Esma E992 User manual

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

1

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

2

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

3

Esma Inc.

PO Box 734 450 W. Taft Drive

South Holland, IL 60473

708-331-1855 800-276-2466 FAX 708-331-8919

Instructions for

Model E992 Passivation

Ultrasonic Washer

Introduction

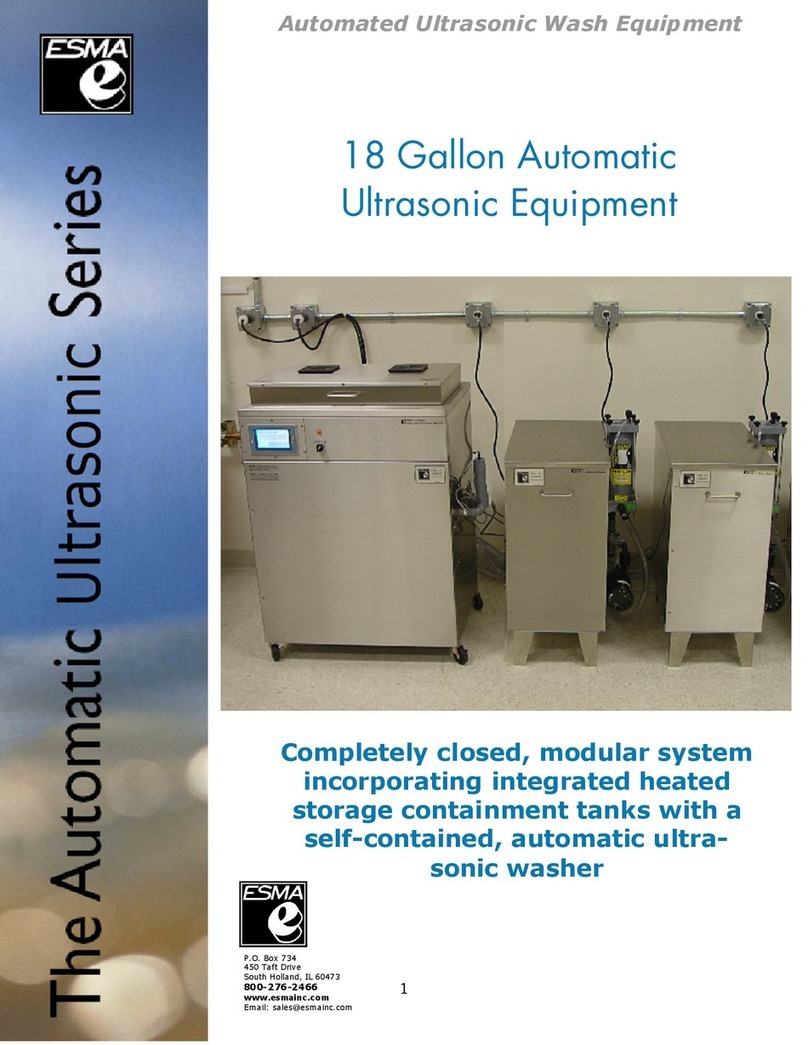

The Model E992 ultrasonic washer is equipped with three, 30 gallon heated storage

tanks (HST) for alkaline cleaning solution, citric acid or nitric acid solution and

rinse water. Pump filter systems are also incorporated into the HST’s. The

complete system also uses fresh DI water for a final rinse cycle.

The unit is housed in a 304 stainless steel console. The tank is manufactured from

SS 316 with 36 double potting transducers mounted on the bottom. The tank is

fitted with a SS hinged cover, which houses the fans and heaters for air drying.

Inside the console there are 2 Power Module boxes (generators) and the drain

pumps. The Power Modules contain the self-tuning modular circuit boards, high

velocity fans to cool the electronics, and RFI filters to eliminate any high

frequency interference. A control box is mounted on the rear of the console unit

and contains the programmable controller and other related components.

A Beijer HMI panel mount interface is included with the unit allowing monitoring

of the on-line operation and modifying of the program, as well as data collection of

the passivation process.

