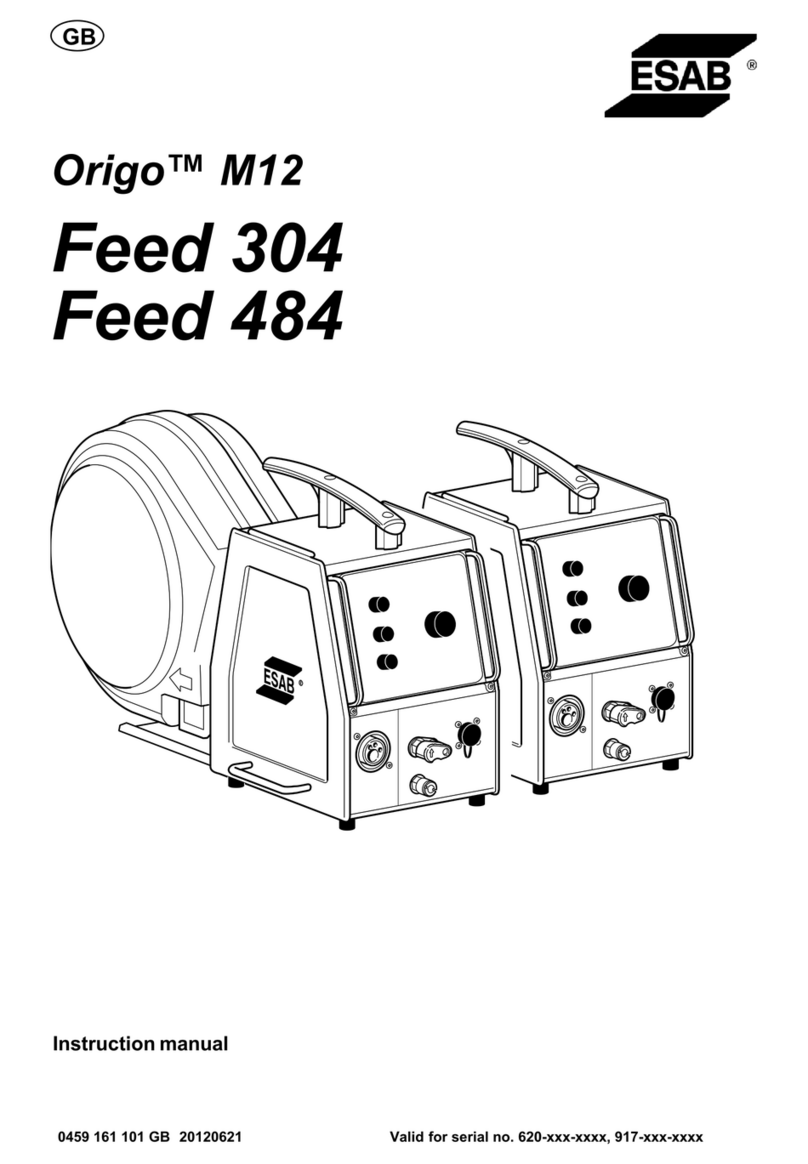

ESAB Origo M 12 Feed 304 User manual

ESAB

ESAB CUTMASTER A60 User manual

ESAB

ESAB ESABMig C420 User manual

ESAB

ESAB ET 186i AC/DC User manual

ESAB

ESAB LTR 160 User manual

ESAB

ESAB 100i User manual

ESAB

ESAB PowerCut 400 User manual

ESAB

ESAB ES 180i Pro User manual

ESAB

ESAB RobustFeed AVS User manual

ESAB

ESAB Fabricator ET 410iP User manual

ESAB

ESAB Aristo YardFeed 2000 User manual

ESAB

ESAB 100i User manual

ESAB

ESAB Plasmarc EPP-450 User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual

Elettro

Elettro HI-MIG 3000 SYNERGIC instruction manual