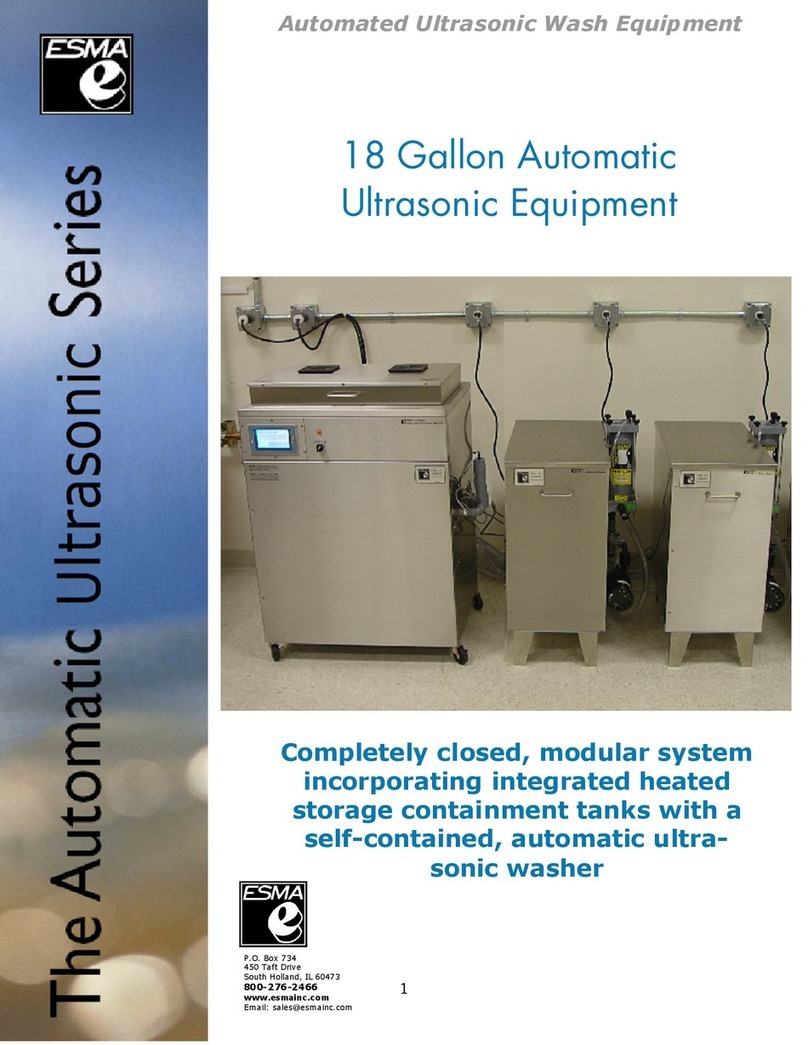

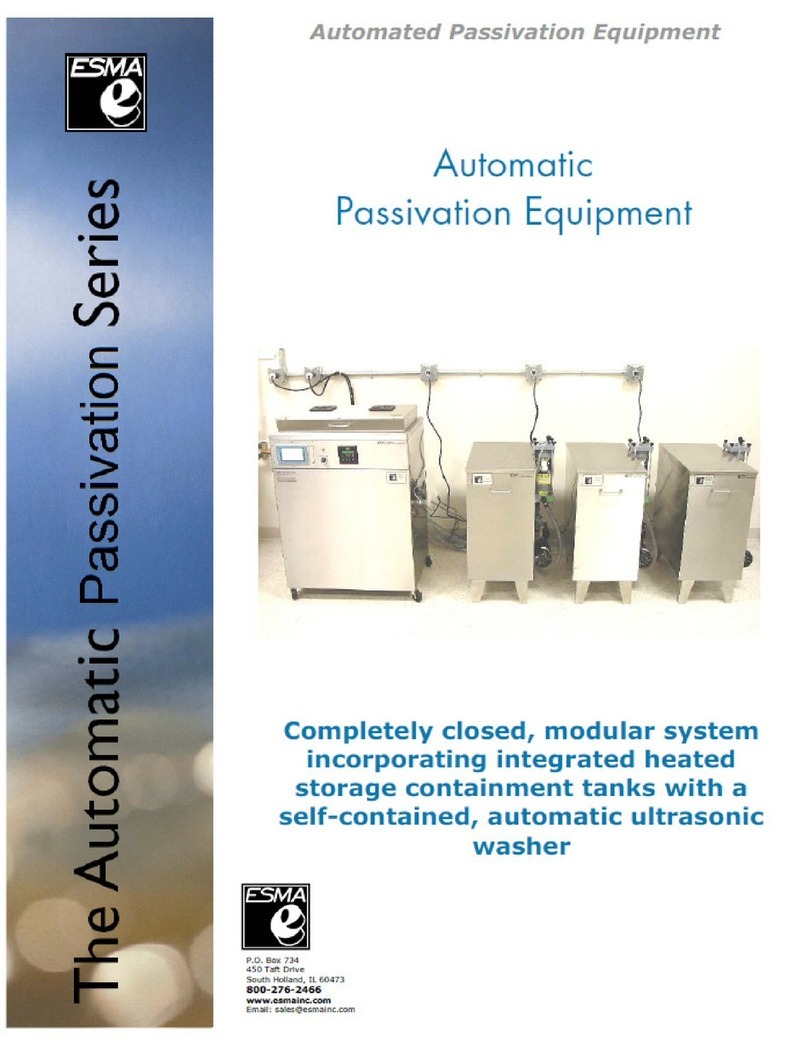

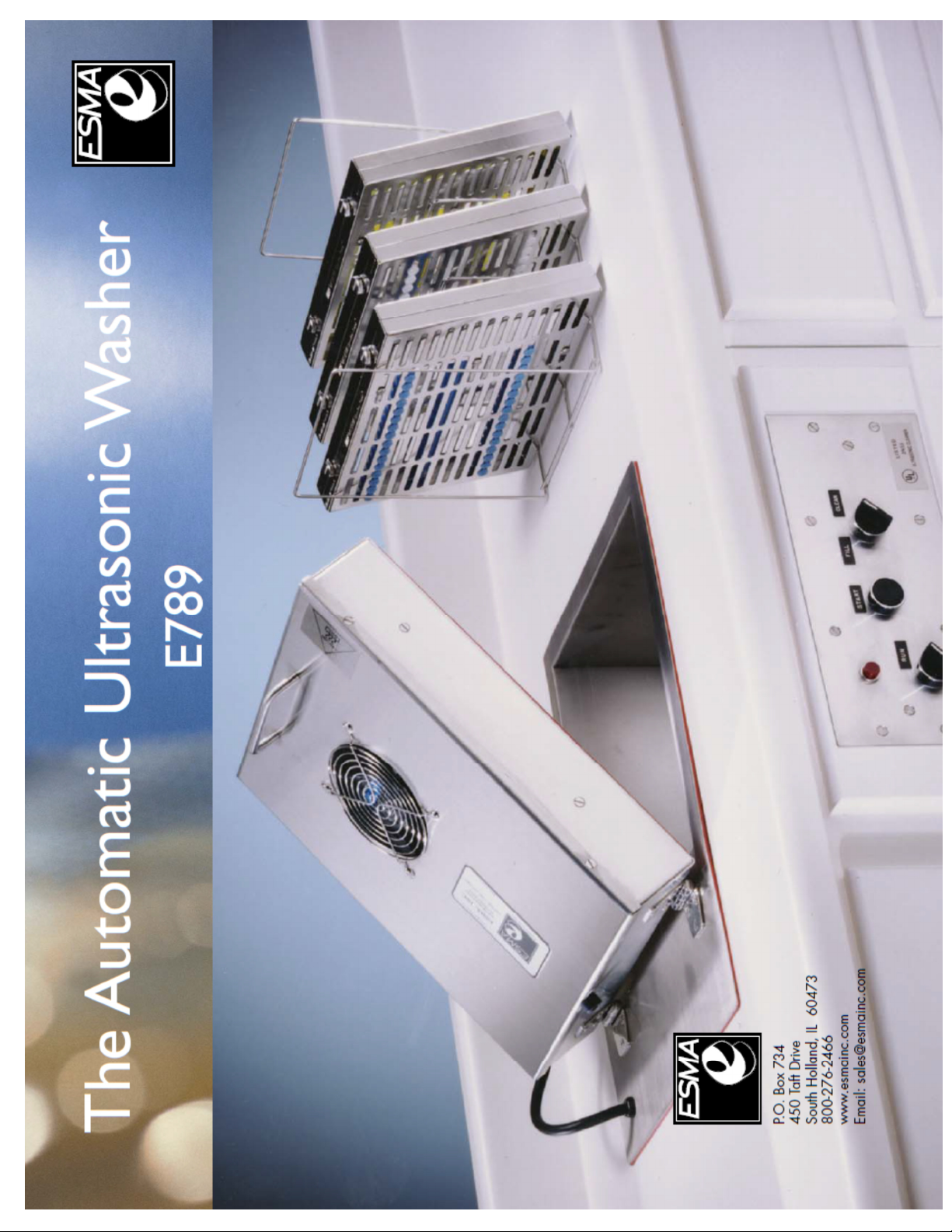

Esma E789 User manual

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

1

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

2

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

3

Instructions for Ultrasonic Washer

E789 (U.L. Approved)

1. IN RODUC ION

The E789 Automatic Ultrasonic Washer automatically performs a cleaning

cycle, the major steps of which are:

•Ultrasonic cleaning

•Ultrasonic rinsing (hot tap water)

•Hot air drying

The E789 unit has a primary rinse solenoid, which is connected to the hot tap

water supply. The E789 is equipped with a chemical metering pump for

precision distribution of the exact amount of liquid detergent concentrate. Use

only Esma brand detergent concentrates when operating the E789 with

metering pump. The result is a finished product ready for the next step

(sterilizing, packaging, assembly, storage). The unit consists of four sections:

1) ank Module-to be installed in the counter 2) Control Module-to be

installed in front of counter 3) Power Module to be installed under the counter

and 4) Metering Pump which is to be located under counter.

he ank Module is manufactured from 316 stainless steel with 12 potting

transducers mounted on the bottom. The tank is equipped with two fill

solenoids (E789 has only one), a drain solenoid and a low level control to

prevent electronic damage if water pressure is lost. The tank is fitted with a

304 stainless hinged cover housing the fan and heater for air-drying.

he Control Module is manufactured from 304 stainless and contains the

switches to start the ILL, CLEAN or ULL CYCLE cycles and stop the process

manually, if needed.

