Esma E889 User manual

1

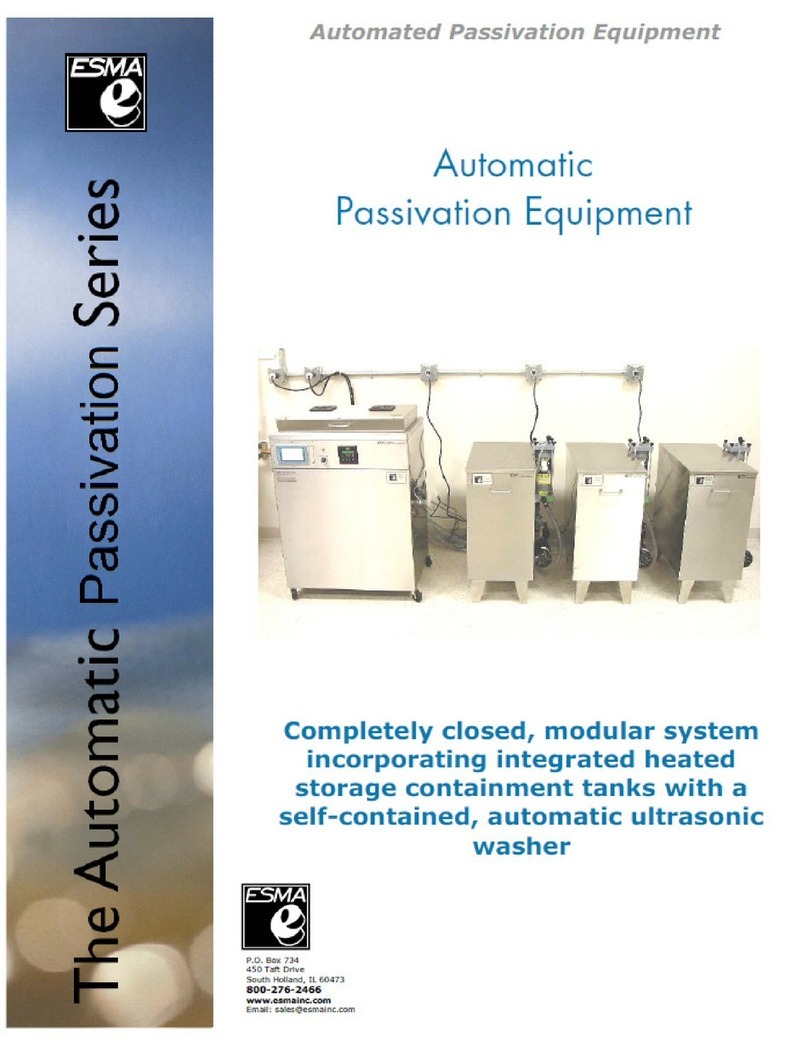

Automated Ultrasonic Wash Equipment

P.O. Box 734

450 Taft Drive

South Holland, IL 0473

800-276-2466

www.esmainc.com

Email: sales@esmainc.com

18 Gallon Automatic

Ultrasonic Equipment

Completely closed, modular system

incorporating integrated heated

storage containment tanks with a

self-contained, automatic ultra-

sonic washer

2

3

Esma Inc.

PO Box 734 450 W. Taft Drive

South Holland, IL 60473

708-331-1855 800-276-2466 FAX 708-331-8919

Instructions for

Models E889 and E992

Ultrasonic Washers

4

Introduction

The E889 unit has one rinse solenoid (primary) for connection to a

hot water source. The model E992 has two input solenoids (primary and

secondary) for rinses from multiple sources.

The units automatically perform a cleaning cycle the major steps

of which are:

1 - Ultrasonic cleaning

2 - Ultrasonic rinsing (hot tap water)

2a - Ultrasonic rinsing (deionized water) - E992 unit only

3 - Hot Air Drying

The result: a finished product ready for the next step (sterilizing

packaging assembly storage).

The unit is housed in a 304 stainless steel (SS) console. The tank

is manufactured from SS 316 with 36 double potting transducers

mounted on the bottom. The tank is fitted with a SS hinged cover which

houses the fans and heaters for hot air-drying.

Inside the console are Power Relays with accessible fuses for the

115VAC and 230VAC lines Power Module boxes 1 and 2 and pumps.

