SL-1218R Parts List

Part # Description Cost Part # Description Cost

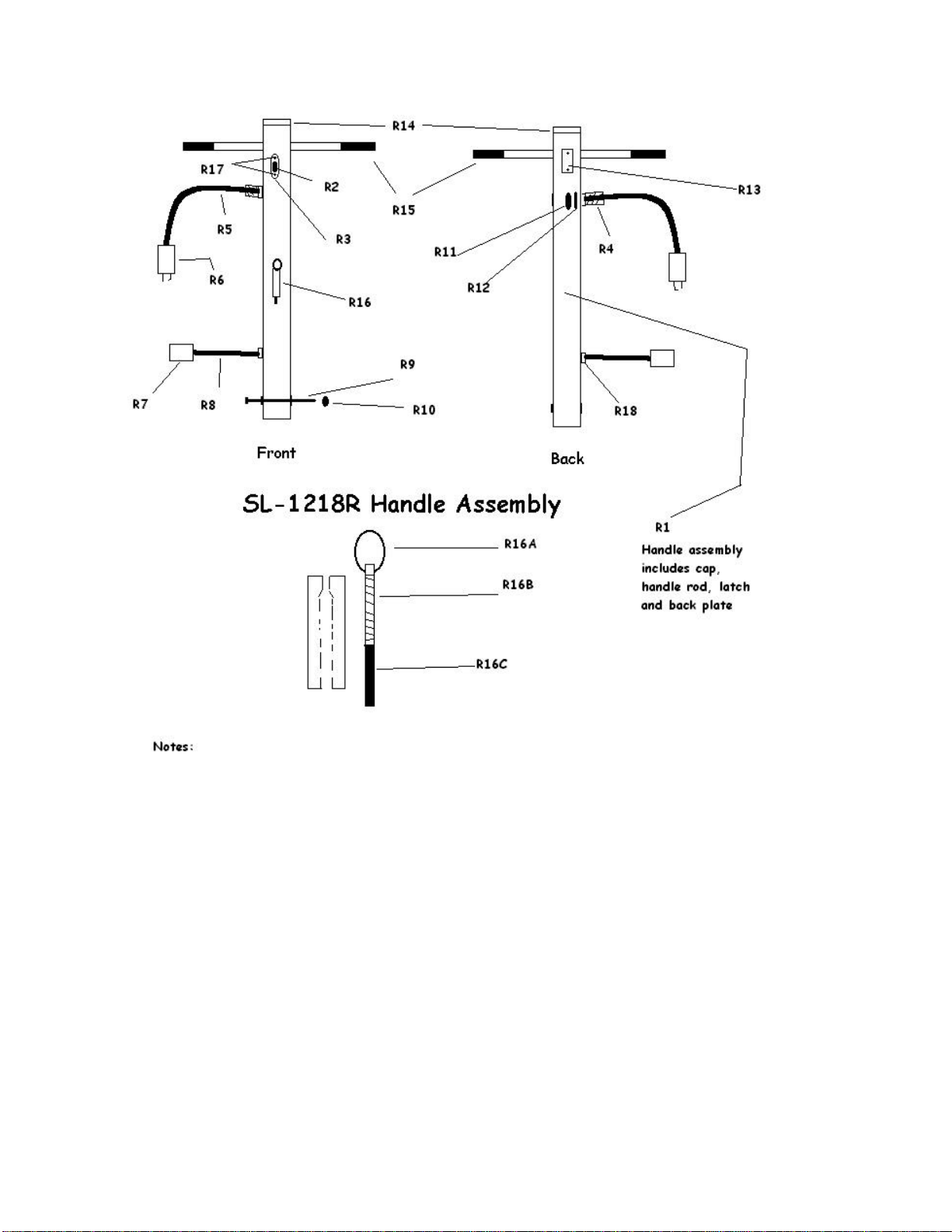

R1 Handle (Includes tube, cap, rod & latch) $95.00 R42 Motor Bell

R2 Switch $13.80 R43 Motor Capacitor

R3 ToggleGuard $8.96 R44 Capacitor Box

R4 StrainReliever $12.65 R44A Capacitor Box Fasteners $1.00

R5 Short Cord (Upper) (14/3 600v 18”) $2.25 R45 Motor Bolts (4) (Set) $1.20

R6 Twist lock (Male) $7.50 R46 Flywheel Bearings (6009 DDL 3614) ea. $16.00

R7 Twist lock (Female) $12.00 R47 Motor Cord $2.25

R8 Short Cord (Lower) (14.3 300v 24”) $3.25 R48 Metal Wire Holder $1.75

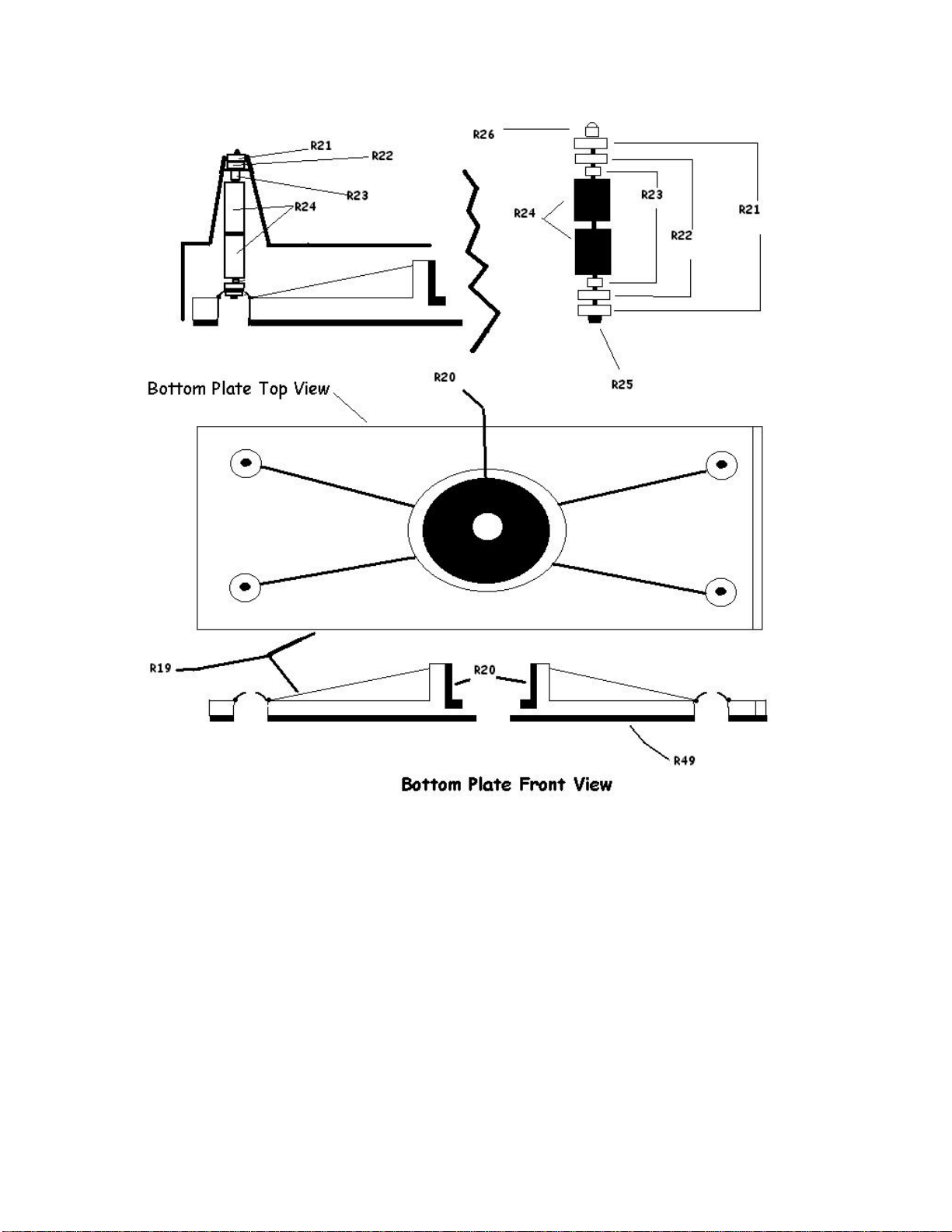

R9 Handle Bolt (¼ 28 X3) $1.90 R49 Carpet (12 X 18 w/5 Holes) $14.00

R10 Handle Nut (1/4 28 Stop Nut) $.70 R50 Vacuum Attachment $89.00

R11 Strain Reliever Nut (Inside Handle) $.30 R50a(L) Vacuum Left Side (w/90 degree)

R12 Strain Reliever Washer (Inside Handle) $.30 R50a(R) Vacuum Right Side (w/90 degree)

R13 Back Plate $4.40 R50b Angle Attachments (4) (On side)

R14 Handle Cover $4.00 R50c 18” Hose (with one cuff) (2ea.)

R15 Handle Grips (2) (ea.) $3.30 R50d Handle Attachment Kit (Screws & Rod)

R16 Latch Assembly R50e 90 Degree Hose Swivel Connection(2ea)

R16A Latch Loop R50f “T” Connector

R16B Latch Spring R50g Zip Straps (2 ea Not shown)

R16C Latch Bar R50h Metal connecting Rod (2 ea. Not shown)

R17 Toggle guard/Back Plate Fasteners (Set) $1.00 R51 25’ Cord Complete $33.00

R18 Cord Grommet $.95 R52 Tower Rebuild Kit (1 Set per machine) $29.20

R19 Bottom Plate (SL001) $142.00 (4ea. R21, R22, R23, R25, R26)