he Power Module contains the self-tuning modular circuit boards,

programmable controller, high velocity fan to cool the electronics and R I filter

to eliminate high frequency noise.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

4

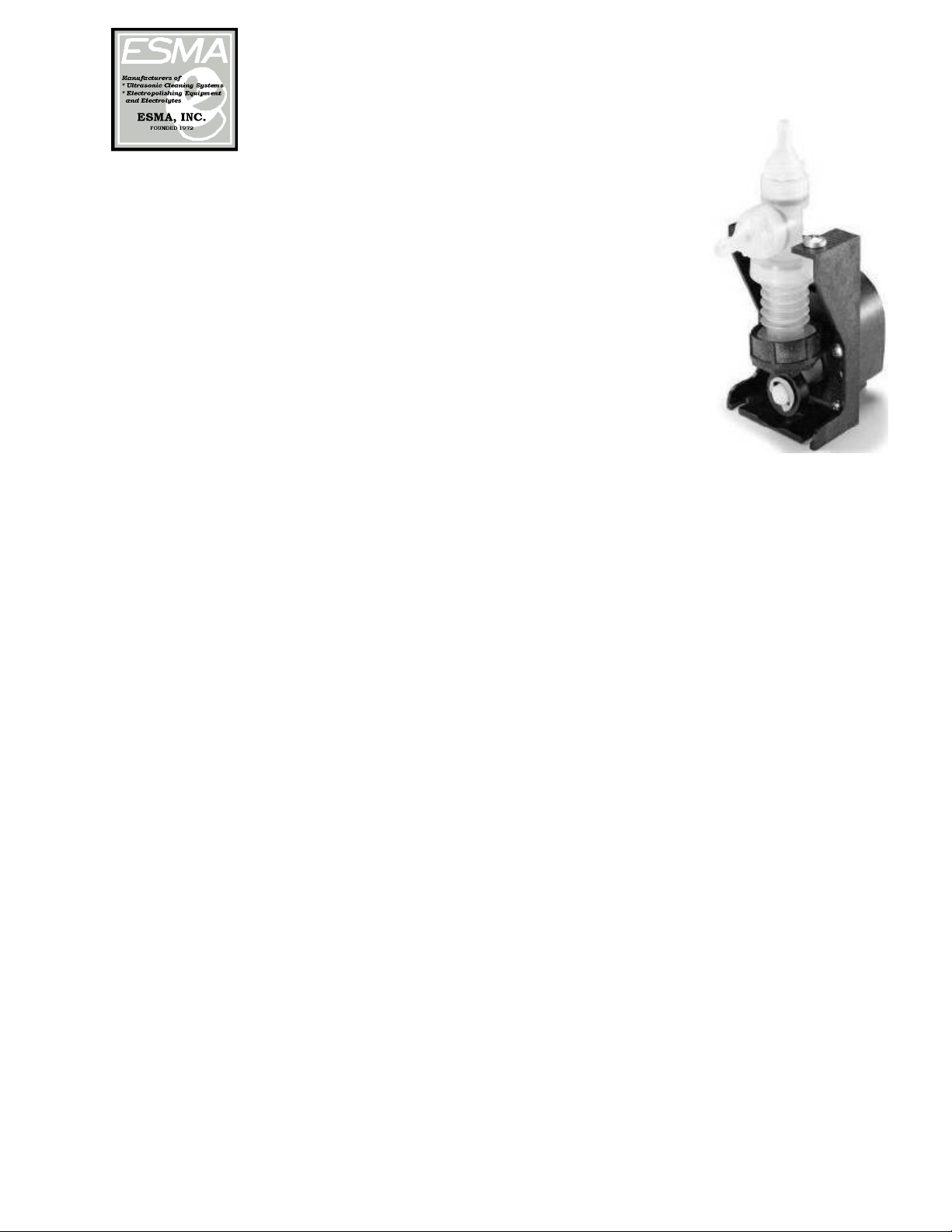

he Metering Pump is a Gorman-Rupp bellows metering pump.

The supplied inlet tube from the metering pump should be

inserted into a gallon jug of Esma cleaning solution concentrate.

The pump is configured to “meter” a 1% concentrate during the

fill cycle, approximately 180ml. Please use only proper detergent

which is formulated for use with the E789 model.

