IGBT MIG-200M User manual

IGBT Inverter Welder

USER’S MANUAL

Model: MIG-200M

FOR YOUR SAFETY

Read and understand this manual before use. Keep this manual for future reference

1

TABLE OF CONTENTS

1. SAFETY..................................................................................................................2

2. GENERAL DESCRIPTION................................................................……………...3

3. MAIN PARAMETERS........................................................................……………...5

4. PANEL INSTRUCTION...........................................................................................6

5. INSTALLATION......................................................................................................8

6. OPERATION.........................................................................................................11

7. CAUTION.............................................................................................................13

8. MAINTENANCE...................................................................................................14

9. DAILY CHECK......................................................................................................15

10.TROUBLE SHOOTING........................................................................................17

11.DIAGRAM.............................................................................................................19

DECLARATION OF CONFORMITY

Hereby we declare that these machines are produced based on relative

Chinese and international standards and they conform to the international safety

standard IEC60974-1. The design and technology adopted in these machines are

under patent protection.

Please read and understand this manual carefully before the installation and

operation of these machines.

1. The contents of this manual may be revised without prior notice and without

obligation.

2. Although carefully checked, there may still be some inaccuracies in this

manual. Please consult us if any.

2

Professional training is needed before operating the machine.

⚫Use labor protection welding supplies authorized by national

security supervision department.

⚫The operator must be qualified personnel with a valid "metal

welding (OFC) operations" operation certificate.

⚫Cut off power before maintenance or repair.

Electric shock—may lead to serious injury or even death.

⚫Install earth device according to the application criteria.

⚫Never touch the live parts when skin bore or wearing wet

gloves/clothes.

⚫Make sure that you are insulated from the ground and work

piece.

⚫Make sure that your working position is safe.

Smoke& gas—may be harmful to health.

⚫Keep the head away from smoke and gas to avoid inhalation

of exhaust gas from welding.

⚫Keep the working environment in good ventilation with exhaust

or ventilation equipment when welding.

Arc radiation—may damage eyes or burn skin.

⚫Wear suitable welding masks and protective clothing to protect

your eyes and body.

⚫Use suitable masks or screens to protect spectators from

harm.

Improper operation may cause fire or explosion.

⚫Welding sparks may result in a fire, so please make sure no

combustible materials nearby and pay attention to fire hazard.

⚫Have a fire extinguisher nearby, and have a trained person to

use it.

⚫Airtight container welding is forbidden

⚫Must not use the machines for other purposes except

welding, such as pipe thawing, battery charging, heating.

1. SAFETY

Welding is dangerous, and may cause damage to you and others, so take good

protection when welding. For details, please refer to the operator safety guidelines in

conformity with the accident prevention requirements of the manufacturer.

3

Hot work piece may cause severe scalding.

⚫Do not contact hot work piece with bare hands.

⚫Cooling is needed during continuous use of the welding torch.

Magnetic fields affect cardiac pacemaker.

⚫Pacemaker users should be away from the welding spot

before medical consultation.

Moving parts may lead to personal injury.

⚫Keep yourself away from moving parts such as fan.

⚫All doors, panels, covers and other protective devices should

be closed during operation.

Please seek professional help when encountering machine

failure.

⚫Consult the relevant contents of this manual if you encounter

any difficulties in installation and operation.

⚫Contact the service center of your supplier to seek

professional help if you still can not fully understand after

reading the manual or still can not solve the problem

according to the manual.

2. GENERAL DESCRIPTION

MIG-200M Welder is an inverter based MIG welder with LCD display. Adopting MCU controller,

together with TFT-LCD, it makes the setting much easier for the user.

This multi-process welder has 4 functions: Flux cored arc welding, MIG welding, TIG, and MMA;

and the MIG spool gun is optional for aluminum welding purpose.

➢Features:

◆4.2inch TFT-LCD, with high resolution, it can show the setting parameters & welding

parameters, which make it quite simple to set.

◆Adopting MCU controlling system, the welding parameters are automatically set

according to the user’s choice, which greatly improves the welding efficiency.

◆With the built-in welding expert database, it increases the welding reliability a lot.

◆Multi-process, makes it applicable for different welding purpose.

4

2.1 Flow Diagram:

2.2 Schematic Diagram:

5

3. MAIN PARAMETERS

3.1 Technical parameters table:

MODEL

MIG-200M

Input voltage (V)

1ph 230V, 50Hz

Welding mode

MIG/FLUX

MMA

TIG

Input current (A)

34

33

21

Input power(KVA)

7.5

7.2

4.7

No-load voltage(V)

60

60

60

Welding current(A)

range (A)

30~200

20~175

20~175

Welding voltage(V)

15.5~24

21~27

10.8~17

Rated duty cycle

35%

35%

35%

Welding wire dia.(mm)

0.6-1.0

N/A

N/A

Electrode dia.(mm)

N/A

1.0-4.0

N/A

Efficiency

85%

Power factor

0.7

Protection class

IP21S

Insulation class

F

* Note: The duty cycle is tested at 40°C has been determined by simulation.

* Note: The Machine with PFC version, can works under the input voltage from 85V to 260V.

While the input voltage is lower than 145V, it will switch to low voltage working mode

automatically, and the output power will be limited. Please restart the machine to recover

to the full output power, after input voltage gets to be higher than 145V.