PLEASE READ THESE INSTRUCTIONS THOROUGHLY BEFORE

INSTALLATION AND OPERATION. CALL (800) 276-2466 IF YOU HAVE

ANY QUESTIONS.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

4

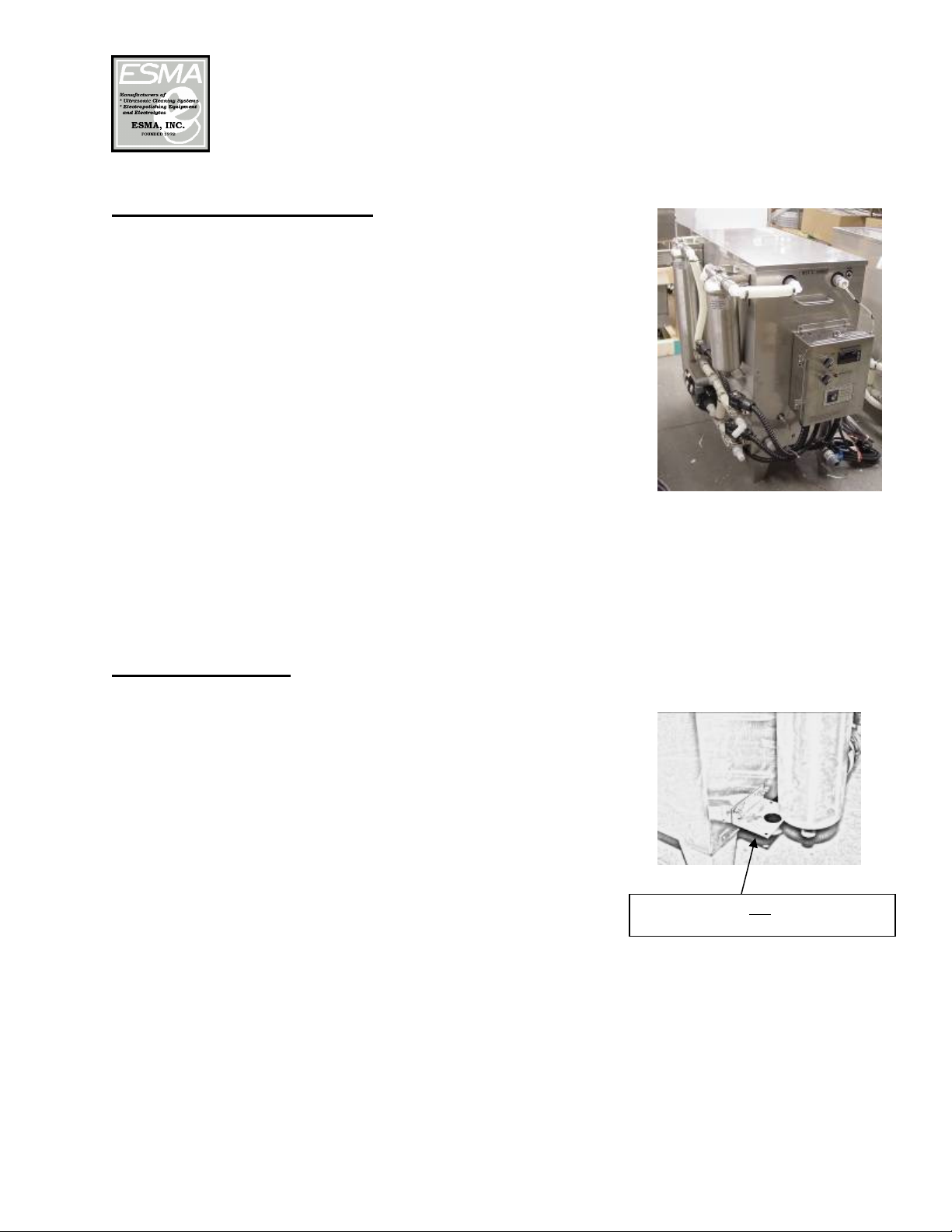

Installation

When unit is removed from skid, the supplied casters must be installed on the

bottom of unit. Place casters with locking brakes on front corners of unit.

The unit has been thoroughly bench-tested and is shipped to the customer ready to

operate. Move the unit into position and lock Caster wheels. Once the position of

the unit has been established, the electrical and plumbing requirements must be

completed by the user.

The power modules inside the unit have been bolted to the bottom of chassis for

shipping. They can remain bolted. However, if either has to be removed for any

reason, the filter screen door on the back of the unit has to be opened. Once the

filter is removed, the screws and bolts (2’’ in each bracket) in hold-down brackets

can be removed. These need not be replaced for normal use and movement of unit.

Leave hold-down bracket fixed to power modules.

Electrical

The E992 unit is wired for 230 VAC. The rating is 9500 watts, single phase

Each Heated Storage Tank (HST) is rated for 1,650 watts(included above),

120VAC, 50/60HZ and is supplied with a cord with a NEMA 5-15 plug. A 15

amp, 125 volt fuse is located underneath the control box. The power cords are

intended to be plugged into the master electrical panel located on the left side of

the E992 unit. The system is designed to be wired at this panel. An electrical

diagram is located inside the panel door and also as an attachment to this manual.

DO NOT OPERATE UNIT WITHOUT PROPER GROUNDING.

