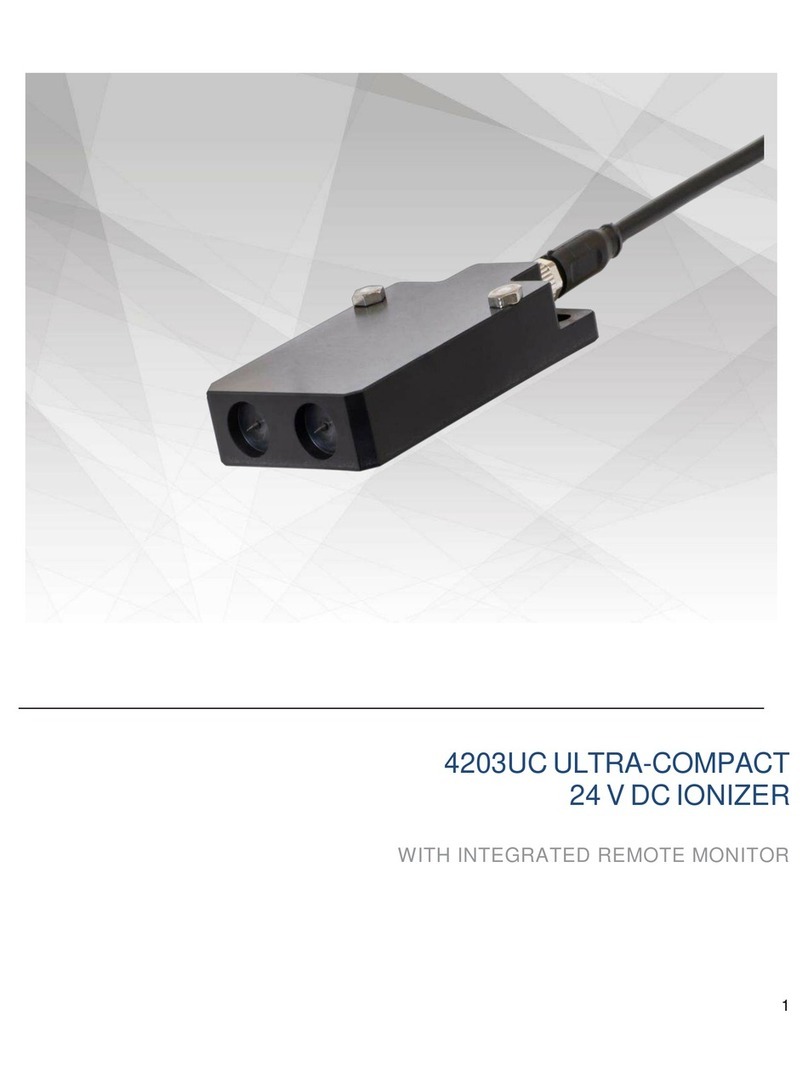

ESDMAN DC0601C User manual

Point of Use Ionizing Blower_DC0601C

Do not disassemble the product without permission.

Do not use in dangerous environment.(such as flammable and explosive)

Do not use in place with plenty of oil or water,high temperature and humidity,

especially in places with condensation.

Thank you very much for purchasing our products, please read the manual in its entirety before

use.

Specification

01 Product Picture

02 Safety

Adopting steady-state DC ionization technology, it is generally used to deal with static

electricity problems during assembly, testing, and packaging. It can also be installed in

equipment to provide rapid static elimination in a limited space to solve static electricity

generated during high-end manufacturing processes.

Steady-state DC ionization technology has the following advantages:

Compact body design, light weight,

Both sides buckles design, can lock the blowing angle,

Stable ion balance,

Longer cleaning and maintenance intervals,

No need for grounding, easy installation,

The emitter tip has high-voltage shielding technology to avoid electric field induction charging,

In the case of low wind speed, it can provide faster static dissipation speed, low wind speed and

low noise, which will not cause much noise to the production environment, making the operator

more comfortable.