PLEASE READ THESE INSTRUCTIONS THOROUGHLY BE ORE

INSTALLATION AND OPERATION. CALL 800-276-2466 I YOU

HAVE ANY QUESTIONS

2. INS ALLA ION

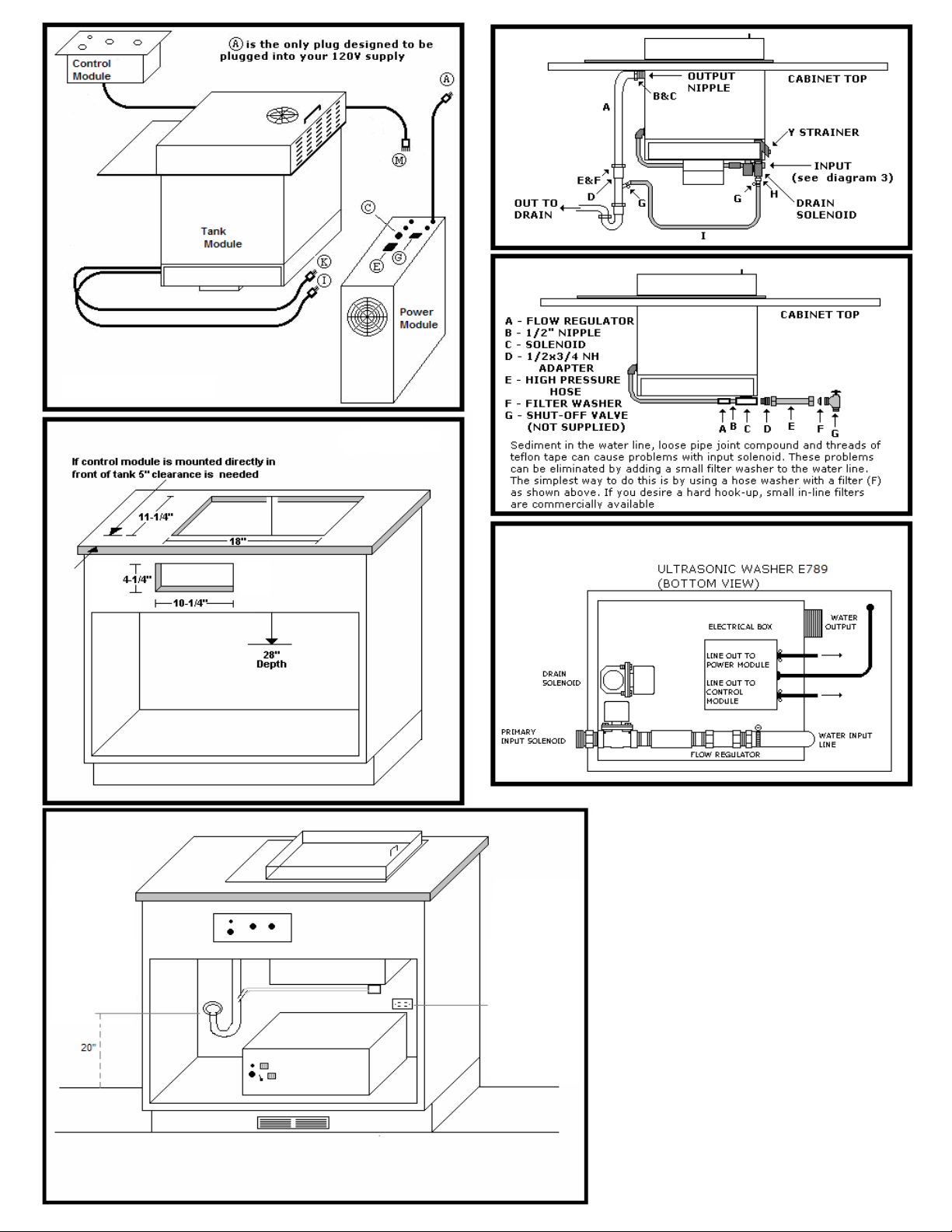

If the control module is to be placed directly in front of tank, allow 5 inches

between counter opening and front of cabinet (diagram 1). Also, 28 inches of

clearance is necessary under the counter for drains.

Control Module - Cut opening of 4 ¼” x 10 ¼” in front of cabinet. The overall

flange of unit on front of cabinet is 5” x 12”, so center unit accordingly. Module

will be mounted later with 4, No. 8 wood screws.

ank Module - Cut opening of 18” x 11 ¼” in top of counter. The overall flange

of unit on top of counter is 20” x 13”, so center unit accordingly. Place tank in

opening and mark on counter the mounting studs welded under top plate.

Remove tank and drill mounting holes with1/4” drill bit. Do not mount tank

until control module opening is cut out.

ank Module should be set in counter first. A gasket is glued to the underside

of the top plate to prevent liquid from seeping into the counter. Place the tank-

mounting studs into the pre-drilled holes in counter and tighten down with 8 x

32 nuts and washers, which are supplied. (DO NOT OVERTIGHTEN).

Power Module measures 8’ x 16” x 18”D. However, 1” of clearance is necessary

both at the front and back of unit for proper ventilation. The electrical

connections, from tank and control modules, attached to the top of the module,

require additional 2 to 3 inches of space.

he Metering Pump should be monitored to assure that there is solution in

the jug. Due to the length of tubing, it will take one cycle for the metering

pump to become “primed”. Once the pump is primed, a 1% solution

concentrate will automatically be added to the water during the fill cycle.

Please regularly check to make sure that there is adequate cleaning solution in

the jug.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

5

3. PLUMBING HOOK-UP

A. Water Input (Diagrams 2 & 3, see last page)

The primary solenoid should be connected to a hot water source.

This solenoid has a ½” NPT female opening. A ½”MNPT x 3/4”MGH

adapter has been supplied for hot water hookup using a standard

washing machine water supply hose (not supplied). It is recommended

that a filter washer be installed into the water supply hose to prevent

sediment debris from entering solenoid from water source. The high-

pressure hose should connect the solenoid to a shut-off valve (not

supplied) at you water source. A flow regulator is incorporated into the

unit; therefore, the shut-off valve must not restrict the flow more than

3.5 GPM.

Also, a backflow regulator (not supplied) may have to be attached at your

water source to comply with local regulations.