The Power Modules contain self-tuning modular circuit boards a

programmable controller high velocity fans to cool the electronics and

an RFI filters to eliminate any high frequency interference.

On the door of the console is mounted a Omron Programming

Console which allows access to the Programmed Sequencer data and

enables the monitoring of the “on-line” operation and the modifying of

the times of the operation. The programmer is a hand held device and

need not be mounted on door.

PLEASE READ THESE INSTRUCTIONS THOROUGHLY BEFORE

INSTALLATION AND OPERATION. CALL (800) 276-2466 IF YOU HAVE

ANY QUESTIONS.

Installation

5

When unit is removed from crate the supplied casters must be

installed on bottom of unit. Place casters with locking brakes on front

corners of unit.

The unit has been thoroughly bench-tested and is shipped to the

Customer ready to operate. Move the unit into position and lock Caster

wheels. Once the position of the unit has been established the electrical

and plumbing requirements must be completed by the user.

The power modules inside the unit have been bolted to the bottom

of chassis for shipping. They can remain bolted. However if they have

to be removed for any reason the filter screen door on the back of the

unit has to be opened. Once the filter is removed the screws and bolts

(2’’ in each bracket) in hold-down brackets can be removed. These need

not be replaced for normal use and movement of unit. Leave hold-down

bracket fixed to power modules.

1. Plumbing Hook-Up

A. Water Input

The primary solenoid should be connected to a hot water source.

The hot water input solenoid (primary) has a ¾’’ NH male fitting

(supplied) to be connected to the high-

pressure hose and filter screen (supplied).

Inside the unit there is a 5.0 GPM flow

regulator. A valve for emergency shut off

should be installed at the water source. This

valve should not restrict the flow more than

5.0 GPM.

Also depending on local regulations a

back flow regulator should be attached to

your water source. The valve and back flow

regulator are not supplied. On E992 units

deionized water is normally connected to the

Secondary solenoid (not pictured) located below the Primary solenoid.

The ¾’’ NH male fitting high-pressure hose and filter are also supplied

for this hookup.

CAUTION: MAKE SURE EXCESS TEFLON TAPE OR PIPE JOINT

COMPOUND DOES NOT GET INTO SOLENOID.

B. Water Output

6

Two pumps have been installed in the unit. One pump is used for

the normal draining of tank and the second pump is used with the

overflow drain during the cascading rinse. On the outside of the console

you will find a ¾” NPT bulkhead coupling which extends through the

back of the cabinet. This fitting comes from the internal pumps and

must be adapted to your drain plumbing using ¾” ID or larger tubing.

2. Electrical

The unit is wired for both 120VAC and

230VAC lines. The ratings are 1850 watts

120VAC 50/60 HZ and 3000 watts 230VAC

60 HZ single phase. The power cords are

supplied for plugging in to your electricity

source. The 230 volt line is supplied with an

NEMA 6-20P plug. The 230V supply must

utilize a third wire as a ground and not a

current carrier. The 120V power cord must

be connected to a three-way grounded outlet.

DO NOT OPERATE UNIT WITHOUT PROPER

GROUNDING. The 230V line is fused at 15 AMP and the 120 volt line at

20 AMP. These fuses are located inside unit on Power Relay enclosure.

3. Control Function

A) Main Switch: When unit is ready for operation turn the main

switch to ON and the indicator light will be ON.

B) Run Stop Switch: Located below the main switch it must be in

the RUN position for the programmable controller to operate. If

during the program cycle you want to stop the process turn

switch to STOP position and program will start over at the

beginning of the cycle when START button is pushed. Use Run

Stop switch only for emergency stopping of unit or to STOP the

program and begin at the beginning. Use the Main switch if you

wish to stop the unit and have the program remain where it is.

4. Selector Switch

7

FILL - Push START button and tank will fill with warm water.

Once the tank is filled instruments or parts can be added to soak.

During prolonged periods of soaking DO NOT CLOSE COVER OF TANK.

CLEAN - When tank is filled with instruments or parts close cover

on tank move switch to CLEAN push START button and the cleaning

cycle will begin. The cleaning cycle can not be started if the fill cycle is

not completed. This is a safety precaution so the ultrasonics will not

operate without water in the tank.

FILL-CLEAN - In this position the cleaning cycle automatically

follows the fill cycle for a full cycle operation. Instruments parts and

any cleaning materials are to be added to an empty tank. Close tank

cover and push START for full cycle operation.