03 Product Description

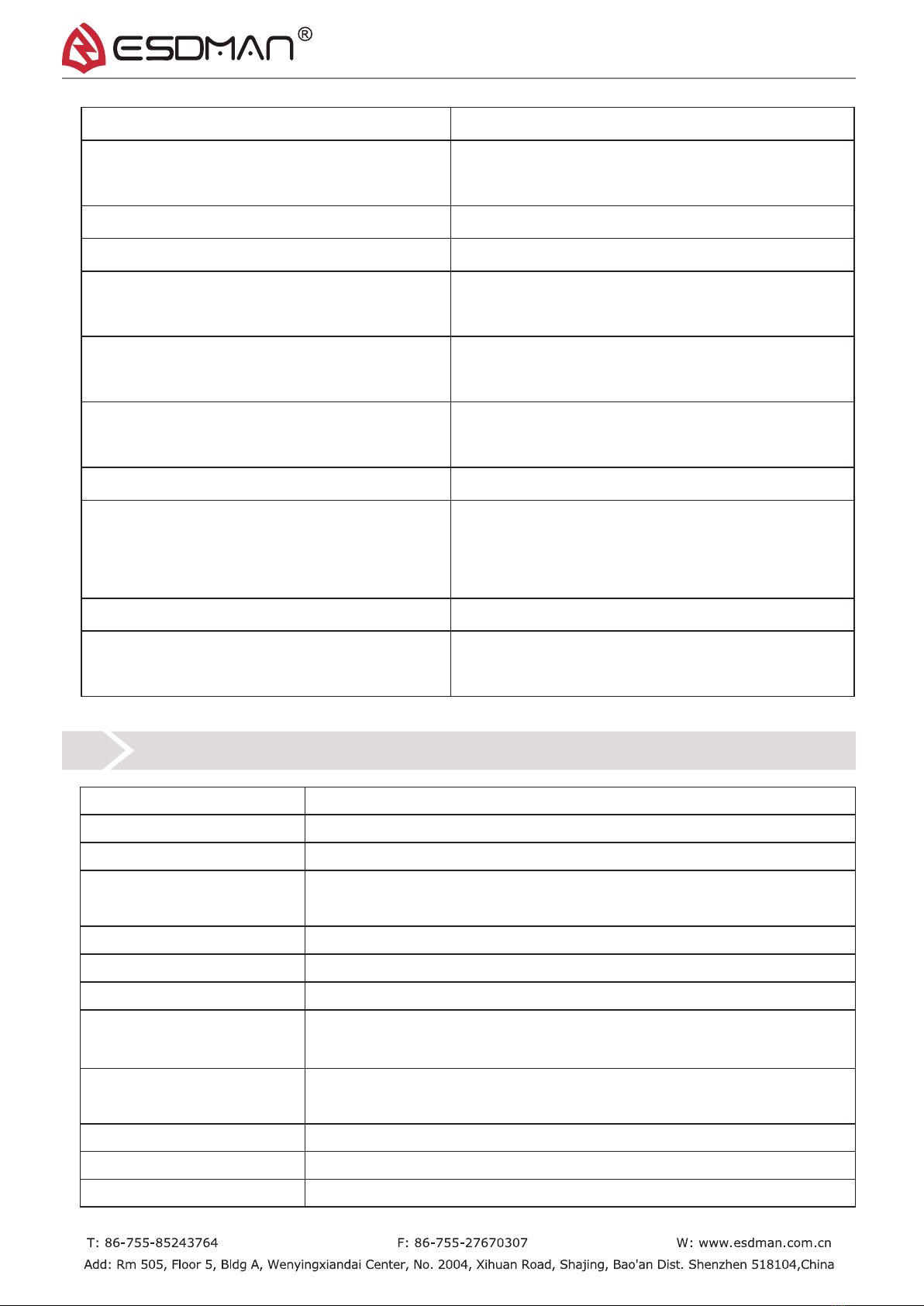

04 Specifications

Model

Input Voltage

Operating Power

Decay Time

Ion Balance

Technology

Emitter Material

Alarm Display

Signal output

Air volume

Ozone

Operating Env.

Dimension

Net weight

Case material

Warranty

Certification

DC0601C

DC24V±5%

Approx. 4.5W

Approx 2.0s ( 30 cm distance, maximum air volume, No dust filter)

±10V

±20V 30CM Distance

Steady-state DC ionization technology

Tungsten

Operation indicator, high voltage normal indicator, high voltage

abnormal indicator, red indicator

When the high voltage is abnormal, the red light will be on, and the

DC24V signal will be output.