3.2 Power supply:

MODEL

MIG-200M

Input voltage (V)

1ph 220V, 50Hz

Min. Power

Power Grid

9.5 KVA

Generator

12 KVA

Input Protection

Fuse

32 A

MCB

32 A

6

4. PANEL INSTRUCTION

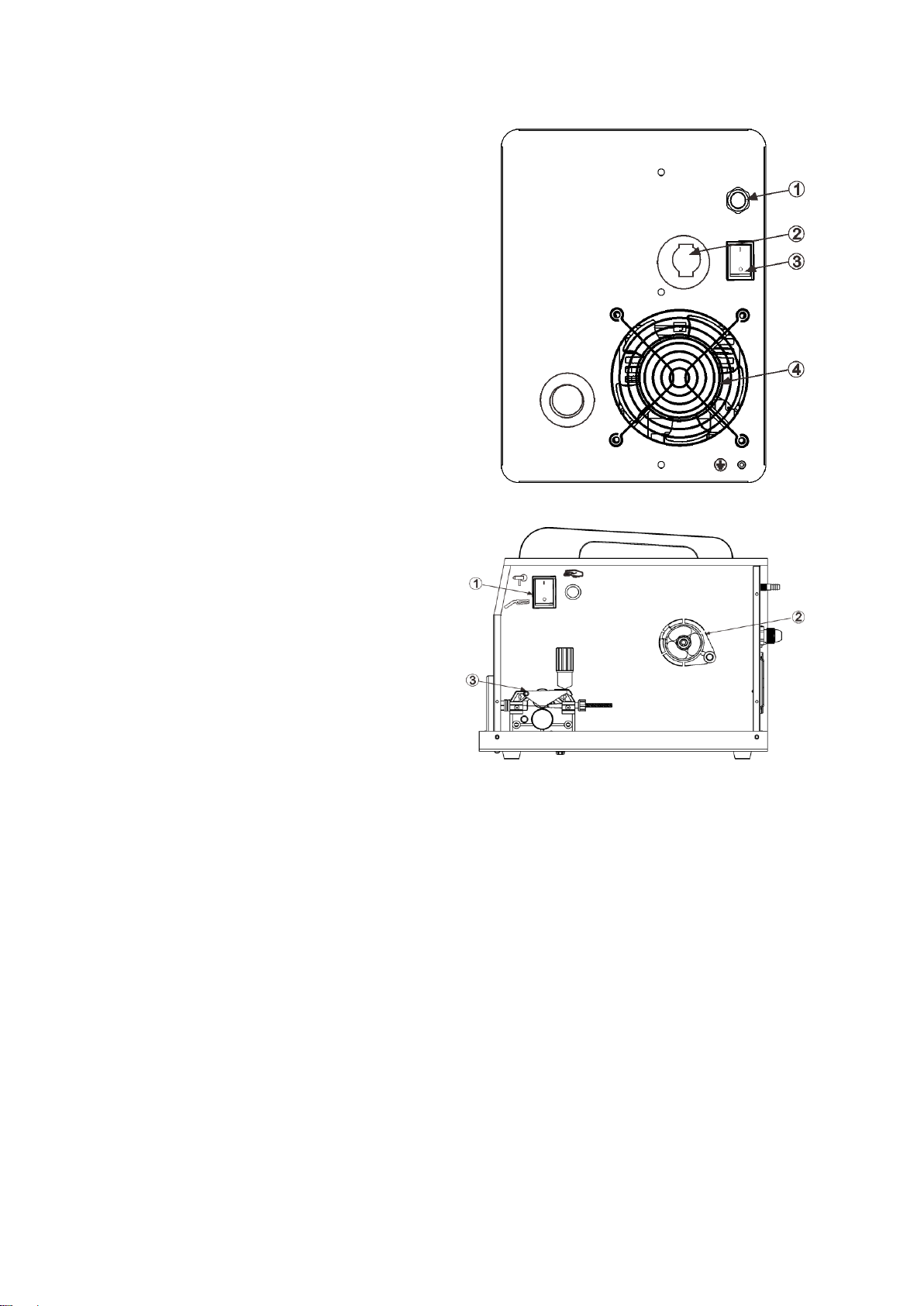

4.1 Front Panel:

1. Adjusting knob: wire speed setting (MIG mode); welding current setting (MMA/TIG mode).

2. Adjusting knob: welding voltage setting (MIG mode); output on/off control (MMA/TIG

mode).

3. LCD: welding technics and parameters display.

4. Home button: return to the main menu, where the user can choose welding technics type

or display setting.

5. Central adjusting knob: rotate to select the parameter, or push to enter/confirm.

6. Return button: return to the last menu.

7. Welding torch connector: make sure the torch is tightly connected and locked before

welding.

8. Spool gun connector: to connect the optional spool gun. It’s usually used to weld

aluminum or aluminum alloy.

9. Welding cable:

a. Under Flux Cored welding mode: connect it to “-”;

b. Under MIG welding mode: connect it to “+”.

10. Output Connector “-”

11. Output Connector “+”

7

4.2 Rear Panel:

1. Gas inlet: to connect the gas hoses.

2. Power switch: Power ON/OFF

3. Fan: cooling down the fan during the work.

4.3 Internal Panel:

1. Selector switch: to choose torch type for

welding.

2. Wire spool holder: to adopt the welding

wire.

3. Wire feeder: under machine MIG torch

type welding, it will work to feed the wire

to torch. Under spool gun mode, it

doesn’t work.