5. Start Switch

With main switch ON and RUN STOP SWITCH set at RUN push

start button and the process will begin.

6. Programming Console

The Programming Console (C200H-PR027-E) manufactured by

Omron is mounted on the front door of cabinet. The programmer is on

whenever the main power is on. The programmer when set properly will

indicate the times of the various processes during the cycle.

Leave the programmer in the run mode and clear the viewing

screen by pressing the monitor clear and monitor buttons in

succession. Now press the clear time 1 and monitor keys and the

timing of each programming step can be monitored.

If a certain function within the program needs to be changed a key

(provided) is inserted into programmer and switched to the program

made and changes can be made in cleaning cycle. ESMA should be

notified and a step by step procedure will be given to simplify any

necessary changes.

8

7. Preliminary Start-Up

After plumbing is completed conduct the following test to

determine if there are any leaks in the system.

CAUTION: On the E992 unit deionized or regular water must be

connected to the secondary solenoid or damage will result to the unit if

no water enters the tank during the second rinse cycle.

A) Turn main power ON

B) RUN-STOP switch must be ON

C) Close cover

D) Turn selector switch to FILL

Push START button and hot water should enter the tank. The unit

has a flow control valve which allows 5.0 GPM so it is important that

the shutoff valve does not restrict the flow to less than 5.0 GPM or the fill

time will have to be increased.

After 150 seconds (or other programmed fill time) the fill solenoid

will close and the water will be up to the overflow drain opening. At this

time shut main power off disconnect electrical plugs from outlets open

cabinet and check for leaks.

Leave selector switch in FILL position push START and hot water

will enter the already full tank and begin to cascade through the overflow

drain. After 150 seconds the FILL solenoid will close.

If no leaks are detected connect power turn main switch ON

move selector switch to CLEAN push START and the cleaning cycle will

begin.

After the ultrasonic cleaning step the tank will drain (with pump).

When the tank is empty (after 150 seconds) shut main off disconnect

power and check for leaks in drain-pump line.

If no leaks are detected connect power turn main ON and

program will complete to finish. Check at each fill stage that water is

coming into tank.

8. Operation

The basic principle of operation is the enhancement and

acceleration of the cleaning action through ultrasonic cavitations.

Instruments or parts to be cleaned are placed in the basket (or cassette

racks) and lowered into the tank.

NEVER PLACE PARTS DIRECTLY ON THE BOTTOM OF THE TANK.

The baskets and cassette racks that can be purchased from ESMA Inc.

have rubber supports to keep parts off bottom of tank.

9

9. Procedure

-Turn main power ON.

-Turn RUN-STOP switch to RUN. (RUN-STOP Switch Should

remain in RUN position at all times).

-Set selector switch to either FILL or FILL-CLEAN positions.

-Add cleaning agent to empty tank (see section on cleaning agents).

-Lower basket with instruments or parts on support rack.

-Close cover.

-Push START button and the selected cleaning program will

automatically proceed.

(Details on selected program are given in Figure 1 depending on setting

of selector switch)

10. Water Consumption

In the progress for E889 12.5 gallons are used on the initial fill

cycle with an additional 22.5 gallons used in the subsequent fill or

rinse—for a total of 35 gallons of hot water used per cycle.

In the program for E992 an additional 22 gallons of deionized

water is used in the secondary rinse.

11. Drying

In the drying portion of the programs the incoming air is heated in

the tank cover to 160-180 degrees F. and forced by the fan through the

tank cover. CAUTION: Do not touch the cover during the drying cycle

because some areas of the cover will be hot.

NEVER place any towel or obstruction over the fan intake on cover.

After 7 minutes of hot air drying a buzzer sounds the end of the

program. The air temperature during the Hot Air Drying can be

increased or decreased by adjusting two thermoswitches located in cover

at hot air exit.

10

12. Cleaning Agent

It is recommended to use a liquid cleaning agent because some

powders take too long to go into solution. ESMA Inc. has liquid cleaners

E589 E882 E484 etc. where it is recommended to use 2 to 4 cups per

tank load. Some general-purpose detergents may be all that is required

to clean your items. Depending on types of parts and debris to be

removed some experimentation will be required with type of cleaners

and concentrations. Remember: Adding too much cleaning agent can

cause a problem with final rinsing of parts.