0.7m³/min

Below 0.004ppm (distance 150mm)

0-40°C 20-75%RH(non condensing)

117*83*64mm Without bracket 138*115*64mmWith bracket H*W*D

Aprpox 0.4Kg

ABS Shell + aluminum alloy oxide bracket

One year

Compact Ionizer

Eliminate static electricity speed 30CM<3.0sec

±20V ion balance, 30cm distance

Suction type design (fan at the front and

discharge emitter at the back)

Both sides buckles design

The discharge emitter can be cleaned with

alcohol cotton through the rear grille

Tungsten material discharge needle

Alarm and equipment monitoring interface

DC24V Input

Meet cleanliness requirements

Features

Small size provides fast static elimination in

limited space

Fast elimination speed

Automatic balance, no need to adjust

Positive and negative ions are more evenly

distributed

The blowing angle can be locked to prevent the

fuselage from sliding to change the blowing angle

Easy maintenance

longer service life

When the high voltage is abnormal, the red light

will be on and the buzzer will sound and output

DC24V signal

Can be powered by device power

Small space is required, reducing the impact on

laminar wind

Benefits

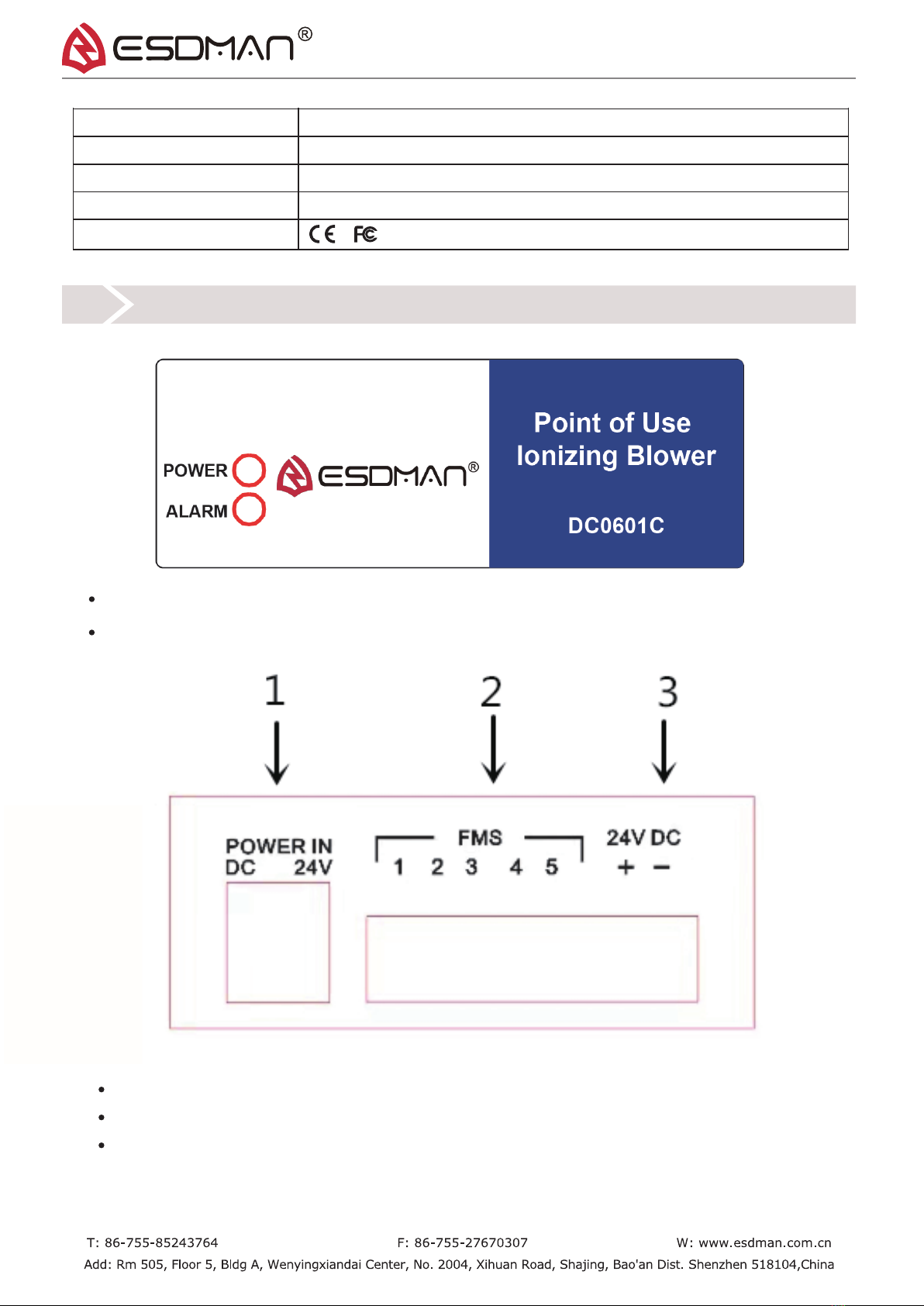

1. DC24V power interface

2. FMS interface

3. The device comes with a DC24V interface

05 Operation Panel Diagram

Model

Input Voltage

Operating Power

Decay Time

Ion Balance

Technology

Emitter Material

Alarm Display

Signal output

Air volume

Ozone

Operating Env.