8

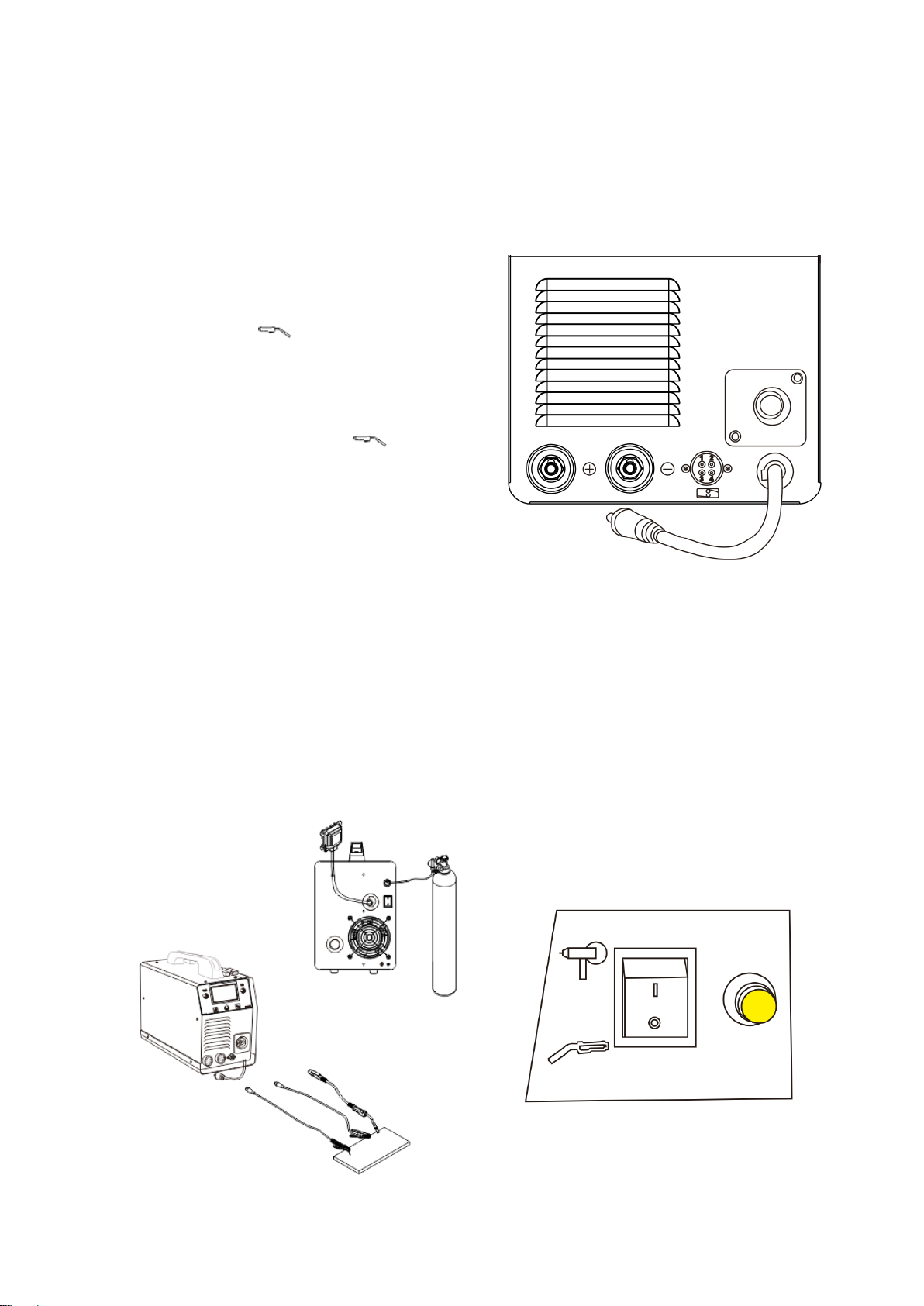

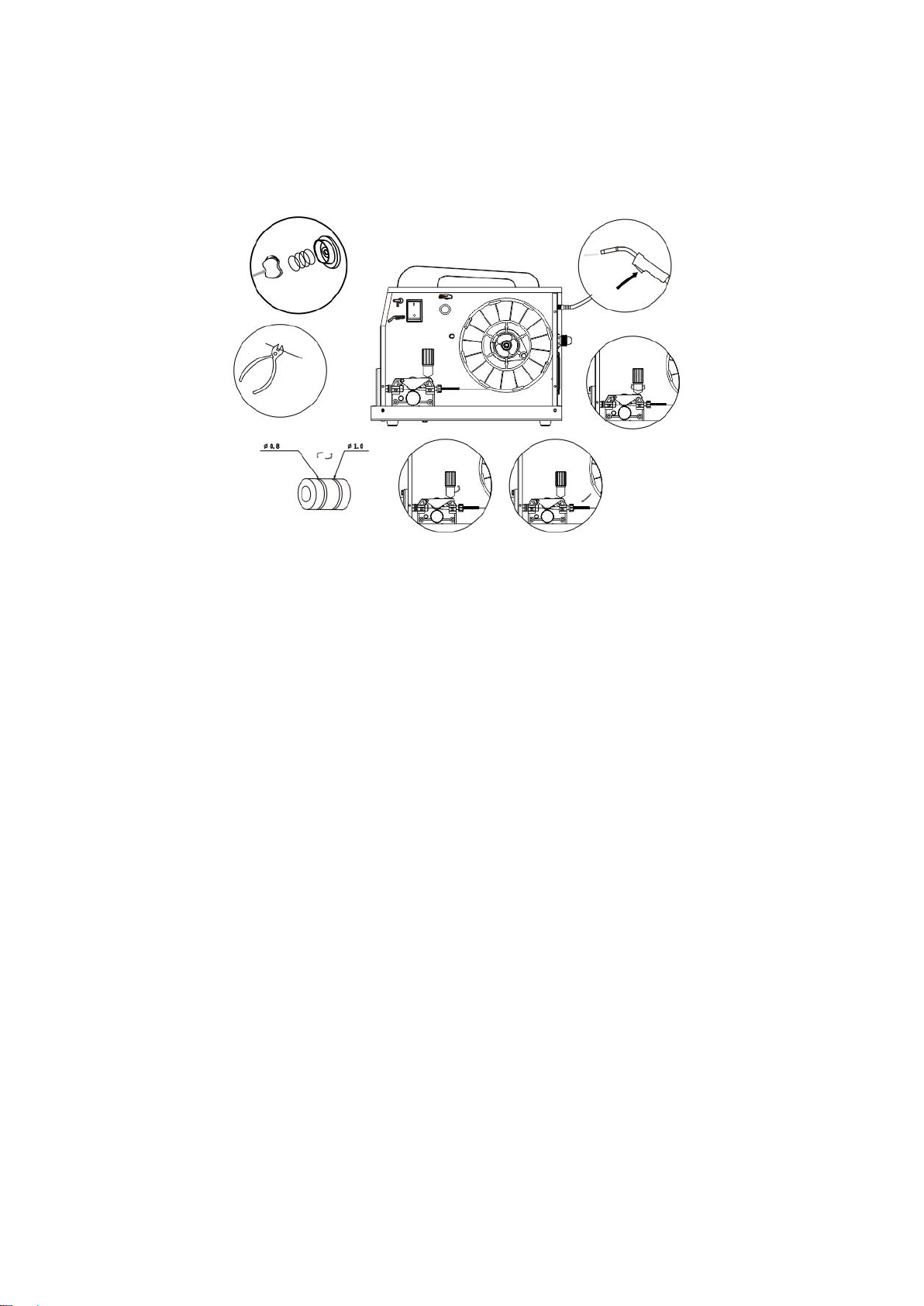

5. INSTALLATION

5.1 Power cord connection:

Connect the machine to the 1phase 220VAC Power supply with leakage protection switch.

5.2 Output cables connection:

5.2.1 Under MIG with solid wire: welding cable

connector connects “+”, earth clamp connects“-”,

torch connect to “”and fasten it.

5.2.2 Under Flux cored welding with flux wire:

welding cable connector connects “-”, earth clamp

connects“+”, torch connect to“”and fasten

it.

5.2.3 Under MMA mode: welding electrode holder

connects “+”, earth clamp connects“-”.

Notice for spool gun:

When using spool gun, please select the torch switch at “Spool Gun” in the internal panel. Please

choose the spool gun with 24V motor, and it is usually used to weld aluminum or aluminum alloy.

Please use AR 100% as protection gas and welding technics mode set at “SPOOL GUN

ALUMINUM”. Then choose the suitable welding wire size and parameters. For the spool gun

connector on the front panel, “1” “2” is for torch switch, “3””4” is for wire feeder. (“3” is to wire

feeder motor +, and “4” is for wire feeder motor -.)

Figure 1 Figure 2

9

5.3 Filler Wire

5.3.1 Threading the filler wire

1. Open the reel housing by pressing on the opening button and install the wire reel in such a way

that it rotates counter clockwise. You can use either a 5 kg (diameter 200 mm) or l kg (100 mm)

wire reel in the machine.

2. Attach the reel with a reel lock.

3. Unfasten the wire end from the reel, but hold on to it all the time.

4. Straighten the wire end for approximately 20 cm and cut the wire in the straightened location.