B. Water Output (Diagram 2, see last page)

1½” x 16” elbow (A), which is supplied, is to be attached with a slip nut

(B) and washer (C) to the 1½” output nipple. (This piece can be hooked

up prior to installation of the tank but that is not necessary. The

tailpiece (D) with ¾” input (supplied) is to be attached to elbow (A) with a

slip nut (E) and adapting washer ( ). Attached to the tailpiece, with

a hose clamp (G), will be 2’ of ¾” hose (I). The other end of this hose is to

be attached to be attached to hose adapter (H), with the hose clamp (G),

after (H) is threaded into the drain solenoid using Teflon tape or joint

compound. A “P” trap (not supplied) is then to be attached to tailpiece

(D) prior to hookup to drain line.

4. ELEC RICAL

The unit is rated at 1500 W, 120 VAC, 50/60 HZ. Only the power module is

plugged into your 120VAC supply (diagram).

The Tank Module has two plugs. Both plugs are attached to power module at

receptacles C & E.

Control Module plug (M) plugs into power module receptacle (G).

Only the plug from power module (A) is to be connected to your power source.

Unit must be electrically grounded. The power cord must be connected to a

three-way grounded outlet. or 2-wire service, an adapter with external ground

wire is necessary. Connect the green grounding wire of the adapter to the

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

6

screw, which holds the electric outlet plate cover to the socket. DO NOT

OPERATE UNIT WITHOUT PROPER GROUNDING. A fuse, 15AMP, 120VAC, is

located on the power module.

5. CON ROL FUNC ION

A. Main Switch: When unit is ready for operation, put the main

switch to ON and the indicator light on the power and the Control

Module will be ON.

B. Run-Stop Switch: Located on Control Module, must be in the RUN

position for the programmable controller to operate. If during the

program cycle you want to stop the process, turn switch to STOP position

and the program cycle will discontinue. Move switch back to RUN

position and program will START over at the beginning of the fill cycle

when start button is pushed.

Use run-stop switch only for emergency stopping of unit.

C. Fill/Clean/Full Cycle Switch:

Fill: When the ill cycle is selected and the START button is

pushed the tank will fill and hold with heated detergent. Use this cycle if

you do not have a full load of instruments and you would like to soak

them until ready to complete the cycle.

Clean: Select Clean cycle only after the fill step above has been

run. Pressing START when there is a full load of instruments will

complete the clean/rinse/dry cycle. You cannot start the clean cycle if

the fill cycle (above) is not completed first.

Full Cycle: When ull Cycle is selected and the START button is

pushed the unit will fill with heated detergent and continue

automatically with the clean/rinse/dry steps.

This is a safety precaution so the ultrasonics will not operate without any

liquid in the tank.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

7

6. PRELIMINARY S AR -UP

After plumbing is completed, conduct the following test to determine if there

are any leaks in the system.

A. Turn main power ON

B. RUN-STOP switch to ON

C. ILL/CLEAN switch to ILL

D. Close cover

Push START button and gradually open the inlet valve you installed in the

rinse line to bleed the air out of the line; them immediately open valve

completely. The unit has a flow control valve which allows 3.5GPM, so it is

important that the inlet valve doesn’t restrict the flow to less than 3.5GPM or

the fill time will have to be increased. After 90 seconds, the fill solenoid will

close, and the water will be up to the overflow drain opening. Possibly, the first

time the inlet valve was not manually opened fast enough to allow 3.5GPM for

the entire 90 seconds. To test the overflow-rinse line, leave ILL/CLEAN switch

on ILL and push the start button and water will flow into tank for additional

90 seconds. Now you can check your plumbing for leaks.

CAU ION: When conducting this leak test, make sure the power module is not

under the plumbing in order to avoid getting the electronics wet.

To test the drain plumbing, move ILL/CLEAN switch to CLEAN and push

START button to start the ultrasonic cleaning cycles (make sure fan inlet and

outlet of power module are not obstructed). The clean cycle will cavitate for 10

minutes before the tank will drain. The entire clean cycle and times are given

in the procedure section. You can stop the clean cycle at any time by turning

the RUN-STOP switch to STOP and the program will revert back to the

beginning of the ILL CYCLE.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

8

7. OPERA ION

The basic principle of operation is the enhancement and

acceleration of the cleaning action through ultrasonic

cavitations. Instruments, or parts to be cleaned, are

placed in the basket (or cassette racks) and lowered into

the tank.

NEVER PLACE PARTS DIRECTLY ON THE BOTTOM O THE TANK.

The baskets and cassette racks have rubber supports to keep parts off bottom

of tank.

8. PROCEDURE

1. Turn main power ON

2. Turn RUN-STOP switch to RUN. (Should remain in RUN position at all

times.

3. Set ILL/CLEAN switch to ILL.

4. Verify that the metering pump inlet supply is inserted into a gallon jug

of an approved Esma cleaning concentrate (see section on cleaning

agents).

5. Lower basket with instruments, or parts, on support rack.

6. Close cover.

7. Push START button and water will enter the tank for 90 seconds.

8. At this point more instruments (or parts) could be added when

available, or move ILL/CLEAN switch to CLEAN, push START button

and the cleaning program will automatically proceed through the cycle

as follows:

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

9

E789 UNI

Function ime/Seconds

1. ill with hot water and Detergent concentrate 60

2. ill with hot water only 30

3. Ultrasonic cleaning 600

4. Drain 180

5. ill 90

6. Ultrasonic 60

7. Ultrasonic/Rinse 60

8. Ultrasonic 60

9. Ultrasonic/Rinse 60

10. Ultrasonic 60

11. Drain 150

12. Drain, Dryer, an 420

13. Drain, an 120

14. Buzzer 5

TOTAL 1835 seconds

(30 ½ minutes)

9. WA ER CONSUMP ION

In the program, 5 gallons of water are used on the initial fill cycle with an

additional 12 gallons used in the fill-rinse steps, C to H, for a total of 17 gallons

of hot water used per cycle.