Dimension

Net weight

Case material

Warranty

Certification

DC0601C

DC24V±5%

Approx. 4.5W

Approx 2.0s ( 30 cm distance, maximum air volume, No dust filter)

±10V

±20V 30CM Distance

Steady-state DC ionization technology

Tungsten

Operation indicator, high voltage normal indicator, high voltage

abnormal indicator, red indicator

When the high voltage is abnormal, the red light will be on, and the

DC24V signal will be output.

0.7m³/min

Below 0.004ppm (distance 150mm)

0-40°C 20-75%RH(non condensing)

117*83*64mm Without bracket 138*115*64mmWith bracket H*W*D

Aprpox 0.4Kg

ABS Shell + aluminum alloy oxide bracket

One year

POWER Operation indicator

ALARM Alarm Indicator

Insert the DC head of the attached power adapter into the power port on the back of the

instrument, connect the power adapter to the AC110-220V socket, the POWER green indicator

light is on, and the instrument is running normally.

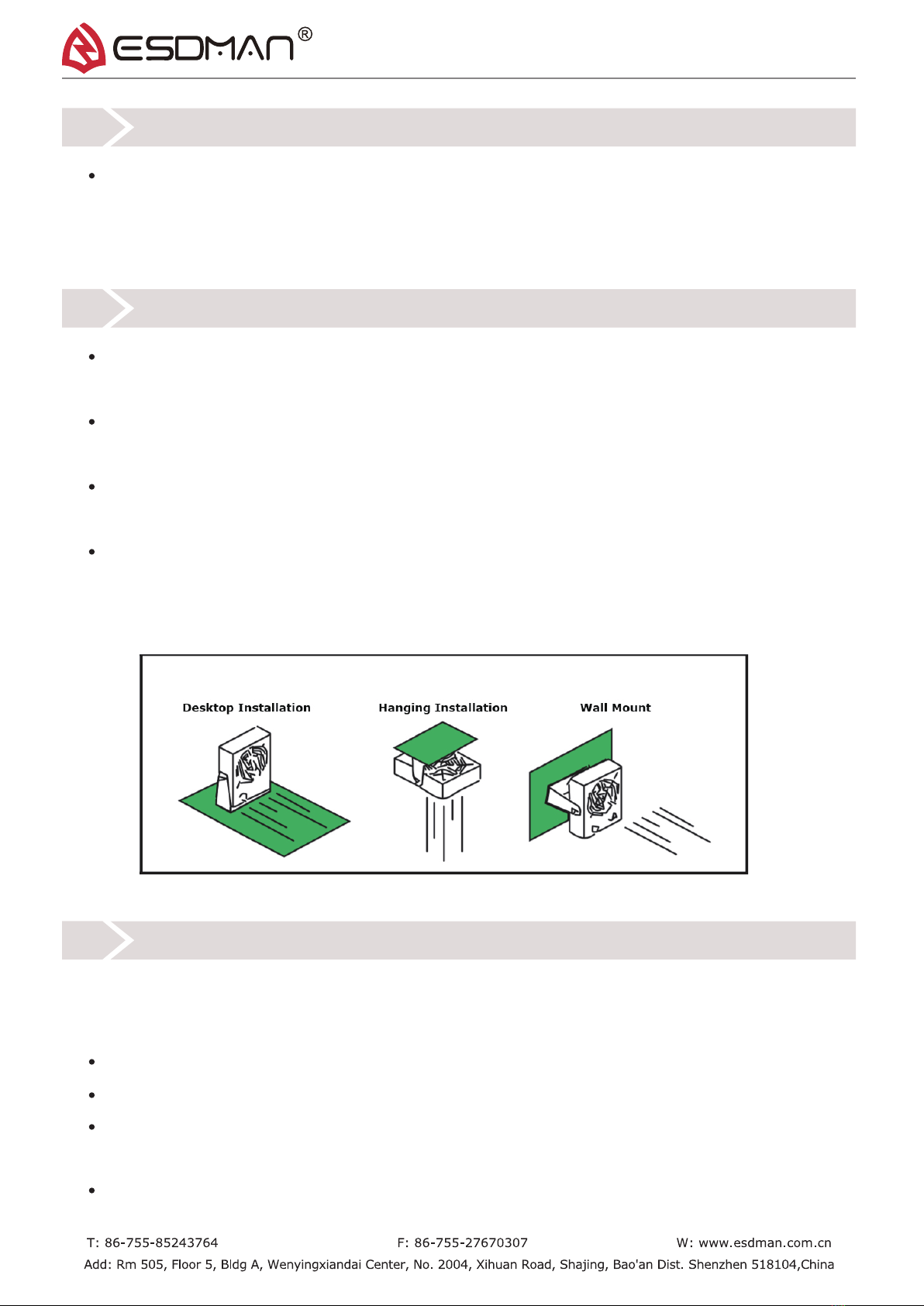

06 Installation

Use M6 screws and nuts to fix the bottom bracket of the fan at an appropriate position that

needs to eliminate static electricity.

When using more than two ionizers, make sure to keep a distance of at least 100mm between

the two.

The distance from the air outlet needs to be at least 100mm away from static objects, and

reverse charging may occur within 100mm.

The ionizer is at least 300mm away from the metal conductor, and the air inlet is at least

150mm away from the wall and other objects.

07 Installation Method

Notice: Ionizer has to be ground properly to make sure ion output automatic balance

Installation Diagram

08 Testing Method

Equipment name: The company uses ME-288B rechargeable flat panel tester (CPM).

The test instrument must be well grounded, and the ionizer under test must be well grounded.

The ion blowing port of the desktop ionizer is centered on the flat tester and tested at different

distances such as 30cm, 60cm, and 90cm.

The test is carried out at maximum air volume and no dust filter.

Test the two performance parameters of bias voltage and dissipation time.

Factory test method:

Field test method:

Test Schematic

During on-site testing, the test panel of the instrument should be placed where the ESD

sensitive components are actually operated.

The specific test method is subject to the instructions of different test instruments.

09 Static Elimination Performance