5. Open the pressure control lever which then opens the feed gear.

6. Thread the wire through the wire's rear guide to the gun's wire guide.

7. Close the feed gear and fasten it with the pressure control lever. Make sure that the wire runs in

the feed roll groove.

8. Adjust the compression pressure with the pressure control lever no higher than to the middle of

the scale .lf the pressure is too high, it removes metal fragments from the wire surface and may

damage the wire. On the other hand, if the pressure is too low, the feed gear slips and the wire

does not run smoothly.

9. Press the welding gun trigger and wait for the wire to come out.

10. Close the reel housing cover.

CAUTION! When driving the wire in to the gun, do not point the gun at yourself or others or

put, for example, your hand in front of the tip, because the cut wire end is extremely sharp.

Also, do not put your fingers near the feed rolls, because they might get squeezed between

the rolls.

10

5.3.2 Changing the feed roll groove

The feed roll groove is factory set for welding filler wires of 0.8-1.0 mm diameter. The feed roll

groove must be changed if you use 0.6 mm thick filler wire.

1. Open the feed roll from the pressure control lever.

2. Switch the machine on from the main switch.

3. Press the welding gun trigger and drive the feed roll in such a position that its locking screw is

up and can be opened.

4. Switch the power off from the main switch.

5. Open the feed roll locking screw with a 2.0 mm Allen wrench approximately half a turn.

6. Pull the feed roll from its shaft.

7. Turn the feed roll and reinstall it to its shaft all the way to the bottom making sure that the screw

is on the shaft's level.