Each heated storage tank (HST) has a separate communication cord with an

amphenol connector to be connected to the sockets at the rear of the washer as

follows:

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

5

Top Left – HST 4 (FUTURE Acid Tank)

Top Right – HST 1 (Clean Storage Tank)

Bottom Right – HST 2 (Rinse Storage Tank)

Bottom Left – HST 3 (Acid Storage Tank)

IMPORTANT TO MATCH THE PLUGS AND

RECEPLACLES OF THE TANKS.

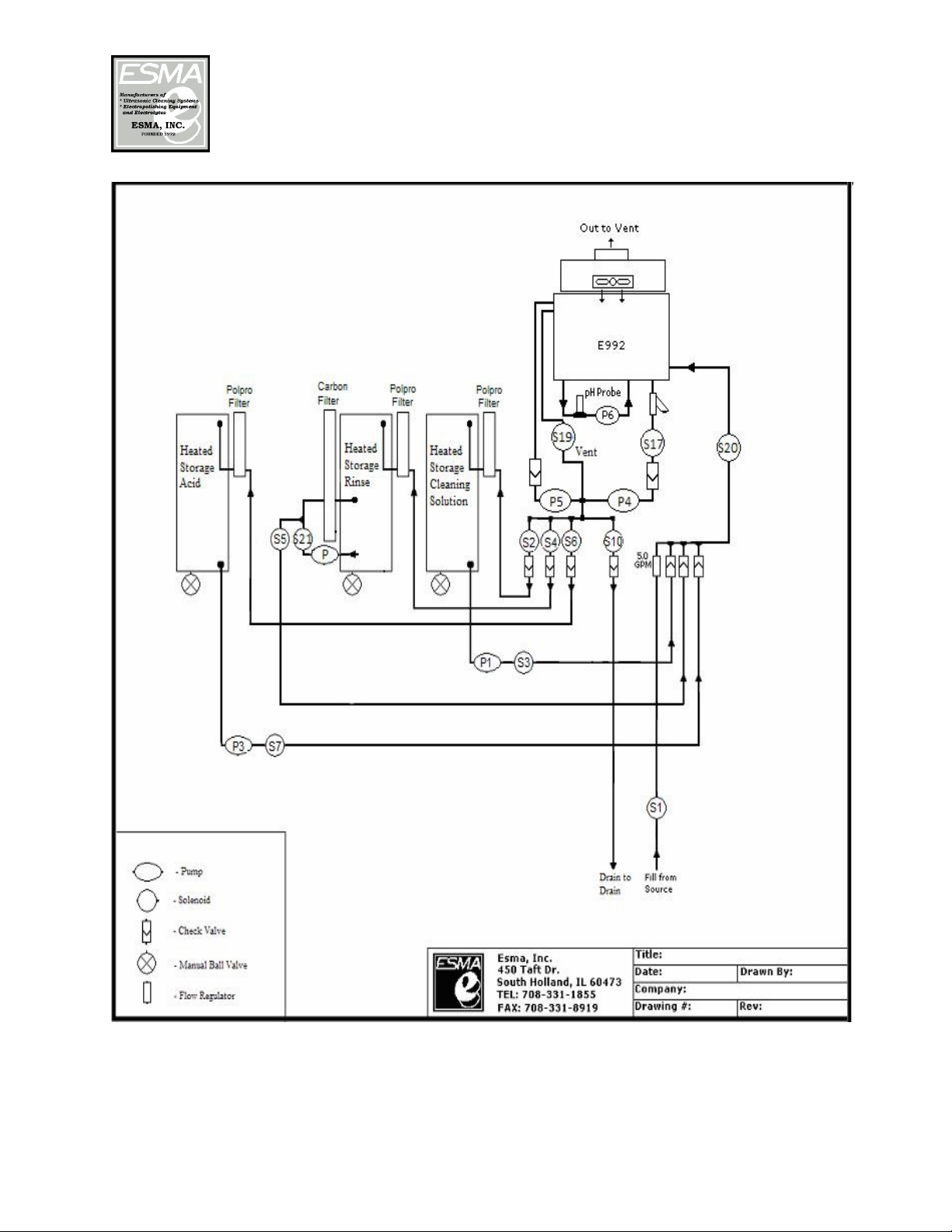

Plumbing Hook-Up

When the system was wrapped up for shipping the hoses which were used in

testing were included and marked. In the event that the tanks are to be located in a

different orientation than was configured in the plant, additional hose will need to

be procured. If the system is set up with HST-1 thru 3 on the right of the washer

the process should be straight-forward (as illustrated, use markings on the included

hoses for connections), setup should be as illustrated below.

Clean

Rinse

Acid

(HST1) (HST2) (HST3)

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

6

** IMPORTANT ** The city sewer line S10 MUST BE VENTED. If you are

plumbing to an overhead drain, you must plumb to a basin and sump pump so that

the system drain pump does not get air-locked during the program.