If any changes in the rinse programs are required, consult the manufacturer.

10. DRYING

Incoming air is heated in the tank cover to 160° and forced by the fan

through the tank chamber before exhausting through the tank cover.

CAUTION: Do not touch the cover during the drying cycle because some areas

will be hot. Also, NEVER place any towel or obstruction over the fan intake on

cover. After 7 minutes of hot air drying, the parts are left in the tank for 2

minutes to allow some cooling to take place before handling. The air

temperature during the hot air drying can be increased or decreased by

adjusting a thermo-switch located in dryer cover at hot air exit. Please contact

manufacturer for more details.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

10

11. PRESOAKING OF INS RUMEN S

or maximum effective cleaning, it is best if blood and other substances do not

dry on the instruments. Therefore, fill the tank with hot water and cleaning

agent and use the tank as a holding vessel for instruments until enough have

accumulated to warrant cleaning.

12. CLEANING AGEN

Use only Esma brand detergent concentrates when operating the E789

with metering pump. Esma produces 3 powerful liquid cleaning agents:

•Esma-Shine E105

•Esma-General Purpose E589

•Esma-Zyme E1240.

DO NOT use powdered detergents; some powders take too long to go into

solution. The metering pump is engineered to pump only the correct amount of

detergent concentrate into the tank during the fill cycle. Esma brand

detergents are formulated to meet the pump ratios. The metering pump has

been factory calibrated to meter in 180ml of detergent concentrate during the

fill cycle. By not using the correct cleaning agent problem can arise with final

rinsing of parts if too much suds are generated.

13. LOW LEVEL SENSOR

A low-level safety device is installed on the tank module to assure that the

ultrasonics will not come on if there is less than three inches of water in the

tank. A stainless probe is fixed in a Teflon plug mounted on the tank wall.

When the liquid in the tank covers the probe the ultrasonics will activate

during the clean or rinse cycles. Periodically, the probe should be wiped off to

prevent insulating residues from cleaning agents, etc. from accumulating.

14. PROGRAMMABLE CON ROLLER

An Omron CPM-20CDR programmable controller (PLC) is used to control the

ILL and CLEANING process. A peripheral device (C200h-PRO27-E) is available

to change the program or modify the times of the process. The memory

protection maintains the program during power interruptions and a flash

memory backup will save the program for 20 days at an ambient temperature

of 77°. PLC status indicators, located on top of the PLC, show the operating

status according to the following table:

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

11

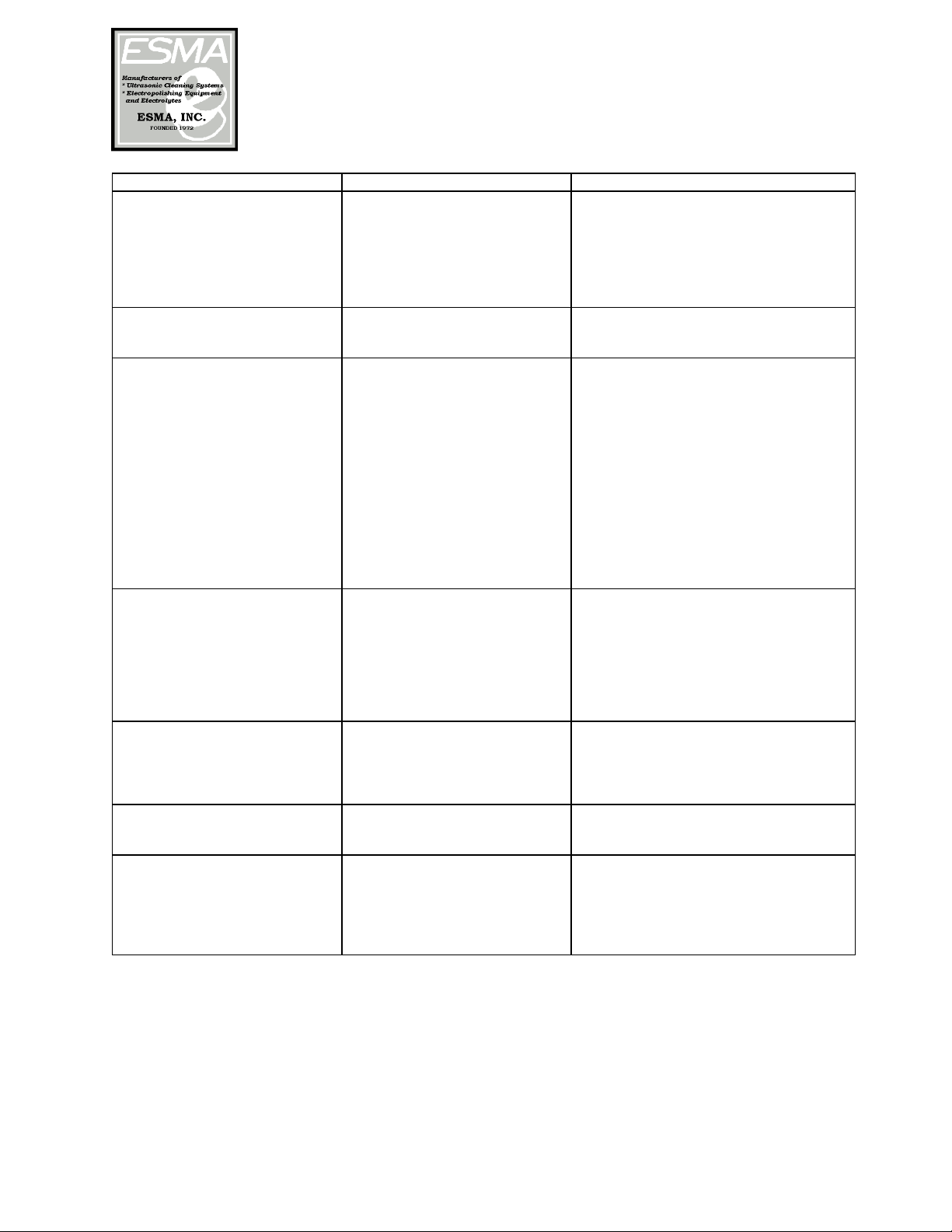

Indicator Status Meaning

POWER (green) ON Power is being supplied to the PLC.

OFF Power isn’t being supplied to the PLC.

RUN (green) ON The PLC is operating in RUN or MONITOR mode.

OFF The PLC is in PROGRAM mode or a fatal error has occurred.

ERROR/ALARM (red) ON A fatal error has occurred. (PLC operation stops.)

FLASHING A non-fatal error has occurred. (PLC operation continues.)

COMM (orange)

ON Data is being transferred via the Peripheral Port.

OFF Data isn’t being transferred via the Peripheral Port.

15. MAIN ENANCE

Periodically, the drain screen in tank will have to be removed and cleaned. The

accumulated lint and debris could slow down the draining enough so tank will

not be emptied of cleaning solution when rinse cycle begins.

Once a month, open power module and vacuum any dust that might have been

drawn in by the fan. Never operate unit with cover of power module off.

The tank is manufactured of 316SS and the modules of 304SS. Clean with a

commercially available cleaner for stainless steel kitchen appliances.

OR ASSISTANCE CALL 800-276-2466 or 708-331-1855

16. ROUBLE SHOO ING

•If there seems to be erratic behavior with a component, or if the fill

and/or clean cycle seem to have changed, always go through the

following procedure:

oTurn RUN-STOP switch momentarily to STOP and then back to

RUN. The program will now clear and revert to the beginning

calling for a ILL CYCLE. Move ILL-CLEAN switch to ILL and

push START regardless of if the tank has water in it.

oIf the problem persists, continue with trouble shooting or call

manufacturer.

•If there is still a problem, look at the PLC located in the Power module.

With MAIN switch ON and RUN-STOP in RUN position. Make sure that

the POWER and RUN lights are ON.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

12

PROBLEM CAUSE REMEDY

Rinse solenoid is noisy,

pulsating and little or no water

coming into tank when output

00 is ON

Particles or other

accumulation has entered

bleed line of solenoid

Low water pressure

Solenoid needs to be cleaned out (see

instruction sheet for fill solenoid)

Make sure filter screen is in place

prior to valve

5-10 PSI water pressure is required to

operate solenoid

No ultrasonics when output 01

is ON. Large cooling fan in

power module is ON.

use blown on circuit boards. Need repair—check that cooling fan is

operating during cleaning.

No ultrasonics when large

cooling fan is O when

output 01 is on

Low water level in tank has

activated low level safety

control

Rise solenoid problem, or

insufficient water supply.

In line fuse to PLC is blown.

Relay for fan and circuit

boards not working.

Low-level safety control is

faulty.

As above (fill solenoid problem)

Replace 1.5Amp/120V fuse

Replace relay

Clean deposit off probe

Contact manufacturer

Dryer gets too hot an inlet on top off cover is

blocked

Thermostat inside cover needs

adjustment

Dryer an not working with

output 06 on

Remove obstacle

Contact manufacturer

Replace in-line fuse to PLC

Dryer is cool with output 03

ON

Thermostat needs adjustment

if there is some heat.

Relay in control module is

faulty

Contact manufacturer

Replace relay

Tank drains with output 02

O

Debris lodged in drain

solenoid

Clean out solenoid (see instructions)

and make sure drain screen in place

in tank

Tank does not drain with

output 0N

Drain screen clogged.

Y strainer clogged

Solenoid not operating

Clean and replace screen.

Clean out Y strainer

In-line fuse to PLC is blown or clean

out solenoid valve

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

13

INSTALLATION INSTRUCTIONS & CABINET REQUIREMENTS OR

ULTRASONIC WASHER MODEL E789

1. INTRODUCTION

The units automatically perform a cleaning cycle, the major steps of which are:

• Ultrasonic cleaning

• Ultrasonic rinsing (hot tap water)

• Ultrasonic rinsing (deionized water)-unit E291 only • Hot air drying

The E789 unit has only one rinse solenoid (primary), which is connected to the hot tap water supply.

The result is a finished product ready for the next step (sterilizing, packaging, assembly, storage).