R20 Rubber Boot (RDO911) $26.00 R53 Handle Assembly Complete $195.00

R21 Tower Spacer (Metal) ea. $1.50

R22 Tower Spacer (Rubber) ea. $.40 R9A Handle Bolt (¼ 28 X3 ½ ) New! $1.90

R23 Inner Tower Spacers (Rubber) ea.(ITS) $.30

R24 Tower Rubbers ea. $3.00

R25 Tower Bolt (¼ 28 x 5 ¼ Hex Head Cap) $1.90

R26 Tower Bolt Acorn Nut $1.00

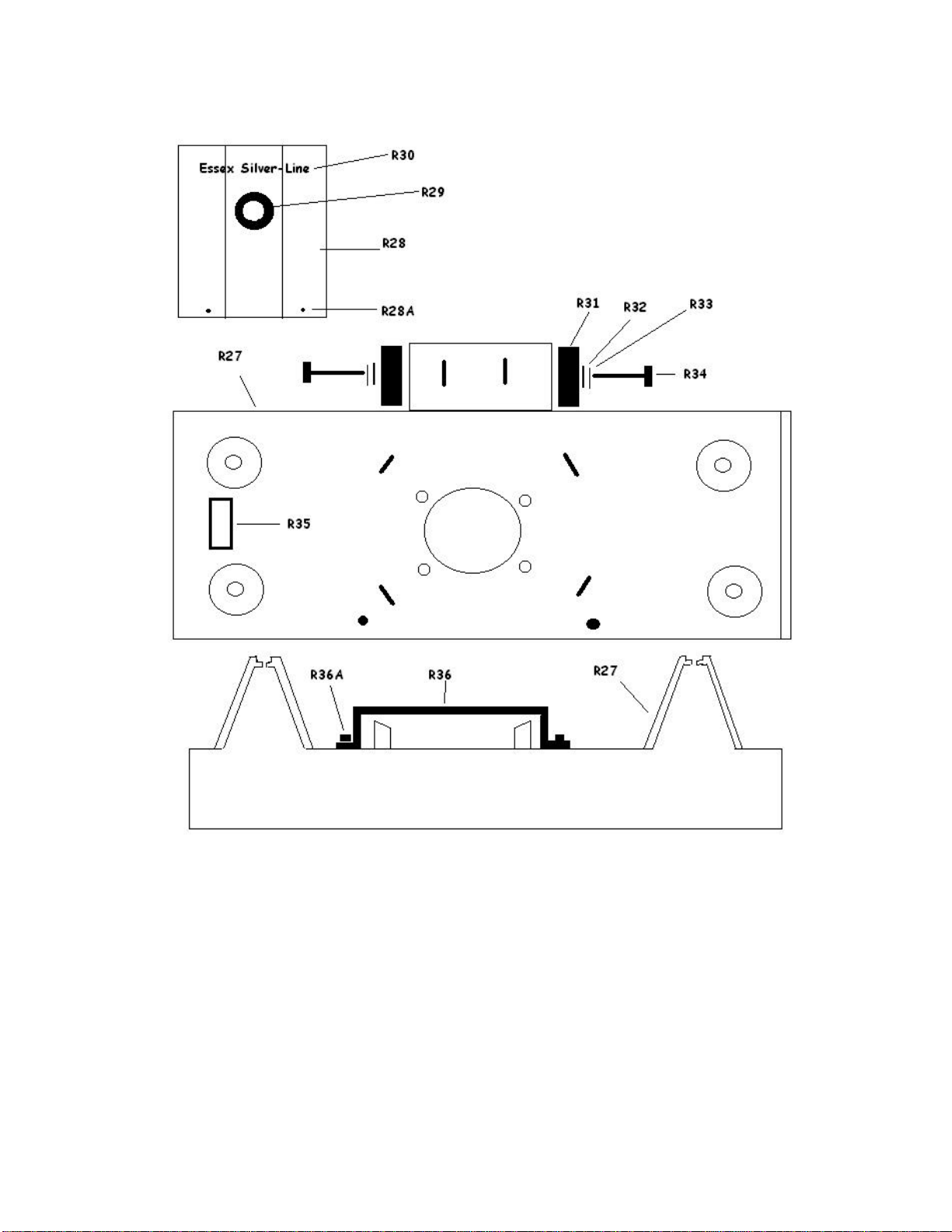

R27 Machine Base SL002) $298.00

R28 Motor Shroud $80.00 Notes:

R28A Motor Shroud Fasteners (Set) $1.20 R17 8-32 X3/8 Rd Hd Scw, #10 Lock washer

R29 Shroud Grommet $1.25 R21 1.000 x .280 X 1.25 Washer Steel

R30 Silver-Line Sticker $3.00 R22 .156 X .100 X 1.25 Washer Rubber

R31 Wheel (ea.) $8.00 R38W .970 x .625 x.100 Metal Spacer

R32 Fiber Washer $.30

R33 Wheel Washer (1/2 SAE Flat) $.30

R34 Wheel Bolt $1.90

R35 Nameplate (Serial Number) $3.00

R36 Lift Handle $9.70

R36A Lift Handle Fasteners (Set) $1.20

R37 Flywheel (1750) Slow Speed (SL003) $70.00 Essex Silver-Line Corporation

R37A Flywheel Set Screw $.30 1118 Lakeview Ave. PO Box 40

R37B Flywheel (3500) Hi Speed $85.00 Dracut, MA 01826

R38 Motor 1hp Baldor $280.00 (978) 957-2116

R38A Motor Armature (Not Shown) Fax (978) 957-6989

R38B Motor Bearings (Not Shown) Toll Free 800 451-5560

R38W Motor Washer (Not Shown) (New Part) www.essex-silver-line.com

R39 Motor Reset Thermo-Protector

R40 Motor Shaft Key $.30

R41 Cooling Fan