FOR ASSISTANCE CALL: 800-276-2466.

•

Solenoid 1 is to be

connected to your

pressurized in-house DI

water supply.

FUTURE CONNECTION

•Connect hose from

Solenoid 9 on HST 4, the

FUTURE Acid Storage

Tank

•Connect hose from the

S7 on the Acid Storage

tank to this fitting.

•Connect hose from the

S5 on the Rinse Storage

tank to this fitting.

•Connect hose from the

S3 on the Clean storage

tank to this fitting

•

Connect hose from Solenoid

“S10” to a vented drain if

needed.

•FUTURE CONNECTION

Connect hose from Solenoid 8 to

the filter chamber on HST 4, the

FUTURE Acid Storage Tank.

•Connect Solenoid “S6” to the

filter chamber on HST 3, the

Acid Storage Tank.

•Connect hose from Solenoid 4 to

the filter chamber on HST 2, the

Rinse Storage Tank.

•Connect hose from Solenoid 2 to

the filter chamber on HST 1, the

Clean Storage Tank

Solenoid Manifold

Rear of E992 Unit

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

7

The following plumbing connections should be made: (See flow diagram above)

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

8

E992

Solenoid 1 “S1” connects (inlet) to the in house pressurized DI water source.

Solenoid 10 “S10” connects (outlet) to your sewer or in house drain. ** IMPORTANT

** the drain line MUST BE VENTED. If you are plumbing to an overhead drain, you

must plumb to a basin and sump pump so that the system drain pump does not get air-

locked during the program. (Drain hose NOT supplied). FOR ASSISTANCE CALL:

800-276-2466

HST1 (Clean)

Solenoid 3 “S3” on the Clean Storage tank connect to bottom inlet fitting on the E992

unit.

A manual ball valve is to be used to empty the storage tank and a high level float switch

is included to prevent overflow.

The inlet port on the 10” filter has a 3/4” barbed fittings. Connect to Solenoid 2 “S2” on

the E992 unit.

HST2 (Rinse) (Unit has 2 filter chambers)

Solenoid 5 “S5” on rinse tank should connect to the middle inlet fitting on the E992 unit.

A manual ball valve is to be used to empty the rinse storage tank.

A manual ball valve is to be used to empty the storage tank and a high level float switch

is included to prevent overflow.

The inlet port on the filter has a 3/4” barbed fittings. Connect to Solenoid 6 “S6” on the

E992 unit.

The Rinse Storage has a 20” filter chamber and a 10” filter chamber. The 20” filter

should be already be connected to Solenoid 21 “S21” for recirculation (See Below). The

10” filter chamber has a 3/4” barbed fittings. Connect to Solenoid 4 “S4” on the E992.

HST3 (Acid)

Solenoid 3 “S3” on the Clean Storage tank connect to bottom inlet fitting on the E992

unit.

A manual ball valve is to be used to empty the storage tank.

A manual ball valve is to be used to empty the storage tank and a high level float switch

is included to prevent overflow.

The inlet port on the 10” filter has a 3/4” barbed fittings. Connect to Solenoid 6 “S6” on

the E992 unit.

Each storage tank is supplied with manual ball valves to drain the tanks when necessary.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

9

Heated Storage Tanks (HST)

After plumbing is completed, fill storage tanks with

appropriate solution. The 30 gallon storage tanks are double

walled insulated. Each tank has 1,400 watts of heat applied to

the bottom of tank controlled by digital temperature controllers

(instructions included) located on the control box. Turn ON the

temperature control and set to the desired temperature (factory

preset to 120°F). Press the MD button and wait for 2 seconds

for current set point to display. The temperature setting can be

changed using the arrow keys. Pressing MD again will return

the controller to run mode. Refer to the product description

sheets of the chemistry for appropriate temperatures. If tank is

full, the liquid heat-up rate is 30°F/hour. Because of the

double wall insulated tank the overnight cool down is minimized if the tank is

covered. A float switch in the tank will turn the heaters off in the event that the

liquid level is too low.

DO NOT TURN HEATERS ON WITHOUT WATER IN STORAGE TANK.

Pump Filter System

Each storage tank is equipped with a filter system with a 10”

SS chamber. The rinse storage is also equipped with a 20” SS

chamber. This provides for continual filtration of the rinse

water and is controlled by a switch on the control box marked

“RECIRCULATE PUMP”. When the switch is on, the rinse

water will recirculate through the 20” carbon filter for water

purification. This recirculation can be turned off at any time.

If turned off then only the 10” filter will be used for

filtration when rinse water is returned to the storage tank

from the E992 unit.