Operating Voltage: DC24V

Test Voltage ±1000V-±100V

Positive

Negative

Positive

Negative

Distance(mm)

Static elimination

time

Residual voltage

Measurement method: use 20PF, 150mm static elimination monitor to measure.

When the air volume is maximum, the dissipation time from ±1000V---±100V.

Different environment test results are different, the above is the reference data, please test

according to the actual use environment.

±20V

300

2.5S

3.0S

600

7.5S

8.9S

900

15.5S

17.6S

Temperature23±3OC

Humidity50%±5%

After the discharge emitter is used for a long time, there will be dust and other pollutants in and

around the discharge emitter.

Use cotton swabs to remove contaminants.

The discharge emitter should be cleaned regularly (approximately 100 hours of use need to

be cleaned once). When the pollution is serious, the cotton swab can be cleaned with alcohol.

Be careful not to damage the discharge emitter when cleaning.

Cleaning of the discharge emitter

10 Routine Maintenance

When the high pressure is abnormal, the red light of ALARM will prompt the operator to

overhaul the fan.

11 Abnormal Alarm

12 Warranty

ESDMAN's products have undergone strict factory inspection. In case of failure, please contact

the nearest ESDMAN office and provide details of the failure.

The warranty period is one year, starting from the day the product is delivered to the place

designated by the purchaser.

This product is inspected and qualified by our company. During normal use during the warranty

period, such as damage or malfunction due to poor design and manufacturing, free maintenance

will be provided.

Warranty

Warranty Period

The discharge emitter is a consumable part and is not covered by the warranty.

Breakage, breakage or malfunction due to abnormal use.

Failure caused by changes or disassembly and maintenance by non-maintenance personnel of

our company.

Failures caused by natural force majeure factors such as fires, natural disasters, floods, and

earthquakes.

Failure caused by external factors such as abnormal voltage.

The following conditions are not covered by the warranty

13 Standard Components (Packing List)

After unpacking, please confirm the package contents first

DC0601C

Power Adapter

Bracket

Fixed Handle

User's Guide

Factory Report

1 Set

1 Unit

1 Unit

2 Units

1 Unit

1 Unit

Table of contents