13. Power Modules 1 and 2

The Power Modules contain the six circuit boards programmable

controller fans relays RFI filters etc. There are six lights one per

circuit board (two on PM1 and four on PM2) to indicate if circuit boards

are operating. To check if all circuit boards are operating open door

slightly when unit is ultrasonically cleaning: all indicator lights must be

ON. If a light is out the corresponding circuit board will have to be

repaired.

14. Programmable Controller

An Omron CPM 1 programmable controller is used to control the

process. The unit has a flash memory backup without a battery.

The controller has indicator lights for inputs and outputs which

are lit during process. The outputs are as follows:

Output Controls

00 Primary solenoid

01 Ultrasonics

02 Drain solenoid

03 Dryer

04 Overflow Pump

05 Buzzer

06 Drain Pump

07 Secondary Solenoid

The Programming Console on cabinet door can be used to monitor

these outputs or change their values. To change their values ESMA

should be notified.

11

15. Maintenance

Periodically the drain screen in tank will have to be removed and

cleaned. Accumulated lint and debris could slow down the draining

resulting in the incomplete removal of cleaning solution before the rinse

cycle starts.

The tank and modules are manufactured of 316 and 304 stainless

steel. Clean with a commercially available cleaner for stainless kitchen

appliances.

Cleaning of Solenoids

A periodic cleaning of all solenoid valves is desirable. The time

between cleanings will vary depending on media and service conditions.

In general if the voltage to the coil is correct sluggish valve operation

excessive leakage or noise indicates that cleaning is required. A bulletin

with maintenance instructions is enclosed.

FOR ASSISTANCE CALL: 800-276-2466

WARRANTY: Unit has one-year guarantee circuit boards two years and

transducer bonds and tank weld seams a lifetime guarantee.

12

Figure 1 - Program times for E889 unit

Select switch: FILL Select switch: CLEAN

Time: 150 seconds

STEP FUNCTION TIME (SECONDS)

1 Ultrasonic cleaning 600

2 Drain 150

3 Fill (hot water) 150

4 Ultrasonic rinsing 60

5 Ultrasonic rinsing (cascade) 60

6 Ultrasonic rinsing 60

7 Ultrasonic rinsing (cascade) 60

8 Ultrasonic rinsing 60

9 Drain 150

10 Dryer Fan Drain 420

11 Buzzer 5

TOTAL: 1775 (29 minutes 35 seconds)

Select switch: FILL-CLEAN

STEP FUNCTION TIME (SECONDS)

1 Fill (hot water) 150

2 Ultrasonic cleaning 600

3 Drain 150

4 Fill (hot water) 150

5 Ultrasonic rinsing 60

6 Ultrasonic rinsing (cascade) 60

7 Ultrasonic rinsing 60

8 Ultrasonic rinsing (cascade) 60

9 Ultrasonic rinsing 60

10 Drain 150

11 Dryer Fan Drain 420

13 Buzzer 5

TOTAL: 1925 (32 minutes 5 seconds)

13

Figure 2 - Program times for E992 unit

Select switch: FILL Select switch: CLEAN

Time: 150 seconds

STEP FUNCTION TIME (SECONDS)

1 Ultrasonic cleaning 600

2 Drain 150

3 Fill (hot water) 150

4 Ultrasonic rinsing 60

5 Ultrasonic rinsing (cascade) 60

6 Ultrasonic rinsing 60

7 Ultrasonic rinsing (cascade) 60

8 Ultrasonic rinsing 60

9 Drain 150

10 Fill (secondary) 150

11 Ultrasonic Rinsing 120

12 Drain 150

13 Dryer Fan Drain 420

14 Buzzer 5

TOTAL: 2195 (36 minutes 35 seconds)

Select switch: FILL-CLEAN

STEP FUNCTION TIME (SECONDS)

1 Fill (hot water) 150

2 Ultrasonic cleaning 600

3 Drain 150

4 Fill (hot water) 150

5 Ultrasonic rinsing 60

6 Ultrasonic rinsing (cascade) 60

7 Ultrasonic rinsing 60

8 Ultrasonic rinsing (cascade) 60

9 Ultrasonic rinsing 60

10 Drain 150

11 Fill (secondary) 150

12 Ultrasonic rinsing 120

13 Drain 150

14 Dryer Fan Drain 420

15 Buzzer 5

TOTAL: 2345 (39 minutes 5 seconds)

This manual suits for next models

1

Table of contents

Other Esma Washer manuals