8. Tighten the feed roll locking screw.

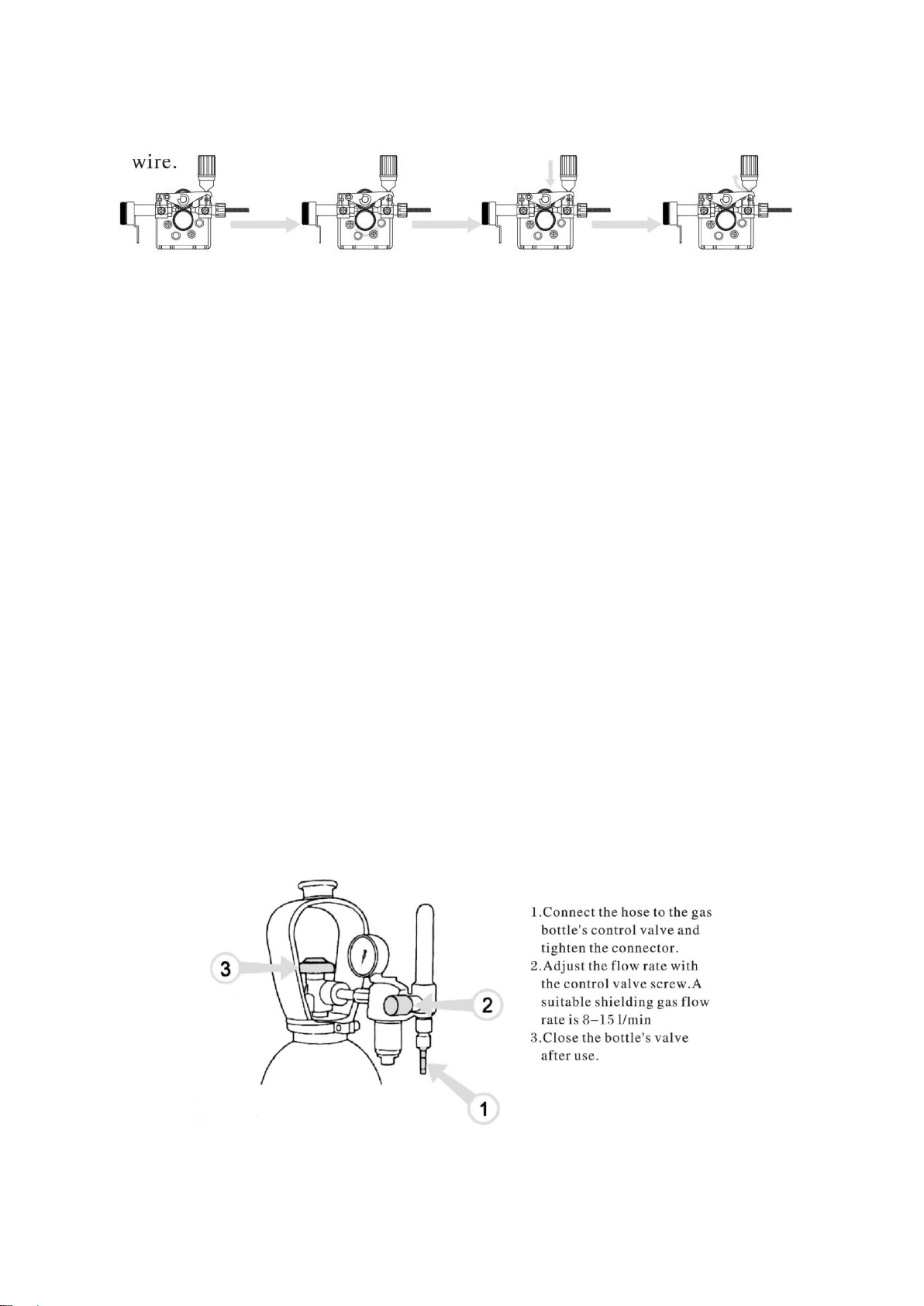

5.4 Shielding gas

The shielding gas used for steel wires is carbon dioxide or a mixture of argon and carbon dioxide

which replaces air in the arc's area. Thickness of the welded sheet and welding power define the

flow rate of the shielding gas.

Connect the bayonet socket of the shielding gas hose to the machine's hose connector and the

hose connector end to the gas bottle's control valve.

NOTE! Use a shielding gas suitable for the material’s welding. Fix the gas bottle securely in

an upright position before installing the control valve.