Filter cartridges can be reordered as follows:

20” Carbon Filters - Part# 50J

10” Carbon Filters – Part# 50I

10” Polo-Pro Filters – Part# 50K Periodically the filter cartridges in the chambers of

the storage systems need to be changed. The filter chambers are higher than the liquid

level of the storage units so the liquid does not need to be drained to change the

cartridges.

Shipping bracket can be removed

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

10

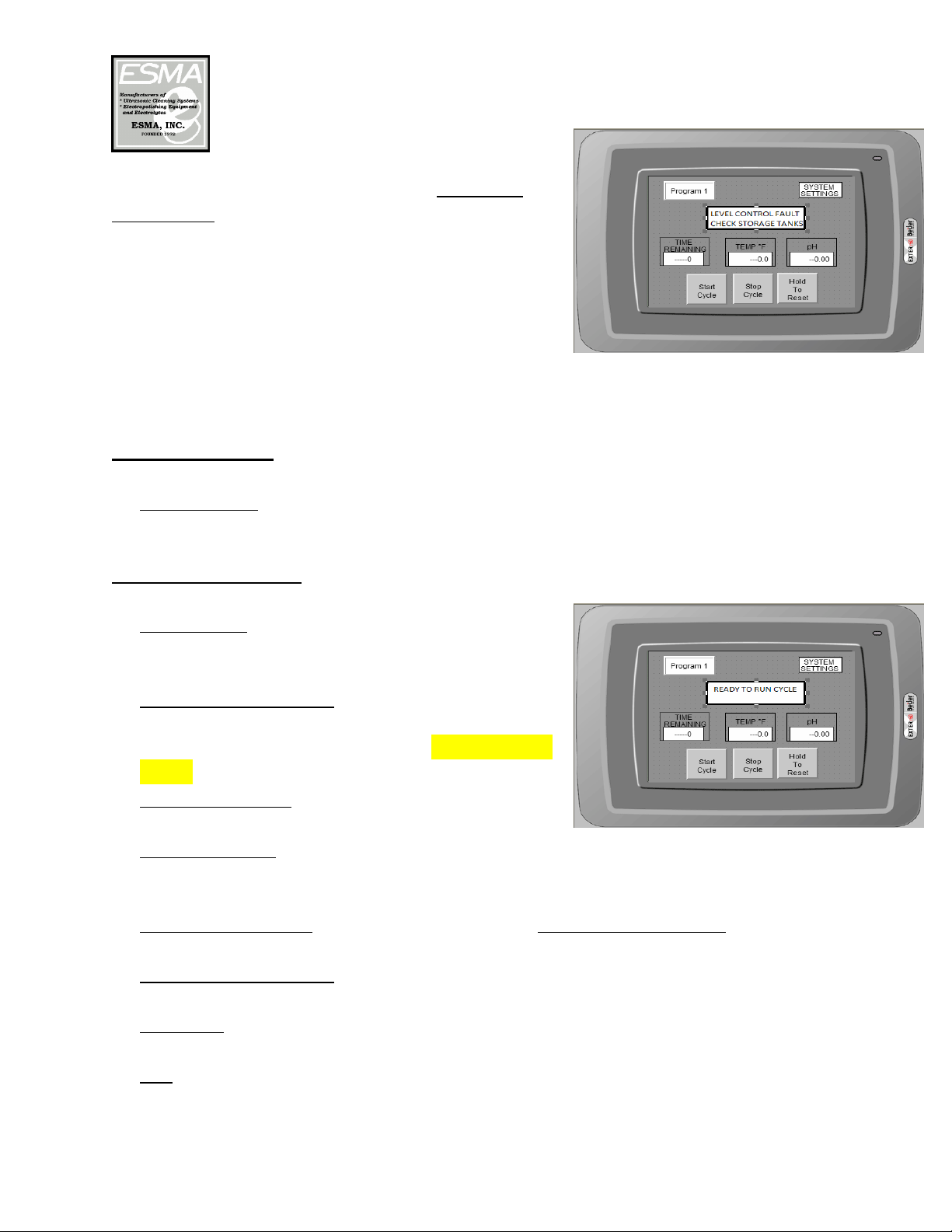

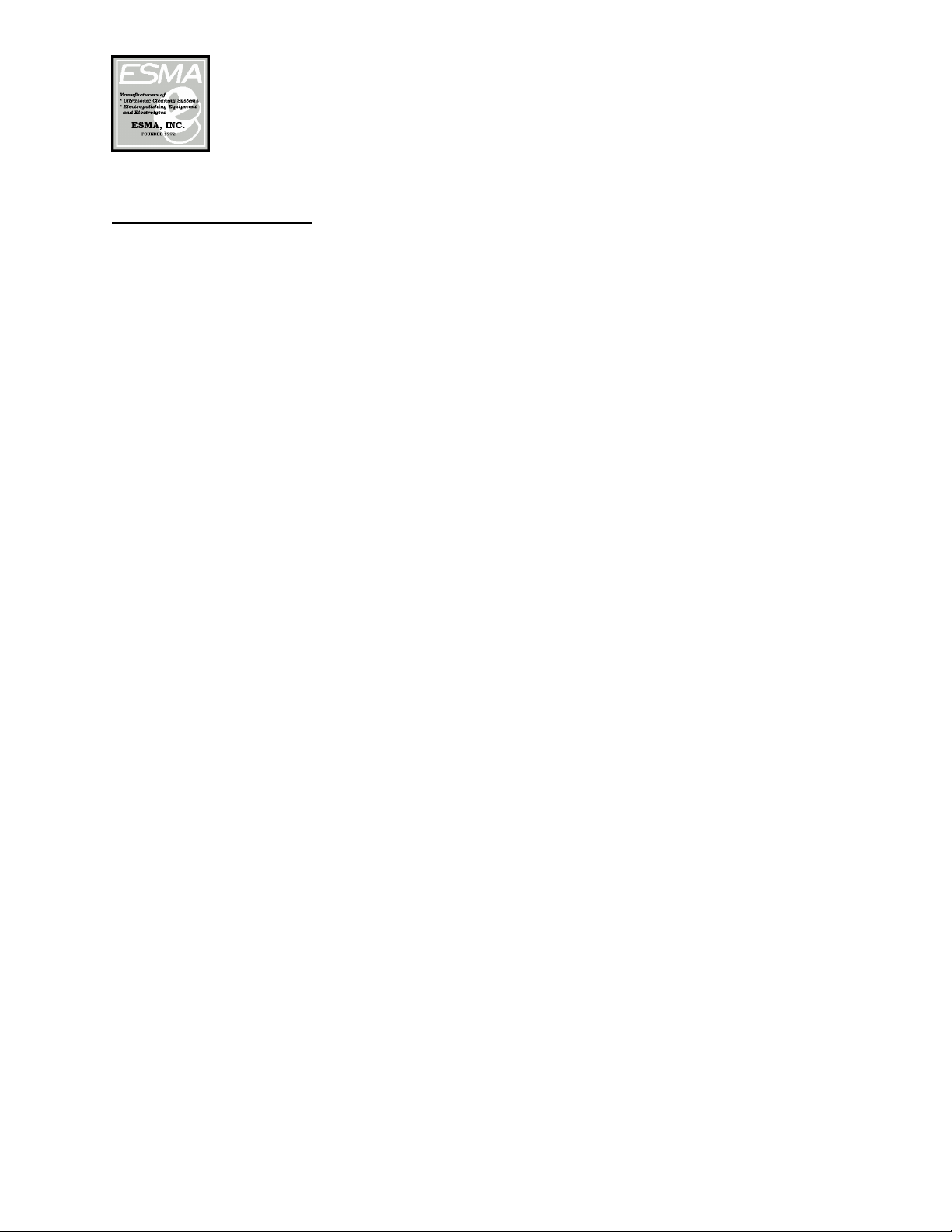

Each storage tank is equipped with a high level

float switch. If the fluid level rises too high, the

float will trigger a system halt indicated on the

HMI (see picture at right). This will indicate that

there is a problem in the system which needs to be

addressed. If the float is reset, pressing START

will resume the program.

Control Function

1. Main Switch: When unit is ready for operation, turn the main switch to ON and

the Interface screen will display “Ready to Run Cycle”.

HMI Display Screen

2. PROGRAM: Pressing this button will open a

drop down menu to select a program. (see

below)

3. SYSTEM SETTINGS: Pressing this button

will open a numeric input pad for password

protection of all the cycle times. The password

is 450

4. START CYCLE: Press the start button to begin

any process.

5. STOP CYCLE: Pressing this button will pause the cycle. Pressing START

CYCLE again will resume the cycle at the same step; however, the timer for

that step will be reset.

6. HOLD TO RESET: Pressing this button and holding for 2 seconds will reset

system. (Button will blink to indicate a reset)

7. TIME REMAINING: This is a display only item and indicates the time

remaining for the current step.

8. TEMP °F: Indicates current temperature of the bath. Temperature settings can

be set in the SYSTEM SETTINGS.

