2Safety

2Safety

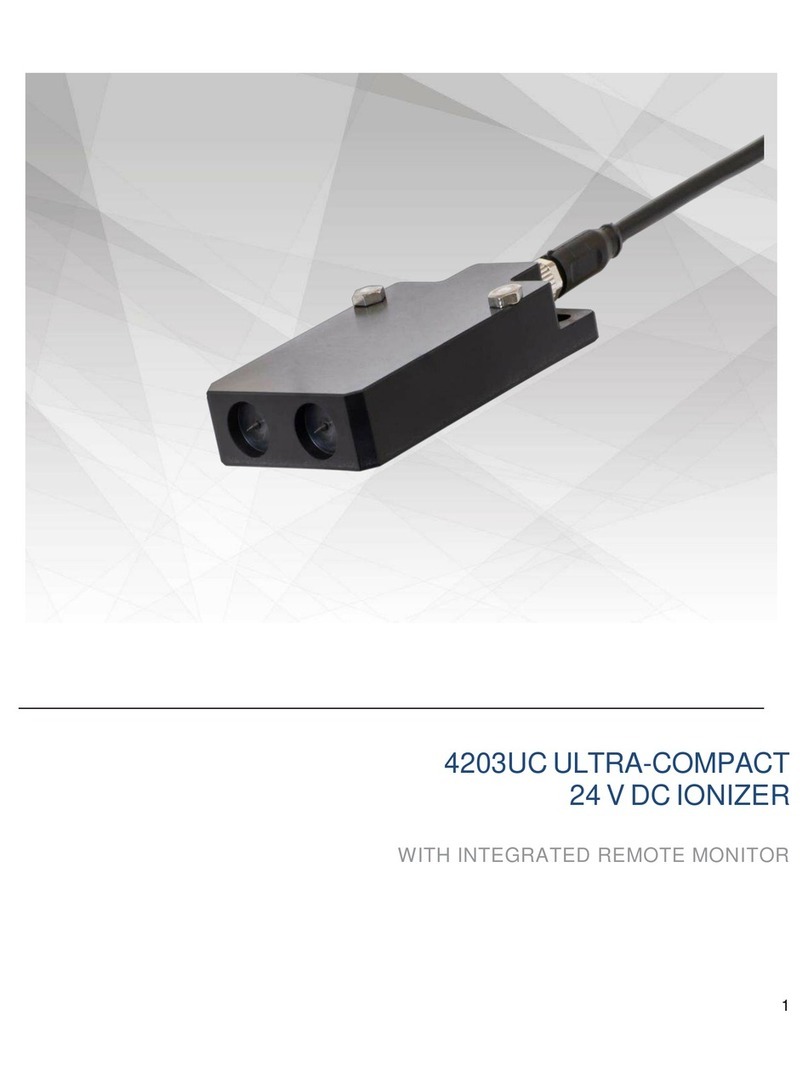

Only persons authorised by the operating firm are permitted to

proceed with tasks on the ionisation unit.

The installer must be an electrician and must be knowledgeable in

the field of mechanical engineering. He must be an expert in

handling and installing compressed air equipment and must wear

personal protective equipment. The installer must read the operating

manual in its entirety.

The operating and maintenance personnel must be instructed in the

handling of compressed air equipment and the resulting dangers.

Personnel must wear personal protective equipment and completely

read the operating manual.

When working on the ionisation unit, switch off the voltage and

compressed air supply and secure the unit to prevent unintentional

restart. Depressurise the compressed air system.

Dangers due to compressed air equipment

Ruptured or broken

compressed air hoses can move erratically and

can injure persons or lead to consequential accidents. Compressed

air can enter the bloodstream through the broken skin, resulting in

an embolism that can lead to death.

Always comply with the safety regulations provided by the

operating company.

Before proceeding with maintenance and/or installation tasks,

ensure the entire system is de-pressurised.

Never direct the jet of compressed air at people or yourself (for

example, to blow dirt off clothes).

Never run a compressed air hose across passageways (tripping

hazard).

Never use compressed air equipment without pressure reducer

and compressed air filter.

Never exceed the permissible operating pressure.

Always use filtered (< 20 μm), dry and oil-free compressed air.

Always use suitable hose clamps to secure compressed air

hoses.

Wearing personal protective equipment for compressed air-

operated products is mandatory (e.g., safety goggles, ear

protection, dust mask, etc.).