11

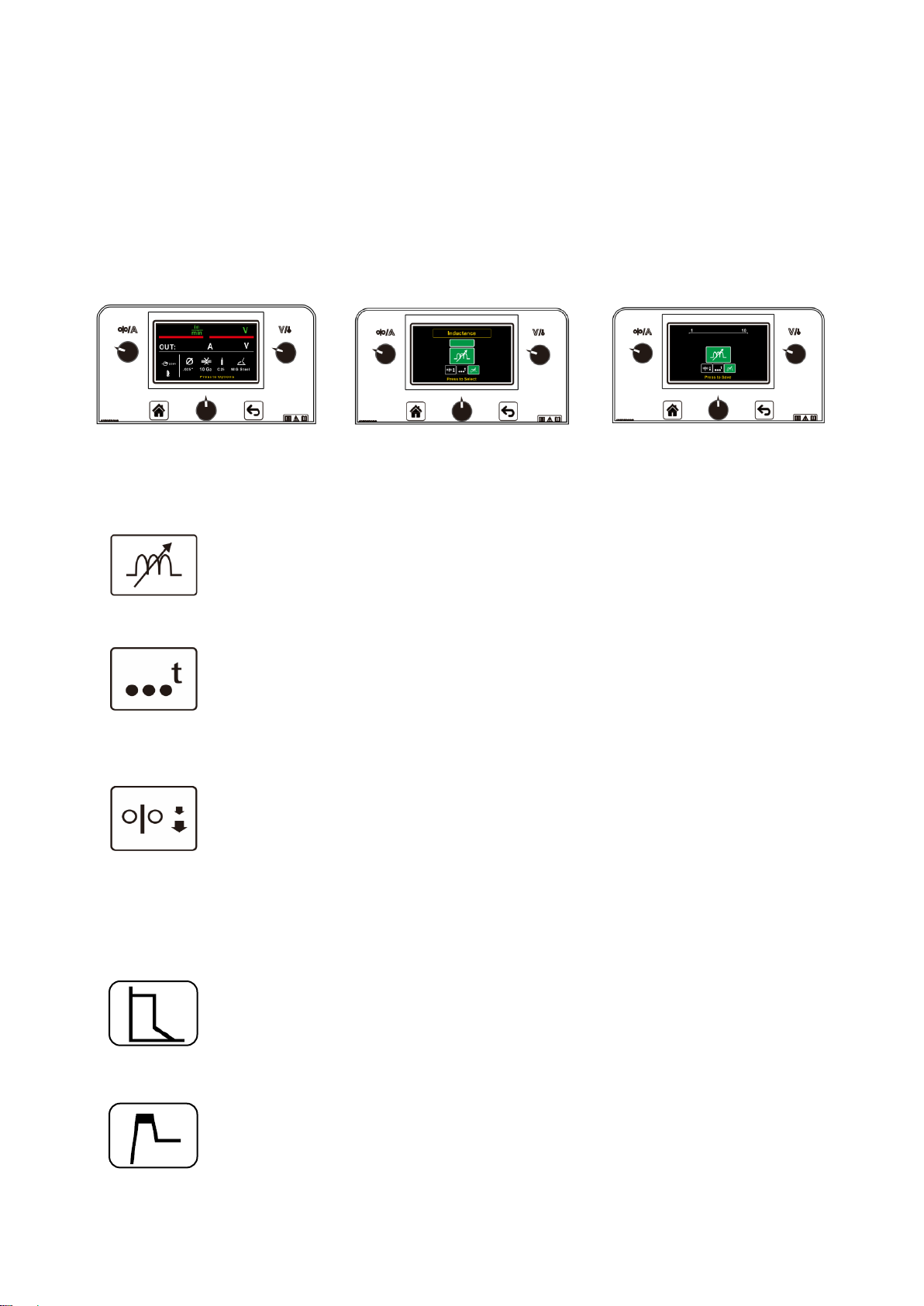

6. OPERATION

6.1 Operation steps:

Please power on the welder, open the gas bottle valve, and adjust the gas pressure to suitable

scale. If not using the spool gun, please select the torch type at “ ” position on the internal

panel.

For the details, please refer to the example below, which is for MIG with mixed gas.

When machine is turn on, please press the central adjusting knob to enter the main menu, after

the program initialization is finished.

Rotate the central adjust knob to select the welding mode

to MIG STEEL C25, and then press the knob to enter this

mode.

The program will guide you the connection for the welding

cable, please do as per request and then press to

continue.

Rotate the knob to select the welding wire diameter and

then press the knob to next step.

Rotate the knob to select the welding material thickness

and then press the knob to enter the pre-welding status.

12

The welding expert system will preset the welding parameters according to the selected wire size

and material thickness. The user can manually fine adjust it as well.

To adjust the welding current, please use the left adjusting knob; and to adjust the welding voltage,

please use the right adjusting knob.

Press the central adjusting knob to enter more parameter setting for MIG, like Run-in WFS,

inductance, spot time, etc.

6.2 Options and settings

MIG Options

The inductance option permits adjusting the arc performance, this option can be

used to help with starting and the weld bead profile. A higher inductance setting

provides a softer arc and alower inductance setting provides a crisper arc.

The spot time option permits adjusting the duration of the welding arc. This is used

for tack welds or spot welds. The spot-time option is available in MIG and Flux

cored welding modes.

The run-in option permits adjusting the wire feed speed prior to the arc being

established. A lower run-in speed permits smooth arc starts. After the arc is

established the run-in value is inactive and the set wire feed speed is present. The

run-in option is available in MIG and Flux cored welding modes.

MMA Options

The arc force option permits the user to control the penetration profile. A high arc

force value creates a crisp arc while a low arc force value creates a soft arc. The arc

force option is available in MMA mode.

The hot start option permits adjusting the amperage during arc initialization. After

the arc is established the welding current will decrease to the output current set by

the user. The hot start option is available in MMA mode.

13

Settings

The brightness of the display can be adjusted within the settings option.

The user interface software settings can be reset to the original factory settings.

Please note that all the saved data will be reset to factory setting.

Information regarding the software revision of the user interface and the software

revision of the inverter board is present in the information section.

The language version of the text present in the user interface software.

The units of measure can be chosen by the user. The units can be selected as metric

or English.

AVAILABLE EQUIPMENT OPTIONS

When using spool gun, please select the torch switch at “Spool Gun” in the internal

panel. The spool gun is recommended for aluminum welding.

Scratching TIG option. Please use the TIG torch with scratching arc start.

To use foot pedal under TIG, please connect it to the machine before usage.

7. CAUTION

1. Working Environment

(1) Welding should be carried out in dry environment with its humidity of 90% or less.

(2) The temperature of the working environment should be between -10℃to 40℃.

(3) Avoid welding in the open air unless sheltered from sunlight and rain. Keep it dry anytime

and do not place it on wet ground or in puddles.

(4) Avoid welding in dusty area or environment with corrosive chemical gas.

(5) Gas shielded arc welding should be operated in environment without strong airflow.

14

The following operation requires sufficient professional

knowledge on electric aspect and comprehensive safety

knowledge. Operators should be holders of valid qualification

certificates which can prove their skills and knowledge. Make

sure the input cable of the machine is cut off from the electricity

utility before uncovering the welding machine.

(1) Check periodically whether inner circuit

connection is ok (esp. plugs). Tighten the loose connection. If

there is oxidization, remove it with sandpaper and then

reconnect.

(2) Keep hands, hair and tools away from the moving

parts such as the fan to avoid personal injury or machine

damage.

(3) Clean the dust periodically with dry and clean

compressed air. If welding in environment with heavy smoke

and pollution, the machine should be cleaned daily. The

pressure of compressed air should be at a proper lever lest the

small parts inside the machine be damaged.

2. Safety Tips

Protection circuit is installed in this machine. If the input voltage or the output current is too high or

machine inside temperature over heating inside, the machine will stop automatically. However,

excessive use (e.g. too high voltage) of machine may also damage machine, so please note:

2.1 Ventilation

High current passes when welding is carried out, thus natural ventilation cannot satisfy the

machine's cooling requirement. Maintain good ventilation through the louvers of the machine. The

minimum distance between the machine and any other objects in or near the working area should

be 30cm. Good ventilation is of critical importance for the normal performance and lifespan of the

machine.