9. pH: Indicated the current pH reading by the probe. pH settings can be set in

the SYSTEM SETTINGS.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

11

Operation

Assuming the storage tanks and filters are filled and heated, the units can be placed

through its initial run. With the MAIN ON and PROGRAM 1 selected, pressing

the START CYCLE button will run a program cycle as shown in the following

table: (Use this grid to record time settings)

Plc

Step

Action

R3 Fill from Clean Tank

R4 Ultrasonic cleaning

R6 Drain to Clean Tank

R8 Fill from Rinse Storage Tank

R9 Ultrasonic rinse cascade to Rinse Storage Tank

R10 Ultrasonics rinse

R12 Drain to Rinse Storage Tank

R14 Fill from HST 3 (or 4) Acid Storage Tank

R15 Ultrasonic passivation

R16 Passivation - NO ultrasonics

R17 Drain to HST 3 (or 4) Acid Storage

R21 Fill from Rinse Storage Tank

R22 Ultrasonic rinse

R24 Ultrasonic rinse cascade to Rinse Storage Tank

R25 Drain to Rinse Storage Tank

R26 Fill from source

R27 Ultrasonic rinse overflowto Drain

R28 Ultrasonics rinse

R30 Drain to Drain

R31 Dry

R32 Dry with drain pump (20-30 seconds only)

R33 Dry

R34 Cool Down

R35 Alarm

Prog2 Prog3

ProgramTimes (seconds)

Prog1

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

12

To access the cycle time settings, select the program to be changed and press the

“System Settings” button on the top of the HMI interface. A password screen will

open. Your password to access this section is “450”. Use the subsequent screens

to make any necessary changes to the times of each cycle. Be aware that fill and

drain times should remain constant. This will assure that the same amount of rinse

water is drained and then re-filled into the Rinse Storage Tank. By pressing the

NEXT screen you will advance to subsequent screens.

A description of each step is as follows:

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

13

pH Meter

A Signet pH meter has been mounted on the panel

for displaying the current pH and temperature of

the tank bath. The program pH meter is tied to the

program with user defined pH limits. If a reading

falls out of limit, the system will stop running and

the HMI interface will read pH error. At this point

the operator will need to manually add solution to

the tank to adjust the pH, or change the limits in

the system. Pressing the start button will resume

the program.

Programmable Controller

An IDEC programmable controller is used to control the process. The unit has a

flash memory backup without a battery. The controller has indicator lights for

inputs and outputs which are lit during process. The system is also equipped with

a Beijer, EXTER model touchscreen interface. The interface allows for data

collection of the passivation process. The following data is collected and stored on

the interface:

Clean time

Clean temp

Clean ph

Rinse time

Rinse temp

Rinse pH

Acid time

Acid temp

Acid pH

Final Rinse time

Final Rinse temp

Final Rinse ph

Dry time

Total cycle time

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

14

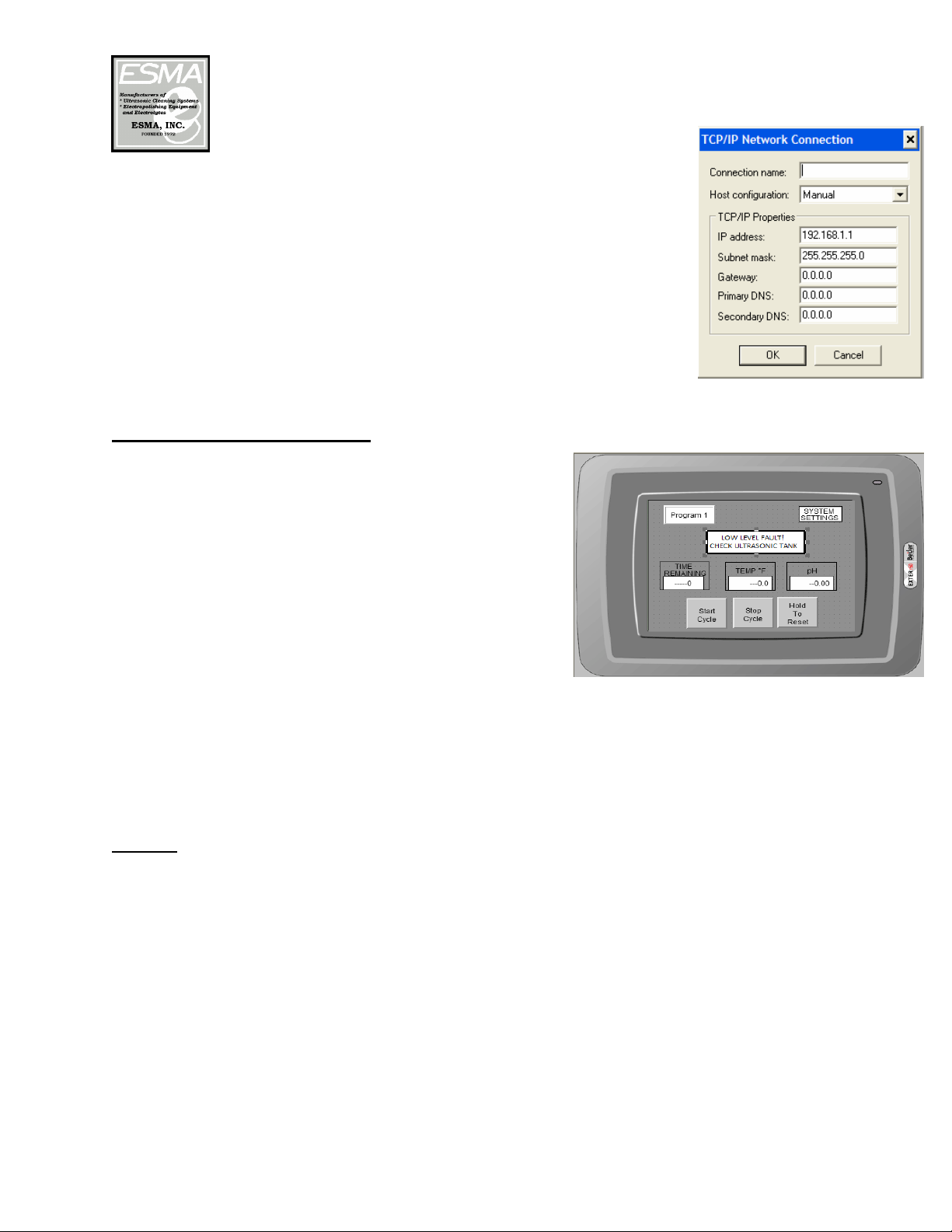

The control box on the rear of the E992 unit has an Ethernet port

for connection to a data collection server (See photo above). An

FTP protocol will need to be used to collect the data.

IP address: 192.168.1.1, Subnet mask: 255.255.255.0

The raw data is comma delimited.

High and low Level Control

The tank has a high level sensor and a low level

sensor located in the tank wall. The high level

control will shut the main input solenoid S20 if the

solution level gets to high in the tank.

A low level sensor in the tank wall is located

approximately 3” from the bottom of the tank.

This sensor will send a signal to the PLC to halt

the program if tripped. The adjacent message will

appear on the interface in the event that this sensor

is tripped, indicating that not enough fluid was pumped into the tank:

Drying

In the drying portion of the programs, the incoming air is heated in the tank cover

to 160-180°F and forced by the fan through the tank cover. CAUTION: Do not

touch the cover during the drying cycle because some areas of the cover will be

hot.

Drying time will vary depending on the number of parts to be dried, if hot or cold

water was used to rinse parts before drying and if the cover is closed. Generally

parts should be dry in 7- 10 minutes.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

15

NEVER place any towel or obstruction over the fan intake on cover. The air

temperature during Hot Air Drying can be increased or decreased by adjusting two

thermo-switches located in cover at hot air exit. The thermo-switches are adjusted

as shown below.

1. Disconnect unit from 120VAC and 230VAC supplies.

2. Remove top plate of dryer cover.

3. Thermostat is located in front of heater.

4. See drawing 1. Turn control knob slightly counter-clockwise to

decrease temperature.

5. Replace top plate and check air temperature. Repeat steps 1-4 if

not satisfactory.

Maintenance

1. Filters-Periodically the filter cartridges need to be changed as describe in a

previous section.

2. Drain Screens-Y strainers are located in the drain and overflow lines.

Periodically the drain screen in these strainers located under the tank inside the

unit will have to be removed and cleaned. Accumulated lint and debris could

slow down the draining, resulting in the incomplete removal of cleaning

solution before the rinse cycle starts.

The tank and modules are manufactured of 316 and 304 stainless steel. Clean with

a commercially available cleaner for stainless kitchen appliances.

Power Modules

The power modules contain the circuit boards, programmable controller, fans,

relays, RFI filters etc. There are 6 lights, one per circuit board to indicate if circuit

boards are operating. To check if all circuit boards are operating, open door

slightly when unit is ultrasonically cleaning; all indicator lights must be ON. If a

light is out, the corresponding circuit board will have to be repaired.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

16

Cleaning of Solenoids

A periodic cleaning of all solenoid valves is desirable. The time between cleanings

will vary, depending on media and service conditions. In general, if the voltage to

the coil is correct, sluggish valve operation, excessive leakage, or noise indicate

that cleaning is required. A bulletin with maintenance instructions is enclosed.

FOR ASSISTANCE CALL: 800-276-2466

WARRANTY: Unit has one year guarantee, circuit boards two years and

transducer bonds and tank weld seams a lifetime guarantee.

Celebrating over 30 years of excellence in manufacturing ultrasonic cleaning

equipment, electropolishing equipment and associated chemistries

ESMA, Inc.

P. O. BOX 734 * SOUTH HOLLAND, IL 60473 * (800)-276-2466 * AX (708)331-8919

Page

17

This manual suits for next models

1

Other Esma Washer manuals