The unit consists of three sections: 1) ank Module-to be installed in the counter 2) Control Module-to

be installed in front of counter and 3) Power Module- to be installed under the counter.

he ank Module is manufactured from 316 stainless steel, with 12 potting transducers mounted on the

bottom. The tank is equipped with two fill solenoids (E789 has only one), a drain solenoid and a low level

control to prevent electronic damage if water pressure is lost. The tank is fitted with a 304 stainless

hinged cover housing the fan and heater for air-drying.

he Control Module is manufactured from 304 stainless and

contains the switches to start the ILL or CLEAN cycles and stop the process manually, if needed.

he Power Module contains the self-tuning modular circuit boards, programmable controller, high

velocity fan to cool the electronics and R I filter to eliminate high frequency noise. PLEASE READ THESE

INSTRUCTIONS THOROUGHLY BE ORE INSTALLATION AND OPERATION. CALL (800) 276-2466 I YOU

HAVE ANY QUESTIONS.

2. INSTALLATION

If the control module is to be placed directly in front of tank, allow 5 inches between counter opening and

front of cabinet (diagram 2). Also, 28 inches of clearance is necessary under the counter for drains.

Control Module-Cut opening of 4-1/4" x 10 1/4" in front of cabinet. The overall flange of unit on front of

cabinet is 5" x 12", so center unit accordingly. Module will be mounted later with 4 No. 8 wood screws.

ank Module-Cut opening of 18" x 11-1/4" in top of counter.

The overall flange of unit on top of counter is 20" x 13", so center unit accordingly. Place tank in opening

and mark on counter the mounting studs welded underneath top plate. Remove tank and drill mounting

holes with 1/4" drill bit. Do not mount tank until control module opening is cut out.

ank Module should be set in counter first. A gasket is glued to the underside of the top plate to prevent

liquid from seeping into the counter. Place the tank-mounting studs into the pre-drilled holes in counter

and tighten down with 8 x 32 nuts and washers, which are supplied. (DO NOT OVERTIGHTEN).

Power Module measures 8" x 16' x 18" D. However, I" clearance is necessary both at the front and back

of unit for proper ventilation. The electrical connections from tank and control modules, attached to the

top of the module, require additional 2 to 3 inches of space.

3. PLUMBING HOOK-UP

A. Water Input (Diagrams 3, 4 & 5, see last page)

The primary solenoid should be connected to a hot water source. This solenoid has a 1/2" NPT female

opening. An adapter and a high-pressure hose, with a filtered washer are supplied. The high-pressure

hose should connect the solenoid to a shut-off valve (not supplied) at your water source. A flow regulator

is incorporated into the unit, therefore, the shut-off valve must riot restrict the flow more than 3.5 GPM.

Also, a backflow regulator (not supplied) may have to be attached at your water source to comply with

local regulations. On Model E291 only, a deionized water source is connected to the secondary solenoid

following the instructions given for the primary solenoid (Diagram 5).

B. Water Output (Diagram 3

,

see last page)

1 1/2" x 16" elbow (A), which is supplied, is to be attached with a slip nut (B) and washer (C) to the 1 1/2"

output nipple. (This piece can be hooked up prior to installation of the tank but that is not necessary).

The tailpiece (D) with 3/4" input (supplied) is to be attached to elbow (A) with a slip nut (E) and an

adapting washer

( ). Attached to the tailpiece, with a hose clamp (G), will be 2' of 3/4 hose (1). The other end of this hose is

to be attached to hose adapter (H), with the hose clamp (G), after (H) is threaded into the drain solenoid

using Teflon tape or joint compound.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

14

A "P' trap (not supplied) is then to be attached to tailpiece (D) prior to hookup to drain line.

4. ELECTRICAL

The unit is rated at 1500 W, 120 VAC, 50/60 HZ. Only the power module is plugged into your 120 VAC supply

(diagram 4).

he ank Module has two plugs. Plug (K) goes to the under side of Control Module and attaches to receptacle (L).

Plug (1) is attached to power module at receptacle (E).

Control Module has two plugs, (M) and (N), which attach to receptacles (C) and (G) on the power module.

Only the plug from power module (A) is to be connected to your power source. Unit must be electrically grounded.

The power cord must be connected to a three-way grounded outlet. or 2- wire service, an adapter with external

ground wire is necessary. Connect the green grounding wire of the adapter to the screw, which holds the electric outlet

plate cover to the socket. DO NOT OPERATE UNIT WITHOUT PROPER GROUNDING. A fuse, 15 AMP 120 VAC, is

located on the power module.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

15

Standard

120 VAC

outlet can

be

located

anywhere

within 6 feet

of unit. Only

the plug from

the power

module will

plug into

outlet

Optimal

drain height

is 12” from

floor.

Maximum

height to be

no more

than 20”

from floor.

Diagram 1

Diagram 3

Diagram 4

Diagram 5

Diagram 2

Diagram 6

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

16

ACCESSORIES

Included with your E789 Unit are the following accessories for installation.

1. ½” tubing to be inserted on the METERING PUMP barbed fitting and

secured with supplied hose clamps. This tube is to be inserted into a gallon

jug of detergent.

2. Brass fittings for INPUT valve and DRAIN SOLENOID

3. PVC Waste Arm. Connects to OUTPUT NIPPLE in

4. Branch Tailpiece. Connects to waste arm (3) and tubing connects to DRAIN

SOLENOID brass fitting

5. Overflow drain screen

6. Control Module mounting screws

7. Tank mounting screws

Table of contents

Other Esma Washer manuals