2.2 Welding operation is forbidden while the machine is overload. Remember to observe the max

load current at any moment (refer to the corresponding duty cycle). Make sure that the welding

current should not exceed the max load current. Overload could obviously shorten the machine's

lifespan, or even damage the machine.

2.3 Over-voltage is forbidden.

Regarding the power supply voltage range of the machine, please refer to “Main Parameters”

table. This machine is of automatic voltage compensation, which enables the maintaining of the

voltage range within the given range. In case that the input voltage exceeds the stipulated value, it

would possibly damage the components of the machine.

2.4Asudden halt may occur while the machine is of overload status. Under this circumstance, it is

unnecessary to restart the machine. Remain the built-in fan working to lower the temperature

inside the machine.

8. MAINTENANCE

(1) Check periodically whether inner circuit connection is in good condition (esp. plugs).

Tighten the loose connection. If there is oxidization, remove it with sandpaper and then

reconnect.

(2) Keep hands, hair and tools away from the moving parts such as the fan to avoid personal

injury or machine damage.

(3) Clean the dust periodically with dry and clean compressed air. If welding environment

with heavy smoke and pollution, the machine should be cleaned daily. The pressure of

compressed air should be at a proper level in order to avoid the small parts inside the

machine to be damaged.

(4) Avoid rain, water and vapor in filter the machine. If there is, dry it and check the insulation

with equipment (including that between the connections and that between the connection

15

and the enclosure). Only when there are no abnormal phenomena anymore, then the

machine can be used.

(5) Check periodically whether the insulation covers of all cables is in good condition. If there

is any dilapidation, rewrap it or replace it.

(6) Put the machine into the original packing in dry location if it is not to be used for a long

time.

9. DAILY MANITENANCE

•Remove welding spatters from the welding gun's tip and check the condition of the

parts. Change damaged parts to new ones immediately.

•Check that the insulating tips of the welding gun's neck are undamaged and in place.

Change damaged insulation parts to new ones immediately.

•Check the tightness of the welding gun's and earth cable's connections.

•Check the condition of the supply voltage and welding cable and replace faulty

cables.

MAINTENANCE OF THE WIRE FEED MECHANISM

Service the wire feed mechanism at least every time the reel is changed

•Check the wear of the feed roll groove and change the feed roll when necessary.

•Clean the welding gun wire guide with compressed air.

Cleaning the wire guide

Pressure of the feed rolls removes metal dust from the filler wire's surface which then finds its

way to the wire guide. If the wire guide is not clean, it gradually clogs up and causes wire feed

malfunctions. Clean the wire guide in the following manner:

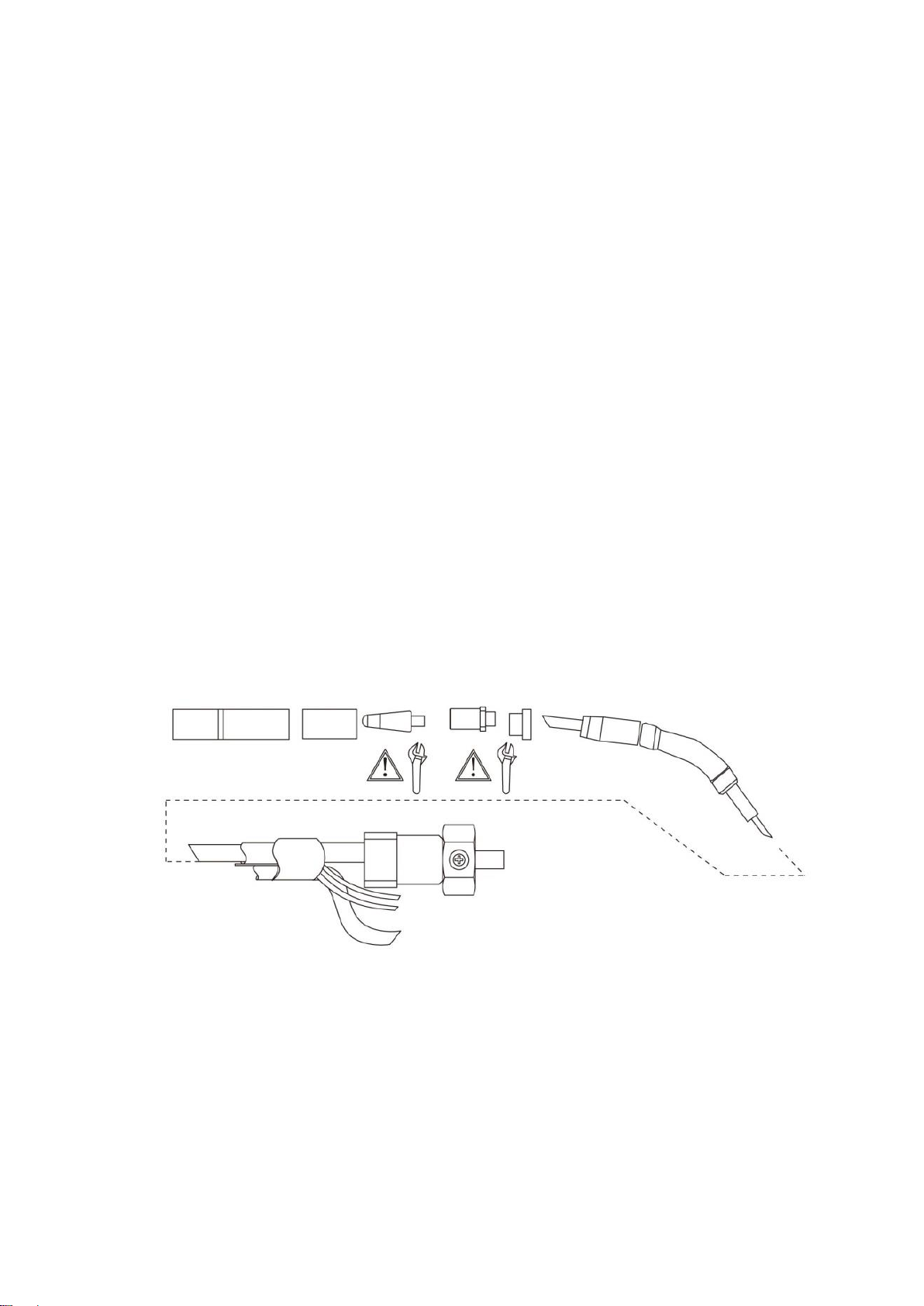

1. Remove the welding gun's gas nozzle, contact tip and contact tip's adapter.

2. With a pneumatic pistol, blow compressed air though the wire guide.

3. Blow the wire feed mechanism and reel housing clean with compressed air.

16

4. Reattach the welding gun's parts, tighten the contact tip and contact tip's adapter to

spanner tightness.

Changing the wire guide

If the wire guide is too worn or totally clogged, change it to a new one according to the

following instructions:

1. Disconnect the welding gun from the machine.

a. Disconnect the cable clamp of the gun's power cable by opening the screws.

b. Disconnect the gun’s power cable from the machine's pole.

c. Disconnect the connector of the trigger conductors from the machine.

d. Open the gun's mounting nut.

e. Extract the gun gently from the machine whereupon all parts come through the front

part's cable hole.

2. Open the mounting nut of the wire guide which exposes the end of the wire guide.

3. Straighten the welding gun's cable and withdraw the wire guide from the gun.

4. Push a new wire guide in to the gun. Make sure that the wire guide enters all the way into

the contact tip's adapter and that there is an O-ring at the machine-end of the guide.

5. Tighten the wire guide in place with the mounting nut.

6. Cut the wire guide 2 mm from the mounting nut and file the sharp edges of the cut round.

7. Reattach the gun in place and tighten the parts to spanner tightness.

17

The following operation requires sufficient professional

knowledge on electric aspect and comprehensive safety

knowledge. Operators should be holders of valid qualification

certificates which can prove their skills and knowledge. Make

sure the input cable of the machine is cut off from the electricity

utility before uncovering the welding machine.

(1) Check periodically whether inner circuit

connection is ok (esp. plugs). Tighten the loose connection. If

there is oxidization, remove it with sandpaper and then

reconnect.

(2) Keep hands, hair and tools away from the moving

parts such as the fan to avoid personal injury or machine

damage.

(3) Clean the dust periodically with dry and clean

compressed air. If welding in environment with heavy smoke

and pollution, the machine should be cleaned daily. The

pressure of compressed air should be at a proper lever lest the

small parts inside the machine be damaged.

(4) Avoid rain, water and vapor infilter the machine. If

there is, dry it and check the insulation with a megger (including

that between the connections and that between the connection

and the case). Only when there is no abnormal phenomena can

welding be continued.

(5) Check periodically whether the insulation skin of all

cables are perfect. If there is any dilapidation, wrap it or replace

it.

(6) Put the machine into the original packing in dry

location if it is not to be used for a long time.

10. TROUBLESHOOTING

PROBLEM

CAUSE

The LCD can’t light up, no wire feeding

during welding, and fan is not working.

•Check if the power switch is on.

•Check if the connected power supply is working.

•Check if the power supply cable is broken.

The LCD is on, fan is working; No wire

feeding during welding.

•Check if the internal wires are well connected.

•Check if any disconnection at the output terminals.

•Check if the control wire or switch on the torch is

broken.

•Check if the control circuit is broken.

•Check if the welding cable is well connected to the

machine.

•Check if the torch type selector is at the right

position for the torch in use.

•If the over-heat light is on, please wait to recover.

The machine output is ok, gas comes

out, but the wire is not feeding

•Check the wire feeding is working or not; if it’s

working, please make sure the wire roller is correct

according to the welding wire.

•Check if the wire tube or nozzle is stuck.

•Make sure the electrode is the right size.

•Check if the torch type selector is at the right

position for the torch in use.

The wire feeding is ok, and welding is

ok, but the gas outlet is abnormal.

•Please check the gas regulator or gas hose.

•Check if the torch is stuck, or any gas leakage.

Welding arc is not stable.

•Please check if the input voltage is correct.

•Please check if the polarity cable connection is

correct.

•Please change the torch head consumables if

they are not in good condition.

•Check if the gas pressure is correct.

18

•Please check if the output cable connection is

loosen.

•Please check if the torch is in good condition.

•Please check if the wire roller size is correct.

•Please check if the electrode size is correct.

Error codes on the LCD.

•The connection between PCB, power control

board and LCD is incorrect. Please restart the

machine.

We are still constantly improving this welder, therefore, some parts of this welder may be

changed in order to achieve the better quality, but the main functions and operations will

not be alternated and changed. Your understanding would be greatly appreciated.

19

11. DIAGRAM

Table of contents

Other IGBT Welding System manuals

Popular Welding System manuals by other brands

Fytech

Fytech FY-92G owner's manual

OEM Tools

OEM Tools 24819 Operating instructions and parts manual

FRONIUS

FRONIUS TSt Series operating instructions

FRONIUS

FRONIUS VR 1500-M operating instructions

Uni-Mig

Uni-Mig VIPER 182 Mk II operating manual

TEAM WELDER

TEAM WELDER MIG drive Synergic puls operating instructions